Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output(W)

110

120

220

230

240

16.0

15.0

9.6

9.2

8.8

50/60

AC/DC

50/60

50/60

50/60

1,700

1,700*1

2,000

2,000

2,000

950

950

1,240

1,240

1,240

2,300

2,300

2,500

2,500

2,500

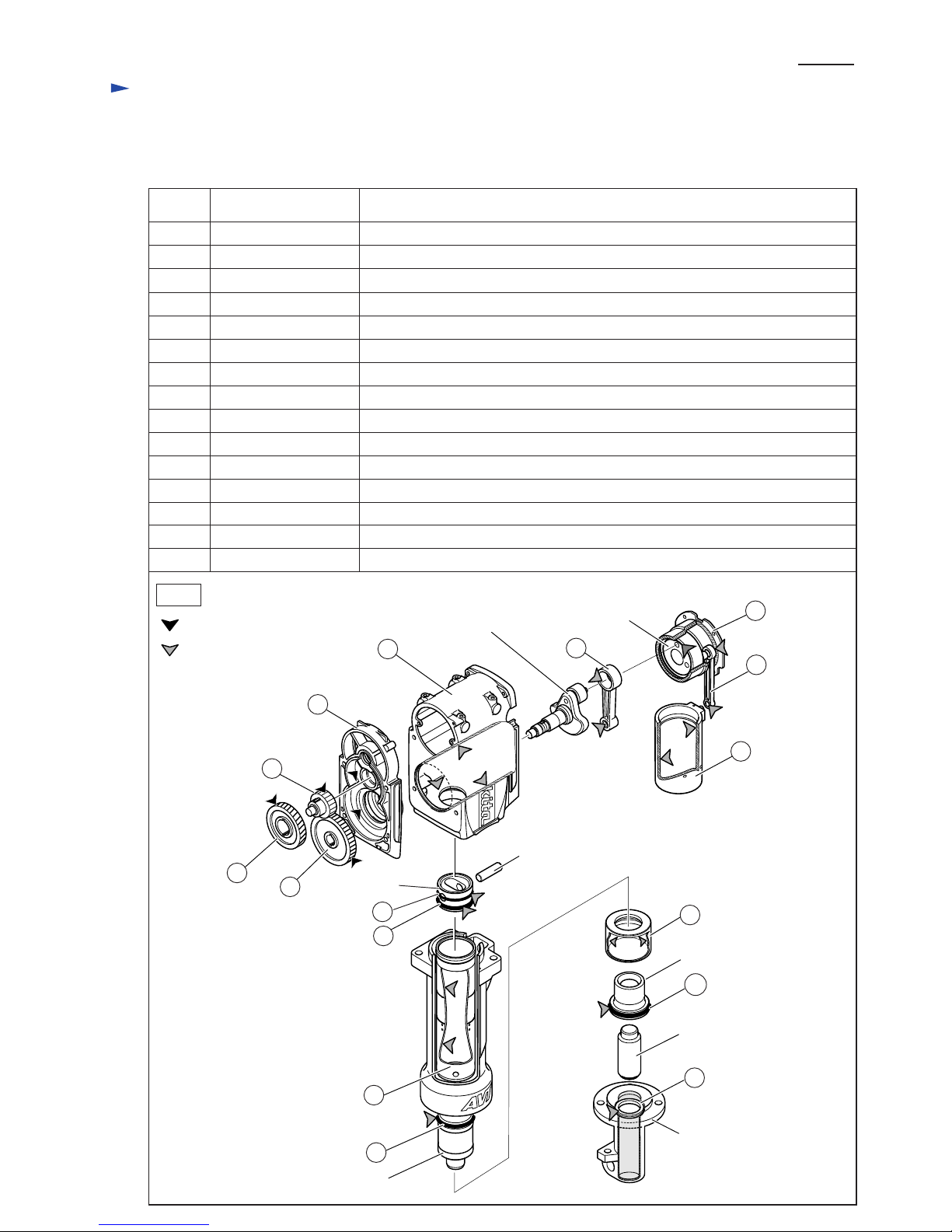

Models No.

Description

PRODUCT

Current (A)

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may differ by country.

P 1 / 20

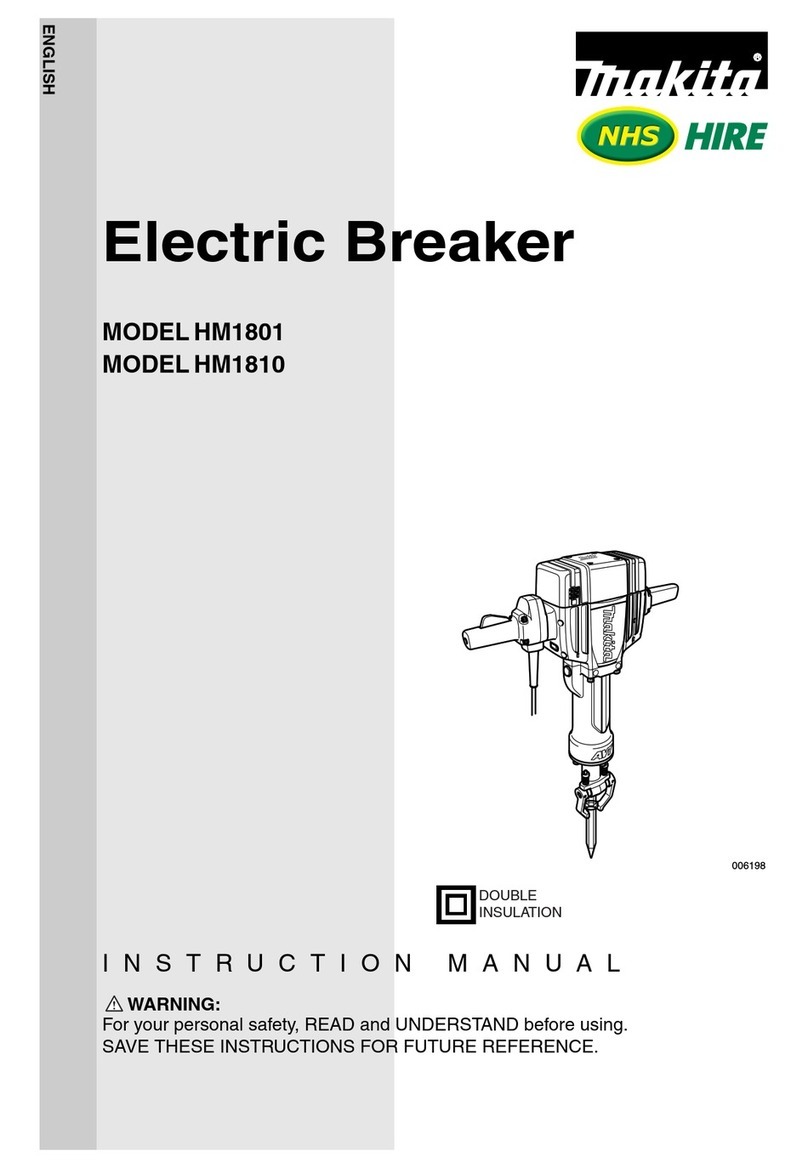

HM1810

Electric Breaker

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 824 (32-1/2)

146 (5-3/4)

633 (25)

L

W

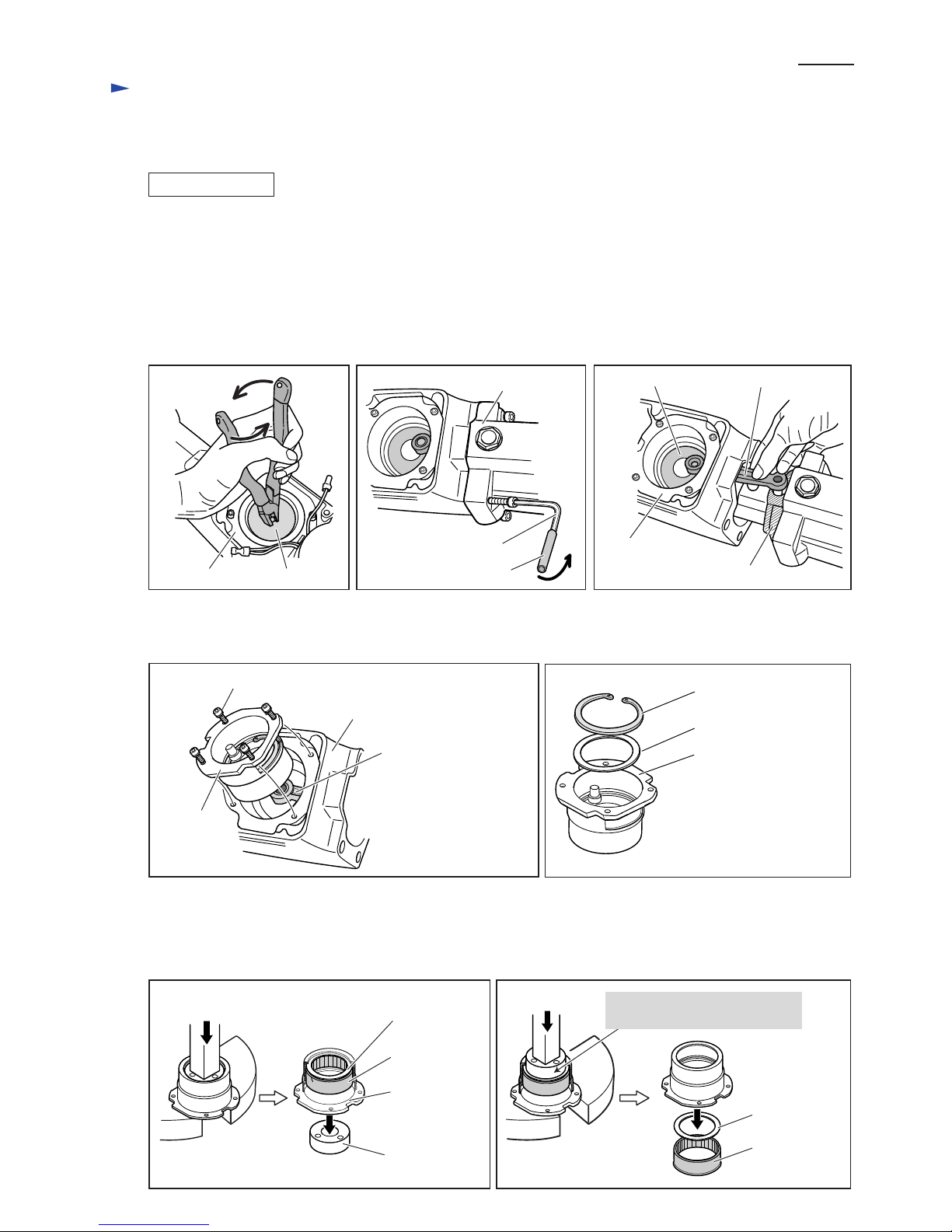

Model HM1810 has been developed as 28.6mm hex shank electric breaker

conforming to the permissible noise level limit of 2006 stage of European

Noise Directive for Outdoor Equipment.

Despite such low noise level, features highest-in-class chipping efficiency.

Also features unique Makita AVT (Anti-Vibration Technology), ensuring

incredibly low vibration.

H

Hex wrench 5 ................ 1 pc

Bull point

Cold chisel

Scaling chisel

Clay spade

Rammer

Blows per min.: bpm=min-1

Model HM1810

Protection from electric shock

Net weight: Kg (lbs)

Power supply cord: m (ft)

Noise*2:

dB(A)

*2: Noise indicates sound power level.

*3: This is the permissible noise level limit of 2006 stage of the "European Noise Directive for Outdoor

Equipment" (2000/14/EC). And in and after 2006, it will be prohibited in Europe to sell the products

with the sound power level exceeding this noise level limit.

The values of the permissible noise level limit listed above are calculated by us in accordance with the

directive. (The calculation is based on the weight of product.)

*4: Vibration level on the catalog for European countries

*1: Continuous Rating Input: Taiwan=1,570W, UK (low voltage)=1,700W, Saudi Arabia (low voltage)=1,650W

Specification

Shank: mm (")

Anti-vibration

technology

Vibration*4: m/s2

1,100

5.0 (16.4) [brazil only: 2.0m (6.6ft)]

Hex 28.6 (1-1/8)

Double insulation

Permissible noise level limit*3

Guaranteed noise level on the

catalog for European countries

Impact energy: J (catalog value) 63

Vibration absorbing handle No

Counterweight mechanism

32 (70.6)

111

No

107

8