BONFIGLIOLI Profinet DGM Series User manual

PROFINET fieldbus

Operating manual

2

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

Exclusion of liability

Allnames,trademarks,productnamesorotherdesignationsgiveninthismanualmaybelegally

protectedevenifthisis notlabelledassuch(e.g.asatrademark).BONFIGLIOLIassumesnoliability

for their free usage.

Theillustrationsandtextshavebeencompiledwithgreatcare.However,thepossibilityoferrors

cannot be ruled out. The compilation is made without anyguarantee.

General note on gender equality

BONFIGLIOLIis awareof howlanguageimpactsongender equalityandalwaysmakesan

effortto reflect this in documentation. Nevertheless, for the sake of readability we are

unable to use non-gender-specific terms throughout anduse the masculine form instead.

© 2016 BONFIGLIOLI RIDUTTORI S.p.A.

All rights reserved byBONFIGLIOLI, includingthose ofreproduction byphotocopyand storagein

electronicmedia.Commercialuseordistributionofthetexts,displayedmodels,diagramsand

photographs appearing in this product is not permitted.

This manualmay not be reproduced, stored,transmitted ortranslatedin anyform orbymeansof

any medium - in whole or in part - without prior writtenpermission.

Bonfiglioli Riduttori S.p.A.

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno

Bologna, Italy

Tel. +39 051 647 3111

Fax +39 051 647 3126

bonfiglioli@bonfiglioli.com

www.bonfiglioli.com

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

3

Contents

1.

General information ....................................................................................5

1.1 Information about documentation................................................................................5

1.1.1 Other applicable documents........................................................................................5

1.1.2 Storing the documentation ..........................................................................................5

1.2 Notes in this manual....................................................................................................6

1.2.1 Warnings.....................................................................................................................6

1.2.2 Warning symbols used................................................................................................7

1.2.3 Signal words ...............................................................................................................7

1.2.4 Information notes ........................................................................................................8

1.3 Symbols used in this manual.......................................................................................9

1.4 Qualified staff..............................................................................................................9

1.5 Proper use................................................................................................................10

1.6 Responsibility............................................................................................................10

1.7 Contacts for information............................................................................................10

1.8 Safety instructions.....................................................................................................10

2.

Device and system description................................................................ 11

2.1 PROFINET................................................................................................................11

2.1.1 Master / slave operation............................................................................................11

2.2 Scope of delivery.......................................................................................................12

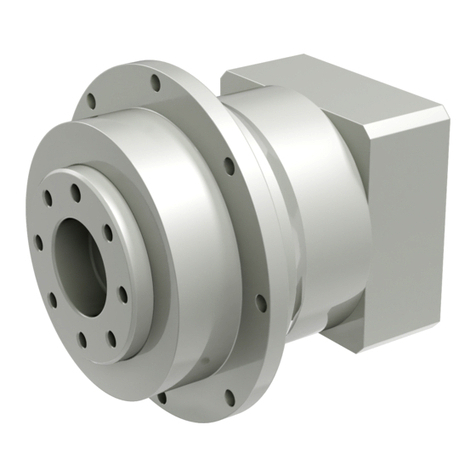

2.3 Item description for DGM...........................................................................................12

2.3.1 Type code for PROFINET (valid until end of February 2016)......................................12

2.3.2 Type code for PROFINET (current)...........................................................................13

2.3.3 Features code...........................................................................................................13

2.4 Hardware components..............................................................................................14

2.4.1 Interfaces on the drive controller ...............................................................................15

2.4.2 Pin assignment for interfaces....................................................................................18

2.4.3 Cable........................................................................................................................18

2.5 Software components................................................................................................18

3.

Installation.................................................................................................. 19

3.1 Configuration of the drive controllerfor PROFINET ...................................................19

3.2 DGM bus address.....................................................................................................19

3.3 Installing the DGM GSDML file..................................................................................19

4.

Accessing data via PROFINET................................................................. 20

4.1 Cyclic data access –Process data Out .....................................................................20

4.1.1 Structure of Process data Out...................................................................................20

4.1.2 Structure of DGM status word ...................................................................................22

4.1.3 Process data Out which canbe parameterized..........................................................23

4.2 Cyclic data access –Process data In........................................................................25

4.2.1 Structure of DGM control word..................................................................................27

4.2.2 Process data In which can be parameterized ............................................................29

4.3 Non-cyclic data access / parameters.........................................................................30

4.3.1 Non-cyclic data .........................................................................................................30

4.3.2 Direct access ............................................................................................................31

4.3.3 Indirect access..........................................................................................................32

4.3.4 Parameter.................................................................................................................33

4

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

5.

Error detection and troubleshooting ....................................................... 42

5.1 Error word of application side....................................................................................42

5.2 Error word of power side ...........................................................................................43

Contents

5

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

1. General information

ThankyouforchoosinganDGMdrivecontrollerwithPROFINETfromBONFIGLIOLIRiduttori S.p.A.

OurDGMlineof drivecontrollersisdesignedtobe universallyusablewithallcommon motor types

and bus systems.

1.1

Information about documentation

Thisdocumentationis asupplementaryoperatingmanualfortheDGMdrivecontrollerwiththe

PROFINETbussystem.Itcontainsalltheimportantinformationyouneedtoinstallandoperatethe

bus system.

Pleasereadtheoperatingmanualsforthedrivecontrollerandbussystemthroughcarefully.

They contain important information for operating the DGM with fieldbus.

We assume no liability for any damage resulting from non-observance of this manual.

Thismanualisan integralpartoftheproductandappliesexclusivelytotheDGMwith

PROFINET from BONFIGLIOLI Riduttori S.p.A.

Provide the operator of the system with this manual so it is available when needed.

1.1.1

Other applicable documents

Thisrefers toallmanuals that describe howtooperate the drivecontroller system andany other

manualsfortheequipmentused.Downloadthe3Dfiles(.stp)forDGMandadapterplatesfrom

www.Bonfiglioli.com.

A description of parameters is available for download (www.Bonfiglioli.com) for parametrizing

thedrivecontrollersystem.Inthedownload,youwillfindalltheinformationrequired for correct

parameterization.

1.1.2

Storing the documentation

Storethisoperatingmanualandallotherapplicabledocumentscarefullysotheyareavailable

when needed.

General information

6

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

Notes in this manual

1.1.3

Warnings

Thewarningsrefertolife-threateningdangers.Seriousinjuriespossiblyresultingindeathmay

occur.

Each warning consists of the following elements:

Fig.: 1 Structure of warnings

1

Warning symbol

2

Signal word

3

Type of danger and its source

4

Possible consequence(s) of failure to comply

5

Corrective actions

General information

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

7

1.1.4

Warning symbols used

Danger

Danger due to electrical shock and discharge

Danger due to burns

Danger due to electromagnetic fields

1.1.5

Signal words

Signal words are used to identify the severity of the danger.

DANGER

Indicatesa directhazardwitha highlevelof risk, which,if not avoided,will result indeathor

serious injury.

WARNING

Indicatesahazardwith amoderatelevel of risk,which,if not avoided, will resultindeathorserious

injury.

CAUTION

Indicatesahazardwithalowlevelof risk,which,if not avoided,may resultinminoror slightinjury

or property damage.

General information

8

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

1.1.6

Information notes

Informationnotescontainimportantinstructionsforthe installationandproblem-freeoperationof

the drivecontroller. Thesemust befollowedat all times. The information notes also point outthat

failure to observe may result in damage to property or financial damages.

IMPORTANT INFORMATION

Thedrivecontrollermayonlybeassembled,operated,maintainedandinstalledbytrainedand

qualified staff.

Fig.: 2 Example of an information note

Symbols within the information notes

Important information

Damage to property possible

Other notes

INFORMATION

Enlarged view

General information

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

9

1.2

Symbols used in this manual

Symbol

Meaning

1., 1., 3. …

Consecutive steps in a handling instruction

Effect of a handling instruction

✓

Result of a handling instruction

List

Fig.: 3 Symbols and icons used

Abbreviations used

Abbreviation

Explanation

Tab.

Table

Fig.

Figure

It.

Item

Ch.

Chapter

1.3

Qualified staff

You will find the "Qualified staff" chapter in the operating manual for the DGM.

General information

10

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

1.4

Proper use

You will find the "Proper use" chapter in the operating manual for the DGM.

1.5

Responsibility

You will find the "Responsibility" chapter in the operating manual for the DGM.

1.6

Contacts for information

More information is available from:

Website address

Customerscanfindtechnicalandgeneralinformationonthefollowingwebsite:

www.Bonfiglioli.com

1.7

Safety instructions

You will find the "Safety instructions" chapter in the operating manual for the DGM.

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

1

1

Device and system description

Arepeatermustbeusedwhenmorethan32devices(e.g.DGM)

are operated on one PROFINET string.

2. Device and system description

Thischaptercontainsinformationon thescopeof deliveryforthedrivecontrollerandthefunction

description.

2.1

PROFINET

ThePROFINETbussystemispartofthefieldbusfamily.Thenetworkisgenerallylinearin

structure. Themaximum data transfer rate toan PROFINETbusmay be up to 100Mbit/s.

The fieldbus cableis only connected via the two M12connector sockets onthe front of the device.

Ensure that the incoming bus cable is connected to the "In" socket and the outgoing one to the

"Out" socket. If connecting the last participant, the "Out" socket should be left free –there is no

need for a terminal resistor.

Fig.: 4 Wiring and bus connection

2.1.1

Master / slave operation

The DGM should only be operated as a PROFINET slave.

2.2

Scope of delivery

ThescopeofdeliveryisdescribedintheDGMbasicdocumentation. The

interface card is part of theDGM.

Device and system description

12

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

2.2.1

Interfaces on the drive controller

The following connections can be found on the DGM with PROFINET interface card.

Size A:

Fig.: 5 Size A “PROFINET” connections

Size A “PROFINET” connections

1

PROFINET "Out"

2

PROFINET "In"

3

Blind plug

4

MMI

5

Potentiometer

6

Grid connection

7

Blind plug STO (mount the EMC threaded connection in the accessory pack)

8

Blind plug STO (mount the EMC threaded connection in the accessory pack)

Device and system description

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

13

Sizes B - C

Fig.: 6 Sizes B - C “PROFINET” connections

Sizes B - C “PROFINET” connections

1

Blind plug STO (install EMC screw connection supplied in the package)

2

Control line

3

PROFINET "Out"

4

PROFINET "In"

5

MMI

6

Potentiometer

7

Blind plug STO (install EMC screw connection supplied in the package)

8

Blind plug STO (install EMC screw connection supplied in the package)

9

Grid connection

Device and system description

14

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

Size D:

Fig.: 7 Size D “PROFINET” connections

Size D “PROFINET” connections

1

Cable screw connection with blind plug

2

Control line

3

PROFINET "Out"

4

PROFINET "In"

5

MMI

6

Potentiometer

7

Blind plug STO (install EMC screw connection supplied in the package)

8

Blind plug STO (install EMC screw connection supplied in the package)

9

Grid connection

Device and system description

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

15

2.2.2

Pin assignment for interfaces

Pin assignment on device side of M12 socket for PROFINET:

PIN no.

Signal

1

TD +

2

RD +

3

TD -

4

RD -

Housing

Shielding

Fig. 8: Round plug connector, 4-pin, M12, D-coded for PROFINET fieldbus

2.2.3

Cable

The following points should be observed when wiring:

Lay bus and power cables as far apart as possible (min. 30 cm),

If cables do cross, an angle of 90° should be observed if possible.

2.3

Software components

What software do I require to operate and configure the drive controller with PROFINET.

TheDGMdrivecontrollercanbeparameterizedusingtheVplus DectoolandMMI (see

operating manual) as well as the PROFINET master.

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

19

DANGER!

Risk of death due to electrical shock!

Death or serious injury!

De-energize drive controller and secure it against being restarted.

3. Installation

3.1

Configuration of the drive controller for PROFINET

In order that the drive controller can be controlled by the fieldbus, the following basic parameters

must be set using the Vplus Dec tool, MMI or PROFINET master:

Set parameter 1.130 (target value source) to fieldbus"9"

Set parameter 1.131 (target value approval) to fieldbus"6"

Thereisalsothepossibilityofconfiguringthebasicparametersusingthemasterviathe

PROFINET.However,thiscanonlybedoneoncethecommunicationhasbeeninstalled.

The user must choose the set of parameters appropriate to him.

3.2

DGM bus address

InorderthatanDGM,equippedwithaPROFINETcommunicationcard,canbeclearly

recognized in a PROFINET system, it must be assigned an IP address.

TheIPaddresscanbeassignedautomaticallyormanually.

Select the corresponding option in themaster.

Parameters6.067(IPnumber),6.068(netmask)and6.069(gateway)canbesettosuitthe

network environment.

Ifparametersarenotset,thefollowingdefault

values apply:

IP:

192.168.0.31

Netmask:

255.255.255.0

Gateway:

0.0.0.0

3.3

Installing the DGM GSDML file

A "device-specific information file" is required to use the DGM drive controller with PROFINET.

Downloadthe"PROFINETfieldbusforDGM"ZIPfilefromthedownloadareaonourwebsite under

the following link:

www.Bonfiglioli.com

Embed the GSDML file as required by the PROFINET master you are using.

20

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

4. Accessing data via PROFINET

Data can be accessed via PROFINET both cyclically and non-cyclically (see chapter 4.3).

Cyclic data isknownas a processimage. It is madeup of data sent bythe PROFINETmaster to

the drive controller and from the drive controller to the PROFINET master.

ThecyclicdatasentfromthePROFINETmastertothedrivecontrollerisknownas

"Process data In".

ThecyclicdatasentfromthedrivecontrollertothePROFINETmasterisknownas

"Process data Out".

4.1

Cyclic data access –Process data Out

4.1.1

Structure of Process data Out

TheprocessdatanamedbelowissentfromthedrivecontrollertothePROFINETmaster.

The data is made up of 10 processvariables.

IMPORTANT INFORMATION

Thankstoa correspondingselection, theDGM also makes it possible foryou towork witha

process image of only 2 process variables. To do this, the "2Word Output" module has to be

dragged & dropped from the hardware catalogue to the corresponding slot. Both process

variables involve the status word and the actualfrequency.

Thefirsttwoprocessvariables(statuswordandactualfrequency)cannot beparameterizedand

arealwayssent.Theremaining8processvariablescanbeconfiguredusingparameters6.080to

6.087 .

The "Process dataOut" availablecanbe found inchapter4.1.3"Processdata Out".

Use DGM pc, MMI or PROFINET master for parameterisation.

Accessing data via PROFINET

OperatingmanualforPROFINETfieldbus|DOC01725815-0003|2016-12 |V2.04EN

21

The structure of the "Process data Out" set in the factory is shown in the following table.

Frame

No.

Address

Data

type

Designation

Unit

Description

1

0x0000

WORD*

Status word

-

cannot be parameterized

2

0x0004

REAL***

Actual frequency

Hz

cannot be parameterized

3

0x0008

REAL

Process data Out 3

(Motor voltage)

V

can be parameterized using

Vplus Dec tool (parameter 6.080)

4

0x000C

REAL

Process data Out 4

(Motor current)

A

can be parameterized using

Vplus Dec tool (parameter 6.081)

5

0x0010

REAL

Process data Out 5

(Grid voltage)

V

can be parameterized using

Vplus Dec tool (parameter 6.082)

6

0x0014

REAL

Process data Out 6

(Target frequency value)

Hz

can be parameterized using

Vplus Dec tool (parameter 6.083)

7

0x0018

DWORD**

Process data Out 7

(Digital inputs with bit

coding)

-

can be parameterized using

Vplus Dec tool (parameter 6.084)

8

0x001C

REAL

Process data Out 8

(Analogue input 1)

V

can be parameterized using

Vplus Dec tool (parameter 6.085)

9

0x0020

DWORD*

Process data Out 9

(Error word 1)

-

can be parameterized using

Vplus Dec tool (parameter 6.086)

10

0x0024

DWORD*

Process data Out 10

(Error word 2)

-

can be parameterized using

Vplus Dec tool (parameter 6.087)

Tab.: 1 Default structure for "Process data Out"

* WORD data type corresponds to UINT16 = 2 bytes

** DWORD data type corresponds to UINT32 = 4 bytes

***REAL data type corresponds to = 4 bytes

IMPORTANT INFORMATION

The32-bitdata(error status, DigOuts, DigIns) has beenbrokendowninto16-bitdata because

the data width of the fieldbuses is limited to 16-bit in someplaces.

If32-bit data access is possible, the 32-bit word is used regardless ofwhetherthe low or high

word is being accessed!

IMPORTANT INFORMATION

TheREALdepictionisthestandardIEEEformat

(Help: 50 % target value = 0X42480000)

The endianness of the fieldbus should be observed for all data types.

Accessing data via PROFINET

22

Operating manual for PROFINET fieldbus | DOC01725815-0003 | 2016-12 | V2.04 EN

4.1.2

Structure of DGM status word

The meanings of the individual bits of the DGM status word are described in the following table.

Bit

Value

Meaning

Description

0

1

Ready for engagement

Grid voltage present, no fault

0

Not ready for engagement

1

1

Ready for operation

No fault / HW enable set

0

Not ready for operation

2

1

Operation

Motor is energised

0

Operation blocked

3

1

Error active

A fault is present

0

Free from faults

4

1

No OFF 2

On 2 off / STW bit 1 set ³(logic can be inverted

with parameter 6.066.)

0

Electr. stop active (OFF 2)

5

1

No OFF 3

On 3 off / STW bit 2 set ³(logic can be inverted

with parameter 6.066)

0

Rapid stop active (OFF 3)

6

1

Engagement inhibit active

1PWM blocked

0

No engagement inhibit

1PWM enabled

7

1

Warning active

2A warning is present

0

No warning

8

1

Nominal/actual value

deviation in tolerance range

Actualvaluewithinatoleranceband

Parameter 6.070 / 6.071

0

Nominal/actual value

deviation outside tolerance

range

9

1

Control from AG

DGMisparameterizedforactivationvia

fieldbus

0

No control from AG

10

1

Target frequency reached

Actualfrequency>=referencevalue

(Parameter 6.072)

0

Target frequency fallen below

Actual frequency < reference value

Continues next page

Table of contents

Other BONFIGLIOLI Servo Drive manuals

Popular Servo Drive manuals by other brands

Overview

Overview Artemis Servotorq II quick start guide

Kollmorgen

Kollmorgen AKM Series instruction manual

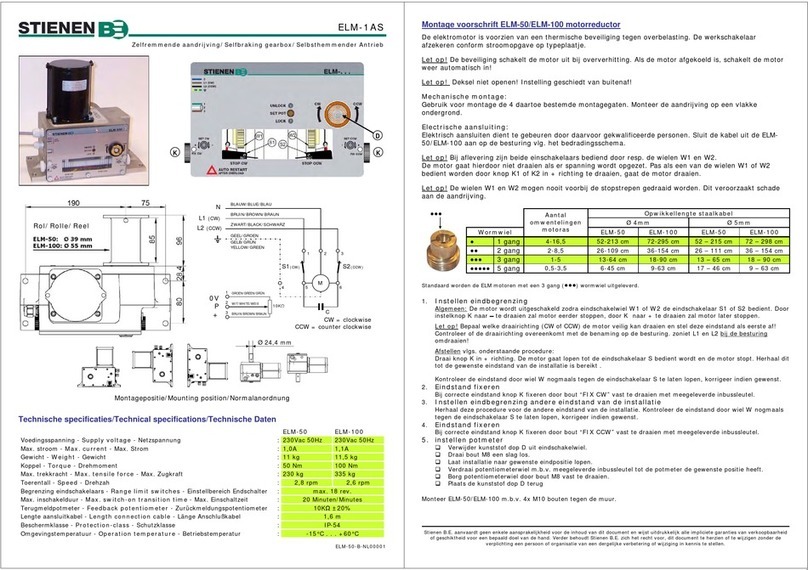

Stienen B.E.

Stienen B.E. ELM Series Mounting instructions

Delta

Delta ASDA-A2 Series instruction sheet

AutomationDirect

AutomationDirect SureServo2 quick start guide

CS-Lab

CS-Lab CSMIO/IP-A Tuning guide

Leadshine Technology Co.

Leadshine Technology Co. DCS303 user manual

Kinco

Kinco CD420 user manual

Kollmorgen

Kollmorgen SERVOSTAR S300 Translation of the original manual

Yuhai

Yuhai SG-AS Series product manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO-J5 MR-J5-G Series user manual

Omron

Omron OMNUC U R88M-U Series user manual