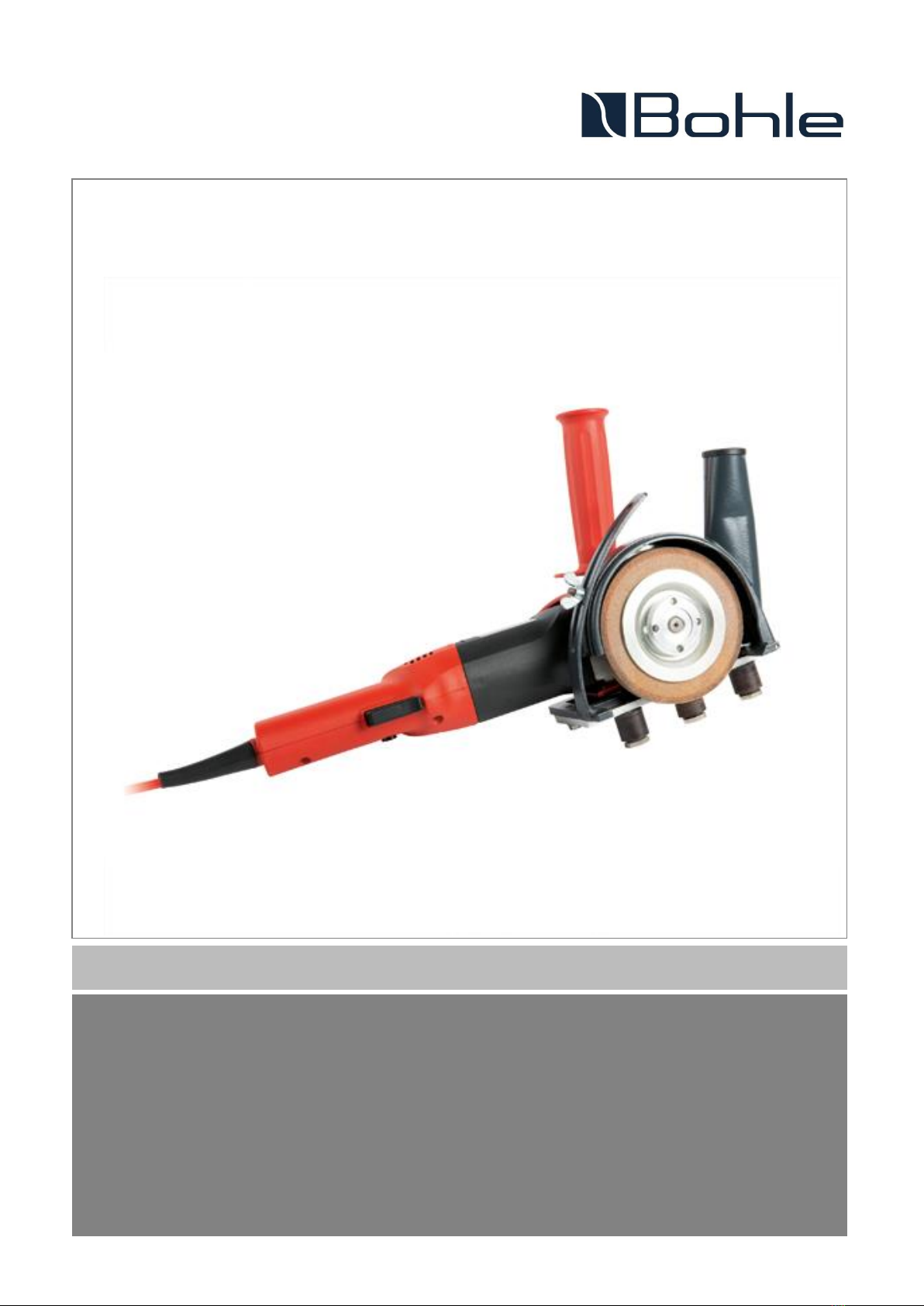

Bohle BO 89.110 User manual

Operating Instructions

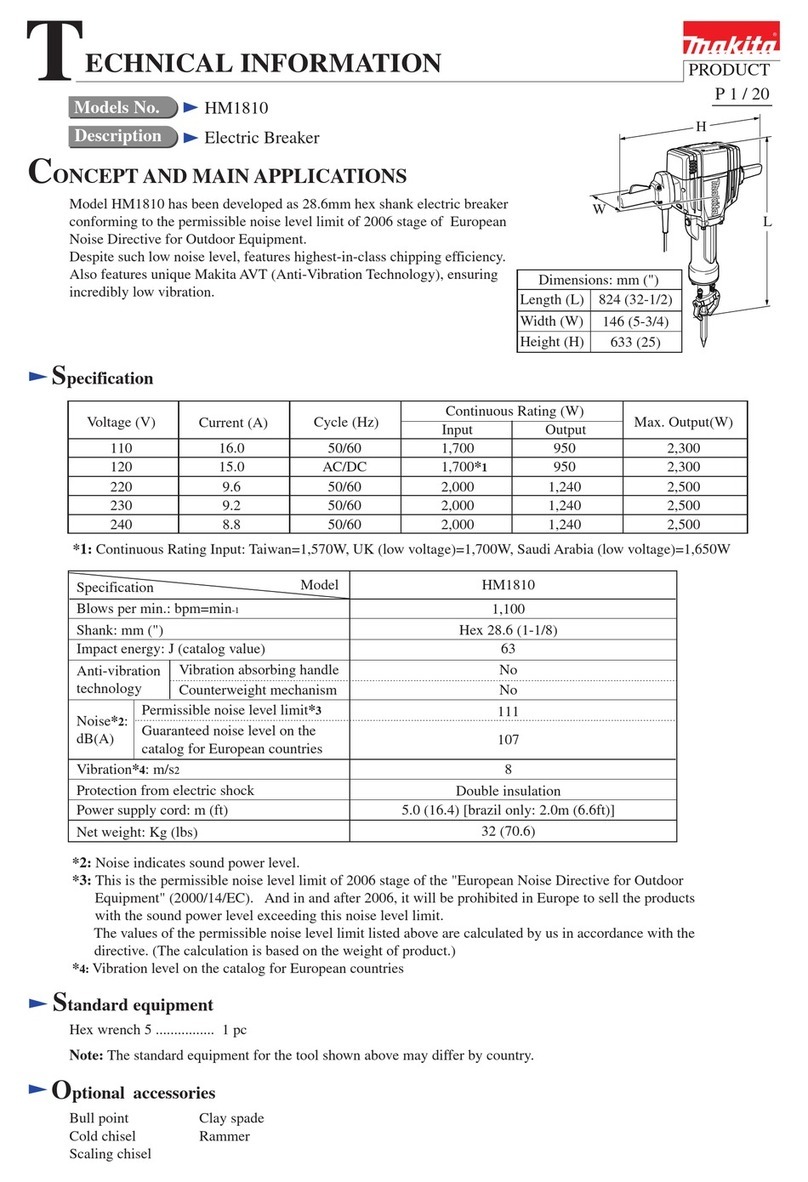

BO 89.110

Edge coating deleter

Operating Instructions Bohle Edge coating deleter –Version 2 E 2

Introduction

Dear customer,

Thank you for purchasing the Bohle Edge coating deleter BO 89.110.

Please read these operating instructions carefully before machine start up. The complete instruction manual should always be

kept close at hand.

For enquiries or spare parts orders and malfunctions, please inform us of the machine type and number.

No part of this operating manual may be reproduced in any form (by printing, photocopying, microfilm or any other method) or

processed, copied or distributed by electronic means without the written permission of Bohle AG.

We reserve the right to make changes in line with technical progress.

This document is the original operating instructions in English.

© Bohle AG. All rights reserved.

Table of Contents

Introduction 2

Table of Contents 2

EC-Declaration of Conformity 3

1. General safety instructions 4

2. Technical Data 5

3. Transport, storage and delivery 5

4. Handling 6

5. Inspection and maintenance 8

6. Spare Parts 8

Operating Instructions Bohle Edge coating deleter –Version 2 E 3

EC-Declaration of Conformity

We hereby declare that the Edge coating deleter

Type

Edge coating deleter BO 89.110

No.

Year

in the supplied version meets the requirements of the following relevant regulations:

EC Machine Guideline (2006/42/EC, annex I)

Low Voltage Guideline 2006/95/EG

EMC Guideline 2004/108/EG

Applicable harmonized standards, especially

DIN EN 60204-1

DIN EN 12100-1

DIN EN 12100-2

Bohle assumes no liability if:

-The edge coating deleter is not used as intended,

-The edge coating deleter is converted or modified without authorisation,

-Components or spare parts from other manufacturers are used,

-The Edge coating deleter is installed incorrectly or by unauthorised persons,

-The Edge coating deleter is not maintained regularly,

-Warnings, instructions and regulations in these operating instructions are not observed.

Intended use

The edge coating deleter is only to be used for the removal of coatings at the edges of glass panes with straight or shaped

edges.

Haan, December 2021

Edgar Höhn

Technical manager of machines, authorised representative for the compilation of technical documentation

Bohle AG, Dieselstraße 10, D-42781 Haan

Operating Instructions Bohle Edge coating deleter –Version 2 E 4

1. General safety instructions

•This Edge coating deleter may only be set up, operated and maintained by authorised, trained and qualified personnel who

are familiar with these instructions. The personnel must be made aware of any residual hazards.

•Bohle guarantees trouble-free operation only with original spare parts and accessories.

•Before use, ensure that all guards are appropriately positioned and undamaged.

•To avoid a malfunction, the operator must operate the Edge coating deleter in accordance with these operating instruc-

tions and applicable regulations.

•In addition to the operating instructions, the generally applicable legal and other binding regulations on accident preven-

tion and environmental protection must be observed.

•Always wear appropriate protective equipment when handling glass.

•Do not make any changes, additions or conversions to the Edge coating deleter device. This applies in particular to safety

devices. Unauthorised modifications and alterations to the Edge coating deleter will invalidate the EC declaration of con-

formity issued.

•The operating instructions must be kept with the unit.

•Regularly check the grinding wheel, protective guard and cable for damage. Replace damaged parts immediately!

•The use of the Edge coating deleter in a potentially explosive (ATEX) area is prohibited.

•During operation, never reach into the working area of the Edge coating deleter by hand or with tools; do not bypass pro-

tective devices. There is a risk of injury!

•The operator must ensure that no unauthorised persons are in the working area during operation. There is a risk of injury!

•Device only to be used in flawless condition. There is a risk of injury!

•It is forbidden to operate the Edge coating deleter under the influence of medication that affects the ability to perceive or

react and under the influence of drugs and alcohol!

•If safety devices are removed during repair work, the Edge coating deleter must not be put back into operation until all

safety devices have been fitted and checked for function.

•Any maintenance work must be done in "OFF" position only. Secure the edge coating deleter against unintentional

switching-on before beginning maintenance work.

•Because of dust formation, masks must be worn when using this tool. The operating company is expected to provide a

suitable grinding dust extraction which has to be connected to the suction piece of the protection cover.

Operating Instructions Bohle Edge coating deleter –Version 2 E 5

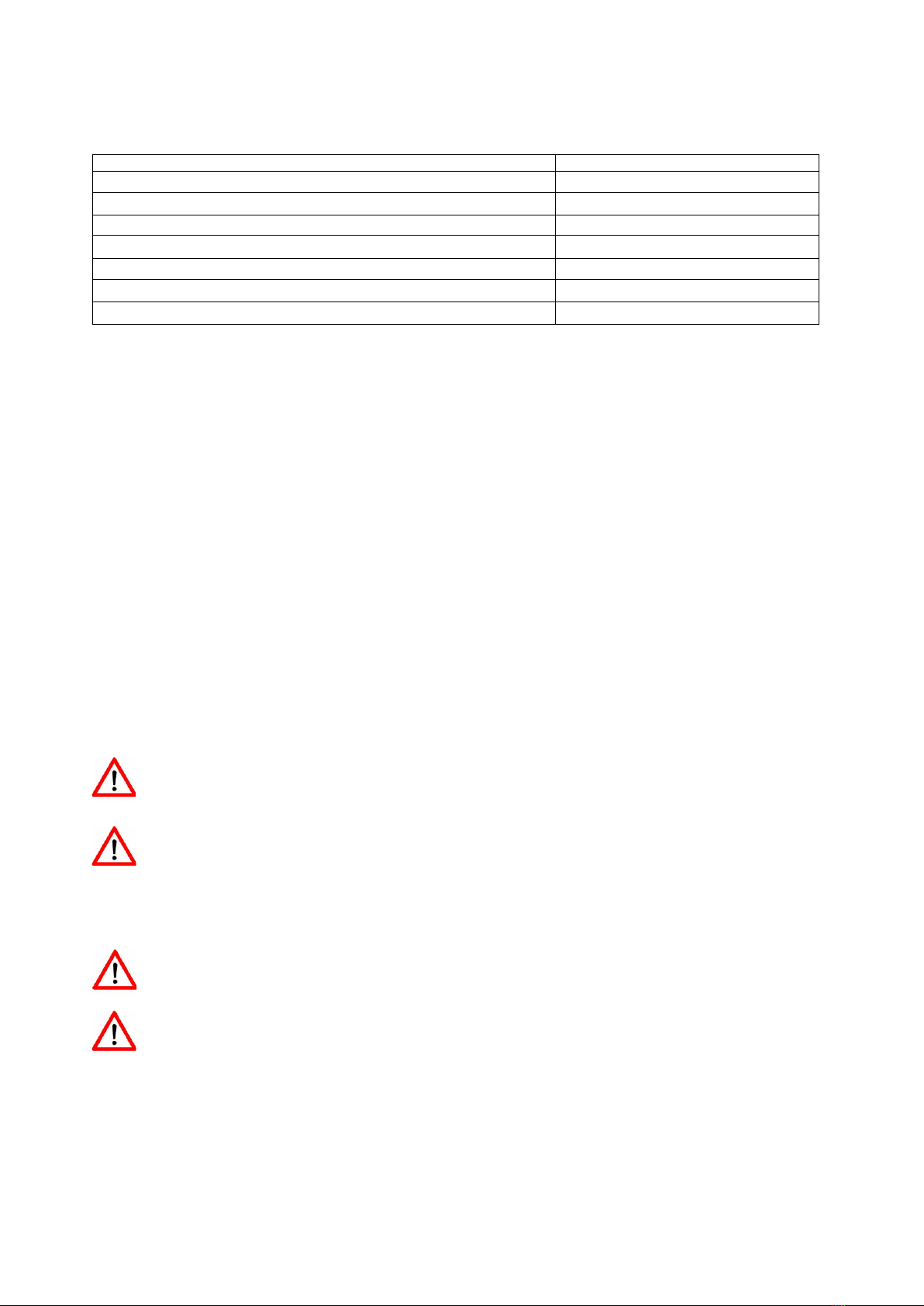

2. Technical Data

Height [mm] max

230

Width [mm] max

130

Length [mm] max

400

Grinding width [mm]

3

Special grinding wheel [mm]

125x10x76,2

Power supply

220-240V, 50Hz

Motor capacity

1200W

Speed

1200 –3700 1/min

The edge coating deleter is a portable, electrically powered grinder which has been developed for the removal of edge

coatings from glass panes.

Mounted on the cover of the angle grinder are adjustable guide rollers, which are used to guide the grinder along the edge of

the glass. The grinding pressure, which is a deciding parameter for the quality of the coating removal, depends on the user

and his care and experience.

The grinding wheels are especially designed to remove coatings from flat glass.

3. Transport, storage and delivery

The Edge coating deleter is delivered assembled in a cardboard box.

Scope of delivery BO 89.110 one Edge coating deleter and one instruction manual

It is essential to check the scope of delivery for completeness and damage. Transport damage must be reported im-

mediately and in writing to the carrier (forwarding agent, railway, etc.).

If there is any damage, the unit must not be used!

Remove all transport locks and packaging materials and take the edge decoating unit out of the packaging.

Be sure to read all operating instructions before use.

Always store the Edge coating deleter in such a way that damage to the grinding wheel is avoided.

Store in a dry and clean place.

Operating Instructions Bohle Edge coating deleter –Version 2 E 6

4. Handling

First, mount the special grinding wheel between the two flanges according to the manufacturer's (FLEX) instructions. The grin-

ding width is generally 10 mm and is determined by the width of the grinding wheel.

Next, check the gap between the guide rollers and the grinding wheel

and adjust, if necessary. To do this, adjust the roller plate accordingly.

By using the different threaded bore holes, the guide rollers can be ar-

ranged according to individual requirements.

For example, the middle roller is advantageous when grinding a

shaped edge.

Grinding a free shape. The guide roller at the grinding area promo-

tes uniformity of the grinding width along the entire length.

The guide roller plate is swivel-mounted at the cover. This allows the guide rollers to be adjusted according to the diameter of

the grinding wheel.

It is important that the guide rollers be set so that the roller is approx. half covered by the grinding wheel. That way the two lugs

on the cover are prevented from touching the glass.

Operating Instructions Bohle Edge coating deleter –Version 2 E 7

Next, check the speed of the grinder (preferably 3000 rpm) and

reset at the speed dial, if necessary. The wheels should gene-

rally be used according to the manufacturer's instructions. In

certain cases, when the outer diameter of the grinding wheel

has decreased due to wear, it could be advantageous to use a

different speed.

After having checked the settings and made any necessary ad-

justments, you are ready to plug the power tool in, make a short

test run and then start the actual work.

Put the glass pane onto a felt-covered table and make sure the

glass pane cannot slide away, e.g. by using stopper rails.

Position the glass so that the edge of the first side to be proces-

sed extends slightly (approx. 5-10 mm) over the table edge. The

entire length of the glass pane needs to be free to allow the

guide rollers to be positioned along the edge.

With the guide rollers resting against the edge of the glass, the edge coating deleter is steadily and evenly guided along the

glass. In doing so, it is the manual work of the operator which determines the forward speed as well as the pressure exerted

when removing the coating.

The work efficiency as well as the service life of the grinding wheels depend not only on the type of coating being removed,

but also very much on the manual skill of the operator. Especially when first touching the grinding wheel down onto the glass

there is a high risk of wear and requires some practice before low-wear working skills are mastered.

After the first side has been ground, the other sides are handled in the same way.

Operating Instructions Bohle Edge coating deleter –Version 2 E 8

5. Inspection and maintenance

Keep the machine clean and dry. Particular care must be taken to ensure that the ventilation slots of the grinding

machine are always kept clean and free.

The guiding elements are maintenance-free.

The maintenance of the angle grinder follows the manufacturer's instructions.

6. Spare parts

For enquiries or spare parts orders and malfunctions, please inform us of the type and production number of the machine. You

can read these on the machine plate.

SP 89.B0001 Plate

SP 89.B0002 Flange

SP 89.B0003 Counterflange

SP 89.B0004 Roller

SP 89.B0007 Guard

SP 89.B0008 Hexagon head screw

Operating Instructions Bohle Edge coating deleter –Version 2 E 9

BO 5300812 Carbon brushes

The following documents from the manufacturer FLEX are attached to the angle grinder used:

Operating instructions, safety instructions, spare parts list

Table of contents

Popular Power Tools manuals by other brands

Norge

Norge 10023321 operating instructions

Erbauer

Erbauer ER2100 Original instructions

Hamach

Hamach 7000 user manual

Matrix

Matrix EJS 800-1 Translation of the original instructions

Pittsburgh Automotive

Pittsburgh Automotive 61912 Owner's manual & safety instructions

Hilti

Hilti BX 3-BT Original operating instructions