BONFIGLIOLI Vectron ACTIVE CUBE Series Instructions for use

www.bonfiglioli.com

Bonfiglioli Riduttori S.p.A.

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno

Bologna, Italy

tel: +39 051 647 3111

fax: +39 051 647 3126

bonfiglioli@bonfiglioli.com

www.bonfiglioli.com

VEC 526 R1

ACTIVE CUBE

Application manual - Positioning

Bonfiglioli has been designing and developing innovative

and reliable power transmission and control solutions

for industry, mobile machinery and renewable energy

applications since 1956.

04/08 Application manual Positioning 1

General Information about the Documentation

This application manual complements the configurations described in the operating

instructions and the „Quick Start Guide“ of the ACU frequency inverters (ACTIVE

Cube series). Configurations 240, 440 and 540, which are described in this applica-

tion manual, contain additional positioning functions.

For better clarity, the documentation is structured according to the customer-specific

requirements made on the frequency inverter.

Quick Start Guide

The Quick Start Guide describes the basic steps required for mechanical and electri-

cal installation of the frequency inverter. The guided commissioning supports you in

the selection of necessary parameters and the software configuration of the fre-

quency inverter.

Operating Instructions

The Operating Instructions describe and document all functions of the frequency

inverter. The parameters required for adapting the frequency inverter to specific

applications as well as the wide range of additional functions are described in detail.

Application Manual

The application manual supplements the documentation for purposeful installation

and commissioning of the frequency inverter. Information on various subjects con-

nected with the use of the frequency inverter are described specific to the applica-

tion.

Installation Instructions

Complementing the Brief Instructions and the Operating Instructions, the Installation

Instructions provide information on how to install and use the additional/optional

components.

If you need a copy of the documentation or additional information, contact your local

representative of BONFIGLIOLI.

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described

may result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in

death, serious injury or material damage.

Caution!

Caution refers to an immediate hazard. Non-compliance may result in personal or

material damage.

Attention!

Attention and the related text refer to a possible behavior or an undesired condition

which can occur during operation.

Note

marks information which facilitates handling for you and supplements the corre-

sponding part of the documentation.

Application manual Positioning 104/08

2 Application manual Positioning 04/08

TABLE OF CONTENTS

1 General Safety Instructions and Information on Use.................................................. 5

1.1 General Information .............................................................................................. 5

1.2 Purpose of the Frequency Inverters...................................................................... 6

1.3 Transport and Storage........................................................................................... 6

1.4 Handling and Installation ...................................................................................... 6

1.5 Electrical Connection ............................................................................................. 7

1.6 Information on Use................................................................................................ 7

1.7 Maintenance and Service....................................................................................... 7

2System description....................................................................................................... 8

2.1 Terminal diagram ACTIVE Cube (ACU) series........................................................ 9

3 Commissioning of the Frequency Inverter................................................................. 10

3.1 Switching on Mains Voltage ................................................................................ 10

3.2 Commissioning of the motor ............................................................................... 11

3.3 Control Inputs and Outputs................................................................................. 12

3.3.1 Factory settings of the digital inputs ...................................................................... 13

3.4 Digital inputs for speed sensor inputs or for other functions ............................. 15

3.5 Positioning - commissioning procedure .............................................................. 16

3.5.1 Getting started .................................................................................................... 18

3.5.1.1 Motor encoder is position encoder at the same time......................................... 18

3.5.1.2 Two different encoders for motor and positioning ............................................ 19

3.5.1.3 No motor encoder, external encoder for positioning ......................................... 20

3.5.1.4 Consider the operation mode settings for speed sensor input............................ 20

3.5.2 Reference system ................................................................................................ 21

3.5.3 Setting up a motion profile ................................................................................... 24

3.5.4 Control via software............................................................................................. 25

3.5.5 Write index and read index for the motion blocks table ........................................... 26

4 Operation Modes of the Positioning........................................................................... 28

4.1 General Issues about Operation Modes .............................................................. 28

4.1.1 Assignment of digital inputs.................................................................................. 29

4.1.1.1 Instructions on MFI1D (multifunction input)..................................................... 30

4.1.2 Operation modes for controlling the positioning operation ....................................... 31

4.1.3 Input and output signals ...................................................................................... 33

4.2 Homing ................................................................................................................ 34

4.2.1 Automatic of manual start of homing..................................................................... 34

4.2.2 Input and output signals for homing...................................................................... 35

4.2.3 Homing mode......................................................................................................37

4.2.4 Home offset ........................................................................................................38

4.2.5 Speed and acceleration of homing operation .......................................................... 38

4.3 Positioning Mode ................................................................................................. 39

4.3.1 Motion block management.................................................................................... 39

4.3.2 VTable................................................................................................................40

4.4 Positioning Mode And Motion Block Data............................................................ 41

4.4.1 Motion Mode ....................................................................................................... 41

4.4.1.1 Motion mode "absolute"................................................................................. 44

4.4.1.2 Motion mode "relative" ..................................................................................44

4.4.1.3 Motion mode "touch probe" (sensor) .............................................................. 45

4.4.1.4 Motion mode "velocity".................................................................................. 47

4.4.1.5 Combination with electronic gear.................................................................... 48

Application manual Positioning 04/082

04/08 Application manual Positioning 3

4.4.2 Motion block data ................................................................................................ 54

4.4.2.1 Target position.............................................................................................. 54

4.4.2.2 Speed ..........................................................................................................54

4.4.2.3 Acceleration and Deceleration ........................................................................ 55

4.4.2.4 Automatic sequence of motion blocks (next motion block) ................................ 55

4.4.2.5 Single motion................................................................................................62

4.4.3 Control of motion................................................................................................. 63

4.4.3.1 Selection of motion block via digital signals (motion block change-over)............. 63

4.4.3.2 Motion block selection via parameter (starting-record number) ......................... 65

4.4.4 Input and output signals for motion blocks ............................................................ 66

4.4.5 Starting, stopping and resuming ........................................................................... 67

4.4.5.1 Starting and stopping positioning.................................................................... 68

4.4.5.2 Resuming interrupted motion blocks ............................................................... 72

4.4.6 Digital signals for indication of status of motion orders............................................ 73

4.5 JOG Mode............................................................................................................. 76

4.5.1 Fixed speed in JOG mode ..................................................................................... 79

4.5.2 Acceleration and Deceleration in JOG Mode............................................................ 81

4.6 Teach-In (Saving Actual Position as Target Position)......................................... 81

4.7 Electronic gear..................................................................................................... 85

4.7.1 Master position source ......................................................................................... 85

4.7.2 Gear factor..........................................................................................................87

4.7.3 Resynchronization................................................................................................87

4.7.4 Phasing function..................................................................................................87

4.8 Monitoring Functions........................................................................................... 90

4.8.1 Travel limits ........................................................................................................90

4.8.2 Hardware limit switches ....................................................................................... 90

4.8.2.1 Hysteresis for hardware limit switch................................................................ 93

4.8.2.2 Fault reaction................................................................................................94

4.8.2.3 Move away from HW limit switches................................................................. 95

4.8.3 Software limit switches......................................................................................... 95

4.8.3.1 Move away from SW limit switches ................................................................. 98

4.8.4 Target window .................................................................................................... 99

4.8.5 Contouring error supervision............................................................................... 100

4.8.6 Warning mask Application .................................................................................. 102

4.9 Speed Override .................................................................................................. 104

4.10 Position Comparator .......................................................................................... 105

4.11 Rotary Table Application ................................................................................... 107

4.12 Position Controller ............................................................................................. 110

4.13 Store the actual position value (latching function)........................................... 112

4.14 Wiring Example.................................................................................................. 113

5 List of homing modes............................................................................................... 115

5.1 Brief Description Homing .................................................................................. 115

5.2 Overview Table of Homing Types ...................................................................... 117

5.3 Graphic Overview of Homing Modes ................................................................. 118

5.4 Terminology....................................................................................................... 119

5.5 Description of Homing Modes............................................................................ 120

5.5.1 Homing Modes with Ref. Signal........................................................................... 121

5.5.2 Homing modes without reference signal .............................................................. 137

5.5.3 Homing modes, only ref. signal and actual position............................................... 150

6 Output Signals and fault messages.......................................................................... 151

6.1 Actual positioning values................................................................................... 151

Application manual Positioning 304/08

4 Application manual Positioning 04/08

6.2 Status word of the positioning .......................................................................... 152

6.3 Status word 411 ................................................................................................ 154

6.4 Digital Positioning Output Signals..................................................................... 155

6.5 Logic Signal Sources for Positioning ................................................................. 156

6.6 Positioning Error Messages ............................................................................... 158

6.7 Positioning Warning Status ............................................................................... 162

6.8 Diagnosis and fault clearance............................................................................ 162

6.8.1 Touch probe: Drive is decelerated or stops .......................................................... 163

6.8.2 Drive jerks/is very load....................................................................................... 163

7Parameter List.......................................................................................................... 164

7.1 Actual Value Menu (VAL) ................................................................................... 164

7.2 Parameter Menu (PARA).................................................................................... 164

7.3 Parameter list, sorted by function..................................................................... 168

Index .....................................................................................................................................170

Application manual Positioning 04/084

04/08 Application manual Positioning 5

1General Safety Instructions and Information on Use

Warning! The specifications and instructions contained in the documentation

must be complied with strictly during installation and commissioning.

Only qualified staff who has read the documentation and, in particular,

the safety instructions carefully is allowed to carry out installation or

commissioning work or to operate the frequency inverters. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter and

has the proper qualification for the job.

The present documentation was prepared with great care and it was subjected to

extensive and repeated reviews. For reasons of clarity, it was not possible to include

all details of all types of the product in the documentation. Neither was it possible to

consider all conceivable installation, operation or maintenance situations. If you re-

quire further information or if you meet with specific problems which are not dealt

with in sufficient detail in the documentation, contact your national BONFIGLIOLI

agent.

We would also like to point out that the contents of this documentation do not form

part of any previous or existing agreement, assurance or legal relationship. Neither

are they intended to supplement or replace such agreements, assurances or legal

relationships. The manufacturer's obligations are exclusively specified in the relevant

purchase contract. This contract also contains all and any warranty regulations which

may apply to the relevant scope of supply. These contractual warranty provisions are

neither extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product

information and omissions in these operating instructions without notice. The manu-

facturer shall not be liable for any damage, injuries or costs which may be caused by

the aforementioned reasons.

1.1 General Information

Warning! The DC-link circuit of the frequency inverter is charged during opera-

tion, i.e. there is always the risk of contact with high voltage. Frequency

inverters are used for driving moving parts and they may become hot at

the surface during operation.

Any unauthorized removal of the necessary covers, improper use,

wrong installation or operation may result in serious injuries or material

damage.

In order to avoid such injuries or damage, only qualified staff may carry

out the transport, installation, setup or maintenance work required. The

standards EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100),

IEC 60664-1 (Cenelec HD 625 or VDE 0110-1), BGV A2 (VBG 4) as well

as the applicable national regulations must be complied with. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter as

well as the possible hazards and has the proper qualification for the job.

Application manual Positioning 504/08

6 Application manual Positioning 04/08

1.2 Purpose of the Frequency Inverters

Warning! The frequency inverters are electrical drive components intended for

installation in industrial plants or machines. Commissioning and start of

operation is not allowed until it has been verified that the machine

meets the requirements of the EC Machinery Directive 98/37/EEC and

EN 60204. In accordance with the CE marking requirements, the fre-

quency inverters also comply with the Low Voltage Directive 72/23/EEC

as well as EN 50178 / DIN VDE 0160 and EN 61800-2. The user shall be

responsible for making sure that the requirements of the EMC Directive

89/336/EEC are met. Frequency inverters are only available at special-

ized dealers and are exclusively intended for professional use as per EN

61000-3-2.

The frequency inverters are also marked with the UL label according to

UL508c, which proves that they also meet the requirements of the CSA

Standard C22.2-No. 14-95.

The technical data, connection specifications and information on ambi-

ent conditions are indicated on the name plate and in the documenta-

tion and must be complied with in any case. Anyone involved in any

kind of work at the device must have read the instructions carefully and

understood them before starting the work.

Do not connect any capacitive loads.

1.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way. Dur-

ing transport and storage the devices must remain in their original packaging. The

units may only be stored in dry rooms which are protected against dust and mois-

ture and are exposed to little temperature deviations only. Observe the climatic con-

ditions according to EN 50178 and the marking on the packaging. The frequency

inverters must not be stored for more than one year without connecting them to

nominal voltage.

1.4 Handling and Installation

Warning! Damaged or destroyed components must not be put into operation

because they may be a health hazard.

The frequency inverters are to be used in accordance with the documentation as

well as the applicable directives and standards. They must be handled carefully and

protected against mechanical stress. Do not bend any components or change the

isolating distances. Do not touch electronic components or contacts. The devices are

equipped with components which are sensitive to electrostatic energy and can easily

be damaged if handled improperly. Any use of damaged or destroyed components

shall be considered as a non-compliance with the applicable standards. Do not re-

move any warning signs from the device.

Application manual Positioning 04/086

04/08 Application manual Positioning 7

1.5 Electrical Connection

Warning! Before any assembly or connection work, discharge the frequency in-

verter. Verify that the frequency inverter is discharged.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information given in the operating instructions and on

the frequency inverter label.

When working at the frequency inverters, comply with the applicable standards BGV

A2 (VBG 4), VDE 0100 and other national directives. Comply with the electrical in-

stallation instructions given in the documentation as well as the relevant directives.

The manufacturer of the industrial machine or plant is responsible for making sure

that the limit values specified in the EMC product standard EN 61800-3 for electrical

variable-speed drives are complied with. The documentation contains information on

EMC-conforming installation. The cables connected to the frequency inverters may

not be subjected to high-voltage insulation tests unless appropriate circuitry meas-

ures are taken before.

1.6 Information on Use

Warning! The frequency inverter may be connected to power supply every 60 s.

This must be considered when operating a mains contactor in jog op-

eration mode. For commissioning or after an emergency stop, a non-

recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start

unexpectedly if the AutoStart function is activated.

If staff is endangered, a restart of the motor must be prevented by

means of external circuitry.

Before commissioning and the start of the operation, make sure to fix

all covers and check the terminals. Check the additional monitoring and

protective devices according to EN 60204 and applicable the safety

directives (e.g. Working Machines Act, Accident Prevention Directives

etc.).

No connection work may be performed, while the system is in opera-

tion.

1.7 Maintenance and Service

Warning! Unauthorized opening and improper interventions can lead to personal

injury or material damage. Repairs on the frequency inverters may only

be carried out by the manufacturer or persons authorized by the manu-

facturer. Check protective equipment regularly.

Application manual Positioning 704/08

8 Application manual Positioning 04/08

2System description

Positioning via motion blocks enables movement by a certain distance or to a target

position. For each motion block, a separate motion profile can be set, including

speed, acceleration and deceleration ramp. When motion blocks are processed au-

tomatically, the drive will react according to the parameterized behavior when it

reaches the target position.

Scope of functions

−Positioning of linear and round axes

−Optimized round axes positioning (shortest way)

−Absolute and relative positioning

−Touch probe positioning for evaluation of sensors, e.g. motion as from this point

−Specification of values and parameter configuration can be done via user-defined

scale (user units)

−32 motion blocks for different target positions and motion profiles

−Automatic motion block sequence, event or time controlled

−Repetition of motion blocks

−Teach-in function for taking over the actual position value as the target position

in the motion block

−JOG mode for manual operation via digital inputs

−Combination of positioning with electronic gear

−Different homing modes for determining the reference point for positioning

−Control via digital inputs or communication module

−Monitoring: Position monitoring via target window, contouring error monitoring,

hardware and software limit switches

−Parameter configuration via commissioning and diagnosis software VPlus

Components required

Frequency inverter ACU (ACTIVE Cube),

Incremental encoder or resolver,

Suitable extension module,

Interface adapter KP232 for port (A),

Commissioning and diagnosis software VPlus, version 4 or

higher (A)

Optional Components

Communication modules (1 option possible),

Port (B):

CM-232 with RS232 interface,

CM-485 with RS485 interface,

CM-PDP-V1 with Profibus–DP-V1 interface,

CM-CAN with CANopen interface

(B)

Epansion modules (1 option possible), port (C):

EM-ENC for detailed evaluation of incremental encoder (TTL

to RS-422A/RS-485 or HTL, DC 5 to 30 V),

EM-IO for additional analog and digital outputs; depending on

module, system bus interface available, too,

EM-RES for resolver evaluation; depending on module, sys-

tem bus interface available, too,

EM-SYS for communication via system bus

(C)

(A)

(B)

(C)

Application manual Positioning 04/088

04/08 Application manual Positioning 9

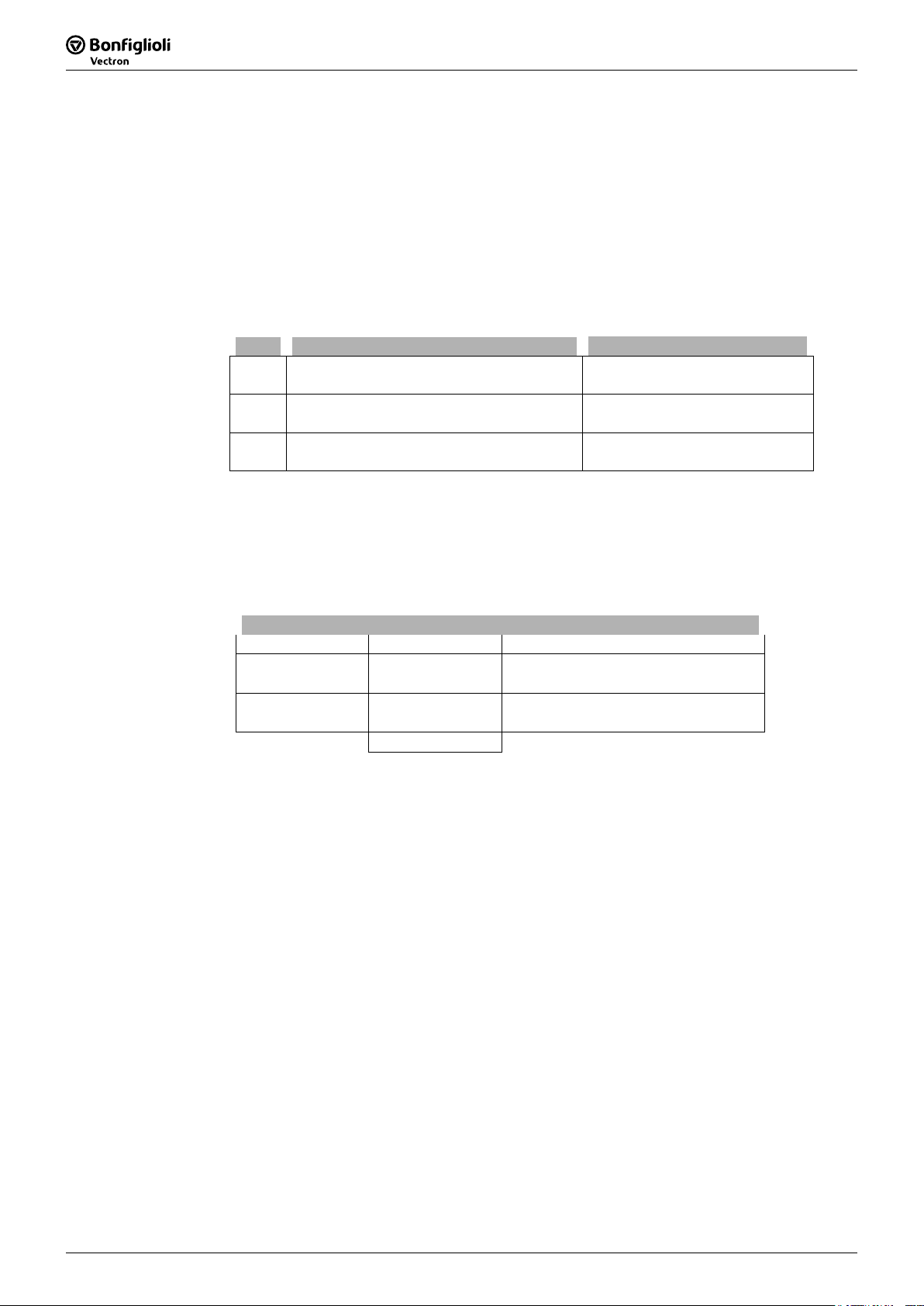

2.1 Terminal diagram ACTIVE Cube (ACU) series

The terminal diagram shows an example of a linear axis, with standard parameter

configuration of digital inputs. The sensor is evaluated using an EM extension mod-

ule.

ACTIVE Cube

RS232

X2

UVW

X410A

EM

X410B

VPlus

1234567

X210A X210B

+20V

GND

S1IND

S2IND

S3IND

S4IND

S5IND

S6IND

S7IND

S1OUTD

MFO1A

10VRef

MFI1D

GND

1234567

STOA

S2 SMFI1DS3

S4S6S5

STOB

Terminal diagram ACTIVE Cube (ACU) series

: clockwise; : Anticlockwise

Switch Function

STOA Wire input S1IND as shut-down path STOA of safety function STO 1)

STOB Wire input S1IND as shut-down path STOB of safety function STO 1)

S2 Start positioning or clockwise operation in JOG mode

S3 Stop positioning or anticlockwise operation in JOG mode

S4 Limit switch for limitation of motion range in positive direction 2)

S5 Limit switch for limitation of motion range in negative direction 2)

S6 Home switch for homing, point of reference for absolute positioning

SMFI1D Change-over between positioning mode and JOG mode (JOG mode in

manual mode)

1) Safety function STO (Safe Torque Off) is wired through two channels via inputs STOA and

STOB. This safety function is described in user manual "Safe Torque Off". The "Safe Torque

Off" user manual must be complied with when using the "Safe Torque Off" function.

2) Different from the factory setting. Assign S4IND and S5IND to the parameters for HW limit

switches. Set Parameter Operation mode 490 of speed sensor 1 to „0 - Off“.

Application manual Positioning 904/08

10 Application manual Positioning 04/08

3Commissioning of the Frequency Inverter

Warning! Carry out the electrical and mechanical installation according to the

operating instructions or the "Quick Start Guide" of the frequency in-

verter. Comply with the safety instructions provided there.

Frequency inverters of the ACU series feature the "Safe Torque Off"

function. In any case comply with the application manual "Safe Torque

Off" when using this safety function.

3.1 Switching on Mains Voltage

After completion of the installation work, make sure to check all control and power

connections again before switching on the mains voltage. If all electrical connections

are correct, make sure that the frequency inverter is not enabled. After power-up,

the frequency inverter carries out a self-test and the relay output (X10) reports

"Fault".

Switch off release of frequency inverter:

Control inputs S1IND (STOA) and S7IND (STOB) open

After a few seconds, the self-test is complete, the relay (X10) picks up and signals

"no fault ".

If the unit is in "as-delivered" condition or after resetting the unit to the factory set-

tings, the guided commissioning procedure is started automatically. On the control

unit, the “SetUP“ menu from the menu branch CTRL is displayed.

Application manual Positioning 04/0810

04/08 Application manual Positioning 11

3.2 Commissioning of the motor

Caution!

During the guided commissioning, comply with the safety instructions in

chapter "General Safety Instructions and Information on Use" and in

the Operating Instructions or the "Quick Start Guide" of the frequency

inverter.

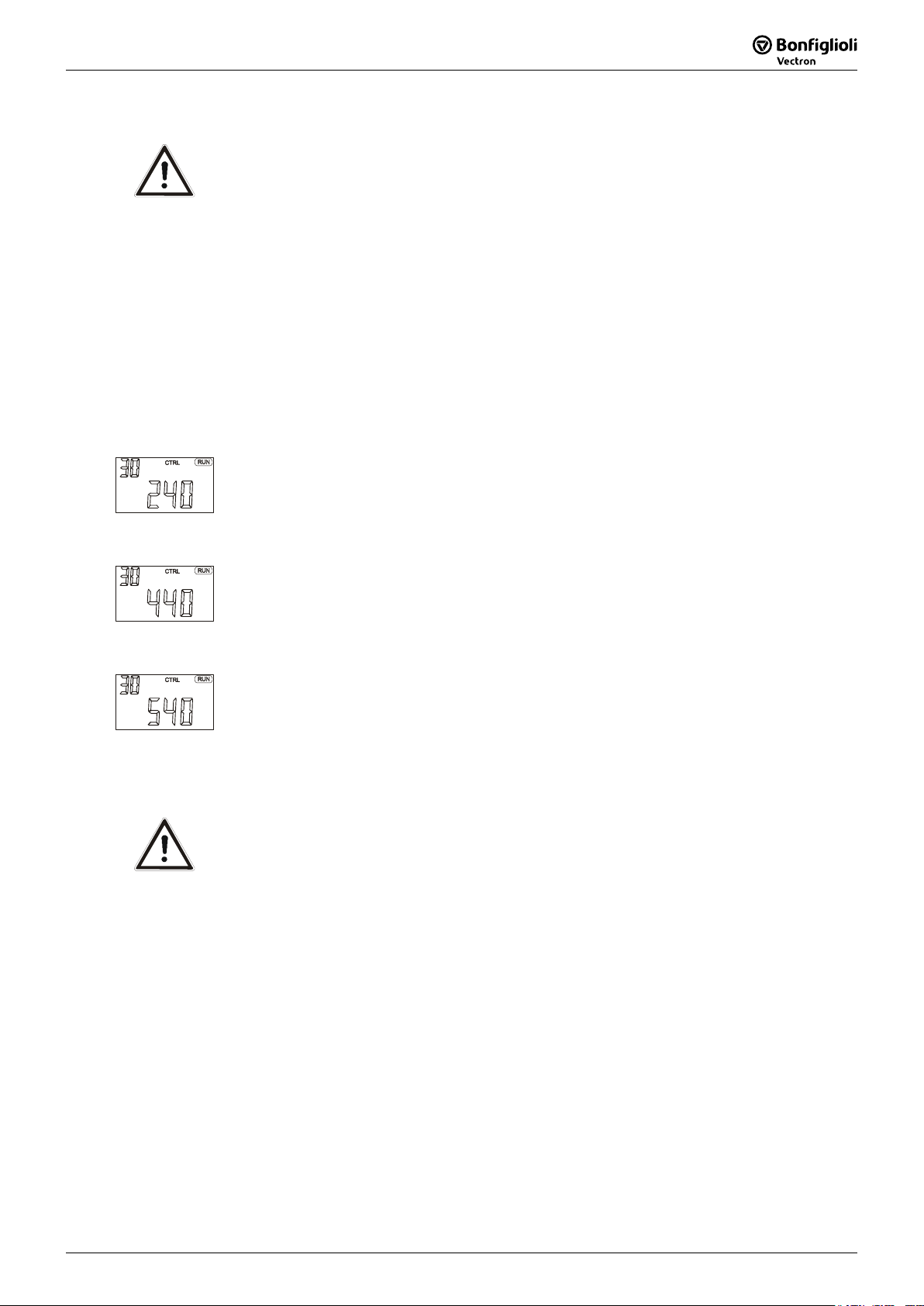

Carry out the guided commissioning procedure of the frequency inverter for one of

the configurations listed below. These configurations contain the motion block posi-

tioning functions.

Note:

The guided commissioning contains the function for parameter identifi-

cation. The parameters are determined by way of measurement and set

accordingly. In the case of higher requirements as regards the accuracy

of the speed/torque control, you should carry out the guided commis-

sioning procedure once again under operating conditions because

part of the machine data depends on the operating temperature.

Configuration 240, field-orientated control with positioning

Configuration 240 extends the field-oriented control of an asynchronous machine by

the positioning functions.

The motor controller and the position controller can use the same encoder (motor

encoder) or different encoders (motor encoder and position encoder).

Configuration 440, sensorless field-orientated control with positioning

Configuration 440 extends the sensorless field-oriented control of an asynchronous

machine by the positioning functions.

The motor is controlled without sensors. The positioning controller can be used via

any encoder input.

Configuration 540, field-orientated control of synchronous machine with

positioning

Configuration 540 extends the field-oriented control of a synchronous machine by

the positioning functions. Extension module EM-RES with resolver interface are re-

quired for this.

The motor controller and the position controller can use the same encoder (motor

encoder) or different encoders (motor encoder and position encoder).

Caution!

To enable control of a synchronous machine in configuration 540, pa-

rameter Offset 382 must be set before the guided commissioning. To

do this, proceed according to the operating instructions for the exten-

sion module EM-RES installed. Otherwise, personal or machine damage

may occur.

Note:

For first commissioning, the drive can be controlled manually, using the

JOG function, via the "FUN" key or the digital inputs.

The processing speed of automatic motion block sequence can be re-

duced for commissioning. To do this, use the speed override function.

Note:

The motor encoder should only be used for motor and position control

in slip-free systems (e.g. linear spindle). In systems where slip may

occur (e.g. wheel/rail systems) always use a position encoder to obtain

optimum results.

Application manual Positioning 1104/08

12 Application manual Positioning 04/08

3.3 Control Inputs and Outputs

The modular structure of the frequency inverters enables a wide spectrum of appli-

cations on the basis of the available hardware and software functionality. The func-

tionality of the control inputs and outputs described in the "Quick Start Guide" and

operating instructions is extended in the described configurations.

Caution!

Switch off power supply before connecting or disconnecting the control

inputs and outputs. Verify that the keyed control inputs and outputs are

deenergized before connecting or disconnecting them. Otherwise, com-

ponents may be damaged.

The unit may only be connected with the power supply switched off.

Make sure that the frequency inverter is discharged.

ACU frequency inverters of ACTIVE Cube series

Control terminal X210A

X210A.1 +20 V voltage output (Imax=180 mA) or

input for external power supply 24 V

X210A.2 GND 20 V/ GND 24 V (ext.)

X210A.3 Safety function, digital input STOA

X210A.4 −Start Positioning

−JOG Clockwise

−Store actual position value (latching)

X210A.5 −Stop Positioning

−JOG Anticlockwise

−Touch probe

X210A.6 Encoder 1 Track B 1) or

freely programmable 2)

X210A.7 Encoder 1 Track A 1) or

freely programmable 2)

Control terminal X210B

X210B.1 Home switch 3) or

Encoder 1 Zero Track Z 4)

X210B.2 Safety function, digital input STOB

X210B.3 Operating message

X210B.4 Analog signal of actual frequency

X210B.5 Supply voltage +10V

X210B.6 −Change-over position control/JOG

mode (JOG mode active)

−Teach-In-Signal

S7IND

S1OUT

MFO1A

+10 V/4 mA

MFI1D

GND 10 V

1

2

3

4

5

6

7

X21

0

A

+20 V / +24 V ext.

GND 20 V / GND 24 V ex

t

STOA

STOB

S1IND

S2IND

S3IND

S4IND

S5IND

S6IND

X210B

1

2

3

4

5

6

7

+B

-

A

Z

X210B.7 Ground 10 V

1) Factory setting in configuration 240

2) If no speed sensor is connected to S4IND/S5IND the digital inputs can be used freely program-

mable (e.g. for hardware limit switches).

3) Factory setting in configurations 240, 440 and 540

4) For evaluation of an encoder zero track an Operation Mode 490 for speed sensor 1 higher than

1000 must be selected. Linking of other functions to this input are not active.

The connection diagram describes the default assignment of control terminals and

functions in the different configurations positioning control. According to the re-

quirements of the application, the other functions can be assigned to the control

terminals.

Note:

In order to fully use the positioning functions, an optional extension

module is required. This module enables, for example, encoder evalua-

tion, motion-block change-over or reference percentage change-over.

Application manual Positioning 04/0812

04/08 Application manual Positioning 13

3.3.1 Factory settings of the digital inputs

Control input functions

Digital

Input

Control

terminal

Control positioning JOG mode /

Teach-in

Digital inputs of frequency inverter:

S1IND X210A.3 Digital input STOA for safety function

S2IND X210A.4 Start

Positioning

Store actual

position value 3)

JOG Clockwise

S3IND X210A.5 Stop Positioning,

Touch probe 1)

JOG Anticlockwise

S4IND X210A.6 Freely programmable or

Encoder 1 Track B

2)

S5IND X210A.7 Freely programmable or

Encoder 1 Track A

2)

S6IND X210B.1 Home switch or

Encoder 1 Zero Track Z

2)

X210B.2 Digital input STOB for safety function

MFI1D X210B.6 Change-over position con-

trol/JOG mode (JOG mode ac-

tive)

Teach-in signal in teach-

in mode

Digital inputs extension module:

EM-S1IND Motion Block Change-Over 1

Alternative: - Encoder 2 Zero Track Z

- Fixed frequency change-over 1

- Fixed percentage value change-over 1

EM-S2IND Motion Block Change-Over 2

Alternative: - Encoder 2 Track A

- Fixed frequency change-over 2

- Fixed percentage value change-over 2

EM-S3IND

depending

on module

Motion Block Change-Over 3

Alternative: - Encoder 2 Track B

1) Comply with the notes in section 4.4.1.3.

2) Dependent on the settings of parameters Configuration 30 and Operation

Mode 490. See chapter 3.5.1.4.

3) Switch on the function via parameter Operation Mode 1280. Comply with the

notes in section 4.13.

Control terminal/ Description

Identification

X210A.4

Start Positioning

The input is assigned to parameter Start Positioning 1222.

When activated, the Starting-Record Number 1228 or another

motion block selected by the motion block change-over function

is started.

The motion blocks can be switched via digital inputs EM-S1IND,

EM-S2IND and EM-S3IND of an extension module.

JOG Clockwise In JOG mode, the drive is moved in positive direction (clockwise)

at an adjustable fixed speed. JOG mode is activated via terminal

X210B.6. In teach-in operation modes (Operation Mode 1221),

the JOG function is activated automatically.

Store actual position

value

The function can be switched on via parameter Operation Mode

1280. With signal edge the actual position value is stored in the

EEPROM and displayed via Latched Position 1281.

Application manual Positioning 1304/08

14 Application manual Positioning 04/08

X210A.5

Stop Positioning The drive stops at the current position at deceleration ramp set in

Deceleration 1206.

JOG Anticlockwise In JOG mode, the drive is moved in negative direction (anti-

clockwise) at an adjustable fixed speed. JOG mode is activated

via terminal X210B.6. In teach-in operation modes (Operation

Mode 1221), the JOG function is activated automatically.

Touch probe Input for momentary contact switch or sensor for setting the

reference position. Effective in Motion Mode 1208 with touch-

probe. Rising or falling edge (depending on setting of Motion

Mode 1208) on input sets the point of reference at the current

position. As soon as the signal is received, the drive moves by

the relative distance of parameter Target Position/Distance

1202. Parameter configuration for digital signal "Stop Position-

ing" should be changed when touch probe mode is used.

X210A.6

Encoder 1 Input Encoder 1 Track B, HTL, DC 12 … 30 V

or freely programma-

ble

Evaluation of parameterized functions if the terminal is not used

as encoder input.

Possible function:

Pos. HW Limit Switch

Input for positive hardware limit switch. Limitation of travel range

in positive direction. The drive reacts according to parameter

Fault Reaction 1143 when the switch is reached. Positive direc-

tion (clockwise direction) is disabled.

Set parameter Pos. HW Limit Switch 1138 = “540 - S4IND in-

verted (Hardware)“. Set Parameter Operation Mode 490 of

speed sensor 1 = “0 - Off”. If X210A.6 is used as encoder input

the HW limit switch function is not evaluated as this input.

X210A.7

Encoder 1 Input Encoder 1 Track A, HTL, DC 12 … 30 V

or freely programma-

ble

Evaluation of parameterized functions if the terminal is not used

as encoder input.

Possible function:

Neg. HW Limit Switch

Input for negative hardware limit switch. Limitation of travel

range in negative direction. The drive reacts according to pa-

rameter Fault Reaction 1143 when the switch is reached. Nega-

tive direction (anticlockwise direction) is disabled.

Set parameter Neg. HW Limit Switch 1137 = “541 - S5IND in-

verted (Hardware)“. Set Parameter Operation Mode 490 of

speed sensor 1 = “0 - Off”. If X210A.7 is used as encoder input

the HW limit switch function is not evaluated as this input.

X210B.1

Home switch Input for reference cams. Marks the point of reference for abso-

lute positioning. Via parameter Home Switch 1139, the logic

status of the switch is evaluated.

or Encoder 1 Input Encoder 1 Zero Track Z, HTL, DC 12 … 30 V.

Select one of the settings 1001 … 1132 (with reference pulse) for

parameter Operation Mode 490.

Application manual Positioning 04/0814

04/08 Application manual Positioning 15

X210B.6

JOG-Mode Active Activates JOG mode. JOG clockwise via terminal X210A.4 or JOG

anticlockwise via terminal X210A.5 is executed.

In teach-in operation modes (Operation Mode 1221), the JOG

function is activated automatically.

Teach-In When a rising signal edge is received, the current position in the

selected motion block is saved as the target position.

The motion block is selected by parameter Starting-Record Num-

ber 1228 or the motion block change-over function (parameters

1224 to 1227 and 1254).

The function is activated via Operation Mode 1221.

Parameter Teach-In-Signal 1239 must be assigned the digital

input signal or the logic signal which is to trigger saving of the

actual position.

3.4 Digital inputs for speed sensor inputs or for other functions

The setting of parameter Operation Mode 490 of speed sensor 1 affects the processing of

functions which are linked to the digital inputs S4IND, S5IND and S6IND:

−In the settings 1 … 132 for Operation Mode 490 the digital inputs S4IND and S5IND are

prepared for speed sensor inputs.

−In the settings 1001 … 1132 for Operation Mode 490 the digital inputs S4IND, S5IND and

S6IND are prepared for speed sensor inputs.

The setting of the digital inputs as speed sensor inputs (1 … 1132 for Operation Mode 490)

has higher priority than the control of other functions via these inputs. Other functions will not

be evaluated.

Set Operation Mode 490 to “0 - Off” if S4IND, S5IND and S6IND shall not be used as speed

sensor inputs but for control of other functions via these inputs.

Selection for

Operation Mode 490

S4IND, S5IND and S6IND as

speed sensor inputs or for other functions

0

Functions which are assigned to the digital inputs S4IND, S5IND and

S6IND will be evaluated. The digital inputs S4IND, S5IND and S6IND

are not prepared as speed sensor inputs.

1 … 132 The digital inputs S4IND and S5IND are prepared as speed sensor in-

puts. Other functions which are assigned to the inputs S4IND and

S5IND will not be evaluated.

1001 … 1132 The digital inputs S4IND, S5IND and S6IND are prepared as speed sen-

sor inputs. Other functions which are assigned to the inputs S4IND,

S5IND and S6IND will not be evaluated.

For the settings of speed sensor inputs also refer to section 3.5.1.

Application manual Positioning 1504/08

16 Application manual Positioning 04/08

3.5 Positioning - commissioning procedure

Terminal assignment:

S1IND (STOA) and S7IND (STOB): LOW signal

S2IND (Start positioning): LOW signal

S3IND (Stop positioning): LOW signal

S4IND and S5IND: encoder track B and track A or for parameterized function

S6IND: home switch or encoder zero track Z

MFI1D (JOG mode): LOW signal

Commissioning of frequency inverter:

Comply with chapter "Commissioning of Frequency Inverter",

set up configuration 240, 440 or 540,

switch on power supply,

start commissioning and diagnosis program VPlus (if not yet done for commission-

ing),

Set up reference system (motion distance per rotation of drive and gear factor),

Select suitable homing mode,

Select encoder source for positioning

For manual mode (JOG mode):

Set up parameters for JOG mode or use factory settings,

Release with HIGH signal on S1IND (STOA) and S7IND (STOB),

Activate JOG mode with HIGH signal at MFI1D, clockwise via S2IND, anticlockwise

via S3IND, perform function test

Entering motion profile:

In VPlus, set up the parameters of the motion blocks,

switch on speed override, in order to position at reduced speed during commission-

ing.

Start positioning:

Check readiness for operation: when green LED is flashing: ready for operation; if

green and red LED are flashing: ready for operation and warning message is pre-

sent, repair fault,

Release with HIGH signal on S1IND (STOA) and S7IND (STOB) and start of position-

ing with HIGH signal on S2IND

For communication via field bus or system bus: Set up other parameters according

to operating instructions of the corresponding extension or communication module.

Motion blocks

The motion profile is defined in motion blocks, indicating the target position, speed

and acceleration. A positioning operation may comprise a maximum of 32 motion

blocks.

Discrete selection: Each of the 32 motion blocks can be selected both via logic sig-

nals and parameters (also for transfer via field bus or system bus).

Cycle: The motion blocks can be repeated or processed in a freely programmable

order.

In the motion blocks, the motion block to be processed next can be identified.

The next motion block can be activated:

- by events, e.g. via digital inputs or logic signals

- after a definable delay

In the motion block, the motion mode is selected: absolute (referred to a fixed ref-

erence position), relative (to moving distance, referred to last position approached)

or "Touch Probe" (to moving distance, referred to a sensor signal on digital input

S3IND).

Application manual Positioning 04/0816

04/08 Application manual Positioning 17

Digital signals for status indication

Digital signals can be influenced depending on the status of a motion order. For

example, a digital signal can be parameterized such that it signals reaching of the

target position or the end of the motion block.

JOG mode

The drive is operated manually via two digital inputs at a parameterizable, fixed

speed. This enables for example functional tests for commissioning and approaching

of positions for teach-in mode.

Teach-In

With this function, any position approached can be entered directly in a motion

block as a target position. The required position can be approached in JOG mode.

The current position value is saved as the target position when an increasing edge

is present on the teach-in terminal.

Homing

To determine the drive speed and position, the frequency inverter captures the sig-

nals from position sensors such as incremental encoders or resolvers. When the

frequency inverter is switched on, there is no relation between the position sensor

and the mechanical position of the axis. In order to determine an absolute point of

reference (reference position) for the positioning operation, a homing operation

must be performed. All absolute position data is referred to this reference position.

By selecting a certain homing mode, you can define in which direction the reference

position is to be found and which type of switch (limit switch, home switch) is used.

In the homing operation, the drive moves to the reference position and stops there.

Monitoring

To limit the motion range and protect the machine, limit switches are connected to

the digital input terminals of the frequency inverter. The behavior of the drive when

reaching the limit switches is parameterizable (e.g. error switch-off, shut down).

Software limit switches enable monitoring of the permissible motion range. Position-

ing commands will be executed only within the range defined by parameters. The

software limit switches are active only after a successful homing operation.

The adjustable target window monitors the current position after performance of a

positioning operation. Reaching of the required position is signaled only if the cur-

rent position is within the target window.

The contouring error monitoring function monitors the maximum permissible devia-

tion of the current position and the required position. This monitoring function de-

termines how accurately the positioning operation must be performed.

Application manual Positioning 1704/08

18 Application manual Positioning 04/08

3.5.1 Getting started

In order to use the positioning function, you must start the frequency inverter in

Configuration 240, 440 or 540. If required, perform a motor measurement. Several

functions will be readjusted as soon as you set up the configuration of the position-

ing operation. This includes the functions of the digital inputs.

Warning! Ensure that your parameterization corresponds to the connected termi-

nals.

For commissioning, you must select different configurations for the following cases:

Case Description Possible Configuration 30

1 Motor encoder is position encoder at the

same time

240, 540

2 Two different encoders for motor and

positioning

240, 540

3 No motor encoder, external encoder for

positioning

440

3.5.1.1 Motor encoder is position encoder at the same time

In slip-free systems, the motor encoder can be used as position encoder at the same

time. By using one encoder for both functions, the overall costs can be reduced.

Configuration 30 = 240 | 540, motor encoder = position encoder

Encoder 1 Encoder 2 Motor controller

Operation Mode

490

Operation Mode

493

Actual Speed Source 766

Division Marks

491

Division Marks

494

Actual Position Source 1141 =

“0 - As P. 766 Actual Speed Source”

Level 495

In the corresponding parameters, set up the properties of the encoders according to

the wiring of Encoder 1 or Encoder 2. The parameters of Encoder 2 are available

only if the corresponding extension module is connected.

Adjust parameter Actual Speed Source 766 to connected encoder.

Adjust parameter Actual Position Source 1141 to "0 - As P. 766 Actual Speed

Source" (corresponds to factory settings).

Application manual Positioning 04/0818

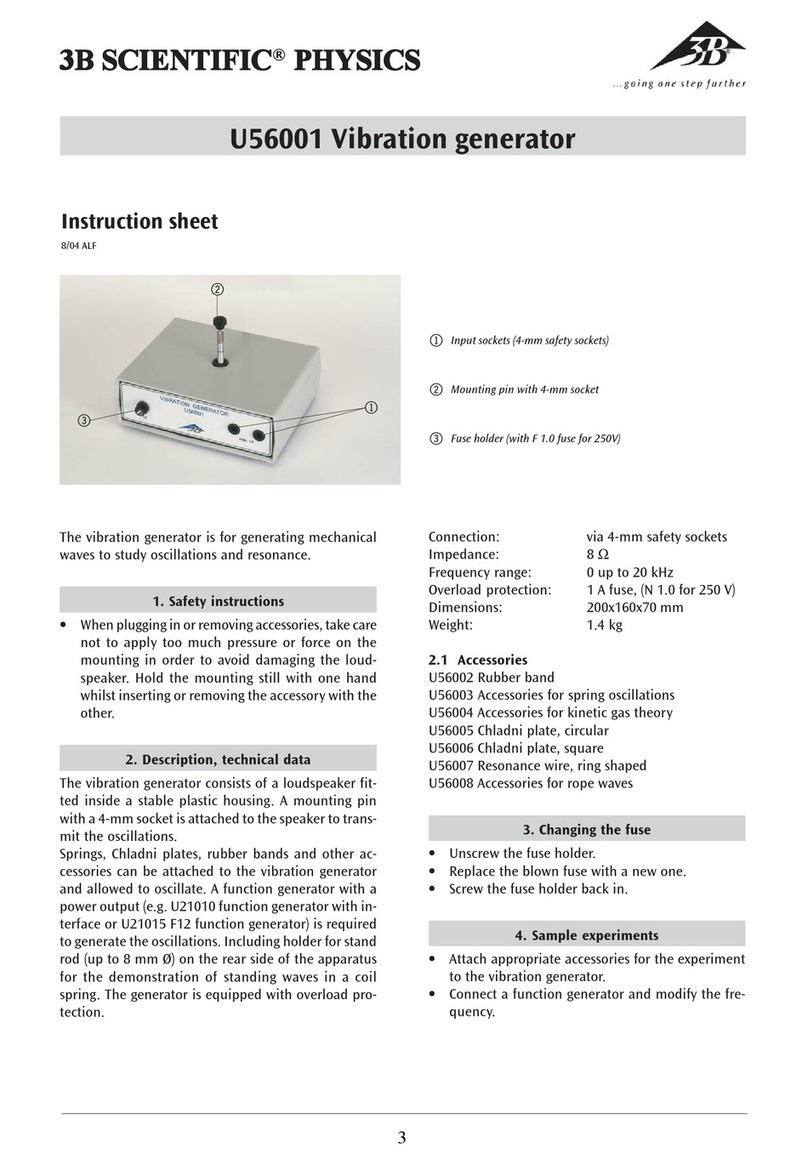

Other manuals for ACTIVE CUBE Series

1

Table of contents

Other BONFIGLIOLI Vectron Inverter manuals

Popular Inverter manuals by other brands

YASKAWA

YASKAWA VS MINI J7 instruction manual

Energizer

Energizer EN150 owner's guide

3B SCIENTIFIC PHYSICS

3B SCIENTIFIC PHYSICS U56001 instruction sheet

Western

Western Leonardo Off-Grid 4kW-5000-48 MG user manual

Velleman

Velleman PI600M user manual

Xantrex

Xantrex XPower Powerpack 400 Plus, 400 R owner's guide

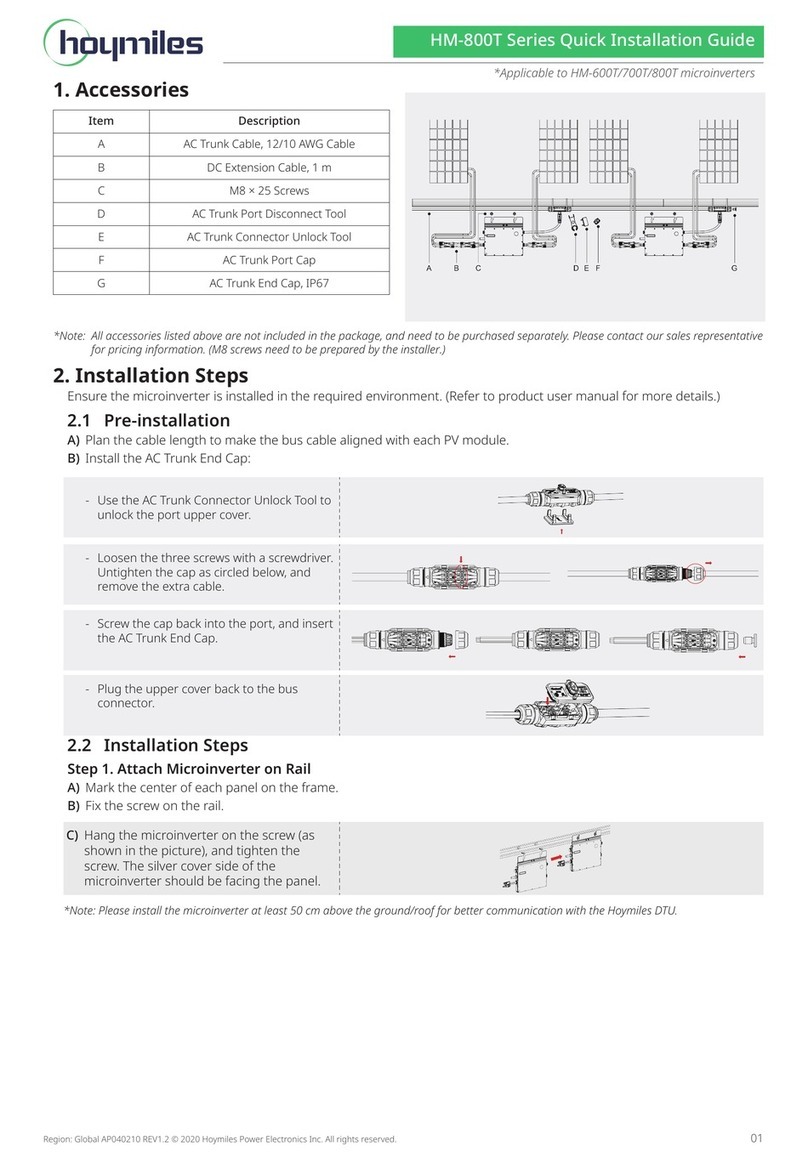

Hoymiles

Hoymiles HM-800T Quick installation guide

Moso

Moso SF1.6KTL-S manual

Siemens

Siemens MICROMASTER Vector Series operating instructions

Siemens

Siemens MICROMASTER 420 Getting started guide

Generac Power Systems

Generac Power Systems 6055 owner's manual

ZUCCHETTI

ZUCCHETTI 3PH 10KTL-15KTL-V2 user manual