rev. 00

6

HPP2

!!! IMPORTANT !!!

Do not run the pump and the hydraulic motor before filling them as specified in the previous

paragraph. Components can be seriously damaged!

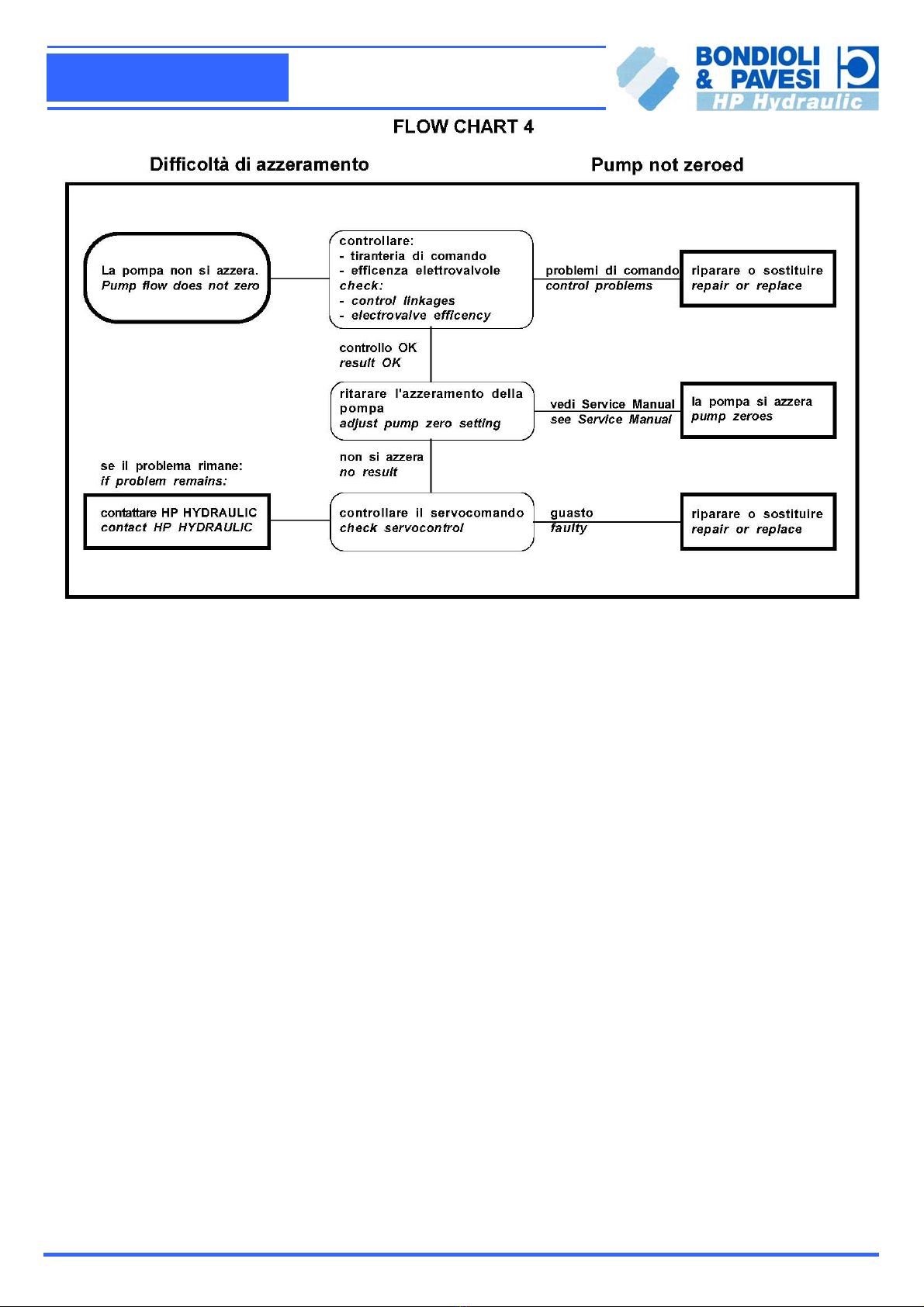

Check that the pump is set to zero displacement.

Run the pump at minimum rpm (e.g. run diesel engine using only starter) until the boost pump begins to work

regularly. Regular charge pump working is shown by the manometer placed on the pump feeding circuit, that

will indicate a few bar minimum pressure. Now it is possible to start up diesel at minimum speed.

Operate with pump control lever in both directions, and check that controlled parts direction of rotation is

correct.

Run transmission until you are sure that all the air has been ejected and there is no mixture of oil and air.

Usually few minutes are sufficient.

Increase rotating speed and check that charge circuit pressure reaches a 18-20 bar value, and that

manometer vacuum on suction line does not exceed a 0.5 bar value with cold oil and 0.2 bar with warm oil.

Increase loading gradually, checking maximum working pressure by means of high pressure manometers.

Check continuously hydraulic fluid level in the tank during machine starting up and, if necessary, fill to proper

level.

Filtration

The selection of a filter depends on many factors, including contamination input rate and scheduled service

periods. Filters must be selected to meet the above requirements using rating parameters of efficency and

capacity.

Filter efficency may be measured using the .Beta. ßx-ratio, that is defined by ISO standard as the ratio of the

number of particles greater than a given size (x) measured in microns upstream of the filter to number of

particles greater than the same size downstream of the filter.

A filter with a ß-ratio within the range of ß15-20=75 (ß10 = 10) or better is typically required.

Since each system is unique, the filtration requirement for that system will be unique and must be determined

by test in each case. It is essential that monitoring of prototypes and evaluation of components and

performance throughout the test program be the final criteria for judging the adequacy of the filtration system.

!!! IMPORTANT !!!

Do all settings with warm oil, at a temperature of about 50°C. Avoid oil leaks and any environmental pollution,

even accidental.

!!! WARNING !!!

!!!!!!!!!!!!!!!!!!!!!!

Pay great attention to all moving machine parts, and observe all safety rules in force. Contact with moving

parts could result in serious injury or death.

Machine flushing

With “machine flushing” we mean the best possible elimination from the hydraulic circuit of all pollution in

hydraulic fluid and machine components.