Bolton Tools BF20VLP User manual

Page 1

MILL MACHINE

DRILL

&

BF20VLP

V LP

Page 2

Table of Contents

Preface

We thank you very much that you have decided for the drilling-milling machine made by supplier.

Changes The illustration of the drilling-milling machine might in some details deviate from the illustrations

of this operating manual but this will have no influence on the operation of the drilling-milling

machine.

Any changes in the construction, equipment and accessories are reserved for reasons of enhan-

cement. Therefore, no claims may be derived from the indications and descriptions. Errors

exepted!

1 Safety

1.1 Safety warnings (warning notes)............................................................................................. 5

1.1.1 Classification of hazards.............................................................................................. 5

1.1.2 Further pictograms....................................................................................................... 6

1.2 Proper use .............................................................................................................................. 6

1.3 Possible dangers caused by the drilling-milling machine........................................................ 7

1.4 Qualification of the staff........................................................................................................... 7

1.4.1 Target group ................................................................................................................ 7

1.5 Safety devices......................................................................................................................... 8

1.5.1 EMERGENCY-STOP button........................................................................................ 8

1.5.2 Protective cover........................................................................................................... 9

1.5.3 Separating protective equipment ................................................................................. 9

1.6 Safety check ......................................................................................................................... 10

1.7 Personnel protective equipment............................................................................................ 10

1.8 For your own safety during operation.................................................................................... 11

1.9 Disconnecting and securing the drilling-milling machine....................................................... 12

1.10 Using lifting equipment.......................................................................................................... 12

1.11 Signs on the drilling-milling machine..................................................................................... 12

2 Technical data

2.1 Power connection.................................................................................................................. 13

2.2 Drilling-milling capacity.......................................................................................................... 13

2.3 Spindle holding fixture........................................................................................................... 13

2.4 Drill-mill head ........................................................................................................................ 13

2.5 Cross table ............................................................................................................................ 13

2.6 Dimensions ........................................................................................................................... 13

2.7 Work area.............................................................................................................................. 13

2.8 Speeds.................................................................................................................................. 13

2.9 Environmental conditions ...................................................................................................... 14

2.10 Operating material................................................................................................................. 14

2.11 Emissions.............................................................................................................................. 14

3 Unpacking and connecting

3.1 Extent of supply .................................................................................................................... 15

3.2 Transport............................................................................................................................... 15

3.3 Storage ................................................................................................................................. 15

3.4 Installation and assembly...................................................................................................... 16

3.4.1 Requirements of the installation site.......................................................................... 16

3.4.2 Load suspension point............................................................................................... 16

3.4.3 Installation.................................................................................................................. 16

3.4.4 Installation drawing.................................................................................................... 17

3.5 Installation plan .................................................................................................. 18

3.6 Installation plan ............................................................................................... 19

3.7 Installation plan of optional substructure............................................................................... 20

3.8 First use ................................................................................................................................ 21

3.8.1 Cleaning and lubricating ............................................................................................ 21

3.9 Optional accessory................................................................................................................ 22

BF20

6 Ersatzteile - Spare parts BF20 VLP

Page 3

4Operation

4.1 Safety....................................................................................................................................23

4.2 Control and indicating elements............................................................................................23

4.2.1 Control panel..............................................................................................................24

4.3 Switching on the drilling-milling machine...............................................................................26

4.4 Switching off the drilling-milling machine...............................................................................26

4.5 Inserting a tool.......................................................................................................................26

4.5.1 Installation..................................................................................................................26

4.5.2 Disassembly...............................................................................................................26

4.5.3 Use of collet chucks...................................................................................................27

4.6 Clamping the workpieces......................................................................................................27

4.7 Changing the speed range....................................................................................................27

4.8 Selecting the speed...............................................................................................................28

4.8.1 Standards values for cutting speeds..........................................................................28

4.8.2 Standard values for speeds with HSS – Eco – twist drilling.......................................29

4.9 Manual spindle sleeve feed with the fine feed.......................................................................30

4.10 Digital display for spindle sleeve travel .................................................................................30

4.10.1 Technical data............................................................................................................30

4.10.2 Design........................................................................................................................31

4.10.3 Malfunctions...............................................................................................................31

4.11 Manual spindle sleeve feed with the spindle sleeve lever.....................................................32

4.12 Swivelling the drill-mill head..................................................................................................32

4.12.1 Shifting the drill-mill head...........................................................................................32

4.13 Assembly of the optional adapter for a high speed motor.....................................................32

4.13.1 Drawing adapter for a high speed motor....................................................................34

4.14 Assembly of the column on the lathe ....................................................................................34

4.14.1 Drawing adapter.........................................................................................................35

5 Maintenance

5.1 Safety....................................................................................................................................36

5.1.1 Preparation ................................................................................................................36

5.1.2 Restarting...................................................................................................................37

5.2 Inspection and maintenance .................................................................................................37

5.3 Repair....................................................................................................................................41

5.4 Setting instructions control ....................................................................................................42

6.1 Kreuztisch - Cross table ........................................................................................................43

6.2 Kreuztisch ab Baujahr 2007 - Cross table starting from year of construction 2007 ..............44

6.3 Säule 1 von 2 - Column 1 of 2...............................................................................................45

6.4 Säule 2 von 2 - Column 2 of 2...............................................................................................46

6.5 Säule 2 von 2 ab Baujahr 2007 - Column 2 of 2 starting from year of construction 2007.....47

6.6 Fräskopf 1 von 2 - Milling head 1 of 2 ...................................................................................48

6.7 Fräskopf 2 von 2 - Milling head 2 of 2 ...................................................................................49

6.8 Fräskopf 2 von 2 - Milling head 2 of 2 ...................................................................................50

6.9 Optionaler unterbau - Optional sub structure .......................................................................51

6.10 Schaltplan - Wiring diagram ..................................................................................................52

6.10.1 Ersatzteilliste - Spare part list.....................................................................................53

7 Malfunctions

7.1 Malfunctions on the drilling-milling machine..........................................................................57

8 Appendix

8.1 Copyright...............................................................................................................................58

8.2 Terminology/Glossary ...........................................................................................................58

8.3 Warranty................................................................................................................................59

8.4 Disposal.................................................................................................................................59

8.5 RoHS , 2002/95/EC...............................................................................................................59

8.6 Product follow-up...................................................................................................................60

8.7 EC - Declaration of Conformity..............................................................................................61

9 Index

Page 4

1 Safety

Glossary of symbols

This part of the operating manual

explains the meaning and use of the warning references contained in the operating

manual,

explains how to use the drilling-milling machine properly,

highlights the dangers that might arise for you and others if these instructions are not

obeyed,

informs you on how to prevent dangers.

In addition to this operating manual please observe

applicable laws and regulations,

legal regulations for accident prevention,

the prohibition, warning and mandatory signs as well as the warning notes on the drilling-

milling machine.

Always keep this documentation close to the drilling-milling machine.

gives additional indications

calls on you to act

enumerations

Page 5

1.1 Safety warnings (warning notes)

1.1.1 Classification of hazards

We classify the safety warnings into various levels. The table below gives an overview of the

classification of symbols (pictograms) and warnings for the specific danger and its (possible)

consequences.

Pictogram Alarm expres-

sion Definition/Consequences

DANGER! Imminent danger that will cause serious injury or death to

persons.

WARNING! Risk: a danger that might cause serious injury or death to

persons.

CAUTION! Danger or unsafe procedure that might cause injury to

persons or damage to property.

ATTENTION!

Situation that could cause damage to the drilling-milling

machine and to the product and other types of damage.

No risk of injury to persons.

INFORMATION

Application tips and other important/helpful or useful infor-

mation and notes.

No dangerous or harmful consequences for persons or

objects.

In the case of specific dangers, we replace the pictogram by

or

general dan-

ger with a warning

of injuries to

hands, hazardous

electrical

voltage,

rotating parts.

Page 6

1.1.2 Further pictograms

1.2 Proper use

WARNING!

In the event of improper use, the drilling-milling machine

• will endanger the staff,

• will endanger the drilling-milling machine and other material property of the operator,

• may affect the proper operation of the drilling-milling machine.

The drilling-milling machine is designed and manufactured to be used for milling and drilling cold

metals or other non-flammable materials that do not constitute a health hazard by using com-

mercial milling and drilling tools.

The drilling-milling machine must only be installed and operated in a dry and well-ventilated

place.

If the drilling-milling machine is used in any way other than described above, modified without

the authorisation of the company or operated with diffe-

rent process data, then the drilling-milling machine is being used improperly.

We do not take any liability for damages caused by improper use.

We would like to stress that any modifications to the construction or technical or technological

modifications that have not been authorised by the company

will also render the guara ntee null and void. It is also part of proper use that

the maximum values for the drilling-milling machine are complied with,

the operating manual is observed,

inspection and maintenance instructions are observed.

“Technical data“ on page 13

Activation forbidden! Read the operating

manual before the

machine is first used!

Pull the mains plug! Use protective goggles!

Use protective gloves! Use protective boots! Wear a safety suit! Use ear protection!

Protect the environ-

ment!

Page 7

WARNING!

Very serious injury due to improper use.

It is forbidden to make any modifications or alterations to the operating values of the dril-

ling-milling machine. These could endanger the staff and cause damage to the drilling-

milling machine.

1.3 Possible dangers caused by the drilling-milling machine.

The drilling-milling machine was built using the latest technological advances.

Nonetheless there remains a residual risk, since the drilling-milling machine operates with

high revolutions,

rotating parts and tools,

electrical voltage and currents.

We have used construction resources and safety techniques to minimise the health risk to the

staff resulting from these hazards.

If the drilling-milling machine is used and maintained by staff who are not duly qualified, there

may be a risk by the drilling-milling machine resulting from incorrect operation or unsuitable

maintenance.

INFORMATION

All persons involved in assembly, commissioning, operation and maintenance must

be duly qualified,

strictly follow this operating manual.

Disconnect the drilling-milling machine whenever cleaning or maintenance work is being carried

out.

WARNING!

The drilling-milling machine may only be used with the safety devices activated.

Disconnect the drilling-milling machine whenever you detect a failure in the safety

devices or when they are not fitted!

All additional installations carried out by the operator need to incorporate the prescribed

safety devices.

This will be your responsibility being the machine operator!

“Safety devices“ on page 8

1.4 Qualification of the staff

1.4.1 Target group

This manual is addressed to

the operator,

the user,

the maintenance staff.

The warning notes therefore refer to both operation and maintenance of the drilling-milling

machine.

Always disconnect the drilling-milling machine plug from the mains. This will prevent it from

being used by unauthorised staff.

Page 8

INFORMATION

All persons involved in assembly, commissioning, operation and maintenance must

be duly qualified,

strictly follow this operating manual.

In the event of improper use

there may be a risk to the staff,

there may be a risk to the drilling-milling machine and other material property,

may affect proper operation of the drilling-milling machine.

1.5 Safety devices

Use the drilling-milling machine only with properly functioning safety devices.

Stop the drilling-milling machine immediately if there is a failure in the safety device or if it is not

functioning for any reason.

It is your responsibility!

If a safety device has been activated or has failed, the drilling-milling machine must only be used

when

the cause of the failure has been removed,

it has been verified that there is no danger resulting for the staff or objects.

WARNING!

If you bypass, remove or override a safety device in any other way, your are endangering

yourself and other persons working with the drilling-milling machine. The possible con-

sequences are

• damage as a result of components or parts of components flying off at high speed,

• contact with rotating parts,

• fatal electrocution.

The drilling-milling machine includes the following safety devices:

an EMERGENCY-STOP button,

a protective cover on the drill-mill head,

a separating protective equipment on the milling spindle.

1.5.1 EMERGENCY-STOP button

The EMERGENCY-STOP button switches

the drilling-milling machine off.

“Switching on the drilling-milling

machine“ on page 26

Fig.1-1: EMERGENCY-STOP button

EMERGENCY-STOP

Page 9

ATTENTION!

The EMERGENCY-STOP button switches off the drilling-milling machine immediately.

Only press the EMERGENCY-STOP button in case of danger! If the button is actuated in

order to stop the drilling-milling machine generally you might damage tools or workpie-

ces.

After actuating the button, turn it to the right, in order to restart the machine.

1.5.2 Protective cover

The drill-mill head is fitted with a protective

cover.

WARNING!

Remove the protective cover only after

the mains plug has been pulled out of

the socket.

Fig.1-2: Protective cover

1.5.3 Separating protective equipment

Adjust the correct height of the protective

equipment before starting work.

Fig.1-3: Separating protective equipment

Protective cover

Locking screw

Page 10

1.6 Safety check

Check the drilling-milling machine regularly.

Check all safety devices

before starting work,

once a week (with permanent operation),

after every maintenance and repair operation.

1.7 Personnel protective equipment

For certain work peersonnel protective equipment is required.

Protect your face and eyes: During all work and specifically work during which your face and eyes

are exposed to hazards, a safety helmet with a face guard should be worn.

Use protective gloves when handling pieces with sharp edges.

Use safety shoes when you position, dismantle or transport heavy components.

Use ear protection if the noise level (immission) in the workplace exceeds 80 dB (A).

Before starting work, make sure that the prescribed individual protection gear is available at the

workplace.

CAUTION!

Dirty or contaminated personnel protective equipment can cause disease. Clean it each

time after it has been used and once a week.

General check

Equipment Check OK

Protective covers Fitted, firmly bolted and not damaged

Labels,

markings Installed and legible

Run test

Equipment Check OK

EMERGENCY-STOP but-

ton When the EMERGENCY-STOP button is activated, the drilling-

milling machine should switch off. A restart will not be possible

until the EMERGENCY-STOP button has been unlocked and the

ON switch has been activated.

Separating protective

equipment around the dril-

ling and milling spindle

Only switch on the drilling-milling machine if the protective equip-

ment is closed.

Page 11

1.8 For your own safety during operation

WARNING!

Before activating the drilling-milling machine, double-check that this will not endanger

other people or cause damage to equipment.

Avoid any unsafe working practises:

Make sure your work does not endanger anyone.

The instructions in this manual need to be observed during assembly, handling, mainte-

nance and repair.

Use protective goggles.

Switch off the drilling-milling machine before measuring the workpiece.

Do not work on the drilling-milling machine if your concentration is reduced, for example,

because you are taking medication.

Stay on the drilling-milling machine until the working spindle has come to a complete halt.

Use the prescribed protective equipment. Make sure to wear a well-fitting work suit, when

necessary, a hairnet.

Do not use protective gloves during drilling or milling work.

Unplug the shockproof plug from the mains, before changing the tool.

Use suitable devices for removing drilling and milling chips.

Make sure your work does not endanger anyone.

Clamp the workpiece tightly before activating the drilling-milling machine.

In the description of work with and on the drilling-milling machine we highlight the dangers spe-

cific to that work.

Fig.1-4: BF 20 VLP

Page 12

1.9 Disconnecting and securing the drilling-milling machine

Pull out the mains plug before starting maintenance and repair work.

1.10 Using lifting equipment

WARNING!

Use of unstable lifting equipment and load suspension devices that break under load can

cause very serious injury or even death.

Check that the lifting equipment and load suspension devices are of sufficient load capa-

city and in perfect condition.

Observe the rules for preventing accidents issued by your association for the prevention

of occupational accidents and safety in the workplace or other inspection authorities.

Hold the loads properly.

Never walk under suspended loads!

1.11 Signs on the drilling-milling machine

BF20 VLP

1/2" / 2 1/2"

Width [in]

Depth [in]

Height [in]

Total weight [kg]

Width [in]

Depth [in]

Height [in]

T - slot size / distance [in]

7"

X-axis travel [in]

Y-axis travel [in]

Table width [in]

Table length [in]

Z-axis travel [in]

Sleeve travel [in]

Spindle holding fixture

Working radius [in]

max. 3/5"

Milling capacity of inserted tooth cutter [in]

Milling capacity of end-mill cutter [in]

Drilling capacity [ in]

Engine

Page 13

2 Technical data

The following information gives the dimensions and weight and is the manufacturer’s authorised

machine data.

2.1 Power connection

2.2 Drilling-milling capacity

Ø

Ø

Ø

2.3 Spindle holding fixture

2.4 Drill-mill head

Swivelling + / - 90°

Reduction stages 2

2.5 Cross table

2.6 Dimensions

2.7 Work area

2.8 Speeds

Reduction stage slow [min-1] approx. 50 - 1400

750W/110V/60HZ

max.4/5"

max.2 1/2"

7 3/10"

3/8"

1 9/10"

14 1/2"

27 1/2"

6 4/5"

18 4/5"

33 4/5"

34 1/4"

21 3/5"

4 1/2"

78 3/4"

86 3/5"

59"

BF20 VLP

BF20 VLP

BF20 VLP

BF20 VLP

BF20 VLP

BF20 VLP

BF20 VLP

Page 14

Reduction stage fast [min-1] approx. 100 - 2900

2.9 Environmental

conditions

Temperature 5-35 °C

Humidity 25 - 80%

2.10 Operating material

Reduction stage

Blank steel parts Mobilgrease OGL 007 or,

Mobilux EP 004, or Mobil XHP

acid-free oil, e.g. weapon oil, motor oil

2.11 Emissions

The noise level (emission) of the drilling-milling machine is below 78 dB(A). If the drilling-mil-

ling machine is installed in an area where various machines are in operation, the acoustic

influence (emission) on the user of the drilling-milling machine may exceed 85 dB(A) at the

workplace.

We recommended the use of soundproofing ear protection. Remember that the duration of the

noise pollution, the type and characteristics of the working area and operation of other machi-

nes influence the noise level at the workplace.

BF20 VLP

BF20 VLP

BF20 VLP

Page 15

3 Unpacking and connecting

INFORMATION

The drilling-milling machine comes pre-assembled.

3.1 Extent of supply

When the drilling-milling machine is delivered, immediately check that the machine has not been

damaged during shipping and that all components are included. Also check that no fastening

screws have come loose.

Compare the parts supplied with the information on packing list.

3.2 Transport

WARNING!

Machine parts falling off forklift trucks or other transport vehicles could cause very

serious or even fatal injuries. Follow the instructions and information on the transport

case:

• centres of gravity

• suspension points

• weights

• means of transport to be used

• prescribed shipping position

WARNING!

Use of unstable lifting equipment and load suspension devices that break under load can

cause very serious injuries or even death.

Check that the lifting and load suspension gear has sufficient load capacity and that it is

in perfect condition.

Observe the rules for preventing accidents.

Hold the loads properly.

Never walk under suspended loads!

3.3 Storage

ATTENTION!

Improper storage may cause important parts to be damaged or destroyed.

Store packed or unpacked parts only under the intended environmental conditions.

“Environmental conditions“ on page 14

Consult the company if the drilling-milling machine or

accessories have to be stored for a period of more than three months or under different environ-

mental conditions than those given here.

Page 16

3.4 Installation and assembly

3.4.1 Requirements of the installation site

The working area for operation, maintenance and repair work must not be hindered.

The mains plug of the drilling-milling machine must be freely accessible.

3.4.2 Load suspension point

WARNING!

Danger of crushing and overturning. Proceed with extreme caution when lifting, installing and

assembling the machine.

Secure the load suspension device around the drill-mill head. Use a lifting sling for this pur-

pose.

Clamp all the clamping levers at the drilling-milling machine before lifting the drilling-milling

machine.

Make sure that no add-on pieces or varnished parts are damaged due to the load suspen-

sion.

3.4.3 Installation

Check the horizontal orientation of the base of the drilling-milling machine with a spirit level.

Check that the foundation has sufficient floor-load capacity and rigidity. The total weight

amounts from 103 to 115 kg.

ATTENTION!

Insufficient rigidity of the foundation leads to the superposition of vibrations between the

drilling-milling machine and the foundation (natural frequency of components). Insuf-

ficient rigidity of the entire milling machine assembly also rapidly causes the machine to

reach critical speeds, with unpleasant vibrations, leading to bad milling results.

Position the drilling-milling machine on the intended foundation.

Attach the drilling-milling machine using the provided recesses in the machine base.

WARNING!

The quality of the substructure and the kind of fixture of the machine stand to the sub-

structure has to assimilate the loads of the drilling-milling machine. The substructure

needs to be even. Please check the horizontal alignment of the substructure of the dril-

ling-milling machine.

Fix the drilling-milling machine to the substructure at the provided recesses at the stand. When

using an optionally available machine substructure, it also needs to be anchored safely and

firmly. We recommend the use of shear connector cartridges or heavy-duty bolts.

Page 17

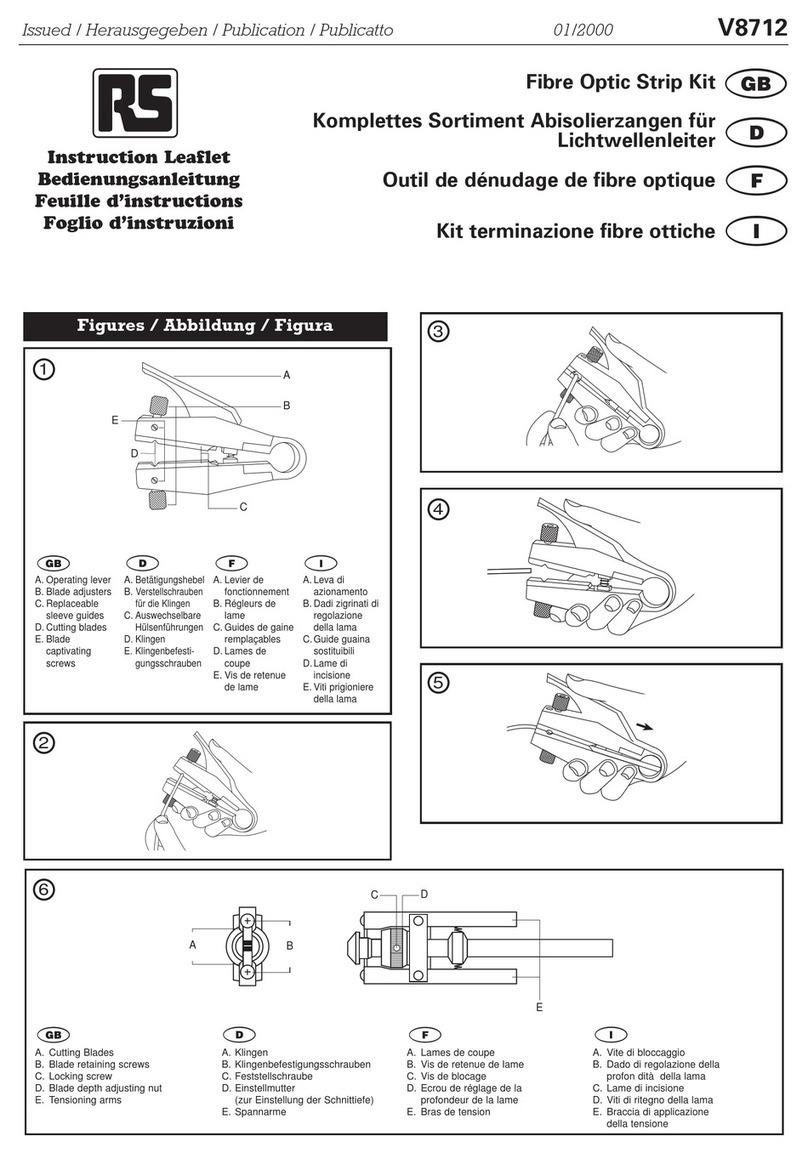

3.4.4 Installation drawing

Fig.3-1: Machine base

3/5"

13 2/5"

1/2"

8 3/5"

10 4/5"

3.5 Installation plan BF20 V

Page 18

Gezeichnet

Datum Name

11.10.2006 Mücke

930

718

274 340

374

168

182

290

498

180

156

194

584

3.6 Installation plan BF20 VLP

Page 19

Gezeichnet

Ktllit

Datum Name

16.10.2006 Mücke

36 1/4“

19 2/5”

10 4/5"

36 3/5”

23"

27 1/2"

13 2/5"

6 1/10" 14 3/5"

7 3/5"

6 3/5"

7 1/10"

7"

Page 20

3.7 Installation plan of optional substructure

Fig.3-2: Substructure 3353003

1 1/5"

35 2/5"

19 3/5"

19 3/5"

29 1/2"

10"

8"

6 3/10"

8 3/5"

9"

72"

1 7/10"

16 1/2"

17 3/10"

8 4/5"

11/20"

Fig.3-2: Substructure 3353003

This manual suits for next models

1

Table of contents

Other Bolton Tools Tools manuals