Mark the boards for the drawer

on

the inside with

identifying letters

near

bottom edge (See Fig. 5). The

reverse

sides of the board will be the outside of the

finished drawer. The outside of the boards

are

always

clamped toward the dovetail base and all pieces

are

routed in

an

"inside-out" position. They

are

reversed

to

assemble. The front piece (B) should be 3%" longer

and 3%" wider than the opening less clearance. The

rabbet

cut

on

the inside of the front board should be

3/a” wide and 7/16" deep. The side pieces (A and C)

should be the

same

size. (See chart

on

page 3for

computing proper sizes and recommended material

thicknesses.)

Insert board (A) between front clamping bar and front

surface of dovetail base with bottom edge toward left

stop

screw.

Temporarily clamp board (A) "inside-out"

to

the left front of the fixture

so

that

it

extends above

the base (See Fig.

II).

This is done

to

assist in proper-

ly positioning of board (B).

Insert board (B) between top clamping bar and top

surface of dovetail base with bottom edge against left

stop

screw

and flush with extended portion of board

(A). Tighten top clamp knobs (E)

to

hold board (B)

securely. Attach dovetail template (F)

to

the dovetail

base with spacers (G) located inside brackets (See Fig.

8). Holding template

flat

on

boards with

one

hand,

tighten template clamp knobs (H) securely. Be

sure

Template finger ends

are

parallel

to

edge of board (B)

to

assure

even

fit

after cutting. Relocate board (A)

so

that

it

is flush with the top board (B) and against

stop

screw

in left front of dovetail base. Tighten

front clamp knobs (I)

to

hold board (A) securely.

Loosen top clamp knobs (E) and

remove

board (B)

from the base and replace with

a

piece of scrap lumber

of the

some

wood. This provides support in

area

of

cut

in board (A) which prevents splintering

as

the

cut-

ter

bit

moves

through

cut.

USE CAUTION WHEN OPERATING ROUTER AT

EITHER EXTREME END OF DOVETAIL TEMPLATE.

DOVETAIL CUTTER BIT MAY MAKE CONTACT

WITH ANGLE BRACKET IF MOVED TOO FAR OUT-

SIDE FIRST OR FINAL CUT.

ROUTING

To make

sure

all adjustments and settings

are

as

re-

quired,

it

is best

to

first make

a

trial

cut

on

two

pieces

of scrap lumber of the

same

wood that is

to

be used.

Allowance should be made in

fit

of dovetail for gluing

when completed joints

are

assembled. A"too tight"

condition in

fit

will force glue

out

of dovetail joint

causing

a

dry joint.

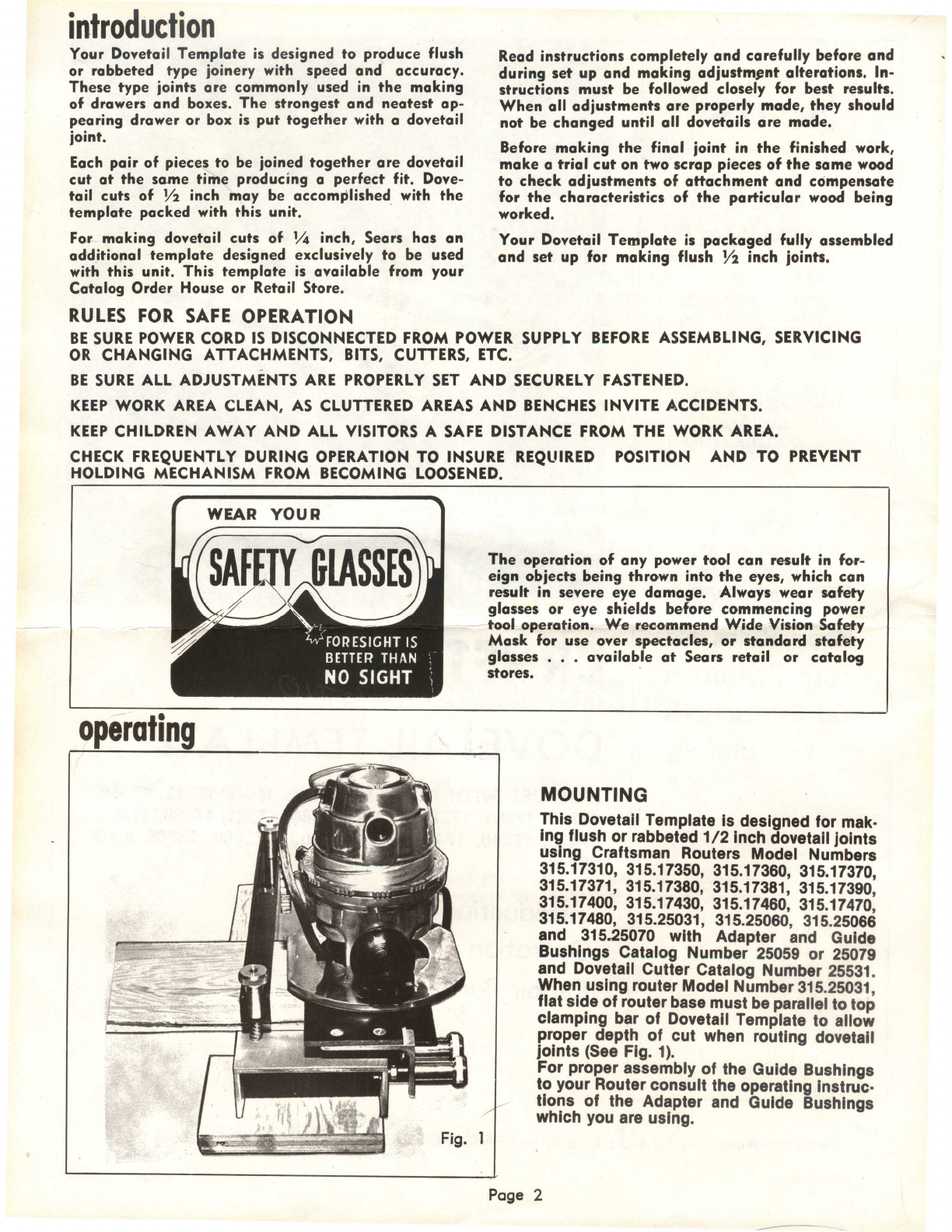

Place Router with base resting flat

on

dovetail

tem-

plate

so

that the guide bushing engages along the

edge of board (A). Make

a

straight

cut

from right

to

left

across

board (A, See Fig. 9). This is done

to

pre-

vent chipping the wood when the Router is moved in

and

out

of the fingers of the dovetail template.

Cut the dovetail joint, feeding the Router from left

to

right until the completed edge is accomplished. Before

removing the Router from the dovetail template,

recut

the dovetail, moving the Router from right

to

left

to

correct

any imperfections.

When the dovetail joint is completed wait until

cutter

bit has stopped completely before removing the Rout-

er

from the dovetail template. This precaution will

prevent damage

to

the template. When removing the

Router,

it

should

not

be lifted but should be moved

toward the operator until clear. Loosen template

clamp knobs and

remove

dovetail template. Without

removing board (A) loosen top clamp knobs (E),

re-

move

scrap piece and replace with piece that is

to

be

finished front board (B), flush with edge of board (A).

(Fig.

I2

Tighten top clamp knobs (E) firmly. After board (B) is

properly positioned, loosen front clamp knobs (I) and

remove

board (A). Attach dovetail template (F)

to

the

dovetail base with spacers (G) located outside brackets

(See Fig. 12). Holding template flat

on

boards with

one

hand, tighten template knobs (H) securely. Cut”

dovetail joint in board (B)

as

a

single piece. Loosen

all clamp

screws

and

remove

routed» sections.

Insert board (C) between front clamping bar and front

surface of dovetail base with bottom edge toward right

stop

screw.

Temporarily clamp board (C) "inside-out"

to

the right front of the fixture

so

that

it

extends

above the base. This is done

to

assist in properly posi-

tioning of board (B).

Insert board (B) between top clamping bar and ‘top

surface of dovetail base with bottom edge against

right stop

screw

and flush with extended portion of

board (C). Tighten top clamp knobs

to

hold board (B)

securely. Attach dovetail template

to

the dovetail base

with spacers located inside brackets. Holding template

flat

on

boards with

one

hand, tighten template clamp

knobs securely. Relocate board (C)

so

that

it

is flush

with the top of board (B) and against stop

screw

in

right front of dovetail base. Tighten front clamp knobs

to

hold board (C) securely. Loosen top clamp knobs

and

remove

board (B) from'the base and replace with

a

piece of scrap lumber of the

some

wood. This pro-

vides support in

area

of

cut

in board (C) which pre-

vents splintering

as

the

cutter

bit

moves

through cut.

Cut dovetail joint

as

described above.

Loosen all clamp

screws

and

remove

routed sections.

Dovetail

cuts

in board (D) and boards (A and C) may

be accomplished by following instructions

as

described

under "FLUSH FRONT DRAWER OR BOX."

MAKING ADJUSTMENTS

IF THE JOINT IS TOO TIGHT, raise the

cutter

bit very

slightly

to

make the

cut

more

shallow. (Follow depth

adjustment instructions

as

described in Router Own-

ers

Manual.)

IF THE JOINT IS TOO LOOSE, lower the

cutter

bit

very slightly

to

make the

cut

deeper.

IF THE FIT IS TOO DEEP,

turn

lock

nut

(J, See Fig. 3)

in

a

counter-clockwise direction until desired depth is

reached. (Adjust lock

nuts

equally and carefully).

IF THE FIT IS TOO SHALLOW,

turn

lock

nut

(J, See

Fig. 8) in

a

clockwise direction until desired depth is

reached.

WHEN ALL ADJUSTMENTS ARE PROPERLY MADE,

THEY SHOULD NOT BE CHANGED UNTIL ALL

DOVETAILS ARE CUT.

ROUT DOVETAIL FROM THE FRONT ONLY

—

DO

NOT RAISE OR LOWER ROUTER OR CUTTER BIT

WHILE BIT IS BETWEEN DOVETAIL TEMPLATE

FINGERS. KEEP ROUTER BASE FLAT AGAINST

TEMPLATE.

I

Page 6