The Andersons DI2020 User manual

Professional 75lb Dual Impeller

Broadcast Spreader

MODEL #DI2020 ASSEMBLY INSTRUCTIONS

P80000_M52098_Rev_June2020

Professional 75lb Dual Impeller

Broadcast Spreader

MODEL #DI2020 ASSEMBLY INSTRUCTIONS

PAGE 1

Thank you!

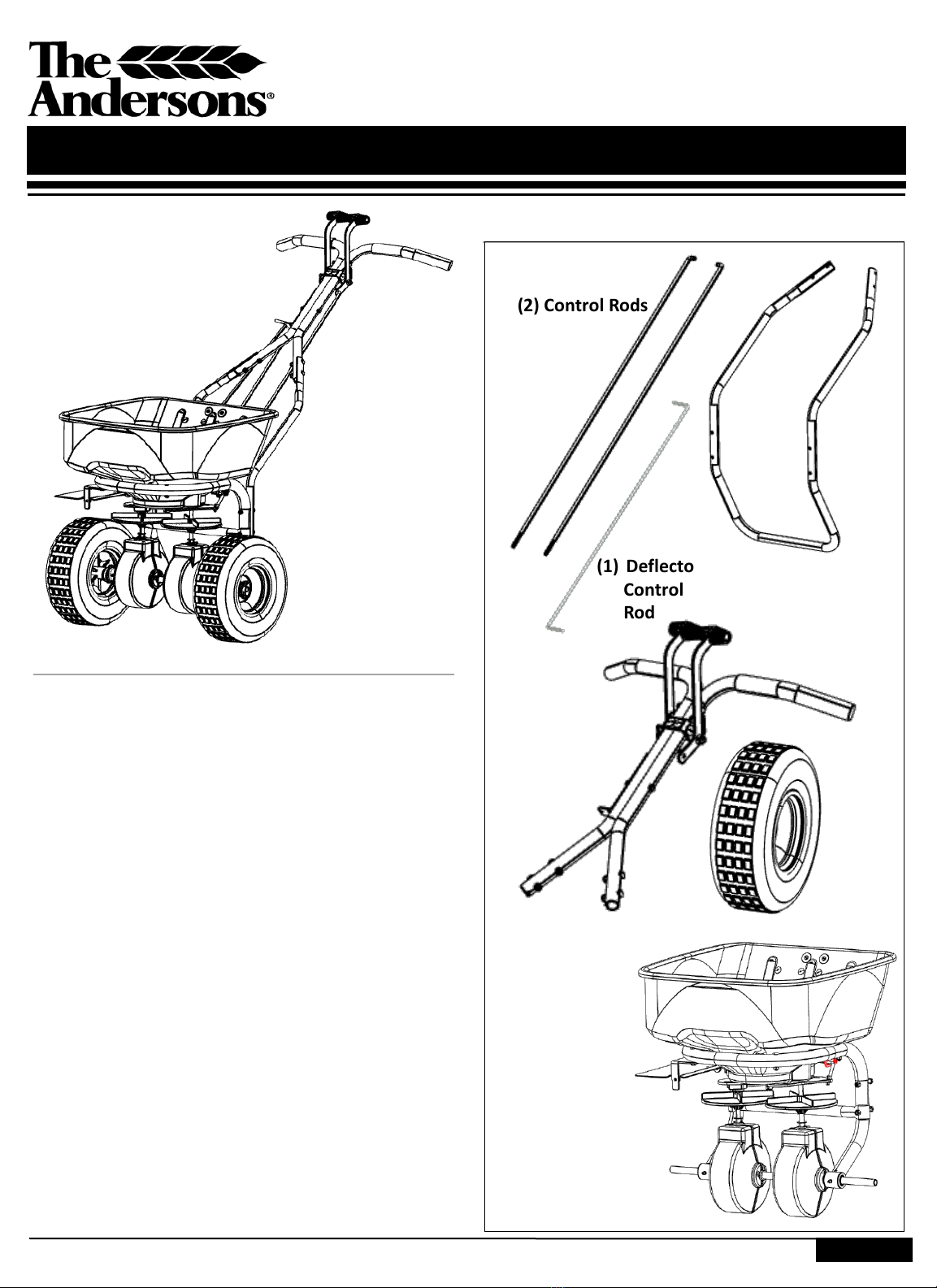

IN THE BOX

You have purchased the highest quality professional

broadcast spreader on the market. Featuring an

advanced design duel impeller system. This spreader

provides a symmetrical spread pattern, eliminating the

potential for uneven application. The dual impeller design

provides superior flexibility in spreading a variety of

granule types and seeds. A single adjustment of the rate

plate is all that is required to deliver a uniform application

each time.

While your spreader is mostly assembled, to minimize

shipping costs, you will need to attach the tires, frame

rest, upper handle, and control rods.

Before you begin, you will need the following tools to

assemble your DI2020 spreader:

Two 7/16” box wrenches,

One 1/2”

One 3/8” box wrench

(2) Control Rods

Helpful Hints

(1) Deflector

Control

Rod

(2) Tires

P15043

(1) Frame Rest

79008

(1) Upper Handle

Assembly

60368

(1) Hopper

Frame

Assembly

Other Items:

(1) Rain cover

(1) Hopper screen

(1) Hardware pack

The hardware kit include additional spare hardware:

-Cotter pin (for retaining tire)

-(2) 2 ¼” stainless bolts

-(2) ¼” stainless nuts

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

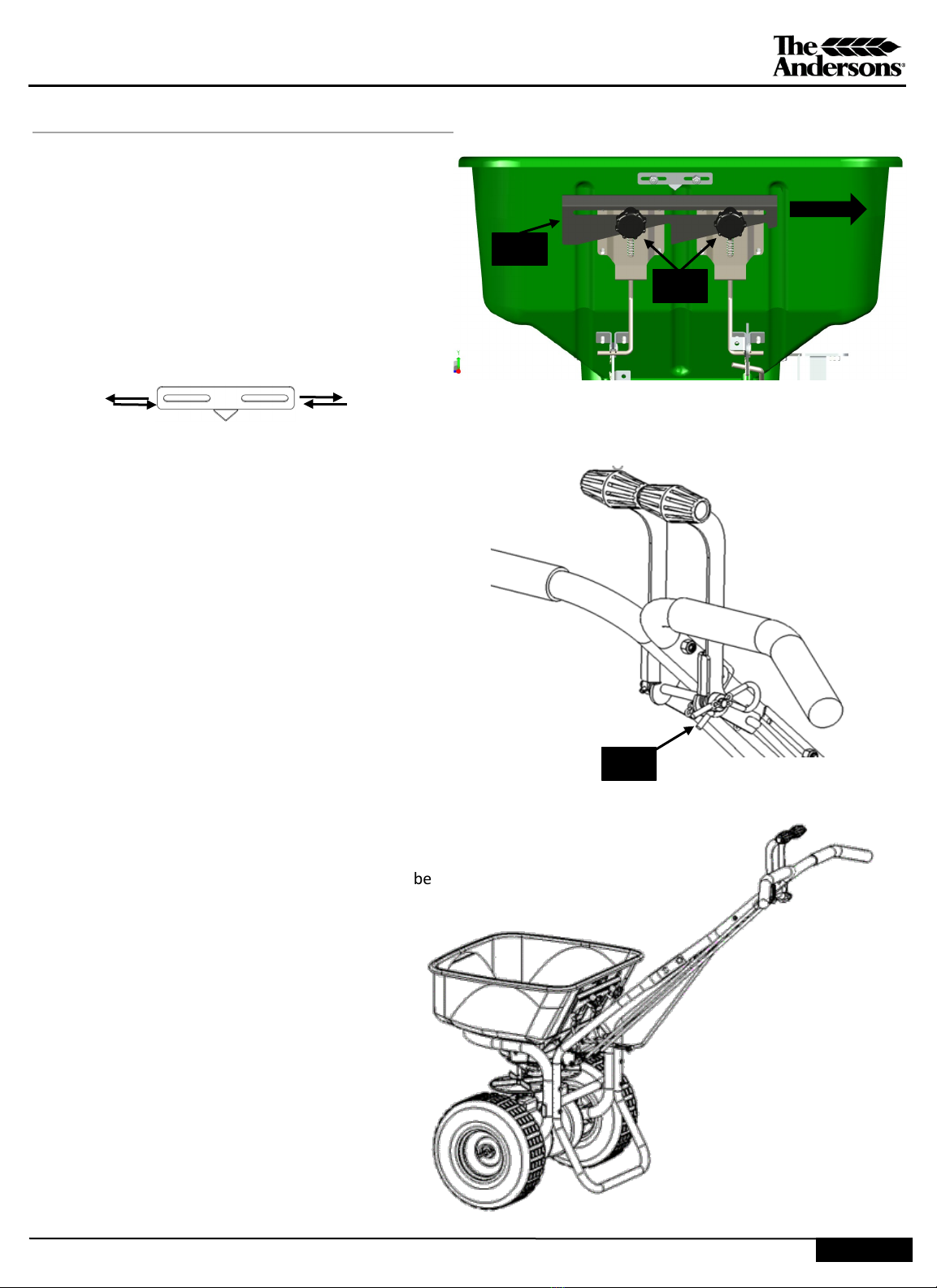

STEP 1: Remove from the box and set aside the

hardware pack containing control rods, deflector rod,

and calibrator keys. Also remove the wheel, hopper

cover, and screen.

STEP 2: Remove all inserts from the box to release the

hopper and frame assembly.

PAGE 2

ASSEMBLY: 20 minutes

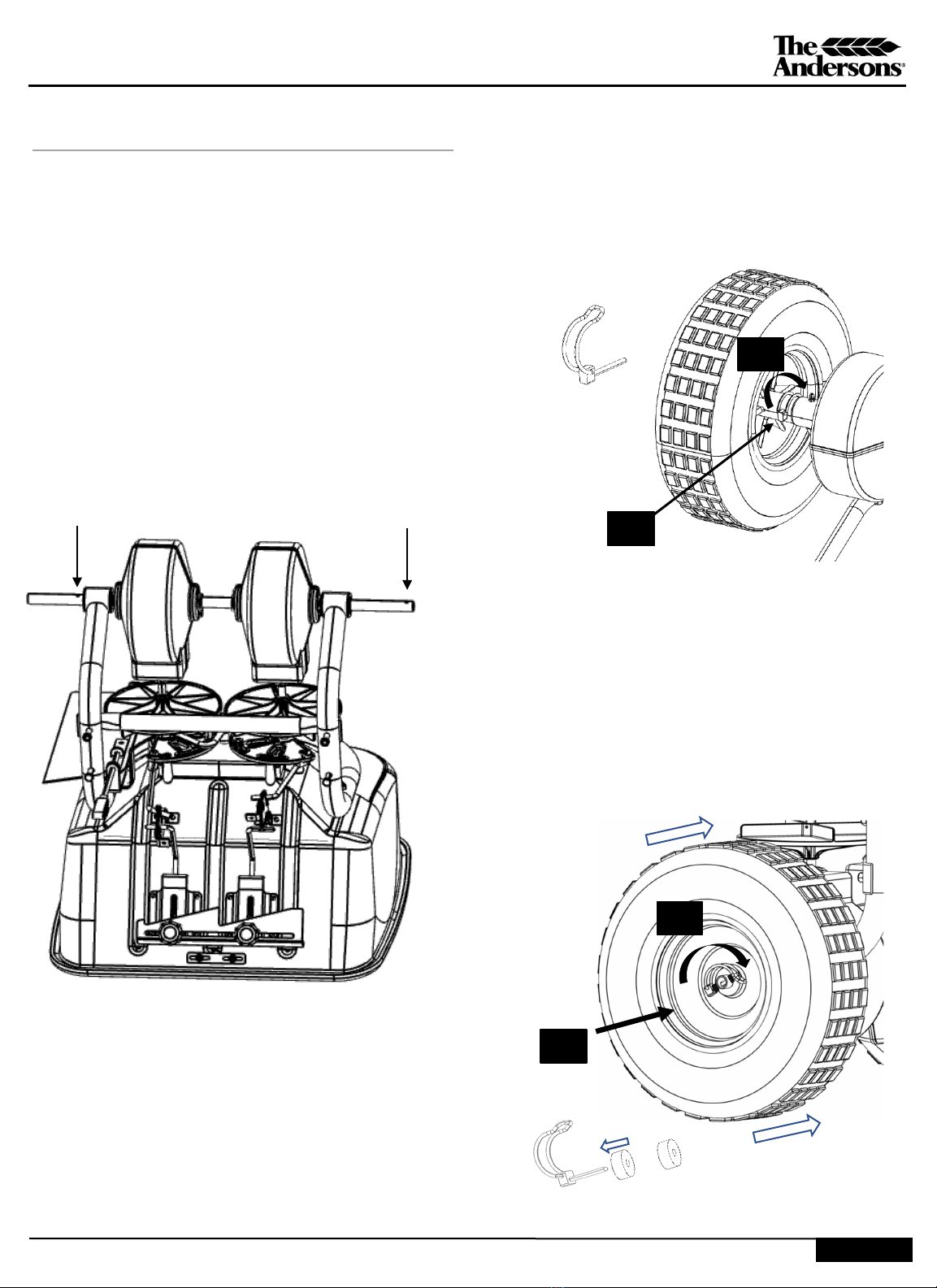

STEP 3: Lift the hopper frame assembly out of the

box and place on level surface. Remove the

second wheel from the box and set aside. Place

the hopper on a level surface in the following

orientation. Notice the holes in the axle. One is

inboard and one is in an outboard location to the

centerline of the spreader.

(A) Inboard (B) Outboard

Locate two quick release tire clips from the

hardware bag. Orient both tires with the longer

portion of the hub facing inward.

4.1

4.2

Spring clip

STEP 4: Start with the inboard (A) tire and insert

(4.1) the wheel spring clip through the hole of the

orange rim, through the axle, and then flip (4.2)

the spring clip over the axle.

STEP 5: Move to the outboard (B) tire. Slide the

tire on the axle and install one spacer on the wheel

spring clip (5.1). Then put the spring clip through

the axle hole on the outside of the orange rim.

Install a second spacer on the wheel spring clip and

flip (5.2) the clip over the axle as shown below .

Push rim inward while inserting spring clip through

the axle. The tire should rotate freely.

5.1

5.2

Spring clip

& spacers

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 3

ASSEMBLY: continued

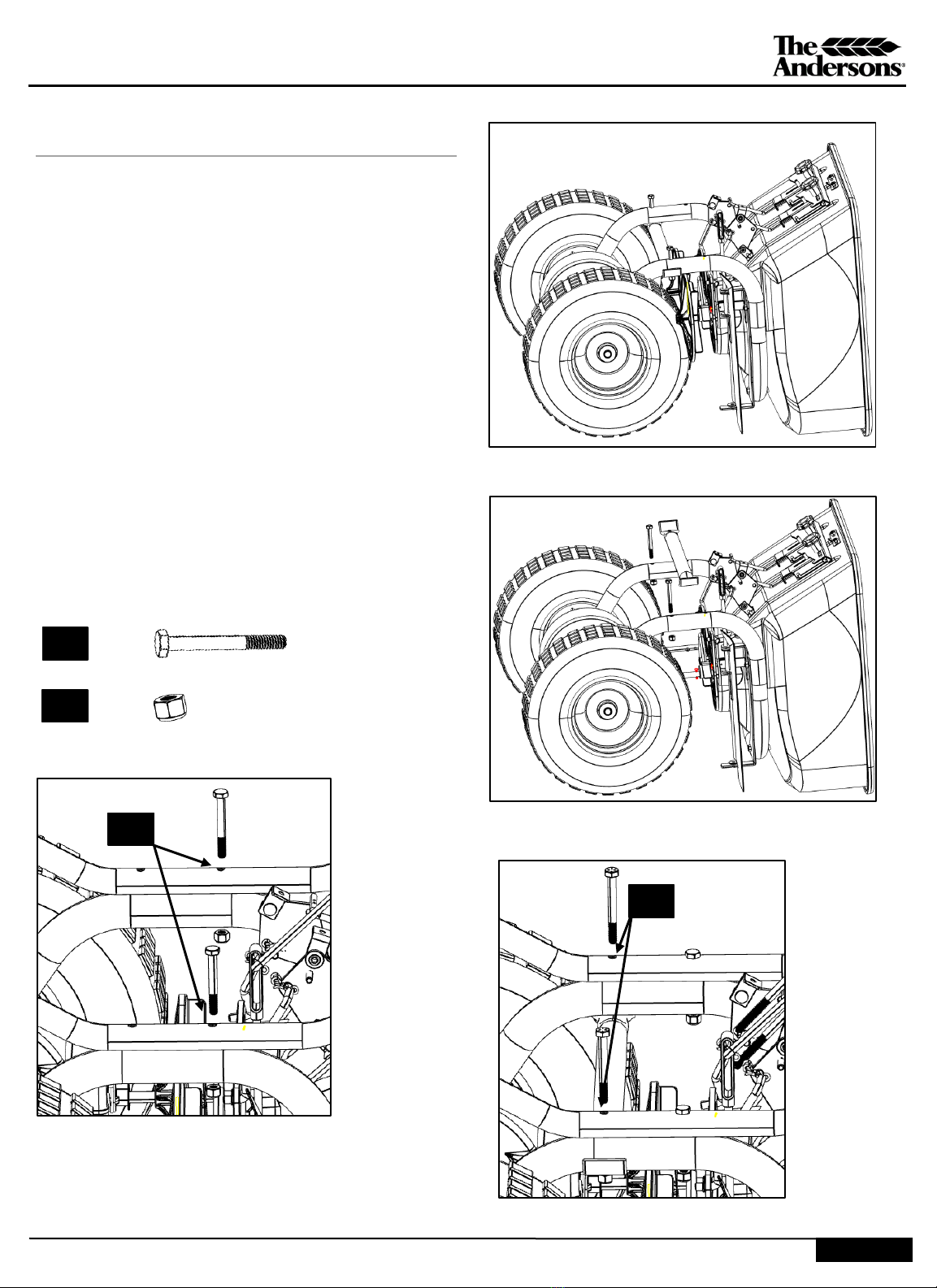

STEP 6: Position the spreader laying forward on

wheels and hopper as shown in Figure 6.3.

Figure 6.4 -Remove the cross brace by removing

two bolts and lock nuts. Keep the hardware for

reinstallation in step 6.6.

Figure 6.5 -Attach the lower frame rest to the

hopper assembly utilizing the two top holes. Two

(6.1) 1/4”x 2-1/4” bolts and two 1/4-20 nylon lock

nuts (6.2) are needed to make the assembly.

Install but do not tighten the lock nuts until next

step.

Figure 6.6 –Complete the rest assembly by

utilizing the two bottom holes. Reinsert the two

1/4”x 2-1/4” bolts that were removed in step 6.4

through the rest, then the frame, then the cross

brace. Install two 1/4-20 nylon lock nuts (6.2) and

now tighten all four lock nuts.

Figure 6.4 –Remove cross brace by removing 2 bolts and

lock nuts

6.1

6.2

4 x

4 x

Figure 6.3 -Starting Position –Attach Rest to Frame

Figure 6.5 –insert bolts and loosely tighten lock

nuts

6.2

Figure 6.6 –insert brace and tighten bottom lock nuts

6.2

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 4

ASSEMBLY: 20 minutes

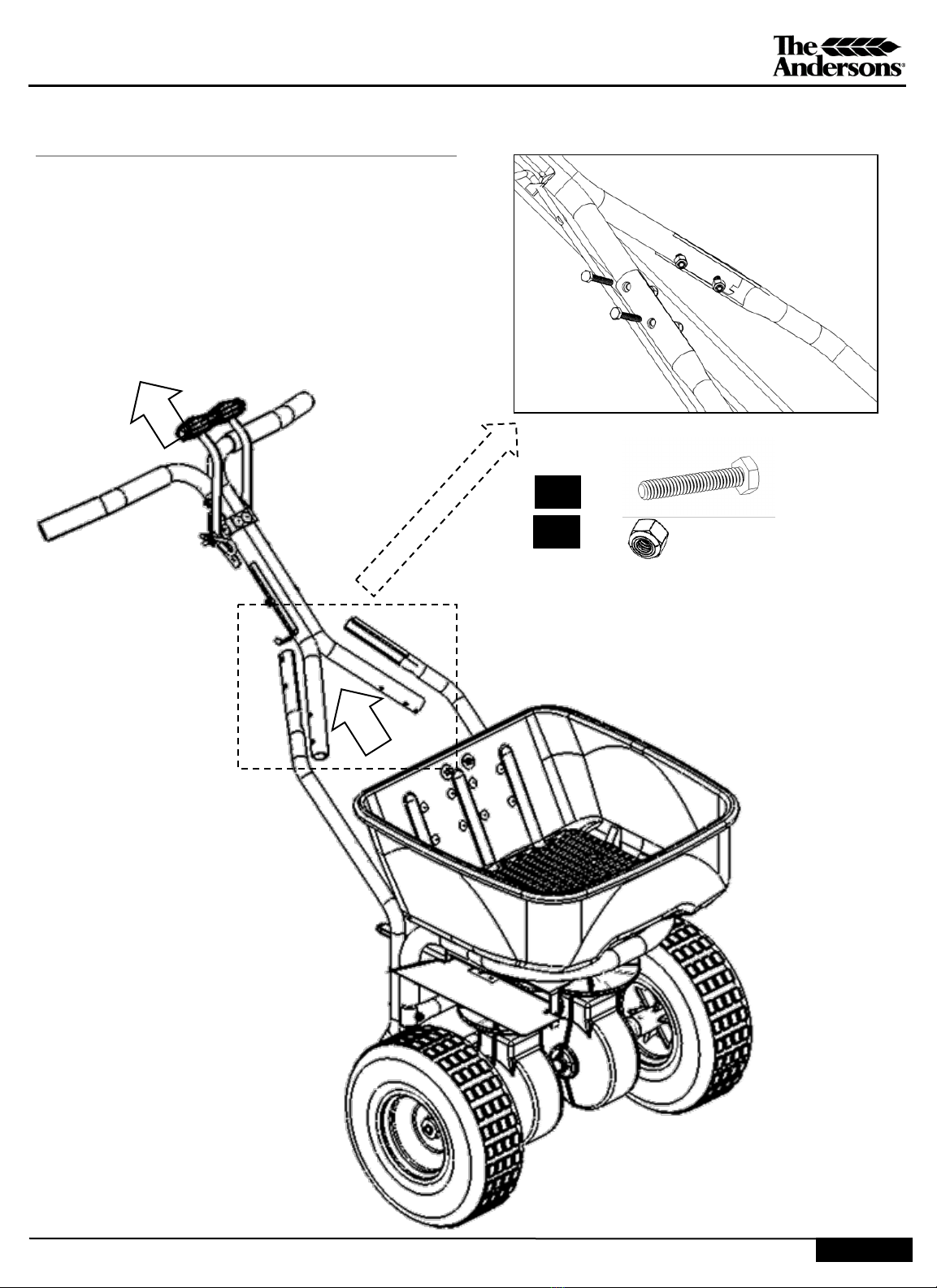

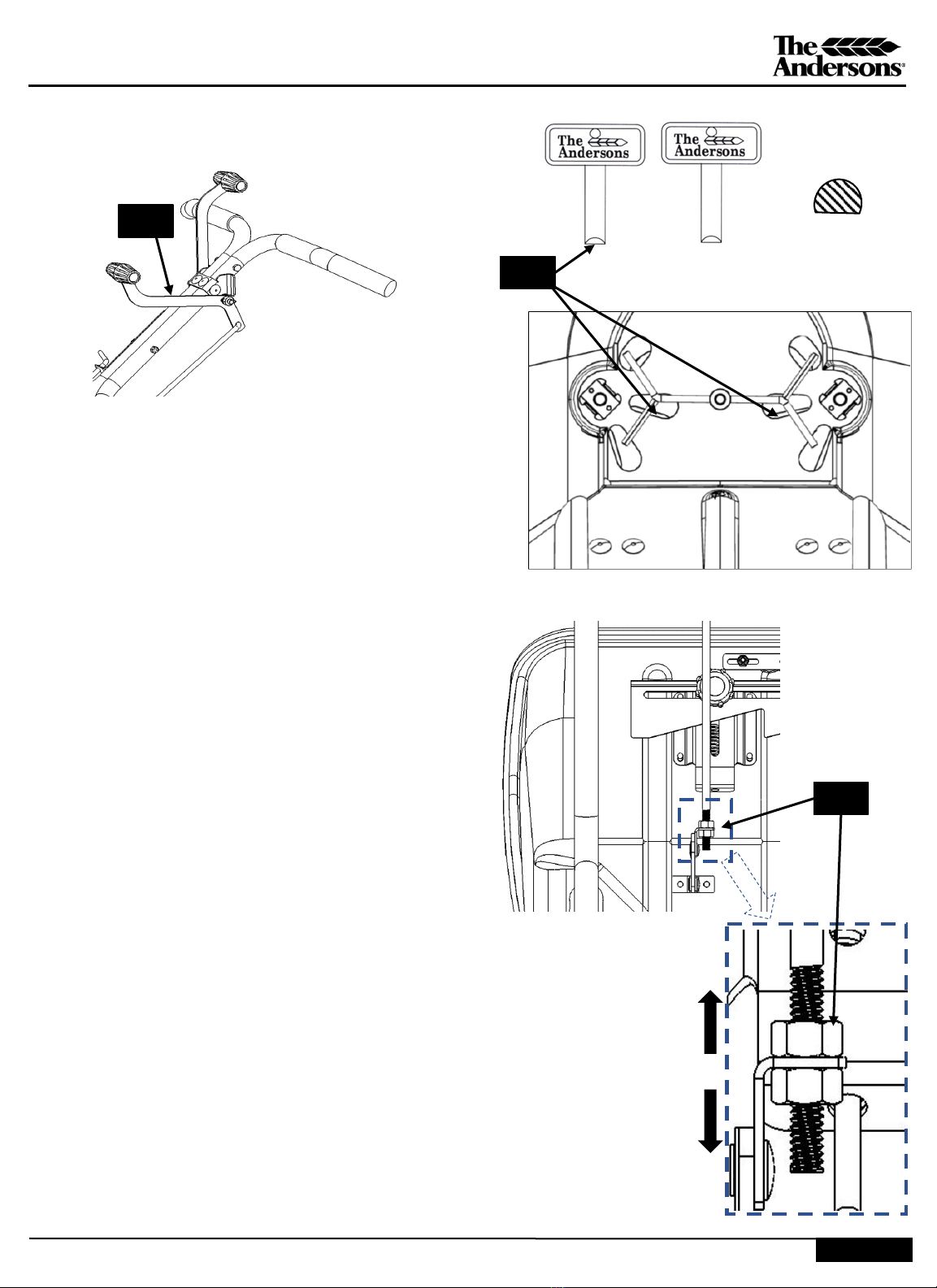

STEP 7: Position the spreader upright on wheels.

Place handles inside of the rest as shown in the

outlined box below and pull upward to mate the

handle in place with the rest.

Attach the upper handle to the frame rest installed

in Step 6 using four (7.1) 1/4” x 1 ½” hex bolts and

four 1/4” nuts (7.2). See closeup Figure 7.3

Upper handle to frame rest -Figure 7.3

7.1

7.2

4 x

4 x

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

ASSEMBLY: 20 minutes

STEP 8.1: Attach control rods to spreader shut off

pivots. Install one 5/16” hex nut (8.1) on each

control rod as close as possible, to the halfway point

of the threaded portion. Look at the rods and make

sure the initial nut is threaded equally up the rod,

this is to give you a clean starting point for

calibration.

Insert control rods into pivot assembly. Note the

position of the 90 Degree brackets at 8.1. The

brackets must be in an upright position. Once the

control rods are inserted, place the remaining two

5/16” hex nuts (8.1) on the bottom of the control

rod. Finger-tighten these nuts in place, they will be

adjusted during calibration.

See CALIBRATION section at the end of these

assembly instructions. See Figure 8.3 for close-up

drawing.

.

8.2

8.1 4 x

2 x

STEP 8.2 -Insert the curved end of control

rods through the shut off handle levers and

secure with the two infinity spring clips

(8.2). See Figure 8.4 for close-up.

Figure 8.3 –attach control

rods at bottom

8.1

8.1

Attach control rods to shut off pivots-Figure 8.4

8.2

8.2

PAGE 5

Thread up, opening

shut off

Thread down, closing

shut off

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 6

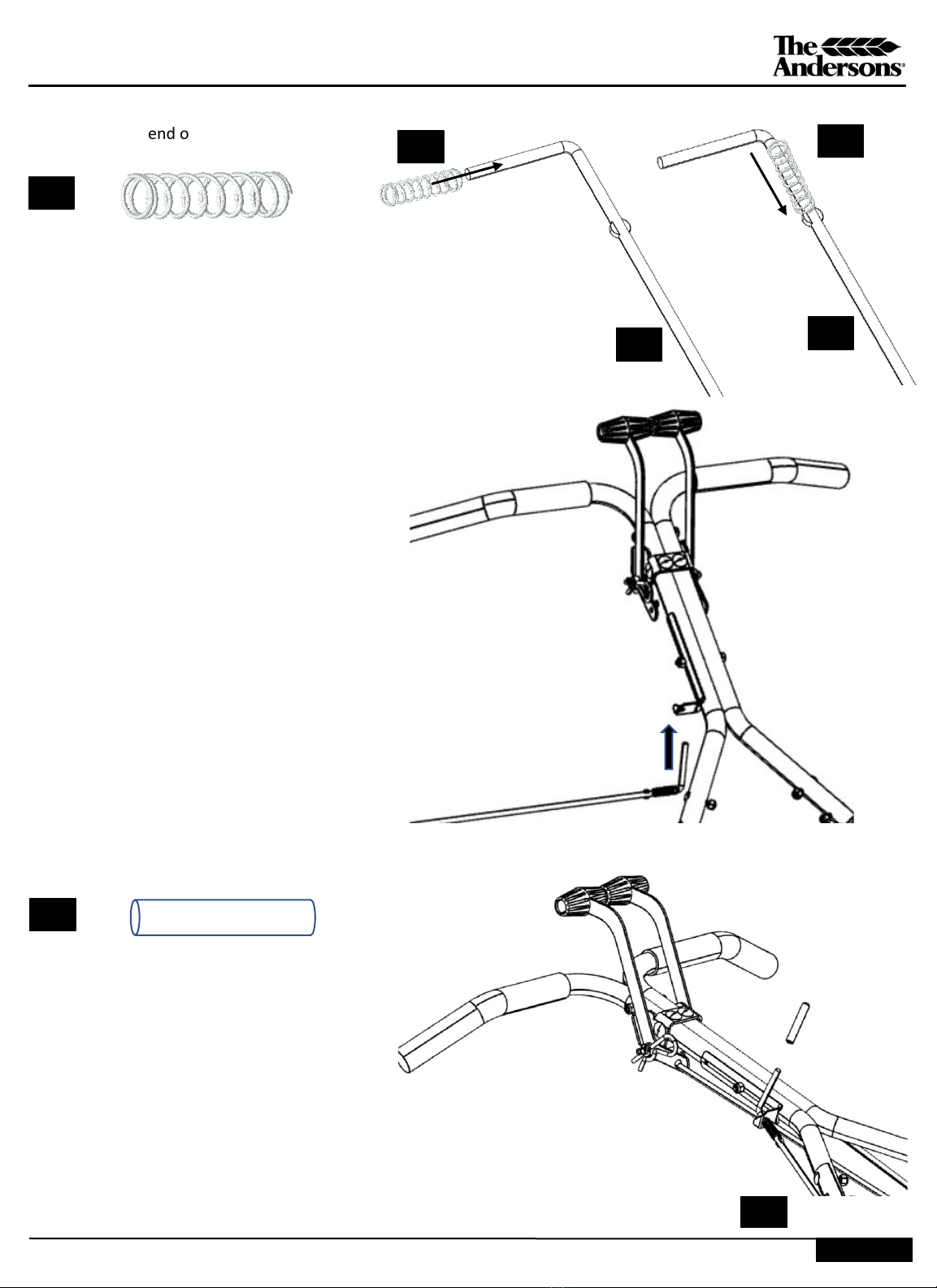

STEP 9: Install the 2” long deflector spring (9.1)

onto the coined end of the deflector control rod

(9.2).

9.1

9.3

1 x

1 x

9.2

9.1

9.2

9.1

Place deflector control rod grip (9.3) on the

top end of the deflector control rod.

Insert deflector control rod through the

bottom of the bracket mounted on upper

handle assembly.

9.3

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 7

STEP 9 <continued> Insert lower portion of

deflector control rod through the metal slot

attached to deflector shield. With deflector in

the raised position, insert the deflector control

rod from outboard position towards the

inboard position and through metal loop.

Secure rod with infinity spring clip (9.4).

1 x

9.4

9.4

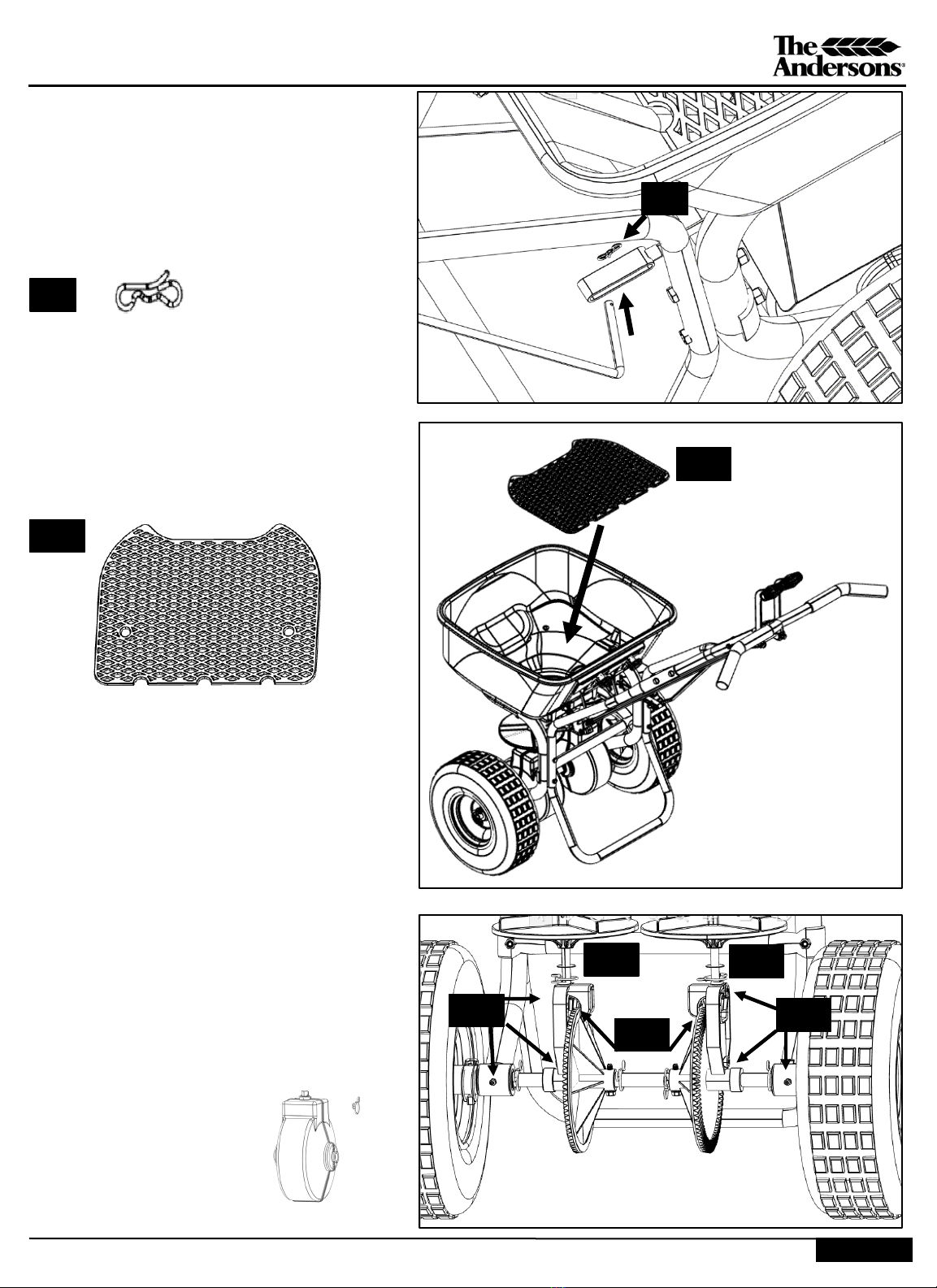

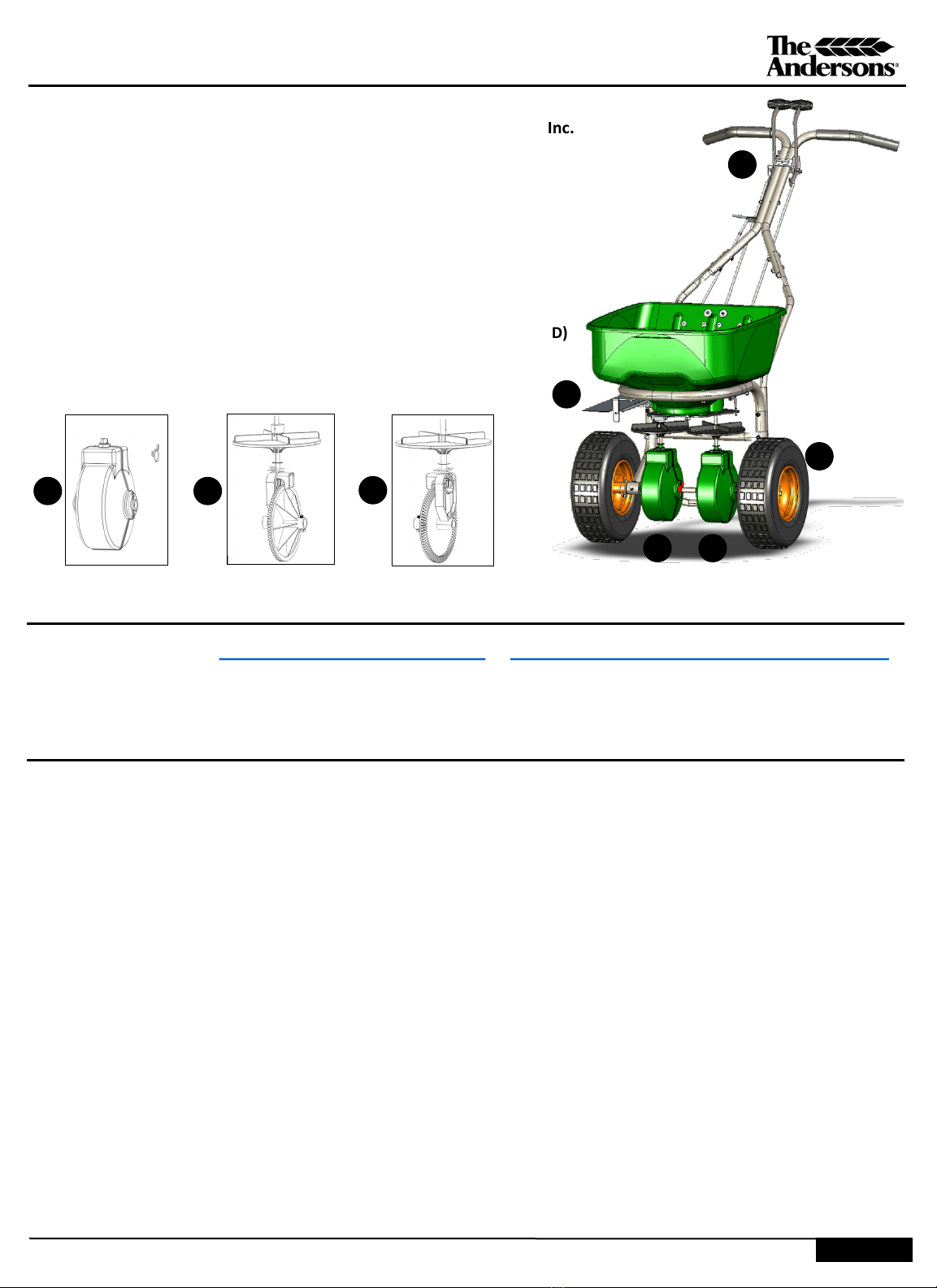

STEP 10: Place screen inside of the hopper so that

the cutouts align with hoppers interior shape.

10.1

STEP 11: Place hopper rain cover on the unit.

STEP 12: Remove the four gear box cover halves.

Using a grease gun, lightly lubricate grease fittings

12.1 on the axle bearing housings and gear carrier.

The bearings are already lubricated from the

factory so there is no need to put more than 1

handle pump into the fitting. Do not overfill. Apply

a small (less is more) amount of grease to the gear

teeth 12.2.

Re-install the four gearbox cover halves and secure

with the three retainer clips 12.3.

12.1 12.1

12.3

12.2

12.3

10.1

18126

3x

The unit was shipped with this spare hardware:

-Cotter pin (for retaining tire)

-(2) 2 ¼” stainless bolts

-(2) ¼” stainless nuts

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 8

CALIBRATION: 10 minutes

STEP 13: Your spreader should be calibrated before first

use. Once complete, the spreader should not need

further calibration unless the spreader is disassembled

or damaged.

STEP 13.1: If the pointer is not set at setting “I”, pull

both shut off handles back to the closed position.

Loosen the rate plate knobs (13.2). Slide the (13.1) rate

control plate to the right until you reach the “I” setting.

Tighten the rate plate knobs (13.2).

13.1

13.2

STEP 14: Remove the lever tether pin (14.1) so that

the handles move independently. Each side is to be

calibrated individually. For this process, it is best to:

•Have your unit on the ground in an upright

position

•Keep your tools located close so you can reach

them while manipulating the controls

Tools Required:

o3/8” Wrench (nut on the rate indicator)

oPhillips screwdriver (Screw for rate

indicator)

o1/2” Wrench (nut on the control rod)

•Kneel next to the unit, to one side of the unit, so

the handle is to your dominate side

•This is the approach for a right-handed person

•This gives you easy access to both areas you will be

manipulating for this step

14.1

A B C D E F G H I J K L M N O P

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 9

STEP 15: Start with left hand lever. Push the lever forward to

“open” position. See Image (15.1) below. Verify the opening

size using one of your calibration keys shown in image (15.2).

YOUR KEY WIL GO DIRECTLY INBOARD OF THE AGITATOR

(15.2). The FLAT portion of the key should be facing the

handlebars.

Flat side towards

handlebars

Key cross section

15.1

15.2

•If the key will not fit, that shutoff will need adjusted to

be more open.

•If the key is not contacting both sides, that side will

need adjusted to be more closed. (see threading detail

at right).

STEP 16: To adjust shutoff for BASELINE calibration:

Tool required: two 1/2” wrenches

•Push that lever forward to the open position

and loosen the nuts (16.1)

•Thread the nuts (both) in the same direction

needed. Making many small adjustments is

much more effective than making fewer big

adjustments until you are satisfied with the fit

of the calibration key.

•Tighten each nut (16.1) against the shut off

pivot

•Repeat this process for the other side.

Now that you have completed the baseline adjustment for

both sides, recheck the unit to fine-tune the calibration.

The next step will fine tune the spreader to reach the final

accuracy for maximum performance. Thread up, opening

shut off

Thread down, closing

shut off

16.1

P80000_M52098_Rev_June2020

ASSEMBLY & OPERATIONS MANUAL

PAGE 10

Thread up, opening

shut off

Thread down, closing

shut off

STEP 17: FINE TUNE CALIBRATION

Start by pushing both control levers forward and re-

inserting the calibration key(s) into the hole locations to

check the opening size. If both keys on both sides fit snug,

your spreader is fully calibrated.

If the key will not fit, that side will need adjusted to be

more open. If the key is not contacting both sides, that side

will need adjusted to be more closed. (see threading

detail). To adjust:

•Push that lever forward to the open position

and loosen the control lever nuts (16.1)

•Thread the nuts (both) in the same direction

needed. Making many small adjustments is

much more effective than making fewer big

adjustments until you are satisfied with the fit

of the calibration key.

•Repeat this for the other side.

If you are still having difficulty, contact us.

Congratulations, your spreader is now calibrated and ready

for operation. Re-insert the lever tether pin (Step 14).

16.1

OPERATION:

1) Check product bag for the desired rate setting and

swath width. The DI2020 uses the same rate setting

letter as the following Anderson models:

LCO-1000

AP 2000 & SR 2000

The DI2020 has a 12” wider effective swath width

than listed for the Anderson models. The rate

setting is achieved by loosening the rate control

knob and sliding the rate control plate until the

pointer aligns with desired letter.

1) When filling the hopper, make sure both operating

handles are in the closed position. Inserted in the

operating handles is a spring clip which allows for

independent use of each lever when removed.

2) Begin pushing the spreader forward before

engaging the levers to the desired open position;

close both levers prior to stopping.

3) When spreading material, a 3 MPH (brisk walk) is

recommended for even coverage. The hopper

should be level to the ground when in motion.

Tipping the spreader hopper too far forward or

backward may result in uneven product application

4) The settings on the product label are only

recommended starting points for calculating

product application rate. Test rate and effective

swath width on a small area prior to treating

desired turf area. Actual application rate can vary

depending on walking speed, wind, spread

material condition, and spreader condition.

5) The deflector shield is used to block off fertilizer

particles from the right portion of the swath width.

Use of the deflector shield is vital when applying

product near surfaces such as roads, driveways, etc.

When ready to apply, flip the side deflector shield

into the down position and remove lever tether pin

for independent lever operation. When the

deflector is in use, you will only use the left lever

while keeping the right one in the closed position.

P80000_M52098_Rev_June2020

PARTS LIST

CUSTOMER SERVICE

ONE YEAR WARRANTY

PAGE 11

The Andersons warrants to Purchaser the following:

1. Product will be free of defects in materials and workmanship for a period of one year from date of purchase.

2. The axle gear, gear support, pinion gear, axle, and axle bearings have a limited lifetime warranty to be free of defects in

materials and workmanship.

3. If the spreader is used for commercial rental the Limited Warranty shall be limited to a period of 90 days.

4. All unit and part replacement will be performed at the reasonable discretion of The Andersons.

5. Labor charges are not covered, and the unit need not be returned to the dealer for warranty service.

6. Proof of purchase must be supplied to The Andersons.

7. For warranty questions, contact Andersons at 1-800-225-2639.

The Andersons sole obligation under this warranty is limited to repairing or replacing the defective part.

This warranty does not extend to any Product or parts thereof that have been allowed to corrode, subjected to misuse, neglect,

accident, or modification by anyone other than The Andersons or that have been affixed to any nonstandard accessory attachment

or that have been used, stored, installed, maintained operated in violation of The Andersons instructions or standard industry

practice. No agent, employee or representative of The Andersons has any authority to bind The Andersons to any affirmation,

representation or warranty concerning the Product and any affirmation, representation or warranty made by any agent, employee

or representative shall not be enforceable by Purchaser.

THIS WARRANTY EXTENDS ONLY TO THE ORIGINAL PURCHASER AND IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED

WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS OR INTENDED

USE FOR A PARTICULAR PURPOSE AND OF ANY OTHER OBLIGATION ON THE PART OF The Andersons. The Andersons SHALL NOT

BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL LOSS, DAMAGE OR EXPENSE DIRECTLY OR INDIRECTLY ARISING

FROM THE USE OF ANY OF THE PRODUCT INCLUDING, BUT NOT LIMITED TO, DAMAGE OR LOSS OF OTHER PROPERTY OR

EQUIPMENT, LOSS OF PROFITS OR REVENUE, COST OF CAPITAL, COST OF PURCHASED OR REPLACEMENT GOODS, OR CLAIMS OF

CUSTOMERS OF PURCHASER.

1-800-225-2639 | www.andersonsturf.com | help@andersonsplantnutrient.com

The Andersons Inc, 1947 Briarfield Blvd, Maumee, OH 43537

1. P790161LG ANDERSONS RAIN COVER

2. 18126 GRATE / HOPPER SCREEN

3. P1000060 STAINLESS STEEL DEFLECTOR KIT

4. P15043 TIRE WHEEL & ORANGE RIM

5. 78003 GEAR COVER KIT

6. 78002 IMPELLER, GEAR, CAM & PINION ASSEMBLY

7. 78001 IMPELLER, GEAR, & PINION ASSEMBLY

8. 60368 UPPER HANDLE ASSEMBLY

9. 60262 HARDWARE PACK (CONTROL RODS, BOLTS, SPRING

CLIPS, LOCK NUTS, CALIBRATION KEYS, DEFLECTOR ROD)

10. 60336 ANDERSONS GREEN HOPPER

11. 79008 FRAME -REST

12. 79006 FRAME –HOPPER & AXLE

For replacement parts, call 574.848.7491

Service parts for Andersons spreaders are sold by EarthWay Products, Inc.

6 7

4

3

8

5 6 7

3x

Table of contents

Other The Andersons Spreader manuals

Popular Spreader manuals by other brands

Fimco

Fimco MS-25BU owner's manual

Art's Way

Art's Way X350 Operator manual & illustrated parts list

Shindaiwa

Shindaiwa RS76 owner's manual

H&S

H&S 5134 Operator's manual

Precision Products

Precision Products SB4300RD Parts list and instructions

Buyers Products Company

Buyers Products Company TGS01B installation instructions