Bondtech Prusa i3 Setup guide

Bondtech for Prusa i3

Assembly and installation manual

This work is licensed under a GNU General Public License v3.0

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 1

Table of Contents

Acknowledgements 1

Introduction 1

Compatibility 2

What’s in the box? 2

Mechanical Installation 3

What you need 3

Preparation 3

Software Configuration 15

Set new E-step value 15

Acknowledgements

This is a co-development work with awesome guys in the Prusa Community like

Chris Warkocki, Grégorie Saunier (Bear Upgrades), Olof Ogland, Erik Bjorgan, Josh

Jones, Kyle Wiehe, Marc Evertz, Matt Harrison, Ocie Ward, Sando Bendig, Vecko

Kojchevski (Vecko Extruder), Steven Mölby that have provided excellent feedback

and suggestions of how to develop the "perfect" extruder setup for the Prusa series

printer. A lot of work has been spent in this project and we have tried to listen to all

the inputs in order to find a solution that can be fitted to a Prusa I3 MK2, MK2S,

MK2.5 and MK3.

Introduction

This kit contains the necessary parts to convert to our freshly designed

extruder that uses 3:1 gearing ratio for improved precision and resolution,

optimized geometry for the heat-sink cooling and many other improved

features.

It also reduces the moving weight to reduce vibrations and ghosting.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 2

Compatibility

The upgrade is compatible with the following machines:

- Prusa i3 MK2

- Prusa i3 MK2s

- Prusa i3 MK2,5

- Prusa i3 MK3

What’s in the box?

All customers

1x Bondtech extruder for Prusa i3.

1x PTFE tube (80mm).

1x SLS printed Extruder front.

1x SLS printed Extruder rear.

1x Bag with screws and bolts.

1x Fan shroud.

1x Mounting bracket.

MK2, MK2s, MK2.5 and MK3 without BMG

1x Nema17 Pancake stepper motor.

1x Stepper motor cable.

1x Shaft with 50T gear.

1x Thumbscrew.

2x Ball bearings.

1x 3x32mm shaft.

1x Sensor cover

MK2 and Mk2s

2x Needle bearing.

1x 3x20mm shaft.

1x Primary drive wheel (direct).

1x Secondary drive wheel (direct).

1x Sensor cover

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 3

Mechanical Installation

What you need

To install the upgrade you will need.

- M1.5- Hex Wrench

- M2.5- Hex Wrench

- Hobby knife with sharp tip or similar.

Recommended: Download and print out Bondtech’s PTFE fixture for precise

measurement of the tube length. STL-file available at

https://github.com/BondtechAB/Bondtech_Prusa_i3/tree/master/CAD-Files

Preparation

Remove your old extruder. Use Prusa’s extruder assembly guide to reverse the

steps if you need to. This kit will use a different motor, so you can unwrap the cables,

remove your current motor to prepare for a new one.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 4

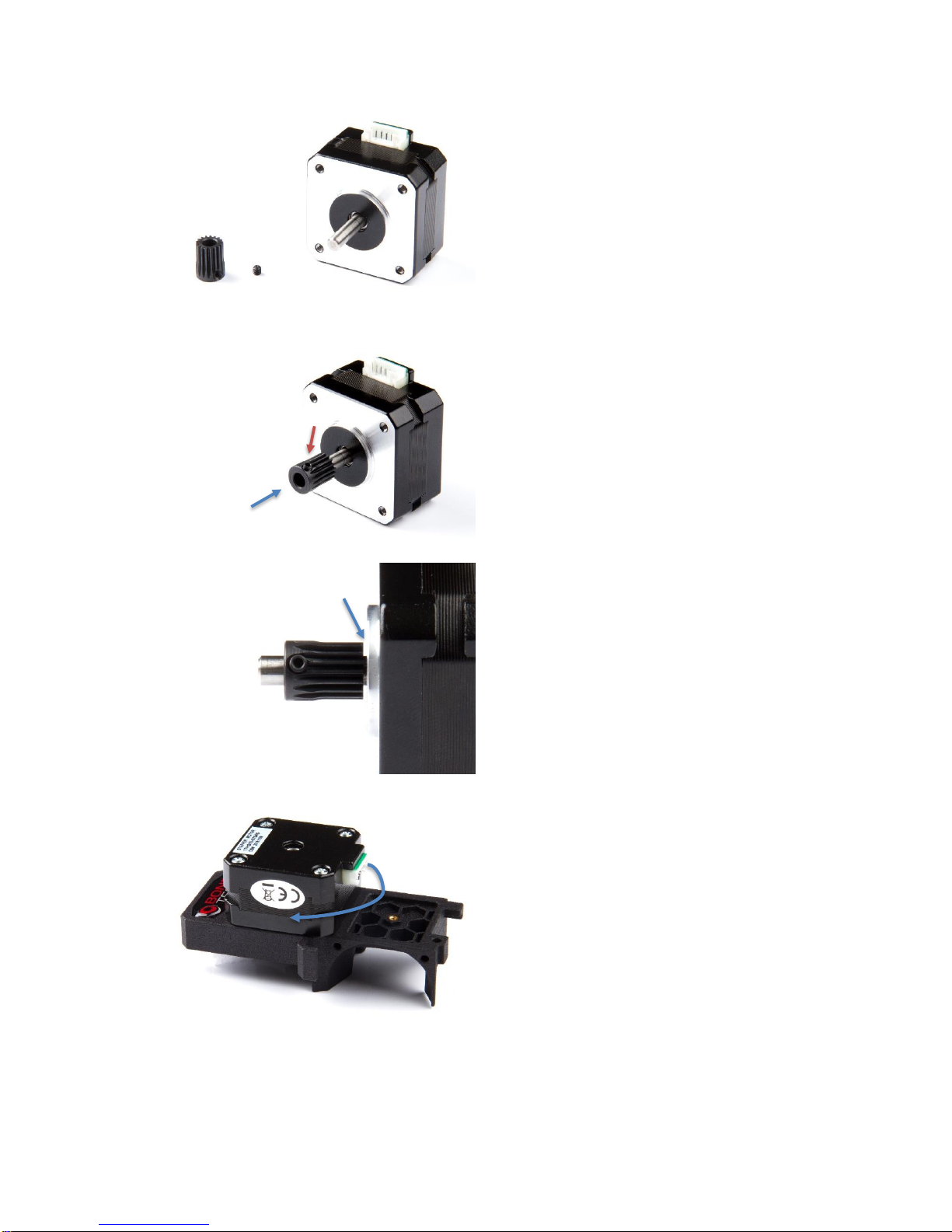

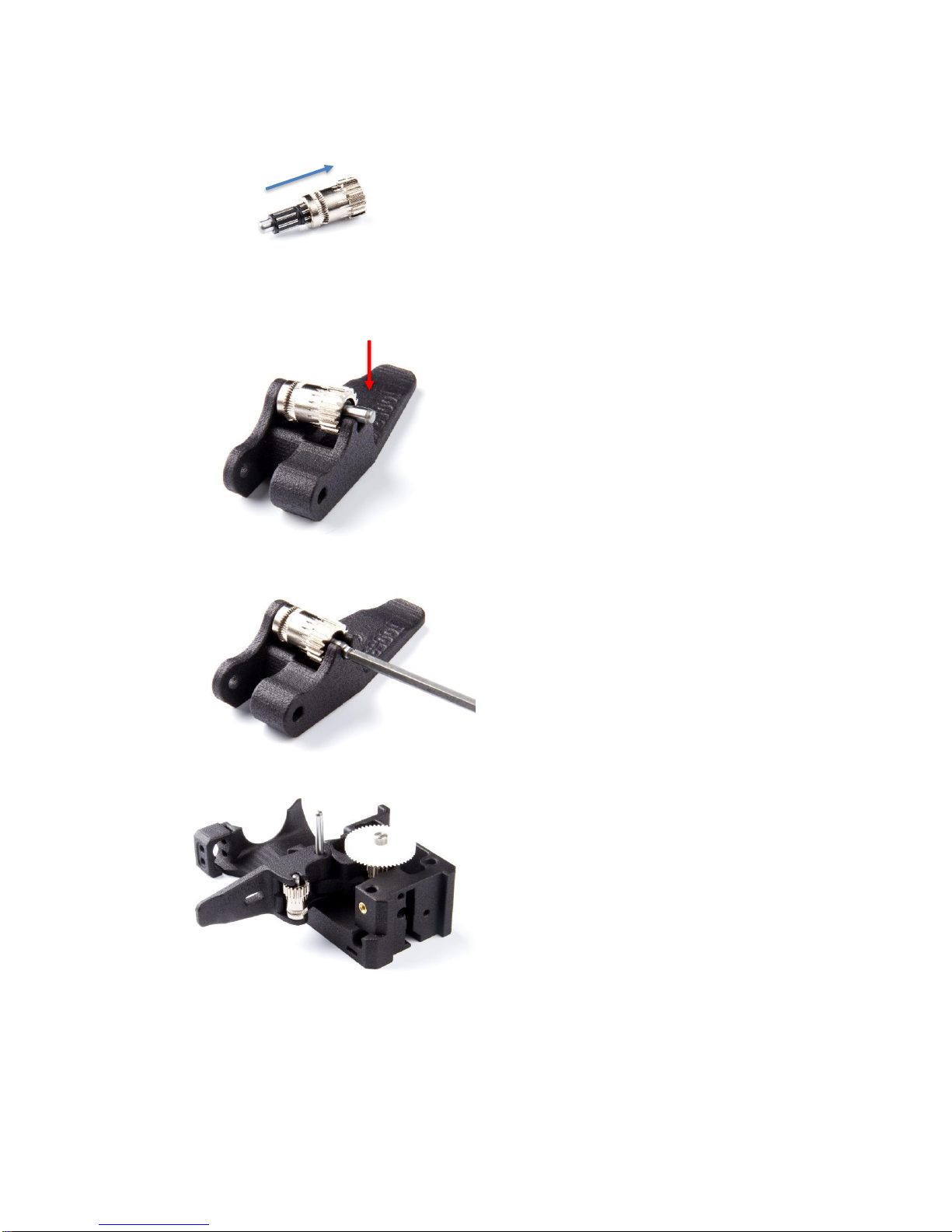

●Preparing your motor.

●Insert the M2x3 setscrew and

slide the motor gear onto the

shaft as oriented in the picture.

●Leave a 1-1,5 mm gap between

the gear and the motor and

tighten it using your 1,5mm Allen

key.

Recommended: Use Loctite to

secure the screw.

•Assembly the extruder front.

•Place the motor on the extruder

front and orient the cable

connection as you choose.

(Downwards or to the left.)

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 5

●Insert three M3 screws and

loosely tighten them using a

2.5mm Allen key.

•M3x8

•M3x12

•M3x25

●Insert a ball bearing. Ensure it is

fully pressed down into the slot.

●Insert the shaft with the white

plastic gear into the bearing.

Rotate the shaft to ensure correct

alignment of the gears.

•Tighten the screws with

reasonable force.

•Important: Be careful

when tighten the M3x12

screw to avoid damaging

the pocket!

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 6

●Insert a square nut into the

pocket.

●Prepare the extruder rear.

Insert a ball bearing and press it

down using a primary drive gear.

•If you are using the bear X-

carriage remove hex cover plug

by pushing it from the rear side.

This hole is for a M3 nut.

●Press the primary drive gear

down until the groves align with

the filament path.

●Slide the shaft inside the drive

gear. Note the orientation of the

parts. The hole and the flat

surface on the shaft must align.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 7

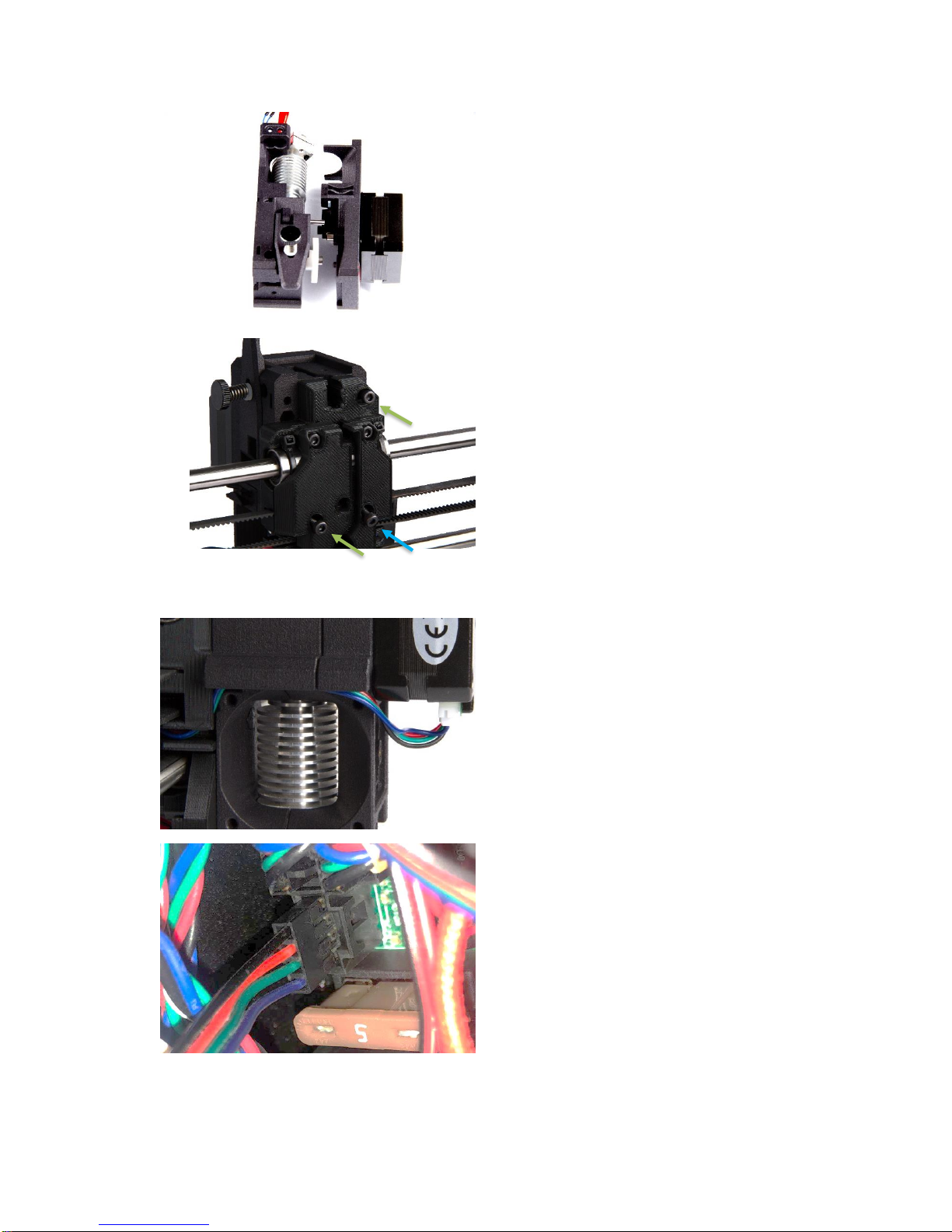

●Insert the M3x2 setscrew and

tighten it with your 1,5 Allen key.

Important: Ensure the groves

align with the filament path!

Recommended: Use Loctite to

secure the screw.

Important: If the setscrew is

not properly aligned with the

flat surface it will stick out and

start grinding on the

secondary drive gear when you

start printing!

•Assemble the hinge.

•Slide the two needle bearings

onto the 3x20 mm shaft.

•Use a small dab of lithium based

grease to lubricate the bearings

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 8

•Slide the shaft with the bearings

through the secondary drive gear.

•Align the gear with the hinge as

shown in the photo and press the

shaft down until you hear the

click.

•Carefully press the shaft in place

using your 2.5mm Allen key.

•Put a small dab of lithium based

grease on the gear section to

reduce friction. Make sure that

you do not get it on the drive

section of the gear.

●Install the hinge to the extruder

rear using the 3x32mm shaft.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 9

●Install the thumbscrew.

•If you are a MK2/s user

insert a square nut in the

front pocket for the Pinda

Probe.

●Prepare the HotEnd. Take the

new supplied PTFE tube. Cut one

of the ends according to Prusas

recommendation, using a knife or

a razor. Using this fixture will

help. (Credits to Olof Ogland)

●Insert the newly cut end of the

tube into the HotEnd.

●Cut the tube 6.3 mm from the top

of the HotEnd. Save the

remaining piece for the sensor

cover.

●Recommended: Use Bondtech’s

cutting fixture for precise

measurement. STL-file is

available at:

https://github.com/BondtechAB/B

ondtech_Prusa_i3/tree/master/C

AD-Files

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 10

●Use a knife or razor to chamfer

the inside of the tube for better

filament guidance.

Important: Do not let any left

over from the tube fall into the

HotEnd we recommend you

remove the tube before

chamfer the inside!

●Insert a push fit clip between the

HotEnd and the collet.

●Recommended: Add a small

piece of tape, 5x20mm on the

inner ring. The low friction

between the parts may cause the

HotEnd to rotate to easily when

installed.

●Install the HotEnd into the

extruder rear, angled as shown in

the photo. And push it in place.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 11

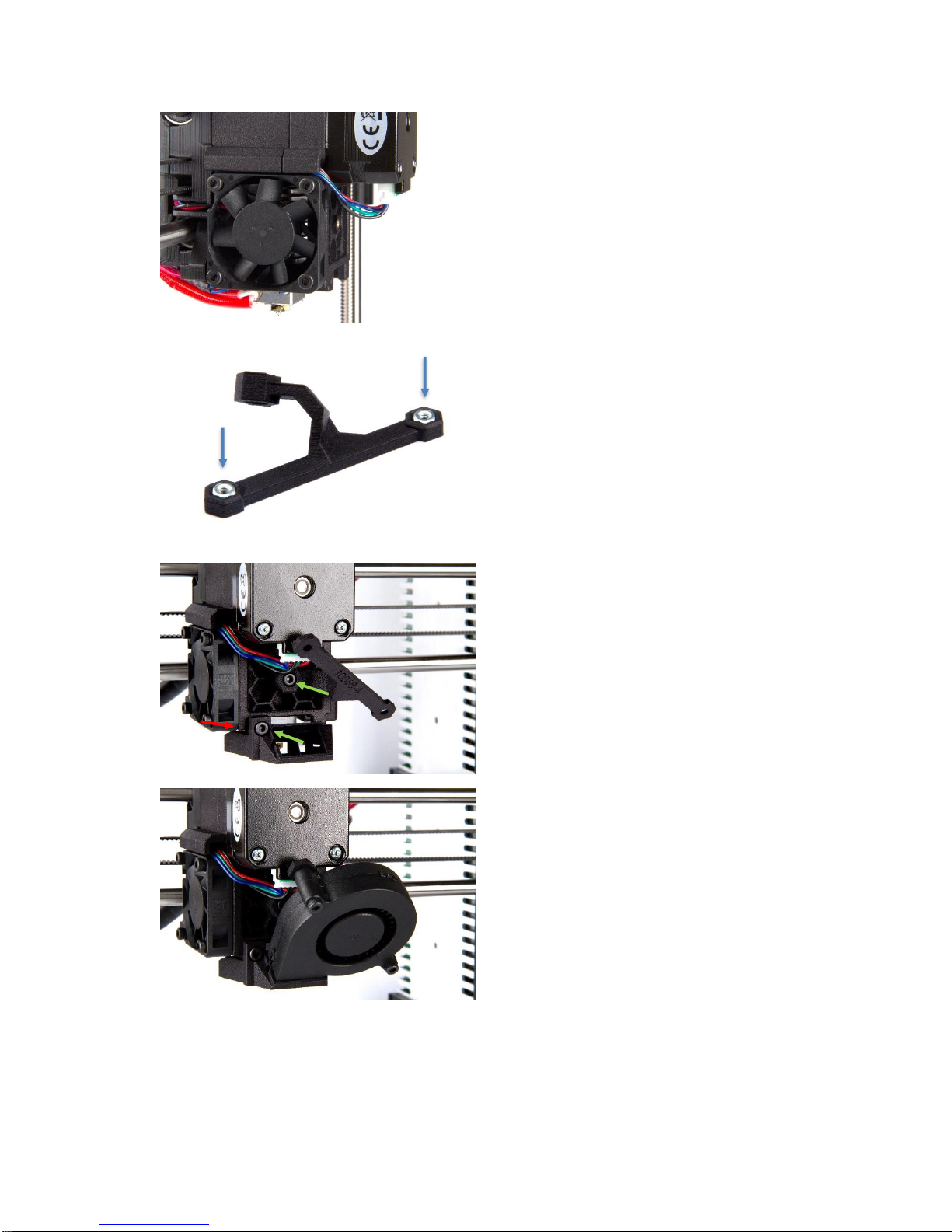

•Attach the front onto the rear

part. Push the HotEnd upwards

to align the neck correctly.

•Ensure everything is aligned and

carefully clamp the parts

together.

Important: The parts should fit

together easy. Do not use any

excessive force!

•Install the extruder to your X-

Carriage using three M3 screws.

•M3x40

•M3x45

Important: These screws are

sized to use on your stock

MK2,5/MK3 carriage or the

modified MK2/s carriage. If you

have another carriage different

screw length could be

necessary!

●Connect the cable to the motor

and use the cable path to the left

of the extruder for guidance.

●When connecting the cable to

you board ensure the black cable

is the top most cable or the motor

will rotate the wrong way!

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 12

●Install your 40x40 fan using four

M3x12 screws.

●Press down the hex nuts into the

pockets of the mounting bracket.

●Install the mounting bracket and

fan shroud using two M3x10

screw.

•M3x10

●Place two hex nuts into the slots

on the mounting bracket and

slide your 5015-blower fan down

the fan shroud and mount it using

two M3x20 screws.

●Place the cable in the channel on

the right side of the extruder to

help guide the way.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 13

●The position of the P.I.N.D.A

probe depends on your version of

the printer. MK2/s users place the

probe to right (Closer to the X-

axis) MK2.5 and MK3 users place

the probe to the left (furthest

away from the X-axis).

●Optional P.I.N.D.A cable position.

This technique is developed by

Grégoire Saunier, creator of the

Bear Extruder, to improve air flow

and reduce turbulence. Check

out his work here:

●MK2.5, MK3 users insert a

square nut into the right slot

(MK2s in the left as shown

earlier). Secure the P.I.N.D.A

using a M3x16 screw.

•Square nut

•M3x16

Reminder: Adjust the height of

the probe according to Prusa’s

instructions.

●Cut a 14.5mm long piece of the

left-over PTFE Tube and insert it

into the filament path on top of

the extruder.

Recommended: Before inserting

the tube use a knife or razor to

chamfer the inside of the tube for

better filament guidance.

●If you have a filament sensor

install it according to Prusa’s

instructions.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 14

●Place the sensor cover on top

and fasten it using two M3x8

screws.

Installation manual extruder upgrade for Bondtech_Prusa_i3 V1.1 15

Software Configuration

As the new extruder uses a gear reduction to create a high extrusion resolution and

high torque the E-step value needs to be changed. The E-step value tells the printer

how many steps to send to the motor for each mm of filament.

Set new E-step value

The E-step value is set using a G-code file that you can download here:

These files are used to set the new E-step value on the printer. On MK2, MK2S and

MK2.5 the E-step value should be 415 as it uses 16-bit microstepping, on MK3 it

shall be 830 as it uses 32-bit microstepping, this is valid for standard 1.8-degree

stepper motors, if a 0.9 degree motor is used the E-step needs to be doubled, so

830 and 1660.

Copy the file to the SD-card and put it in the printer, select to print the file and the

new e-step value will be set and saved to the controller.

Good luck with your Bondtech feeder!

If you have any questions please first read the FAQ

(http://www.bondtech.se/en/faq/). If the question still hasn’t been answered feel free

to contact us by email or our online chat.

Repslagarvägen 3 J

33153 Värnamo

Sweden

e-mail: [email protected]

phone: +46702220193

web: www.bondtech.se

VAT-registration number: SE556995564301

This manual suits for next models

3

Table of contents

Other Bondtech 3D Printer manuals

Bondtech

Bondtech Wanhao D9 V1.7 Setup guide

Bondtech

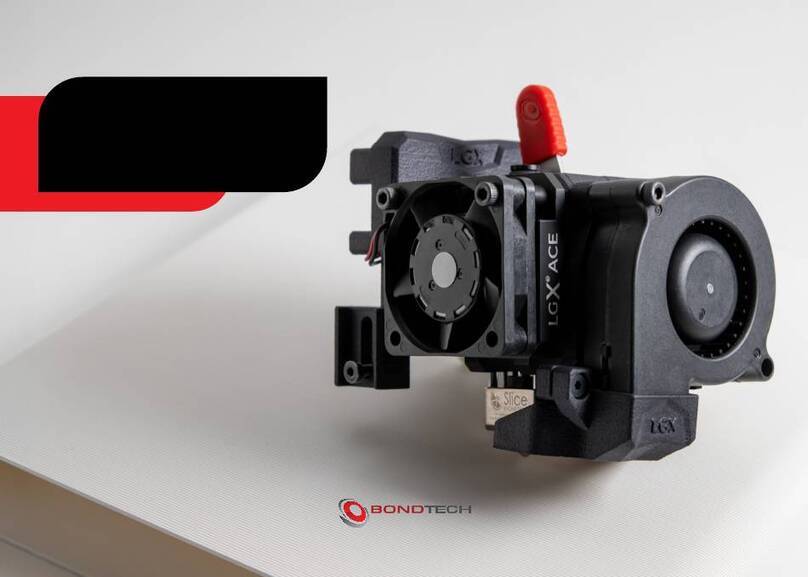

Bondtech LGX ACE User manual

Bondtech

Bondtech ULTIMAKER 2.85 User manual

Bondtech

Bondtech LGX PRO User manual

Bondtech

Bondtech Raise3D DualDirect Setup guide

Bondtech

Bondtech LGX ACE and Mosquito User manual

Bondtech

Bondtech Raise3D N1 Setup guide

Bondtech

Bondtech BMG Setup guide