BOGBALLE S Series User manual

0407-17-08-18 V8

S-line

Operator’s Manual

S-line

GB

S-line

1

CONTENTS

SUBJECT

Page

MAIN SETTINGS

…………………………………..…

2

OVERVIEW

……………………………………..

3

PRACTICAL USE................................................

……………………………………..

4

CHECK OF SPREADER –before use

……………………………………..

7

TECHNICAL SPECIFICATIONS, general

……………………………………..

8

TECHNICAL SPECIFICATIONS, specific

……………………………………..

8

STANDARD EQUIPMENT

……………………………………..

8

OPTIONAL EQUIPMENT

……………………………………..

9

MAINTENANCE AND CARE

Normal maintenance………………….........9

Protection, friction clutch .…………..........10

Lubrication………………………………….11

Generally…………………………………. ..11

Spreading vanes…………………………. 11

……………………………………..

9

GUARANTEE / RESPONSIBILITY

……………………………………..

12

GENERALLY

……………………………………..

12

SAFETY and PROTECTION against ACCIDENTS

……………………………………..

12

USING THE CALIBRATION KIT

……………………………………..

13

S2 TRAIL

Overview………………….. .......................15

Practical use .………….............................16

Agitator…………………………………. .....16

Wheel slip…………………………………. 17

Technical data general/specific................18

Optional equipment…………....................18

……………………………………..

15

EC DECLARATION OF CONFORMITY

…………………………………..…

19

PICTOGRAMS

……………………………………..

20

SYMBOL EXPLANATION

……………………………………..

21

NOTES

……………………………………..

22

NB. Fitting instructions for different optional equipment

–are supplied with the optional equipment!

SPECIAL ATTENTION PLEASE!

In order to avoid that the material ’compress’ with the risk of

blocking the agitator and outlet follow these rules:

Always fill in the material cautiously –in a steady flow!

Never put pressure on the material during/after filling!

Avoid to ”compact” the material when driving for a longer period of time!

When the shutter/outlet is closed the spreading disc / agitator should not rotate!

NEVER leave the spreader with material in the hopper!

S-line

2

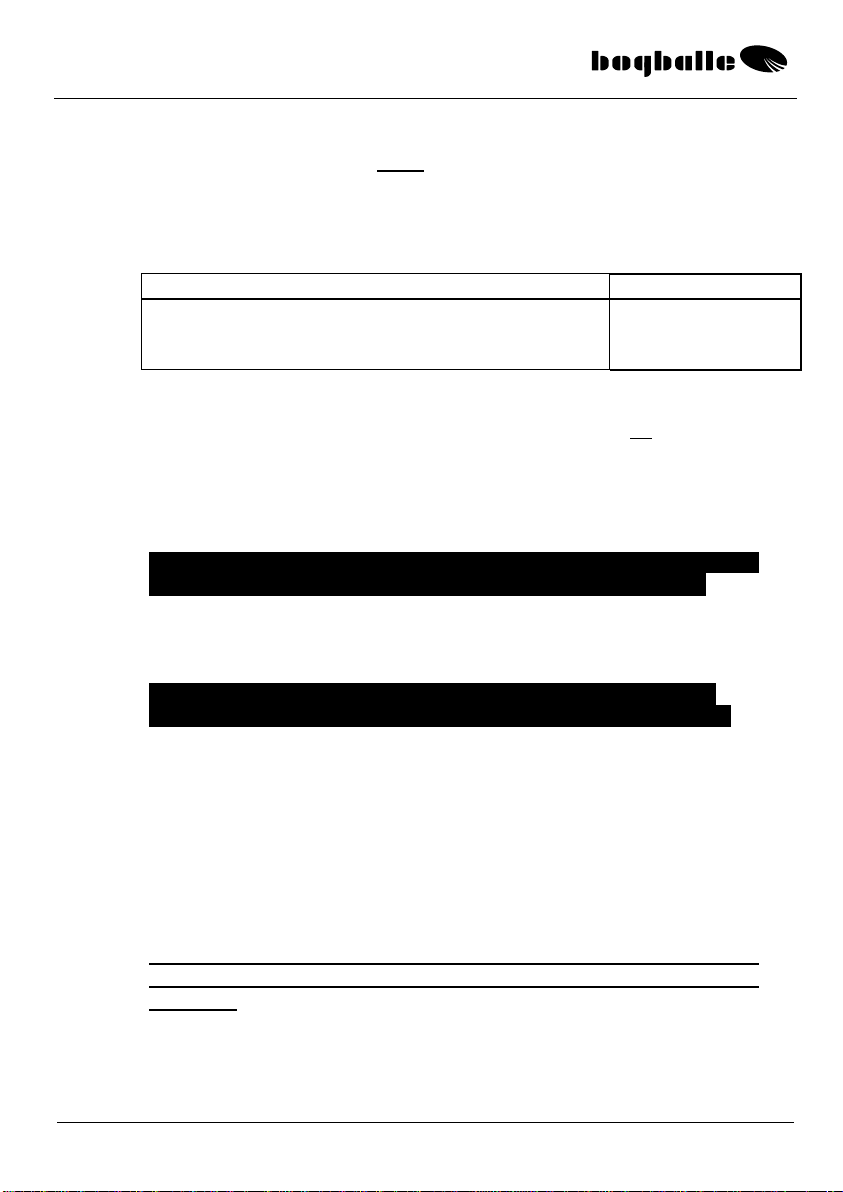

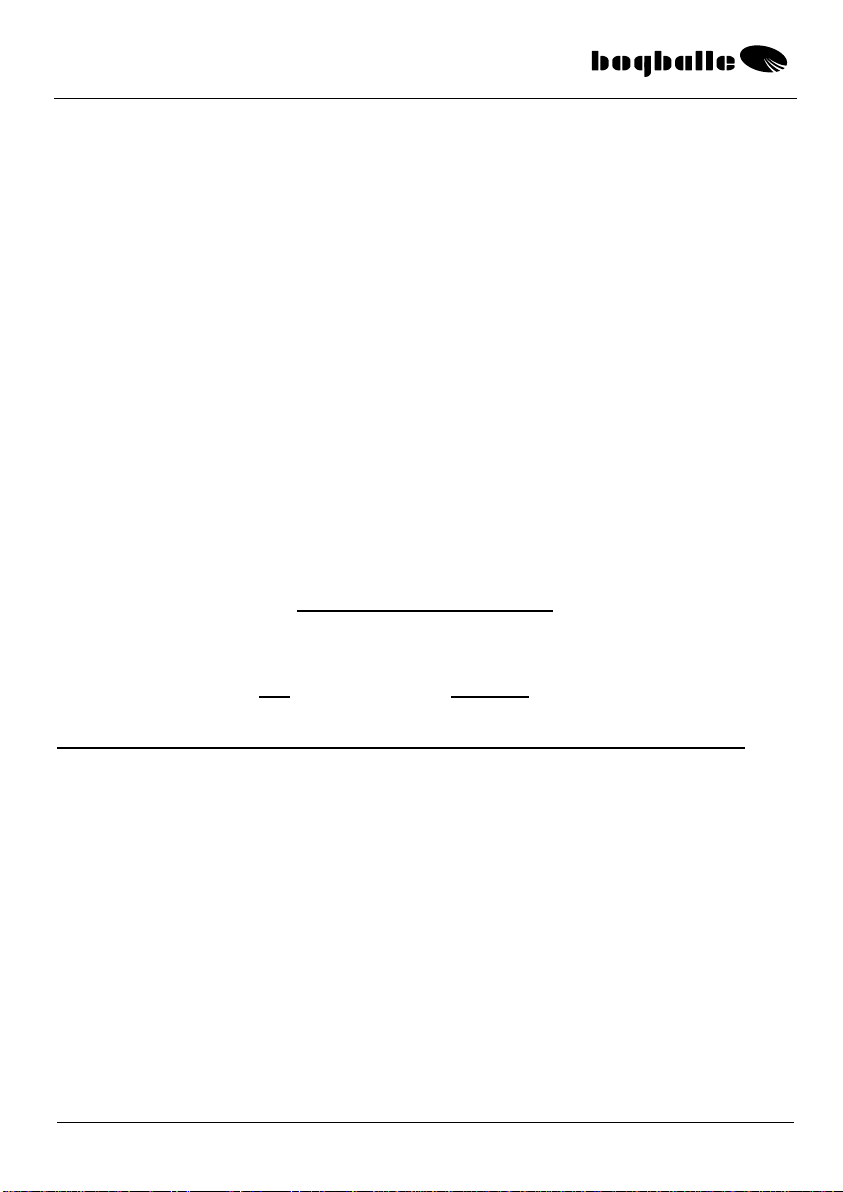

MAIN SETTINGS

PTO- speed 400 RPM.

TILT-angle Mounted Horizontal

WORKING HEIGHT from ground to disc 60 CM

QUANTITY SETTING See chart G/M2

VANE POSITION See chart

LIMITER f/ SPREAD WIDTH See chart

Spread Chart

Example

Spread Width : 2 Meter

Speed : 15 Km/H

Quantity : 31 G/M2

Scale : 2,50

Vane Setting : All 4 vanes are set in position 2

Limiter : Minimum

PTO: rpm 18-09-2007

2S3

5 10 15 20

0000 0,0 - - -

7322 1,1 3 - 3 - 3 - 3

36 18 12 9 6,0 3 - 3 - 3 - 3

92 46 31 23 15,3 3 - 3 - 3 - 3

145 73 48 36 24,2 3 - 3 - 3 - 3

181 90 60 45 30,2 3 - 3 - 3 - 3

223 111 74 56 37,1 2 - 2 - 2 - 2

277 138 92 69 46,1 2 - 2 - 2 - 2

351 176 117 88 58,5 2 - 2 - 2 - 2

416 208 139 104 69,3 2 - 2 - 2 - 2

452 226 151 113 75,3 2 - 2 - 2 - 2

470 235 157 118 78,4 1 - 2 - 1 - 2

0000 0,0 1 - 2 - 1 - 2

Kg/l

40 40 20 0 1,43

400

Gr/m2

Km/h Kg/min

- 905

5,00

5,50

1,00

1,50

2,00

2,50

8,50

9,00

6,00

6,50

3,00

3,50

4,00

4,50

%

22,6

7,00

7,50

8,00

Kg

1

2

3

4

Scale setting

Material

Setting of limiter

Speed

Quantity G/m2

Vane setting

Vane type

Spread width

Agitator Type

Material Factor

S-line

3

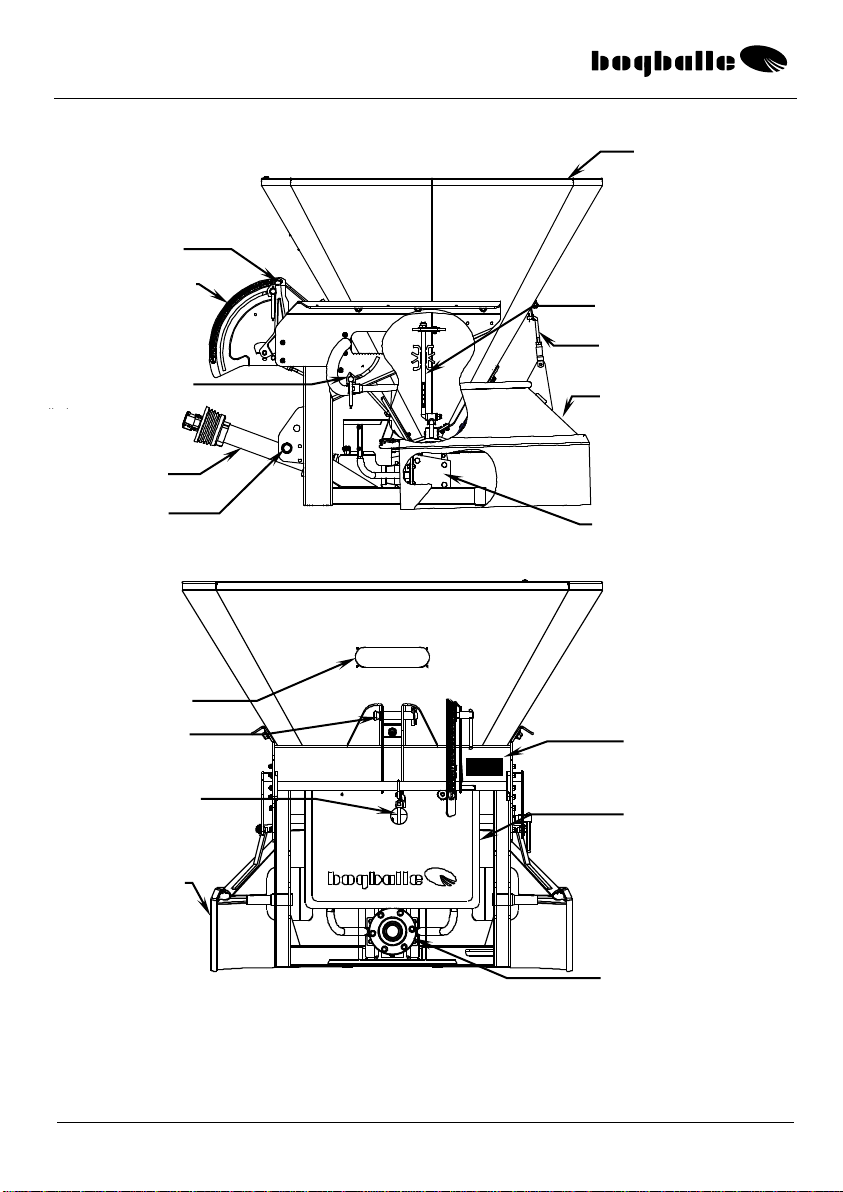

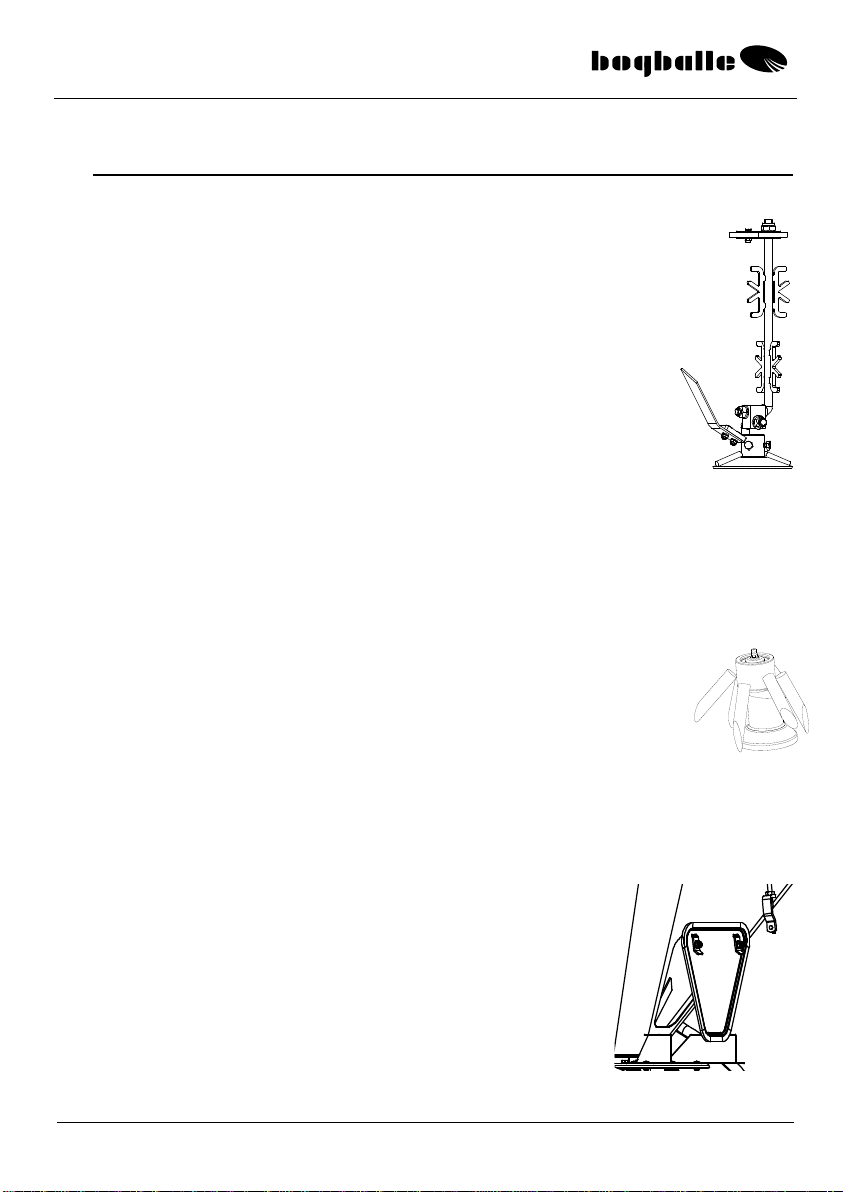

OVERVIEW

Hopper

Angle transmission

Alternatively: Oil motor

Parallel guiding axle

Agitator

Limiter

Setting scale

Fixture for

adjustment of

limiter

Setting pointer

Link pins

PTO-shaft

Connection Rod f/ shutter

Canvas Skirt

Friction clutch

Top link fixture

Serial No.

Inspection window

Mudguard

S-line

4

PRACTICAL USE

When driving with a full hopper it’s NOT recommended to drive on an uneven

surface for a longer period of time –this might cause the material to compact.

The tractor’s stabilization chains must be tightened in order to prevent the spreader

from swinging from side to side while driving.

When the shutter/outlet is closed the spreading disc should not rotate for a longer

period of time. The material will compress and cause heat development and

crushing of the agitator. The agitator can be damaged and involve overheat and

damage of the friction clutch.

When filling the hopper the material has to be filled in cautiously in a steady flow.

Don’t let the material fall in at once and from too high a position. Never put

pressure on the material by pressing the material into the hopper with a

mechanical/hydraulic shovel.

Never leave the spreader with material in the hopper. Not even overnight!

For example, road salt, which is hygroscopic, can by exposure to air of varying

humidity form a coherent mass / lump which might block the outlet of the machine

and prevent the agitator from rotating with possibly defective slip clutch or lack of

power from the oil motor to follow.

At a humidity of more than 75% a salt solution is formed on the salt crystals. If the

humidity is reduced again, the water evaporates and the salt re-crystallize resulting

in the formation of a coherent mass / lump.

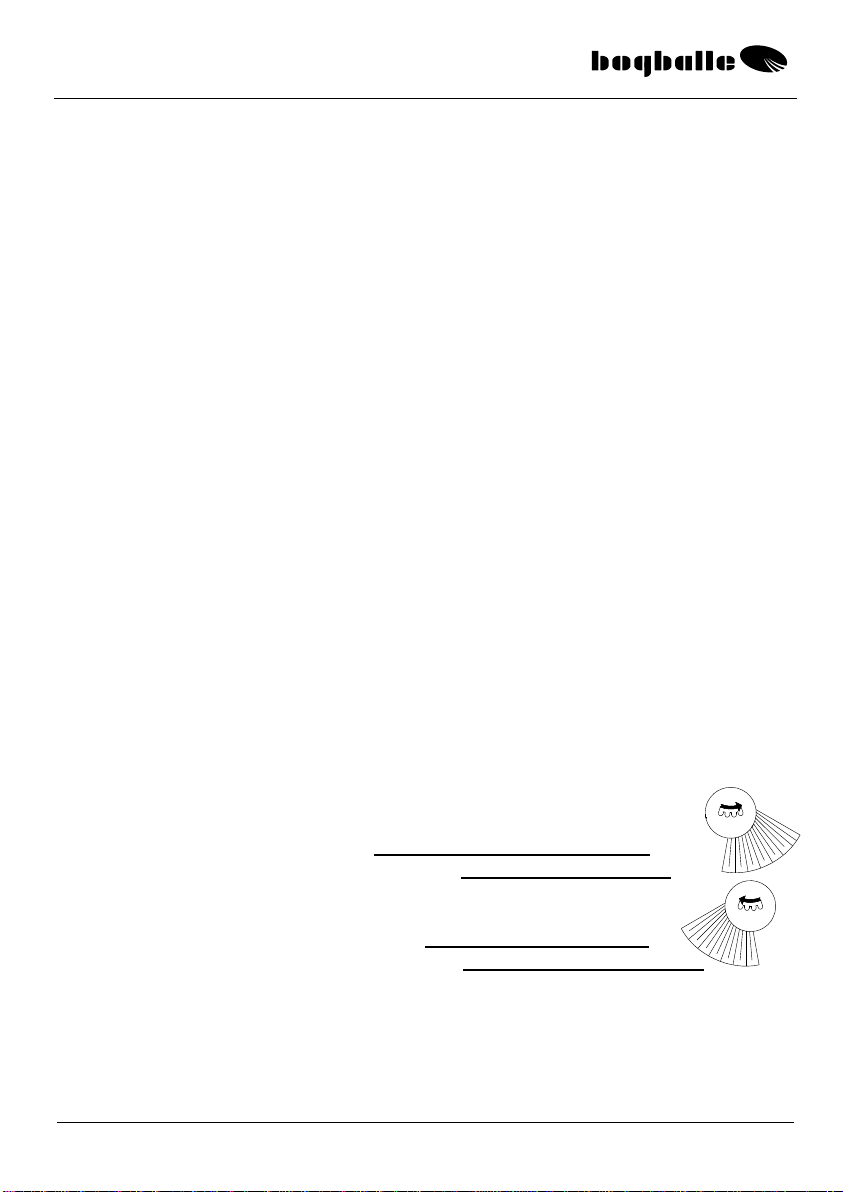

VANE POSITION

The spread chart states the setting of the vanes, i.e.:

1,2,3,4 –or a combination.

Setting / position of the vanes is decisive for the distribution of the material.

Basically the vanes are set according to the spread chart, but in case the material

does not have the wanted distribution from side to side it can be necessary to

adjust the spread pattern by adjustment of the vane position.

oIf the vanes are adjusted against the running direction

(Higher figure), the quantity is increased to the spreader's right side

oIf the vanes are adjusted in the in the running direction

(Lower figure), the quantity is increased to the spreader's left side

oIn order to ensure an even distribution of the material it is often an advantage to set

the vanes in two different positions, for instance 2-3-2-3.

This should be done in such a way that the two vanes placed opposite to each

other are set in the same position.

S-line

5

oThe spreading vanes are set by loosening the vane bolts and then place and fix the

vane in the requested position.

In case the material is supposed to be distributed even more to the left side of

the spreader, the vane's inner fixture can be moved to track B.

PTO-RPMs

The spread chart states the PTO speed:

The PTO revolutions per minute are decisive for the spread width and are also

of importance for the distribution of the material.

If the PTO revolutions per minute are lower than the stated number of

revolutions –the spread width will be reduced and the sidewise distribution will

at the same time be increased to the right of the machine.

The operation of the agitator is directly depending on the number of revolutions

of the PTO. At a low revolution figure the operation of the agitator will be

reduced –at a too high revolution figure the agitator will be under too high

pressure, which involves increased wear and possible defect.

The stated PTO speed MUST be respected.

LIMITER

The spread chart states the respective settings of the limiter:

Minimum : Minimum spread width approx.

1 metre –skirt mounted.

Middle : Middle position marked at lock for

adjustment of the limiter.

Maximum : Max spread width with

limiter in upper position.

Limiter demounted : ÷ limiter is demounted when spreading

for instance mineral fertiliser.

The setting / position of the limiter is decisive for the spread width and can be

steeples adjusted until the required spread width is reached.

Pos 1

Track A,

Standard

Pos 4

Track B

Special

S-line

6

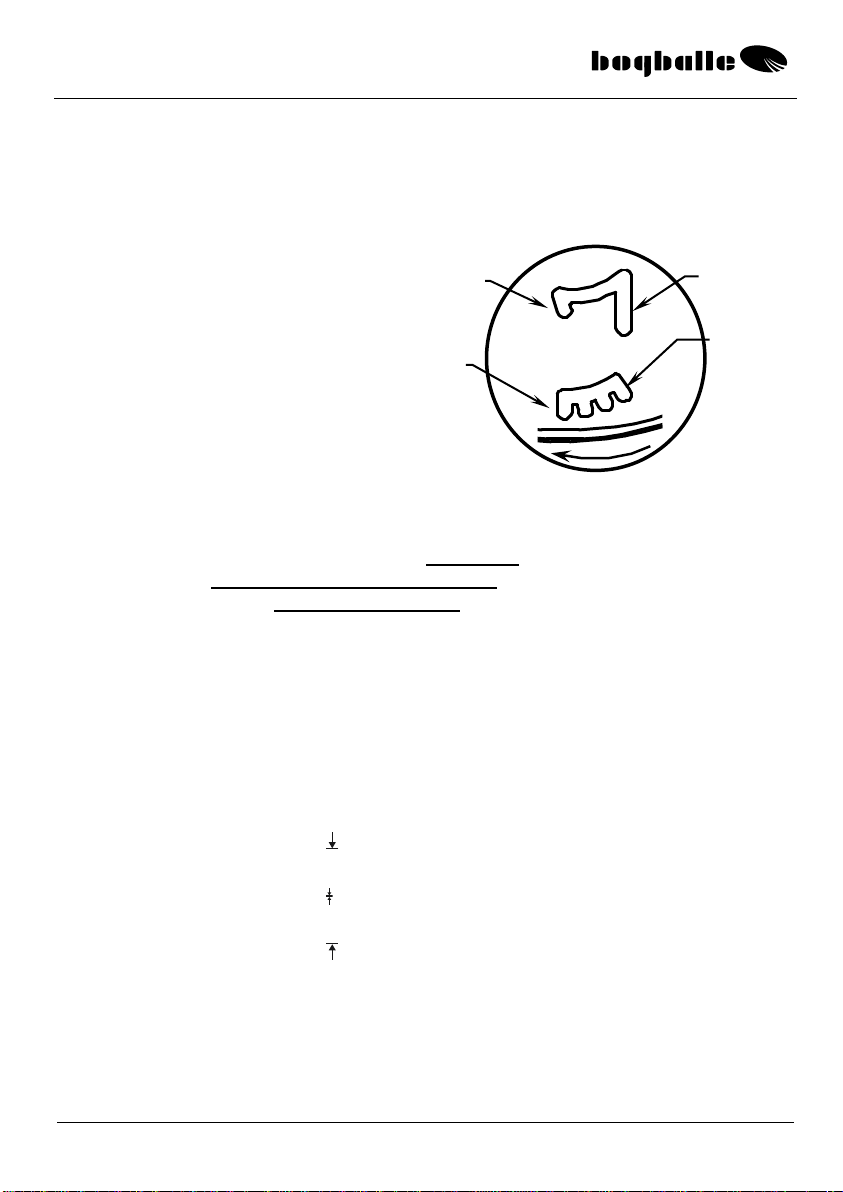

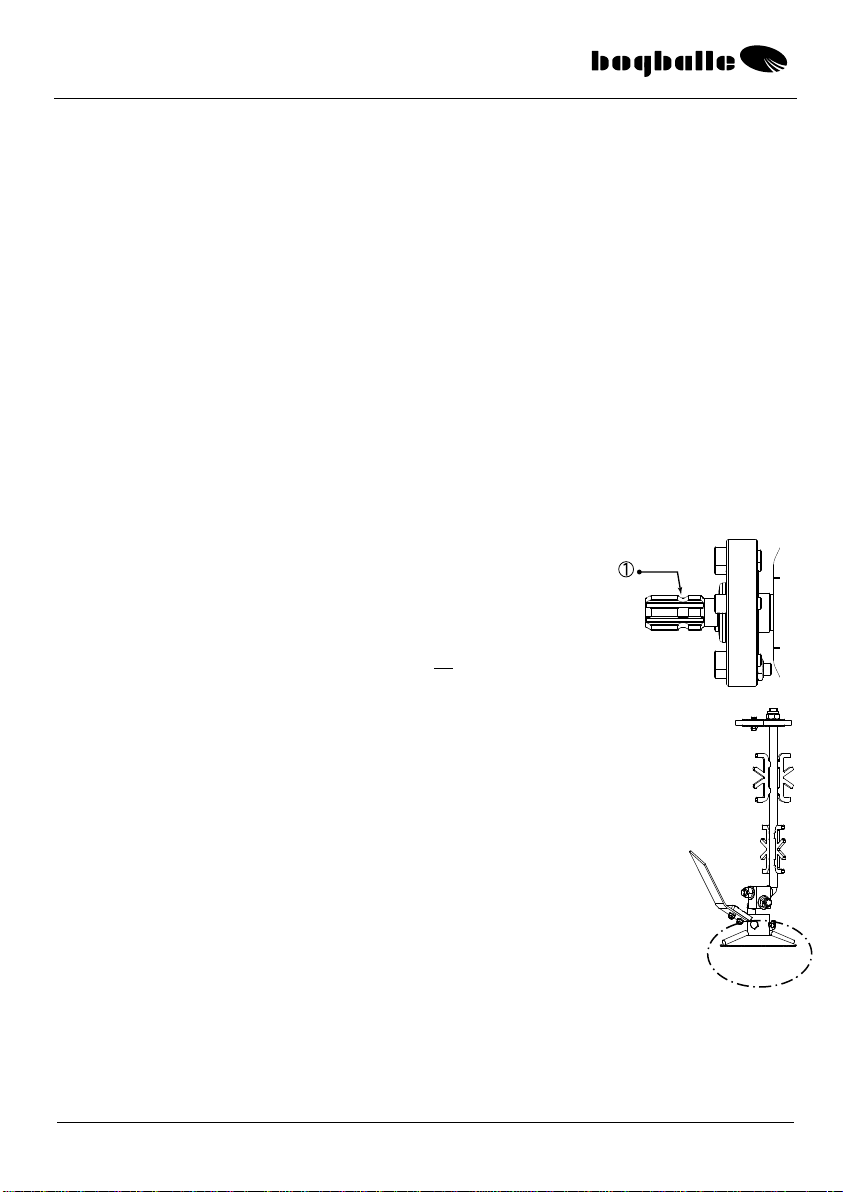

AGITATOR

When driven by PTO the rotation has to be started slowly with the tractor idling.

As standard the spreader is delivered with agitator for humid

SAND and SALT (Agitator with rubber disc).

The operation of the agitator is decisive for ensuring a constant

and uniform material flow.

Material for slippery roads is often difficult to handle because

the material can compress and build bridges with no flow as

result. See the paragraph: ”Special attention please”

The agitator is a wear part that must be checked now and then.

Wear will influence the efficiency of the agitator resulting in

smaller and at last no flow.

The primary wear parts are exchangable and made of hardened steel.

Pay attention to the fact that severe wear of the universal joint may cause

locking of the joint with overheat and defect friction clutch in the transmission

as consequence.

When spreading very rough material / small crushed stones or mineral fertiliser

the special free wheeling agitator is used (optional equipment).

When spreading dry smooth-running materials - for instance dry

salt or urea the special free wheeling agitator is also used.

oAlternatively the standard agitator’s axle is dismounted

(agitator axle with rubber disc) in a way that only the

lower ejector part is used. This solution might induce

crushing/grinding of the material.

SERVICE WINDOW, S3

As an example the hopper's service window can be used

when servicing the spreader's agitator.

The tractor's motor always has to be stopped when the

service window is open!

↑

→

S-line

7

CHECK OF SPREADER - before use

The adjustment and closing shutters must be easy to move. Never

use force. If the system is not easy to move –the reason is often

lack of lubrication of the setting system’s moving part or desiccated

material remains.

The spreading discs must turn easily when the PTO is not

mounted. Alternatively when using oil motor with open flow.

The spreading vanes must be intact and correctly fixed.

The PTO shaft must be of correct length, with suitable

overlap of the axle ends (min. 50 mm.). If the overlap is too

long or too short it will result in a serious damage of the

transmission axle.

DO NOT lift the spreader higher than working height (60 CM).

If the shaft is not of correct length –and if the

transmission is damaged, it will clearly appear from

”press marks ” on the splined axle.

If the axle is pressed, metal fatigue might cause damage after a

period of usage. Such damage is of course not under warranty!

Check that all the bolts are tightened –especially the

bolts securing the spreader’s hopper!

The lower part of the agitator is equipped with a

sealing –the distance between the sealing and the

bottom of the hopper has to be approx. 0,5 mm. If the

distance is larger the agitator/sealing has to be

adjusted to prevent leakage when spreading fine

materials. The adjustment is done via the agitator’s

two pointed screws.

S-line

8

TECHNICAL SPECIFICATIONS, general

Hopper volume

:

S2

S3

Hopper capacity

:

130, 240, 350

500, 775, 1.050

Litres

Spread width

:

Max. 600

Max. 1.600

Kg.

Spreading capacity

:

2 –8

2 –8

Metres

3-point linkage

:

Ca. 5 –350

App. 5 –350

G/M2

Kat. l/II / ISO 730/I

Kat. II / ISO 730/I

S2 / S3 hydra w/ Oil Motor

Oil pressure

:

Min. 120

Max. 140

Min. 140

Max. 175

Bar

Oil Flow

:

Min. 20

Max. 90

Min. 32

Max. 40

L/Min.

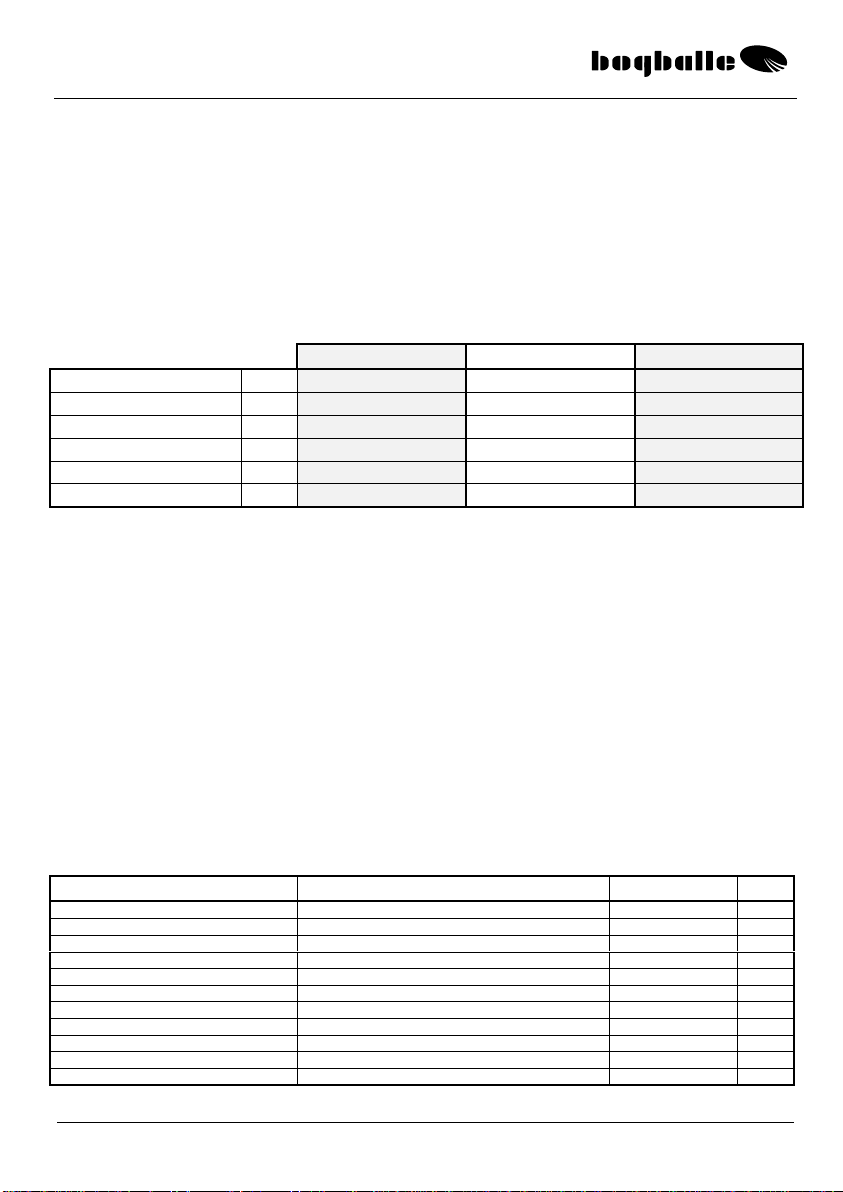

TECHNICAL SPECIFICATIONS, specific

SPECIFICATIONS

S2, 130 l

S2, 240 l

S2, 350 l

S3, 500 l

S3, 775 l

S3, 1.050

Load height

CM

77

96

115

115

133

152

Hopper volume

Litres

130

240

350

500

775

1.050

Hopper capacity, Max.

KG

175

325

470

675

1.045

1.600

Fill opening

CM

70 x 74

70 x 74

70 x 74

114 x 119

114 x 119

114 x 119

Net weight

KG

118

130

142

166

189

212

Total weight

KG

275

437

594

841

1.234

1.812

The hopper capacity is made from hopper volume in litres multiplied with a specific

weight of ~ 1,35 Kg/litres.

STANDARD EQUIPMENT

The S3 is from the factory supplied with the following standard equipment.

PTO Shaft / alternatively w/ oil motor

Agitator f/ Salt and Sand (w/ rubber disc)

Pressure Compensator for protection of agitator

Transmission, with friction / overload clutch (not w/ oil motor)

Spreading vanes

Limiter with skirt

Sieve, mesh size 5 x 5 cm

S-line

9

OPTIONAL EQUIPMENT

A line of useful optional equipment can be supplied –as mentioned below:

COMPONENT

DESCRIPTION

DIMENSION

Module S2

110 Litres

76 x 80

CM

Hopper Cover S2

Foldable

76 x 80

CM

Module S3

275 Litres

120 x 125

CM

Hopper Cover S3

Foldable

120 x 125

CM

Extension Handle

Manual Control

Remote Control of Quantity

Cable

Remote Control of Quantity

Hydraulic

Remote Control of Quantity

Electric motor, actuator

Remote Control of Spread Width

Electric motor, actuator

CALIBRATOR ICON

Ground Speed Related Quantity / Working Width

Traffic Lights

Special Agitator for Rough Material

All BOGBALLE products are subject to a continuous development. Therefore, the list might not always be up-to-date.

MAINTENANCE AND CARE

NORMAL MAINTENANCE

The BOGBALLE machine is manufactured in such a way that it requires a

minimum of maintenance.

In the construction it is considered that cleaning and lubrication can be completed

quickly and thoroughly –without taking apart the machine.

The surface treatment consists of a robust FlexiCoat powder paint –in addition all

essential wear parts and bolt assembling are made of stainless steel.

Many of the machine’s components are greased once and need no extra

maintenance, for instance the central and angle gears of the transmission.

The maintenance mentioned below is absolutely necessary!

”If the machine is maintained – it will still be new - in 5 years!”

”If the machine is not maintained –it will be old –next year!”

The machine must always be thoroughly cleaned after use. The

cleaning should be done with water perhaps including soap. When

using a high-pressure cleaner only use low pressure and do not

clean direct on the axle seals of the transmission and the oil motor.

Do not use grease-removing cleaning liquid –without giving the

machine –right after drying –an application of anti corrosion oil.

S-line

10

It is strongly recommended to grease the machine in a corrosion

protective liquid (for instance oil)–BEFORE using it first time.

Without protection, rust might arise within a few hours in

areas, where the paint has been damaged –salt is very

corrosive.

THEREFORE –generally the machine must be greased

daily in a corrosion protective liquid –when used.

The machine must also be greased before storing.

Please consider that cleaning products and corrosion protecting

liquids might include dissolvent that might dissolve the glue fixing the

transfers.

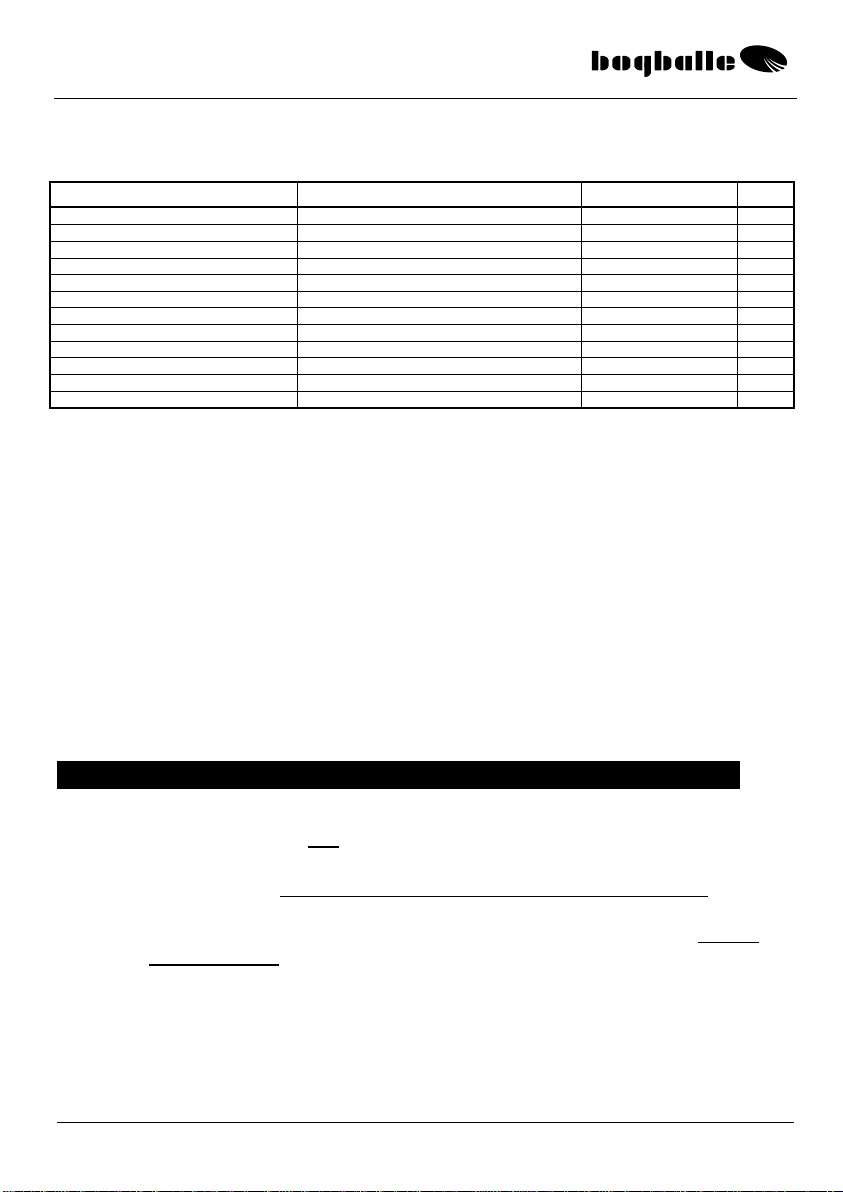

PROTECTION, Friction clutch

The transmission of the machine is equipped with friction / overload

clutch.

The friction clutch is a most important component protecting against

overload –and a damaged transmission and agitator.

The friction clutch must ”slip” at START of the tractor PTO.

If the clutch does not slip –the transmission will be damaged.

The friction clutch is in principle maintenance free, but minimum

once a year the torque must be checked –to make sure that the

torque is between 240 –300 Nm.

If the torque exceeds those limits, dismantle and clean the clutch

components as corrosion or wear might be the reason.

After mantling the clutch, check that the torque limits are within

the mentioned torque limits.

The friction clutch ”slips” approx. 1-2 turns at START of the tractor PTO. This reduces

the load on the components of the transmission to approx. 1/10 of the load to which the

transmission is exposed, if the coupling is not able to ”slip”.

It is always necessary to START the tractor PTO

”slowly / smoothly”!

S-line

11

LUBRICATION

The components below must be greased according to below

instruction.

See the explaining sketch in the paragraph ”OVERVIEW”.

LUBRICATION ONCE A DAY:

COMPONENT

INSTRUCTION

Cardan joint and lock of the PTO

Telescope axles of the PTO

Setting and closing shutter (Bottom of hopper)

Use grease

Use grease

Use grease

PARTS GREASED ONCE:

The angle gear is filled with special grease and needs no lubrication.

GENERALLY

A new machine will always ”move” a little bit in all nuts + bolts.

Therefore, all the machine’s nuts and bolts must be retightened -

first time it is put into operation –after 3 to 5 hours operation.

Exception is the angle gear’s bolts –these are locked and sealed

with Locktite.

Special attention is needed towards the spreader’s 6 M12 bolts

tightening the hopper –these are tightened with a 90 Nm torque.

Be aware that stainless nuts + bolts might ”weld together”. When

mounting such bolts –the thread must be greased with cutting

lubricant or copper grease!

SPREADING VANES

The vanes will be worn due to the material. Therefore, the vanes are

to be considered a wearing part –that must be exchanged

dependent on the quantity and type of material.

Always clean the contact surfaces of the vanes and the

spreading disc for dust etc –before mounting and tightening

the vane!

IF HOLES ARE WORN IN THE VANES THEY MUST BE EXCHANGED AT ONCE!

S-line

12

GUARANTEE / RESPONSIBILITY

Claim conditions are according to Danish legislation. Service and repair are

made free of cost within 12 months from date of purchase on the following

conditions:

That the failure is due to construction or material faults

(Normal wear, missing maintenance and misuse not included).

That the failure is not due to not original components / equipments.

That persons with no technical knowledge to the machine have not tried to repair.

Compensation for person or crop injury does not fall on the supplier.

GENERALLY

This machine is intended for spreading sand, salt, urea and the like on icy roads

and in special cases fertilisers.

Spreading of other flowing materials might also be possible. If so we draw the

attention to data list of the material concerned in order to determine possible safety

or health measures to be taken to minimize any risks.

If the machine is used for spreading material which is not defined in the spread

charts for the spreader, the manufacturer of the machine can never be held

responsible.

SAFETY and PROTECTION

The transmission system of the machine:

PTO shaft, friction clutch and spreading discs w/ vanes –must be considered ”as

dangerous”, and absolute care must be taken with these machine parts, especially

in connection with rotation of the tractor PTO system.

DO NOT LEAVE THE TRACTOR CABIN –WITHOUT STOPPING THE PTO

SYSTEM OF THE TRACTOR!

Never go behind the machine –with rotating spreading discs.

Never clean the machine - with rotating spreading discs.

Never put hand/object into the hopper –with rotating spreading discs.

Always check that the spreading vanes are correctly fixed.

Check that the protection tubes of the PTO are intact.

Check that the security chain of the PTO is fixed.

Check that top link and top link pins are intact and secured by lynch pin.

S-line

13

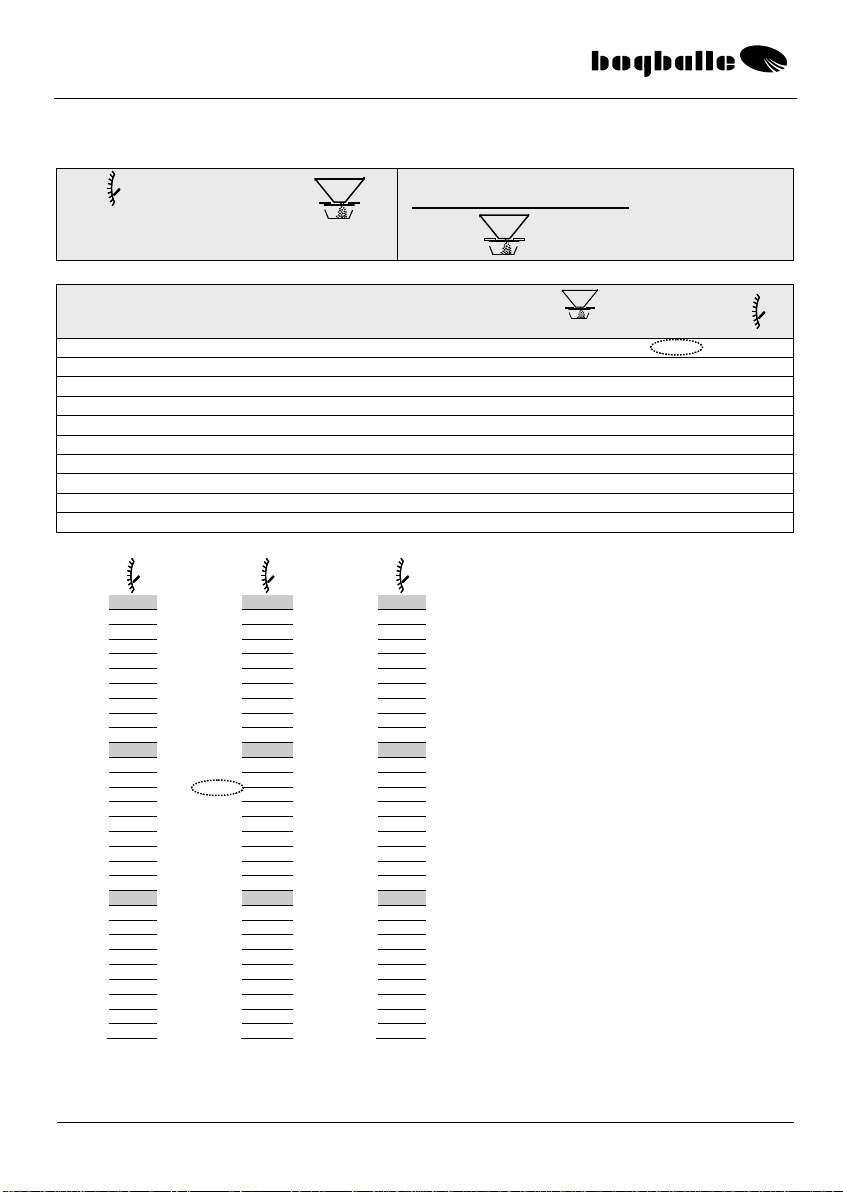

Using the Calibration Kit

Limiter and canvas skirt is used as calibration kit.

Put the limiter in the lowest position with the canvas skirt mounted.

The calibration kit is used for stationary calibration, so that the machine is adjusted

precisely in comparison to the nature of the material in question.

There may be big differences in the material dependent on temperature, humidity

and other climate factors.

Be aware that the nature of the material may vary from supply to supply. It is

therefore recommended to make a calibration test for each new supply.

Is the hopper wet on the inside, the humidity will prevent the fertiliser from falling

down. In such cases minimum 3 calibrations must be made –where the last

calibration quantity is valid.

The calibration kit is also used if the material is not found in the spread chart.

PROCEDURE:

1. The scale stop is fixed at 4,5 on the spreader’s scale

2. Let the PTO-shaft rotate at 400 rpm.

(The materials flow is dependent on the PTO rotations)

3. A calibration test is performed for exactly 30 sec.

(The spreader’s outlet is opened for 30 sec.).

4. The calibration value is weighed

5. The fertiliser’s Flow Factor is calculated cf. the below formula:

Quantity [g/m2] x Spread width [M] x Speed [Km/h] x 20

Calibration value [Kg/30 sec.]

6. In the Flow Factor list on the next page you can find the Flow Factor closest to

the calculated Flow Factor –read off the scale figure or use the Flow Factor

directly and adjust the spreader’s scale.

Symbol explanation:

[Kg/Ha]

:

The wanted quantity

[M]

:

Spread width

[Km/h]

:

Speed

:

Calibration value after 30 sec. at scale figure 4,5

:

Scale 0-9, Flow Factor 645-6575

S-line

14

Flow Factor Calculation

4,5

PTO

400 rpm

[g/m2] x [M] x [Km/h] x 20

[Kg]

=

Flow Factor

[g/m2]

[M]

[Km/t]

Kg

Flow

Factor

Rough Road Salt

:

21

X

6

X

15

/

15

=

2520 ►

4,3

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

:

X

X

/

=

►

Flow

Factor

Flow

Factor

F

L

O

W

F

A

C

T

O

R

0,0

1380

3,0

4080

6,0

0,1

1470

3,1

4170

6,1

0,2

1560

3,2

4260

6,2

0,3

1650

3,3

4350

6,3

0,4

1740

3,4

4440

6,4

0,5

1830

3,5

4530

6,5

0,6

1920

3,6

4620

6,6

0,7

2010

3,7

4710

6,7

0,8

2100

3,8

4800

6,8

0,9

2190

3,9

4890

6,9

1,0

2280

4,0

4980

7,0

1,1

2370

4,1

5065

7,1

1,2

2460

4,2

5150

7,2

1,3

2550

►4,3

5235

7,3

1,4

2640

4,4

5320

7,4

1,5

2730

4,5

5405

7,5

1,6

2820

4,6

5490

7,6

1,7

2910

4,7

5575

7,7

1,8

3000

4,8

5655

7,8

1,9

3090

4,9

5735

7,9

645

2,0

3180

5,0

5815

8,0

715

2,1

3270

5,1

5895

8,1

785

2,2

3360

5,2

5975

8,2

855

2,3

3450

5,3

6050

8,3

930

2,4

3540

5,4

6125

8,4

1005

2,5

3630

5,5

6200

8,5

1080

2,6

3720

5,6

6275

8,6

1155

2,7

3810

5,7

6350

8,7

1230

2,8

3900

5,8

6425

8,8

1305

2,9

3990

5,9

6500

8,9

►

►

30 sec.

▼

S-line

15

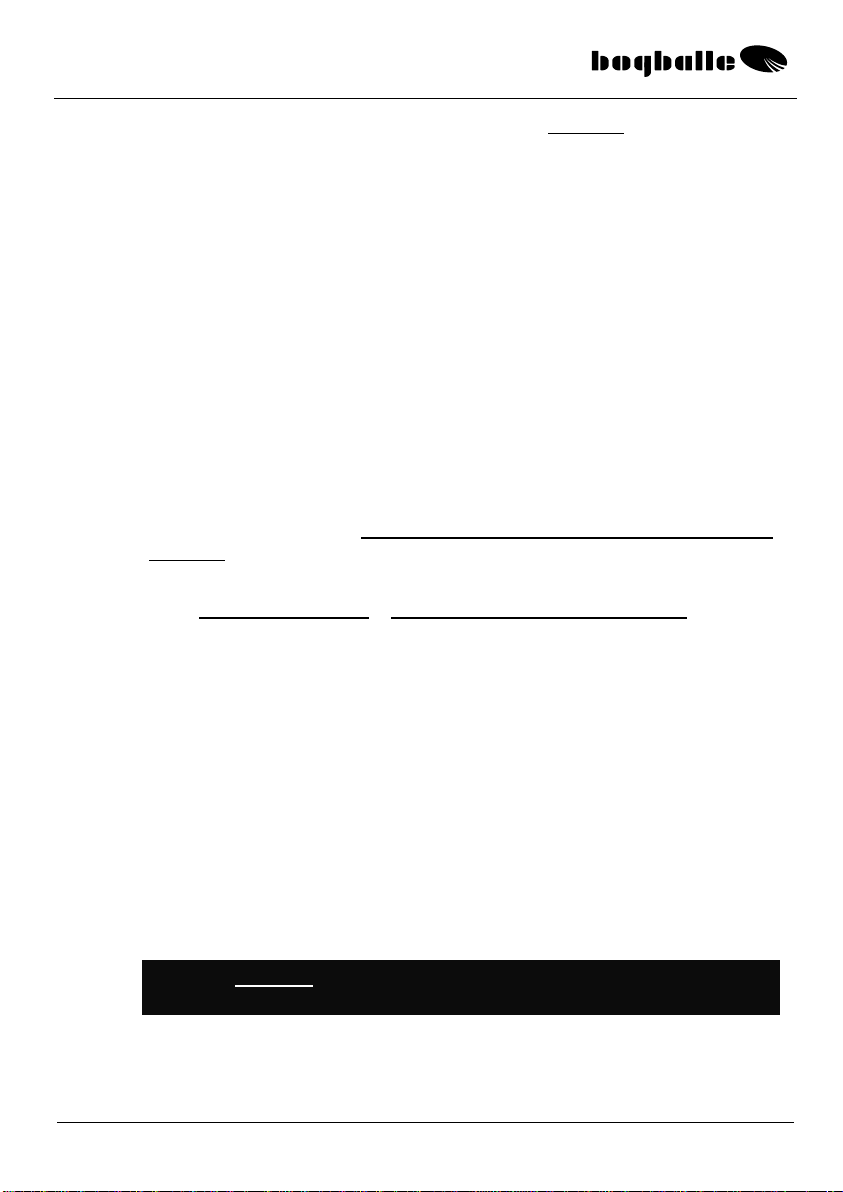

S2-Trail

OVERVIEW

Setting of working

width

Agitator type

Clutch f/ spreading disc

and agitator

Serial No.

Transmission

Setting scale

Handle f/

disengagement

Setting pointer

Drawbar

Lock/adjustment

f/ limiter

Top link

Wheel

S-line

16

PRACTICAL USE

When setting the spreading system of the machine, say vane setting, PTO speed

and limiter, see the paragraph ’PRACTICAL USE’ S2 / S3.

S2 Trail reaches its maximum spread width at 16 Km/h –corresponding to 400

rpms/min. on the spreading disc of the machine. It's not recommended to go faster

than 16 Km/h when spreading as it'll reduce the agitator's functionality and service

life.

Mount the spreader in the draw bar of the pulling vehicle.

The top link of the machine is adjusted in such a way that the spreading disc is

horizontal.

Check that the spreading disc is running easily and that shutter and setting

handle are easy to move.

Take away hard lumps and especially stones.

When driving with a full hopper it is NOT recommended to drive on an uneven

surface for a longer period of time –this might cause the material to compact.

Agitator and spreading disc must be disengaged if more than 100 m are driven

with closed shutter (Avoid if possible that agitator and spreading disc are rotating when the shutter is closed)

Spreading disc and agitator can with advantage be disengaged instead of

closing the shutter –as most types of material stay in the hopper when the

agitator do not rotate.

AGITATOR

Agitator and spreading disc are engaged when the spreader

is stopped.

The spreader is standard supplied with agitator for humit SAND

and SALT (Agitator with rubber disc and rubber fingers).

When spreading very rough material / small crushed stones the

free wheeling agitator is used (Optional equipment).

When spreading dry smooth-running materials –for instance dry salt or urea

the special free wheeling agitator is also used.

oAlternatively the standard agitator’s axle is dismounted (agitator axle

with rubber disc) in a way that only the lower ejector part is used. This

solution might induce crushing/grinding of the material.

S-line

17

Wheel slip

The S2 Trail spreading system is operated by the left wheel of the spreader. In

case the ground is icy and the spreading material is compact –wheel slip may

arise. (The wheel slides on the ground.)

In such cases the following check and changes are recommended:

It must be ensured that no bigger foreign objects in the hopper are causing

blocking of the agitator.

Open the setting handle 100% (scale 9,0) so that possible compacted material

is loosened when driving.

Reduce the air pressure in the pulling tyre for better road grip.

Mounting of a Snow Sock on the pulling wheel (Snow Socks are optional

equipment)

Put spikes in the pulling wheel. (Spike tyre is optional equipment).

Engagement of the spreading system can, if necessary, be made at low speed

less than 5 km/h. Only recommended on icy roads.

Do not mount snow chains

Forward speed for S2 Trail

The spreader should not drive more than 25 Km/h.

Transport only with disengaged spreading system / agitator.

Pay attention to the fact that the S2 trail may ‘tilt’ if the hopper is full and the

machine is driving on a slope or in a sharp turn at speeds higher than 8 km/h.

S-line

18

TECHNICAL DATA, general

S2 Trail

Hopper volume

:

130, 240, 350

Litres

Hopper capacity

:

Max. 600

Kg.

Spread width

:

1 –8

Meter

Spreading capacity

:

Ca. 5 –350

g/m2

TECHNICAL DATA, specific

SPECIFIKATION

S2 Trail, 130 l

S2 Trail, 240 l

S2 Trail, 350 l

Load height

cm

115

133

152

Hopper volume

Litres

130

240

350

Hopper capacity, Max.

Kg

175

325

470

Hopper opening

cm

70 x 74

70 x 74

70 x 74

Net weight

Kg

150

162

174

Total weight

Kg

325

487

600

The hopper capacity is made from hopper volume in litres multiplied with a specific weight of ~ 1,35

Kg/litres. STANDARD EQUIPMENT

The S2 Trail is from the factory supplied with the following standard

equipment.

Agitator f/ Salt and f/ Sand (w/ rubber disc and rubber fingers)

Transmission, with cable operation for disengagement of spreading disc.

Spreading vanes

Limiter w/ canvas skirt

Sieve, mesh size 5 x 5 cm

Manual setting of quantity

OPTIONAL EQUIPMENT

A line of useful optional equipment can be supplied –as mentioned below:

COMPONENT

DESCRIPTION

DIMENSION

Module S2

110 litres

76 x 80

Cm

Hopper cover S2

Tiltable

76 x 80

Cm

Cable control of quantity

Remote control of quantity

Hydraulic

Remote control of quantity

Electric motor, actuator

Remote control of quantity

Electric motor, actuator

CALIBRATOR ICON

Ground speed related quantity / working width

Traffic lights

Special agitator for rough material

Spike tyre

Better friction on icy surfaces

Snow Sock

Better friction on snow-covered surfaces

All BOGBALLE products are subject to a continuous development. Therefore the list might not always be up-to-date.

S-line

19

EC-Declaration of Conformity

Manufacturer:

BOGBALLE A/S

Bogballe · DK-7171 Uldum

Phone +45 7589 3266 Fax +45 7589 3766

Declares that machine:

Sand and salt spreader:

S2 / S3

Is made in conformity with:

directive of 17th May 2006 conc. mutual approximation of the laws of the member states on

machines (2006/42/EØF), with special reference to the enclosure II, A and enclosure I of the

directive, conc. essential safety and health claims in connection with construction and

manufacture of machines.

International/national standards:

DS/EN ISO 12100

DS/EN ISO 13857 1st edition –2008.03.26

DS/EN 349

ISO 500, 1st edition –2004.02.01

DS/EN ISO 4254-1 :2008

DS/EN ISO 4254-8 :2018

When mounted with CALIBRATOR:

Is made in conformity with:

directive of 15th December 2004 conc. mutual approximation of the laws of the member states on

electromagnetic compatibility (2004/108/EØF)

International/national standards:

DS/EN ISO 14982 :2009

DS/EN 61000-6-3 :2007

DS/EN 61000-6-4 :2007

Bogballe, 2018-08-27

Nils Jørn Laursen

This manual suits for next models

2

Table of contents

Other BOGBALLE Spreader manuals