Bongshin BS-3520 User manual

BS-3520

Digital Indicator

The Better Way for Weighing &

Measurements

1

Table of Contents

1. Introduction.....................................................................................................................................3

1-1 Trait ................................................................................................................................................... 3

1-2 Warning ............................................................................................................................................. 4

2. Specification......................................................................................................................................5

3. External Size......................................................................................................................................6

4. Description on Front Panel…...........................................................................................................7

5. Description on Rear Panel................................................................................................................9

5-1 Description on Each Terminal Unit...................................................................................................... 9

5-2 How to Use Terminal Block and Replace Fuse...................................................................................12

6. Calibration………………………............................................................................................................13

6-1 Calibration Mode …………………………........................................................................................... 13

6-2 Digital Calibration Mode..................................................................................................................... 14

6-3 Actual Load Calibration Mode............................................................................................................ 16

6-4 Linearization Calibration Mode .......................................................................................................... 18

6-5 Digital Zero Calibration Mode ............................................................................................................ 21

7. Function Mode.................................................................................................................................24

7-1 Function Setting Method.................................................................................................................... 24

7-2 Function Items ………………............................................................................................................... 25

8. HOLD ………....................................................................................................................................30

8-1 Hold Mode......................................................................................................................................... 30

8-2 Hold Type .......................................................................................................................................... 32

8-3 Hold Operation .................................................................................................................................. 33

9. Relay Mode .....................................................................................................................................35

9-1 Relay Mode ..................................................................................................................................... 35

9-2 Relay Comparator Mode................................................................................................................... 38

9-3 Comparator Hysteresis Function....................................................................................................... 41

2

10. Analog Output...............................................................................................................................45

10-1 Analog Output Mode ...................................................................................................................... 45

10-2 Analog Output Specification and Connection Method..................................................................... 46

10-3 Analog Output Zero and Span Calibration...................................................................................... 47

10-4 Analog Output Zero and Span Minute Calibration........................................................................... 49

11. BCD Output.....................................................................................................................................51

11-1 BCD Parallel Output ......................................................................................................................... 51

12. Serial Output....................................................................................................................................52

12-1 RS-232C/422/485 Serial Interface ....................................................................................................... 52

12-2 Format ……….................................................................................................................................. 54

13. Check Mode ....................................................................................................................................59

13-1 Operation for Each Check Mode............................................................................................................ 59

14. KeyLock Mode ...............................................................................................................................62

14-1 Key Lock Method ............................................................................................................................... 62

14-2 Key Lock Cancellation Method............................................................................................................. 62

15. Repair .............................................................................................................................................63

15-1 Error Message .................................................................................................................................. 63

15-2 Load Cell Inspection........................................................................................................................... 63

15-3 Load Cell Access Diagnosis................................................................................................................. 64

15-4 Pattern of Display Letters ..................................................................................................................... 64

16. Warranty and A/S ............................................................................................................................65

3

1. Introduction

Thank you very much for purchasing this product.

This product is a model adequate for weighing and measurement system.

This equipment is a product equipped with abundant function and various external interface functions to

accommodate diverse wants of user and user can easily use this product with easy handling.

All functions can sufficiently be utilized if you thoroughly read the manual before use.

1-1 Features

BS-3520 is high precision high speed indicator of 96x96mm size.

■High precision 24bit Sigma-Delta A/D converter

■High speed A/D and D/A conversion of 2000 time/sec

■A/D external resolution 1/20,000

■Actual load or digital calibration

■Linearity Compensation Function (4 point excluding zero)

■External display of min/max setting value

■Low, OK, and High relay contact output

■Hold or Peak-hold function

■Basic equipment of Serial Output (RS-232C & RS-422/485)

■Change in relay setting value is available through communication (max. 32 ID)

■Sensor output check function (failure inspection)

■Analog output insulation (option 1, 2)

■Free Voltage Power (AC 85~240V)

4

1-2 Warning

■Check whether or not there was damage in product during the delivery.

■Do not drop or exert server impact on the product.

■Front panel control button is operated with light touch thus do not exert excessive strength.

■Do not use or store product at location with severe temperature change if possible. (-10°C ~ +50°C)

■Do not install the product at location with severe electric noise and vibration.

■Turn off the power switch before connecting peripherals.

■Grounding of equipment shall be conducted in order to prevent electric noise and fall.

■Exertion of voltage or current over maximum allowable value will lead to damage in the product.

■Power voltage shall be set within allowable range.

Use outside allowable range may cause fire, electric shock, and defect.

■Please understand the fact that contents of manual may be changed without in advance notice.

■Please directly contact the agency or our company regarding the inquiries to the contents of manual.

■Please store the manual at location where it can be seen at any time after reading the manual.

5

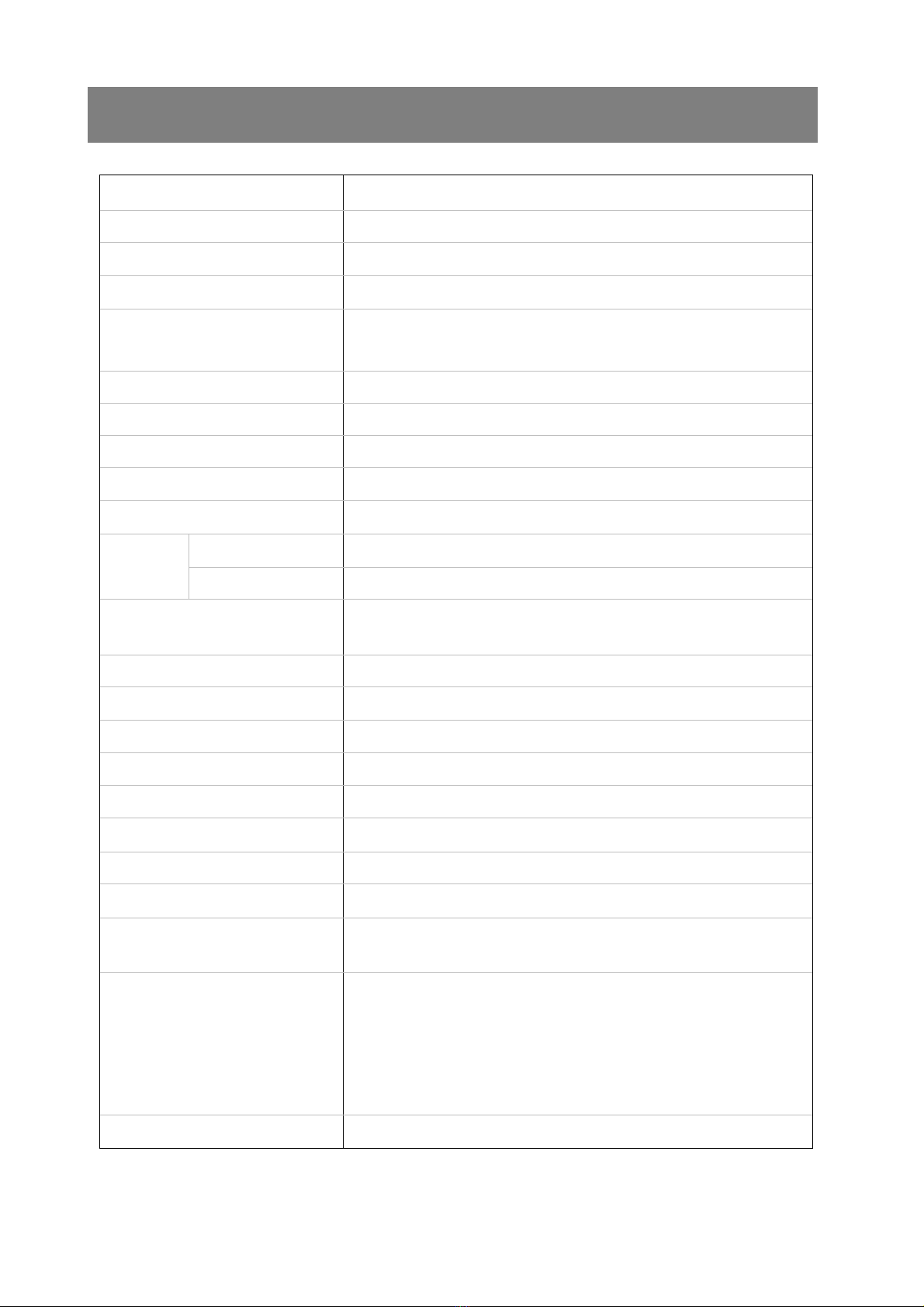

2. Specification

Load Cell excitation DC 5V, 60mA ( 350Ωx 4 load cells can be connected )

Min. Input Sensitivity 0.2μV /Digit (min.)

Non-linearity 0.01% F.S. max.

Analog Input Signal Range -34 mV ~ +34 mV

Temperature drift Zero: ±0.1μV/°C RTI max.

SPAN: 10ppm/°C max.

Input Noise ±0.3μVpp or less

Input Impedance 10MΩor more

A/D Internal Resolution 24 bits

Max. Display Resolution 1/20,000

A/D Sampling Speed 2,000 times/sec

Display

Measurement 7-Segment red LED, 6-Digits 14.1mm high 6digit

High / Low 7-Segment red LED, 5-Digits 8.0mm high 5digit

Range of Max. Display (-) 19999 ~ (+) 19999 (min gradation: 1)

(-)199950 ~ (+)999950 (min gradation: 50)

Display Conversion Speed 1,000 times/sec ~ 1 time/sec

Polarity indication (-) “-“ minus sign

Annunciators LO, OK, HI, HOLD, ZERO

Display increments 1, 2, 5, 10, 20, 50 selectable

Decimal Point Location 0, 0.0, 0.00, 0.000, 0.0000 (selectable to any points)

Power Source AC 85~240V, 50/60Hz (Free Voltage)

Power Consumption Approx. 20VA

Range of Use Temperature -10°C ~ +50°C

Basic Output 0) Relay 3CH Output &

Serial Output (RS-232C & RS-422/485)

Option Output

1) DC 0 ~ ±10V Isolated Analog Output

(Conversion into DC 0 ~ ±5V is available by user)

2) 4 ~ 20mA Isolated Analog Output

(Conversion into DC 0 ~ 20mA is available by user)

3) BCD Parallel Output

Product Weight About 700 g

6

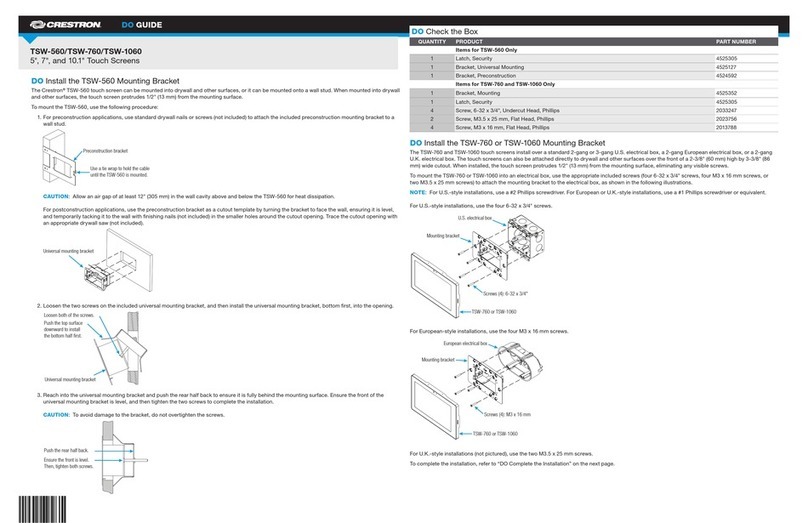

GUIDE

PANEL

3. External Size

PANEL CUT

92

92

91

91

96

96

6126 9

141

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

78910

11 1212345

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

7

4. Description on Front Panel

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

Key Switch

High Display

Weight Value Display

Low Display

Status Lamp

Weight Value Display Display of measurement data and setting value is conducted.

Setting of decimal point is conducted at function mode.

Min/Max Display Min/Max setting value is displayed.

Item and setting value are displayed from function mode.

Status Lamp

LO : It flickers when measurement value is under min. setting value.

It flickers when it is lower or higher than RY1 relay setting value

OK : It flickers when low value ≤measurement value ≤max value.

It flickers when it is lower or higher than RY2 relay setting value.

HI : It flickers when measurement value exceeds max setting.

It flickers when it is lower or higher than RY3 relay setting value.

HOLD : It flickers when hold is conducted.

ZERO : It flickers when measurement value is 0 (zero).

Peak HOLD : Turns on when the hold function is started.

Edge HOLD : Turns on when the value is being held.

8

2

M1

4

4

M1

2

M12

M1

4

42

2

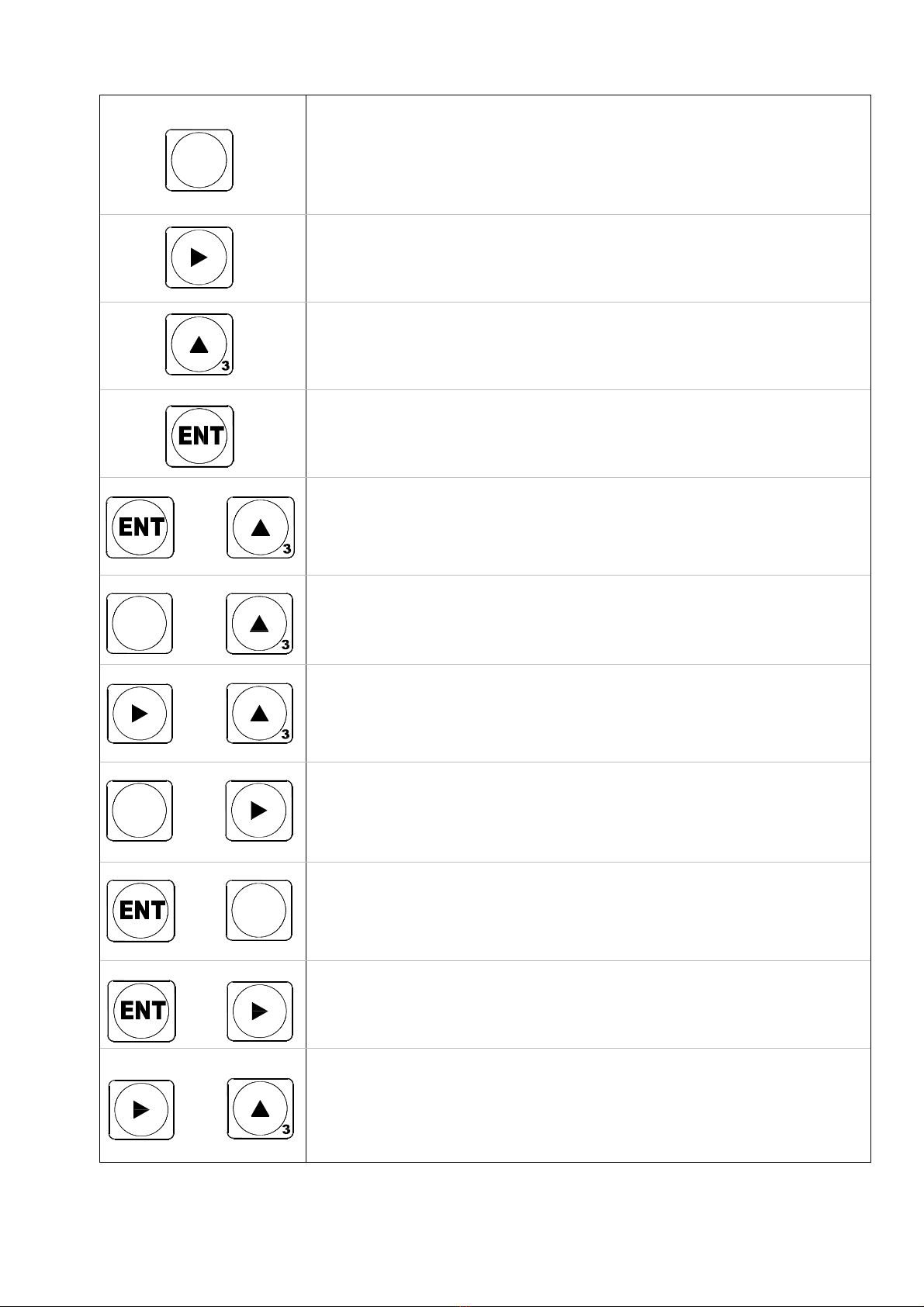

Key Switch

It is used when entering user setting mode from measurement mode.

It is used when exiting to measurement mode from user setting mode.

(ESC function)

It is used as location shift key when entering numerical value of user setting mode.

It is used as calibration mode entry key

It is used as check mode entry key

It is used as a key to increase and decrease the numerical value of selected

number line of user setting mode.

It is used as calibration mode entry key

It is used as check mode entr

y

ke

y

It is used when shifting to next menu from user setting mode.

It is used to save or exit after entering various setting values.

It is used as calibration mode entry key.

+

It is used for zero setting.

(No.3 key while pushing No.4 key or No,.4 key while pushing No.3 key)

+

It is used when entering function mode.

(No. 3 key while pushing No.1 key or No.1 key while pushing No. 3 key)

+

It is used when entering calibration mode.

(No.3 key while pushing No.,2 key or No,.2 key while pushing No.,3 key)

+

It is used when entering relay setting mode.

(No.2 key while pushing No.1 key or No.1 key while pushing No,.2 key)

+

It is used when entering hold mode.

Hold is cancelled when pushing this key once again.

(No.1 key while pushing No.4 key or No.4 key while pushing No.1 key)

+

It is used for key Lock or unlock.

Lock/ unlock is repeated ever time you push this key.

(No.2 key while pushing No.4 key or No.4 key while pushing No.2 key)

Power OFF

+

Power ON

It is used when entering check mode.

Turn the power on when pushing two keys at once after turning off the power

(No.2 key and No.3 key at once)

Itdoesnotmatterwhetheryoupushonekeybeforeanotherortwokeysatonceincaseofmodetoenterby

pushingtwokeys.

9

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

78910

11 1212345

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

78910

11 1212345

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

78910

11 1212345

AC85~AC240V

48Hz~63Hz

+

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

78910111212345

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

Load Cell Input/Output

Option

Grounding

Power

Serial Output

Connection

5. Description on Rear Panel

[StandardSpecification][AnalogOutputOption][BCDOutputOption]

5-1 Description on Each Terminal Unit

5-1-1 Power (AC IN)

Terminal No. Name Contents

L AC IN Power Input Terminal

N AC IN Power Input Terminal

F.G Frame Ground Frame Ground

Access to AC power code is conducted. Input power is AC85~240V and 50/60Hz.

10

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

INPUT OUTPUTLOAD CELL

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

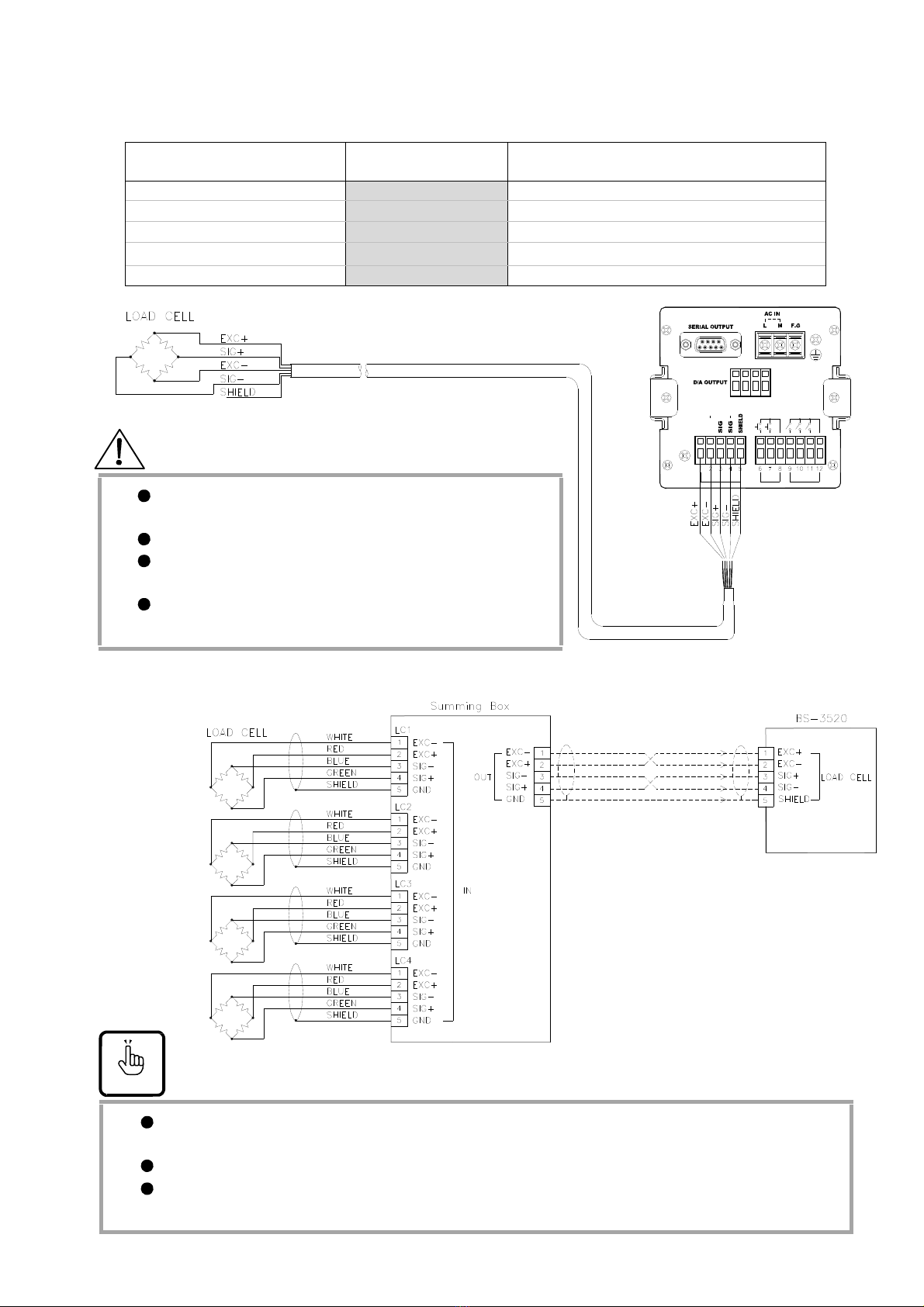

5-1-2 LOAD CELL Connection (1) (2) (3) (4) (5)

Terminal No. Name Contents

1 EXC + Load Cell Voltage (+), Red wire

2 EXC - Load Cell Voltage (-), White wire

3 SIG + Load Cell Input Voltage (+), Green wire

4 SIG - Load Cell Input Voltage (-), Blue wire

5 SHIELD Load Cell Grounding

Warning

Loadcelloutputisveryweakthusloadcellcableshallbe

separatedandtheninstalled.

Pleaseuseshieldcableforloadcellcable.

Incaseofextendingtheloadcellcable,useofloadcellcable

ofourcompanyisrecommended.

ShieldcableofloadcellcableshallbeconnectedtoBS‐3520

terminalonly.

Incaseofsealing,roadcellinputcableSIG+(green)andSIG‐(blue)cableshallbeconnectedtoNo.4and

No.3respectively

.

Theremaybeabnormalityinrelayoperationandoptionoutputwhentheweightisdisplayedin(‐)value.

Pleasecheckwhetherornotcolorofcableforeachmanufacturer’sandloadcellmodelis

differentornotbeforetheconnection.

11

5-1-3 Input (6) (7) (8)

Terminal No. Name Contents

6 ZERO Control terminal of zero function

Valid from COM1 terminal and short circuit (or on coin)

7 HOLD Control terminal of hold function

Valid from COM1 terminal and short circuit (or on coin)

8 COM1 Common terminal of external control

Relay contact or switch or contactless switch such as

Open collector output shall be used.

Arbitrary point hold is conducted at the point of granting

external contact point.

Hold is cancelled when grating the contact point.

PK hold only holds max value during the time contact point

is granted and it is cancelled when contact point is not

granted.

5-1-4 Output (9) (10) (11) (12)

Terminal No. Name Contents

9 L1 LO (RY1) relay output terminal (a, b contact point output based on mode setting)

10 L2 OK (RY2) relay output terminal (a, b contact point output based on mode setting)

11 L3 HI (RY3) relay output terminal (a, b contact point output based on mode setting)

12 COM2 Common terminal for relay output

Output method differs based on relay mode setting.

Refer to relay operation mode.

Relay contact point capacity is 5A 250VAC,

5A 30VDC.

5-1-5 Serial Output

They are RS-232C/ RS-422/ RS-485 output port. (basic equipment)

5-1-6 Option (DAC/BCD OUTPUT)

They are Analog Output DC 0~±5V, 0~±10V, DC 0~20mA, 4~20mA output terminal.

(Selection from function mode)

BCD Parallel Output, Analog Output option is equipped upon selection.

BCD Parallel Output option and Analog Output option cannot be equipped at the

same time.

12

5-2 How to Use Terminal Block and Replace Fuse

5-2-1 How to use terminal block

1) Peel off the sheath at the end of cable.

2) Terminal is opened when putting driver inside the terminal opening device

(top of terminal) and push upward.

3) Terminal is fastened when inserting the cable and pulls back the driver.

Forcedentryofcabletoterminalmaycausethedamageofterminal.

Donotinsertcabletotopofterminaltoinsertdriver.

5-2-2 How to replace fuse

1) Loosen the bolt of rear panel and pull off PCB as illustrated in the figure.

2) Replace the fuse. (Fuse Capacity: 250V 1.0A 20mm)

3) Assembly shall be conducted in reverse of disassembly.

Warning

Itshallbeconductedonlywhenthepoweristurnedoff.

EXC +

EXC

COM2

L 3

L 2

L 1

ZERO

COM1

HOLD

6

INPUT OUTPUTLOAD CELL

7 8 9 10 11 1212345

+-+-

CURR VOLT

AC85~AC240V

48Hz~63Hz

+

Screw

Fuse

13

2

123

4

M1

M1

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

6. CALIBRATION

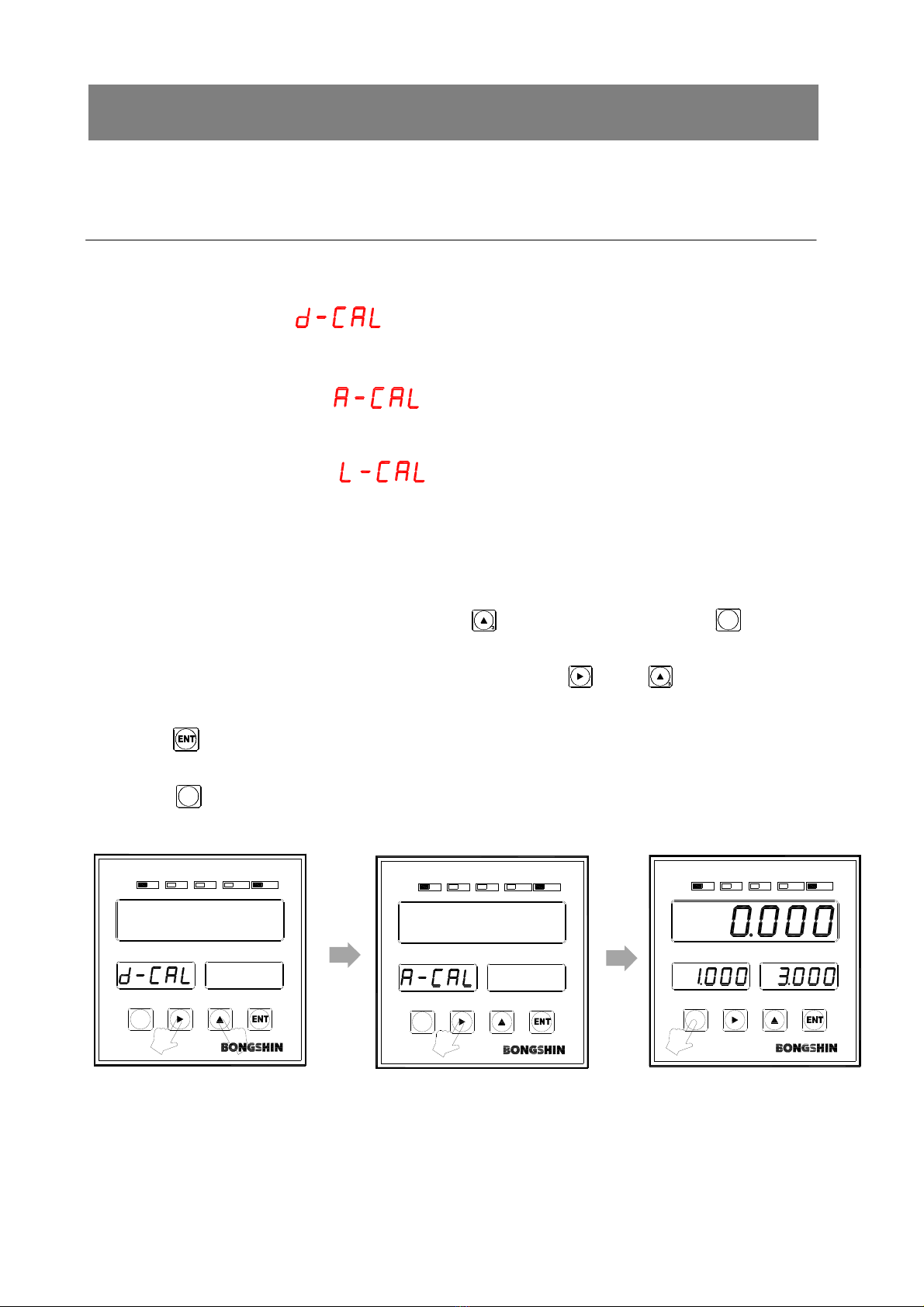

There are 3 types of calibration mode.

6-1 Calibration Mode

6-1-1 Mode

■Digital calibration mode

Calibration shall be conducted not by using the actual load but entering rated output and

rated capacity of sensor with key.

■Actual load calibration mode

It is calibration mode to adjust zero and span with the use of actual load.

■Linearization calibration mode

It is calibration mode to conduct non-linear calibration that reduces the measurement error

through calibration of maximum 4 points excluding zero with the use of actual load

6-1-2 How to select calibration mode

1. It turns into the mode selection status when key is pushed while pushing key is

pushed at measurement status.

2. Mode change and setting value change is available when key or key is pushed at

mode selection status.

3. Push key in order to move onto next stage after saving

the setting value at mode selection status.

3. Push key to cancel the setting and return to measurement mode for mode cancellation.

It is displayed as figure

when pushing no.3 key

while pushing no.2 key.

Change the mode with

No.2 or No.3 key.

(

d-CAL→A-CAL→L-CAL)

Push No.1 key for mode

cancellation.

14

123

123

456

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234 M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

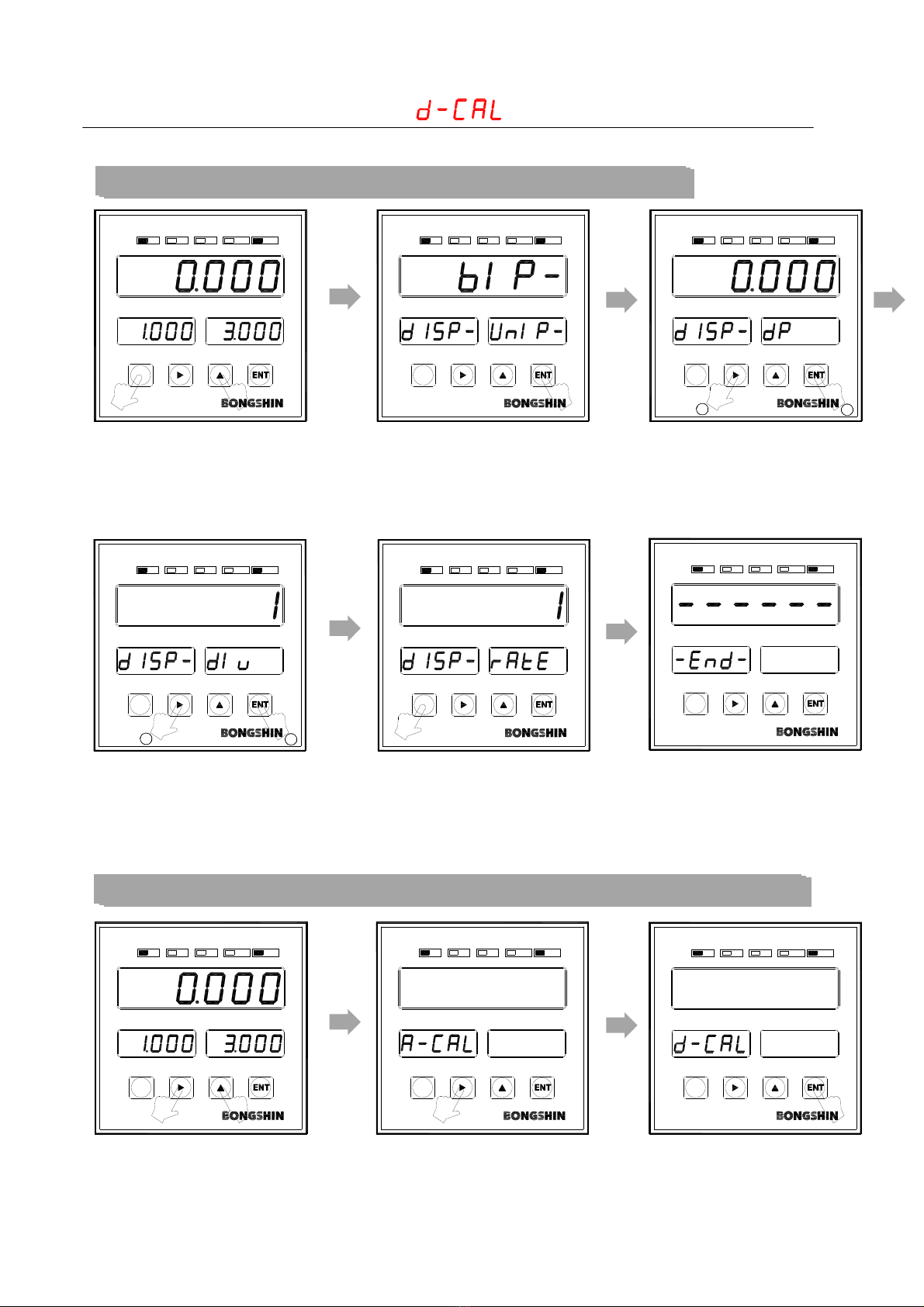

6-2 Digital calibration mode

6-2-1 Calibration Method

Step 1. Decimal point setting and min. gradation setting

When you push No.3 key while

pushing No.1 key, entry to

function mode is available.

It is changed to decimal point

mode when you push No. 4

key.

Push No.4 key by changing

decimal point by pushing No.2

or No.3 key.

Input is completed when yo

u

push No.4 key after changing

Min, unit with the use of

either No.2 or No.3 key.

It is changed in measuremen

t

mode when you push No. 1

Key.

Decimal point change and

minimum unit change have

been completed.

Step 2. Rated output and capacity setting of Load Cell

Push No.3 key while pushing

No,2 key.

Change the mode to d-CAL

with either No.2 or No.3 key.

Enter into d-CAL mode by

pushing No.4 key

15

56

12

4

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12 3

M1234

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

Input load cell rated output

using No. 2 and No.3 key and

Push No.4 key.

(Ex: 2.0000 mV/V)

Input rated capacity of load cell

with the use of No.2 and No,.3

key.

(ex: 15.000 kg)

Digital input is completed when

pushing No.4 key and it returns

to measurement mode.

Step 3. Zero Calibration

Push No.3 key while pushing

No.4 key.

Zero calibration is

completed.

Warning

Althoughthesettingrangeofresolutionis1/20000orlowerbutdisplayisconductedevenwhenit

exceeds20000.

Errormaygeneratefordigitalcalibrationmode.

Conductregularcheckonmeasurementandconductcalibrationuponnecessity.

Calibrationunderinstableenvironmentmaycausethemeasurementerror.

16

123

123

456

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234 M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

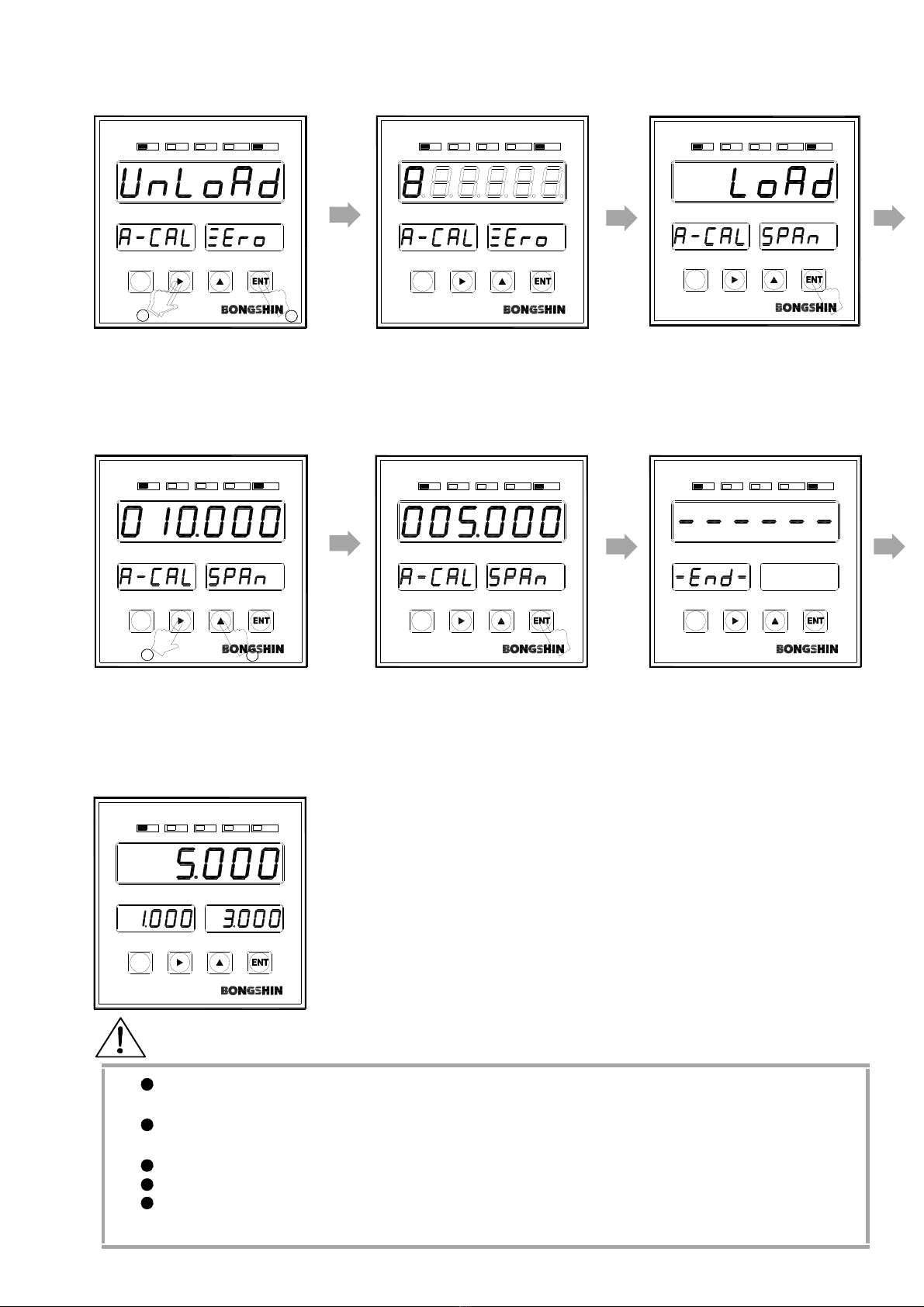

6-3 Actual load calibration mode

6-3-1 Calibration Method

Step 1. Decimal point setting and min. gradation setting

Entry to function mode is

available when pushing No.3

key while pushing No.1 key.

It changes to decimal point

mode when pushing No.4 key.

Push No. 4 key after changing

decimal point by pushing

either No.2 or No.3 key.

Input is completed when yo

u

No.4 key after changing min

unit by pushing either No.2

or No.3 key.

It returns to measurement

mode when pushing No. 1 key.

Decimal point change and

min. unit change have been

completed.

Step 2. Zero calibration and dead weight setting

Push No.3 key while pushing

No. 2 key.

Change the mode to A-CA

L

with either No.2 or No.3 key.

Enter into A-CAL mode by

pushing No.4 key.

17

456

10

789

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234 M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

Select Unload among Load and

Unload with the use of No.2

and No.3 key and push No.4

key when there is nothing on

load cell.

Conduct zero calibration.

It is changed to dead weigh

t

value mode when pushing

No. 4 key after load display.

Input dead weight value with

the use of No. 2 and No,.3

key. Ex) 5.000kg

Push No.4 key after exerting

actual load to load cell.

ErrO is played and it is turned

to LoAd status when load is

small or direction of load is

applied toward (-) direction.

Actual load calibration has

been completed.

Check the dead weight value indicated to display.

Check the zero point return status after lowering the dead weight and

Step2 shall be executed repeatedly when there is abnormality.

Warning

Displayspeedshallbesetasslowaspossibleinfunctionmodeduringcalibrationinorderto

displaystablevalue.

Althoughresolutionsettingrangeis1/20000orlower,displayisstillconductedwhenitexceeds

20000.

Conductregularcheckonmeasurementandconductcalibrationuponnecessity.

Calibrationunderinstableenvironmentmaycausethemeasurementerror.

Itisrecommendedthattheuseofdeadweightwithover2/3ofmaxcapacityisrecommended

inordertoreducetheerror.

18

123

456

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

12

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234 M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

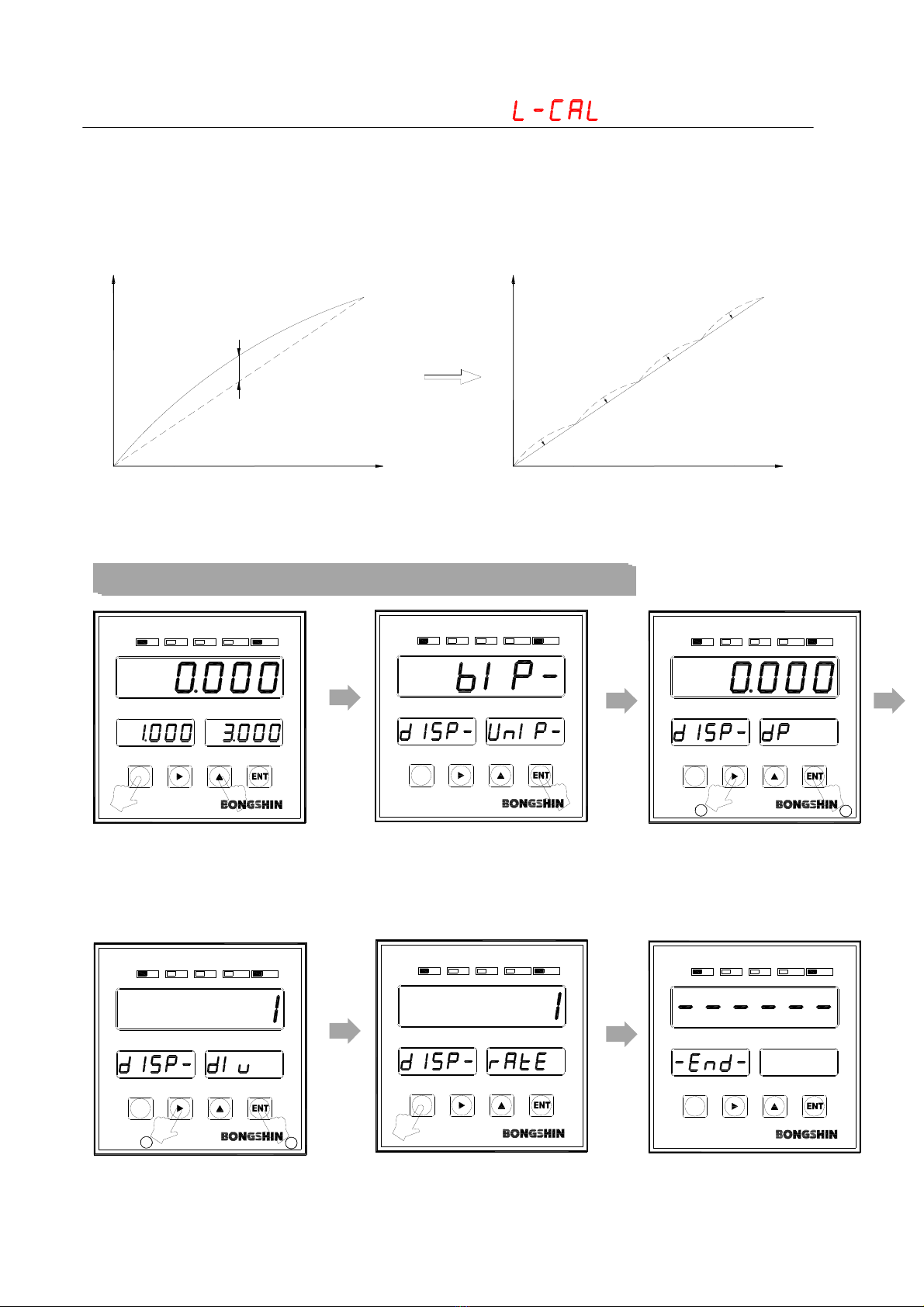

6-4 Linearization Calibration Mode

6-4-1 Calibration Method

A little measurement error may occur in between the max capacity due to trait of measurement

unit even upon the completion of zero and span calibration. Linearization calibration mode is a

type of calibration mode which conducts non-linear calibration that reduces the measurement

error by conducting calibration with max 4 points excluding the zero with the use of actual load.

ZERO

0 Weight Value

Display

Error

ZERO

Before linear compensation After linear compensation

0 Weight Value

Display

Calibration point 1 (Load1)

Calibration point 2 (Load2)

Calibration point 3 (Load3)

SPANSPAN

Step 1. Decimal point setting and min gradation setting

Enter into function mode by

pushing No.3 key while

pushing No.1 key.

It is changed to decimal point

mode when pushing No. 4 key.

Push No.,4 key after changing

decimal point by pushing

either No.2 or No.3 key.

Input is completed when you

push No.4 key after changing

min unit by pushing either

No.2 or No.3 key.

It is changed to measurement

mode when pushing No.1 key..

Decimal point setting and min.

unit setting have been

completed.

19

123

456

789

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1234

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12 3

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

12 3

M1 2 3 4

LO

LOW HIGH

OK HI HOLD ZERO

BS DIGITAL INDICATOR

-3520

Step 2. Zero calibration and dead weight setting

Push No.2 key while pushing

No.3 key .

It is changed into L-CAL mode

when pushing either No.2 or

No.3 key.

Enter into L-CAL mode by

pushing No.4 key.

Check the stability after

display of UnLoad and

push No.4 key when there

is nothing on load cell.

Conduct zero calibration.

Input dead weight value by

using No.2 and No.3 key

after entering 1st dead weight

to measurement unit with

display of Load 1.

1st dead weight value is

stored when you push No.4

key after checking the

stability.

Push No.4 key after entering

the dead weight value with

use of No.2 and No.3 key

and entering 2nd dead

weight upon display of

Load2.

Push No.4 key after entering

the dead weight value with

the use of No.2 and No.3

key and entering 3rd dead

weight upon display of

Load3.

Table of contents

Other Bongshin Touch Panel manuals