Table of Contents

B9Clean General Information ................................................................................ 5

1.1 Declaration of CE Conformity ........................................................................................................... 5

1

Instructions for Safe Use ............................................................................ 6

1.1

Explanation of Symbols ..................................................................................................................... 6

2.2 Transport Damage .............................................................................................................................. 6

2.3 Operator’s Obligations ...................................................................................................................... 7

2.4 Operations and Maintenance Log Book ........................................................................................... 7

2.5 Safety Information .............................................................................................................................. 7

3 Intended Use and Proper Operation .......................................................... 9

3.1 Intended Use ....................................................................................................................................... 9

3.2 Proper Operation ................................................................................................................................ 9

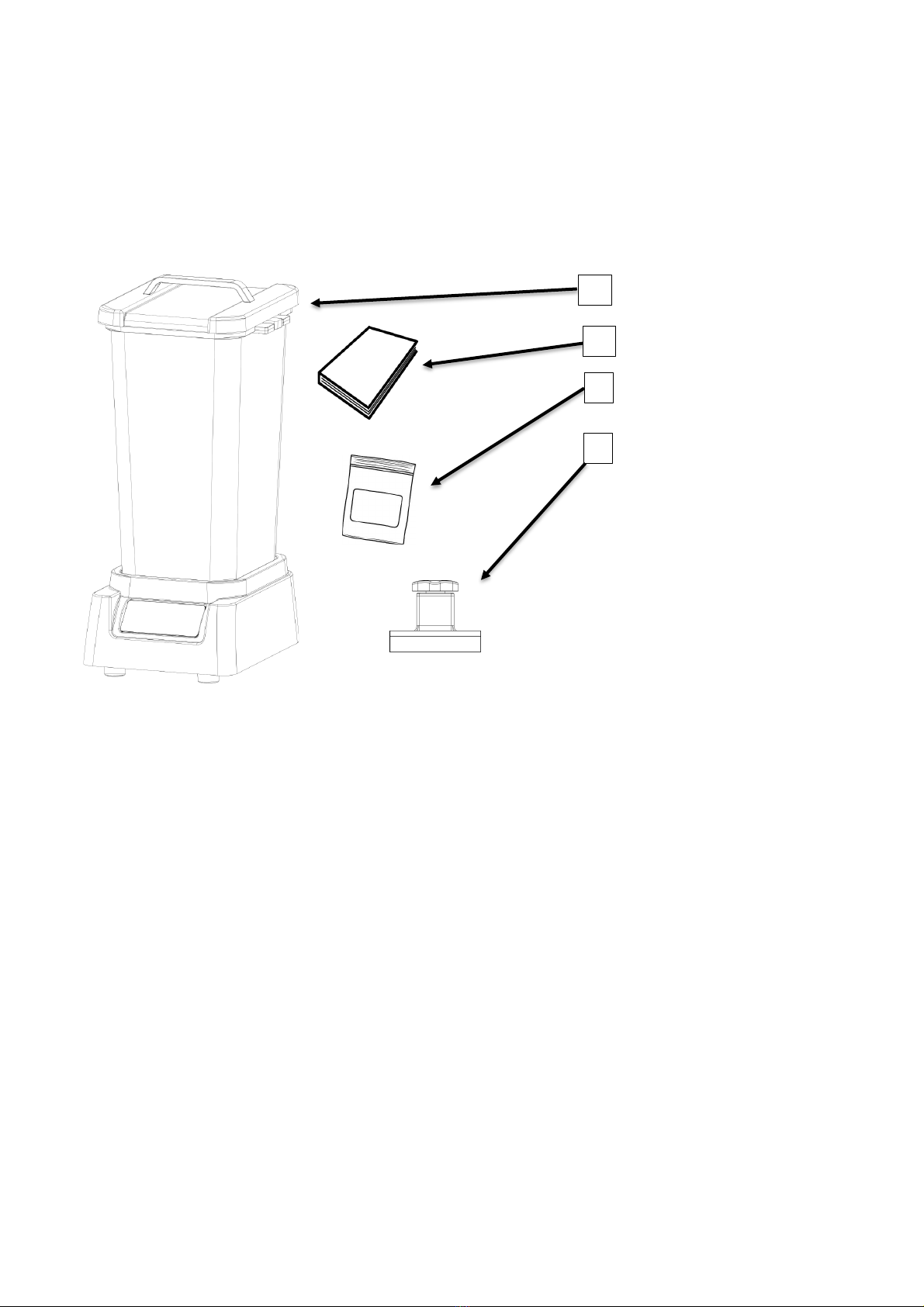

4 Scope of Delivery ....................................................................................... 10

4.1 Scope of Delivery ............................................................................................................................. 10

5 Identification and Interface ....................................................................... 11

5.1 Product Identification ...................................................................................................................... 11

5.2 Control Interface ............................................................................................................................... 11

6 Transport and Installation ......................................................................... 11

6.1 Transport ........................................................................................................................................... 12

6.2 Hardware Setup ................................................................................................................................ 12

7 Operation .................................................................................................... 13

7.3 Positioning the inner container drain plug. ................................................................................... 15

7.4 Placing the parts in the inner container ......................................................................................... 15

7.5 Configuring the cleaning cycle settings ........................................................................................ 16

7.6 Overview of starting, stopping or adjusting the cleaning cycle. ..................................................... 16

7.7 Starting the Cleaning Cycle ................................................................................................................. 17

7.7.3 17

7.7.8 18

7.8 B9Clean Cleaning Procedure .......................................................................................................... 18

8 Safety .......................................................................................................... 18

8.1 Isopropyl Alcohol Draining .................................................................................................................. 18

8.2 Isopropyl Alcohol Containment .......................................................................................................... 18

DO NOT USE Acetone in the B9Clean. Acetone will rapidly destroy acrylic material of containers

and pump. Warranty is void with even single use of Acetone. .................................................... 18

9 Maintenance, Care and Cleaning .............................................................. 18

9.1.1 Unit Cleaning .................................................................................................................................... 18

9.1.2 Build Table Cleaning ........................................................................................................................ 19

9.2 Isopropyl Alcohol ............................................................................................................................. 19

9.2.1 Replacement ..................................................................................................................................... 19

9.2.2 Disposal .............................................................................................................................................. 19

9.3 Non-Repairable Items ...................................................................................................................... 19