Bongshin BS-8300 Quick start guide

1

7CBH9BHG

DF9:579""""""""""&

H97<B=75@ GD97=:=75H=CB " " )

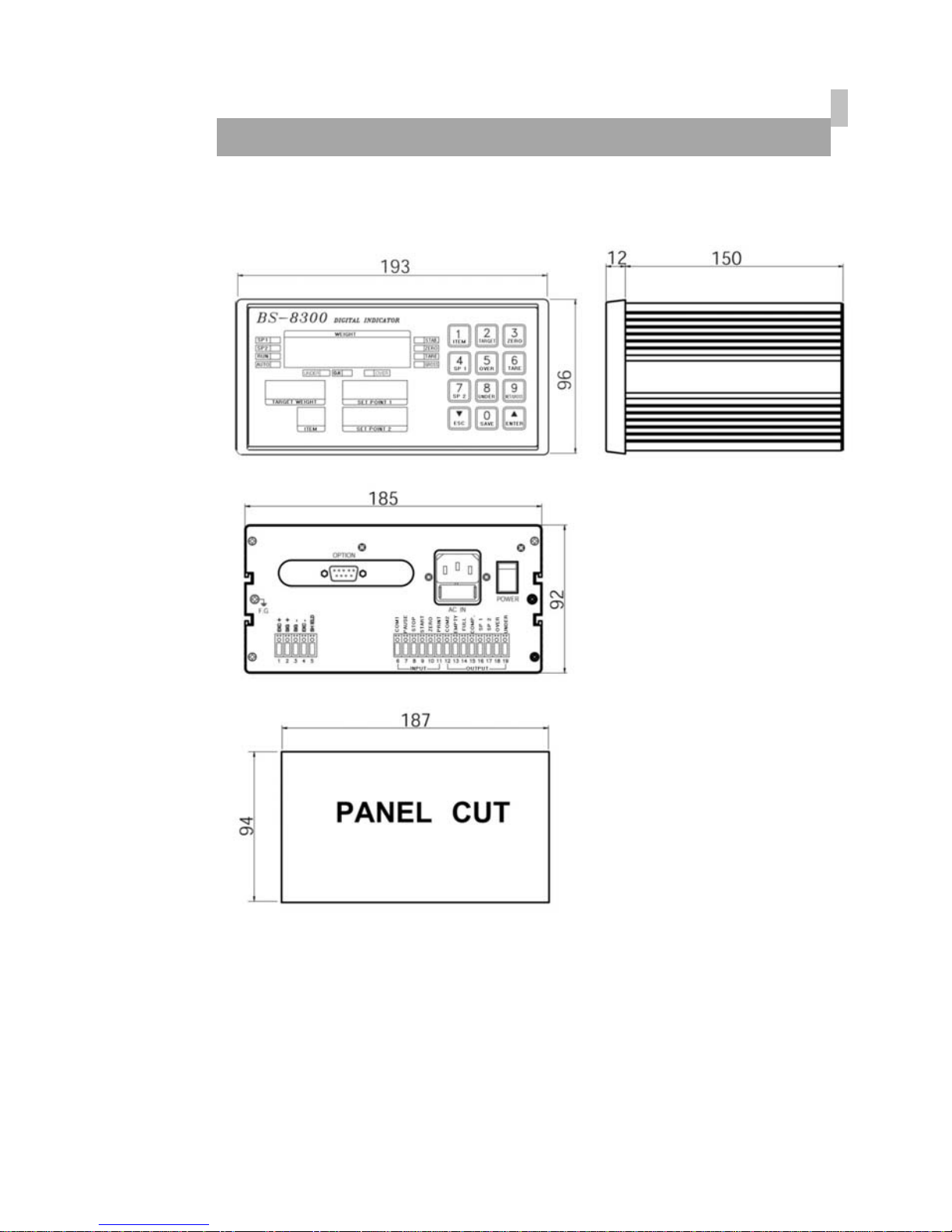

8=A9BG=CBG"""""""""""""+

:FCBHD5B9@"""""""""""",

F95FD5B9@"""""""""""""" %&

=BGH5@@5H=CB"""""%)

75@=6F5H=CB AC89 5WhiU`

"%*

75@=6F5H=CB AC89 G]ai`Uh]cb

&&

G9H!IDAC89"""""""""""&+

G9F=5@=BH9F:579""""""""')

7CBHFC@@=B; K9=;<H " " " " " (%

9ffcfAYggU[Y

5bX HfciV`Y G\cch]b[ " " " ((

2

DF9:579

%"=BHFC8I7H=CB

Thank you very much for your purchasing BONGSHIN Digital Weighing

Indicator of BS-8300.

This Instruction Manual will lead you to use BS-8300 with top reliability,

High speed, high accuracy.

BS-8300 is Digital Weighing Indicator amplifying the analog output from a

load Cell, converting the analog signal to digital data and then displaying

this data

As a weight reading and is designed for flawless performance in your

demanding

Application of input-weighing, output-weighing, accumulating-weighing,

2step control.

Also, an additional option will make Modern Industry demand equipment

that both versatile

And availed to easily connect to other devices

※ Example for application :

1. PACKING EQUIPMENTS FOR MANUAL WEIGHING

2. EQUIPMENTS FOR AUTO-FILLER WEIGHING

3. EQUIPMENTS FOR OUTPUT WEIGHING

4. EQUIPMNETS FOR ACCURACY WEIGHING

5. RECORD-MANAGEMENT FOR PRODUCT WEIGHT

☞ REMARK

- Specification subject to change for improvement without prior notice.

- If changing, the Version No can be increased, but keeps a former

version

As far as possible

3

&"G5:HM7CB8=H=CBG

Please keep the following using conditions certainly

■

EARTH

To avoid an electric error such as a noises in your production line

It should be earthed before installation certainly.

Specially it will be safety to divide the power of Indicator into a load cell.

■

SAFTY CONDITIONS

Don’t use it closed to a explosive gas and an inflammable dust

environments

■

POWER

Use the power under 110/220V 50/60HZ ±10% and divide it into the

power line

■

TEMPERTURE CONDITIONS

Operating Temperature : -10o C ∼ +40o C ( +14o to 104

o F )

Custody Temperature : -40o C ∼ +80o C ( -40o to 176

o F )

■

INSTALLATION LOAD CELL

- Available to use the same load cell of 6pcs ( 350Ω standard )

- A ground should be installed horizontal

-Installing over 2pcs of load cell, please connect each line in parallel

and Insert a variable resistor under 50Ω in EX + line and minimize a output

Accuracy of load cell.

It may occur a weight error by each accuracy of load cell.

-

It may occur a weight error in case of a temperature variation of load cell

-

Please weld(elect spark) at the place installed with load cell and equipments,

Divide the power into a connector of load cell in inevitable case

-

Please connect the below construction of load cell with the above ones using

The earth to the weighing part weighing a material occurring a electro sparks.

4

'":YUhifYg

-

A compact Appearance by DIN regulations ( DIN 193 x 96 Panel system )

- Easy to preset, change, confirm the weight value by the numeral key.

- Improved a convenience and precision of operating with Message

Function.

- Can use or disuse each key function. (SETUP Reference)

- Weight Memory function even in electro spark case.

- Watch-Dog timer guards for self-diagnostics.

- Set up to 1/20,000 display resolution

- Function available to change the unit value such as g,

kg, ton.

( In case of Serial Communication & Printer )

- Various specification of weight conversion speed.

(Digital Filter Function)

- Various option and addition for customer’s satisfaction such as serial

communication, RS-422, Printer, BCD Input and so on.

5

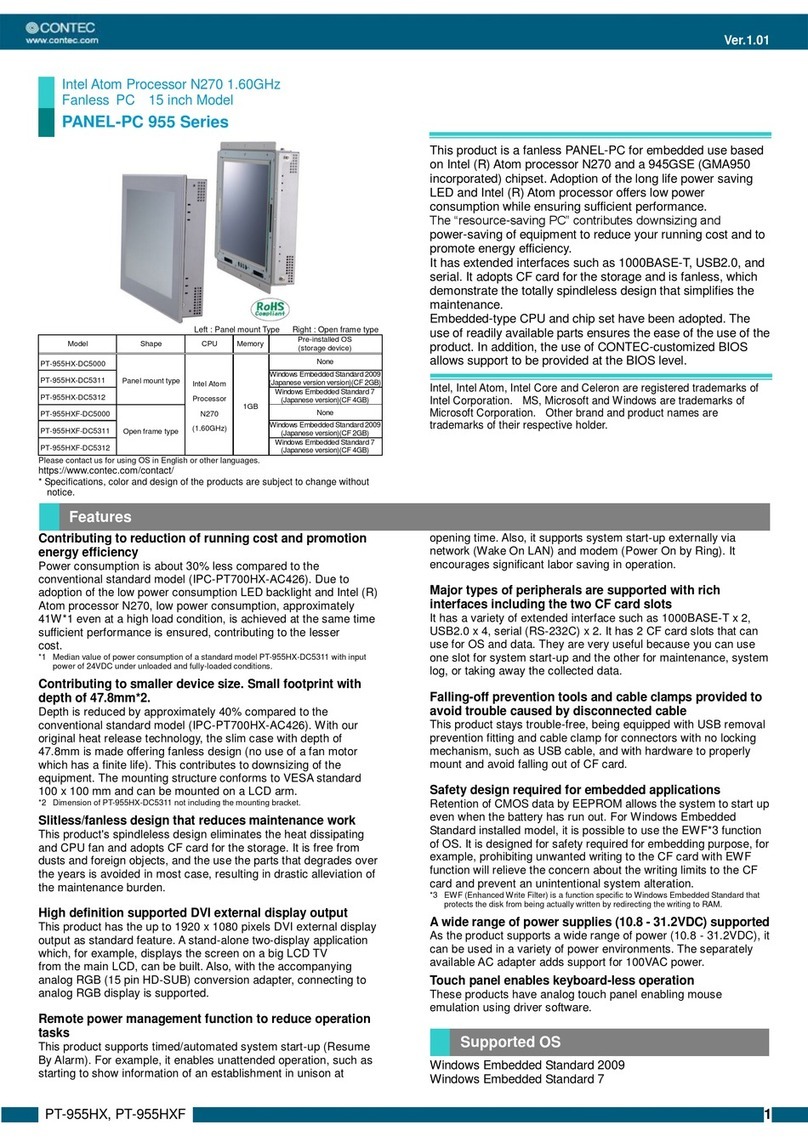

H97<B=75@GD97=:=75H=CB

%"5bU`c[=bdih5#87cbjYfg]cb

@cUXWY``YlW]hUh]cb

Jc`hU[Y

DC 10V ±5%, 300㎃

up to 8 x 350ohm load cells

=bdihgYbg]h]j]hm 0.3 μV/D

GmghYa`]bYUf]hm Within 0.01% F.S.

NYfcUX^ighfUb[Y -1㎷ ~ +34㎷

=bdihJc`hU[Y Max. 34㎷ Min. 5㎷

5WWifUWm Zero drift : ±0.2 μV/℃ RTI max.

Span drift : 20ppm/℃ max.

=bdihBc]gY ±0.3 μV p.p or less

=bdih=adYXUbWY 10 ㏁ (Min.)

5#8WcbjYfhYf Sigma-Delta system

5#8]bhYfbU`fYgc`ih]cb Approximately 200,000 counts

5#8YlhYfbU`fYgc`ih]cb 1/20,000 (Max.)

5#8WcbjYfg]cbgdYYX 50 times/sec

AUl"fYgc`ih]cb 1/20,000

&"8][]hU`DUfh

8]gd`Um 7 Segment LED,

6-Digits, 14.1mm(Height)

8]gd`UmVY`cknYfc “-”minus signal

5XX]h]cbU`gmaVc`g Zero, Stable, Gross, SP1, SP2, AUTO,

RUN, UNDER, OVER

A]b"8]j]g]cb x1, x2, x5, x10, x20, x50, x100

8YW]aU`Dc]bh 0, 0.0, 0.00, 0.000, 0.0000

6

'"HYW\b]WU`

57UXUdhYf AC 110/220V ±10%, 50/60Hz

DckYfWcbgiadh]cb 30 VA

8UhUAYacfm 10 year

CdYfUh]b[hYadYfUhifY

-10℃~+40℃ (+14℉ ~ +104℉ )

<ia]X]hm 85% Rh Max.

CjYfU``X]aYbg]cbg 193(W) x 162(D) x 96(H)

KY][\h 2.5 kg

("Cdh]cb

Cdh]cb–% Serial Interface : RS-232C

Cdh]cb–& Serial Interface : RS-422

Cdh]cb–' Parallel Interface : BCD INPUT

7

8=A9BG=CBG

8

:fcbhDUbY`

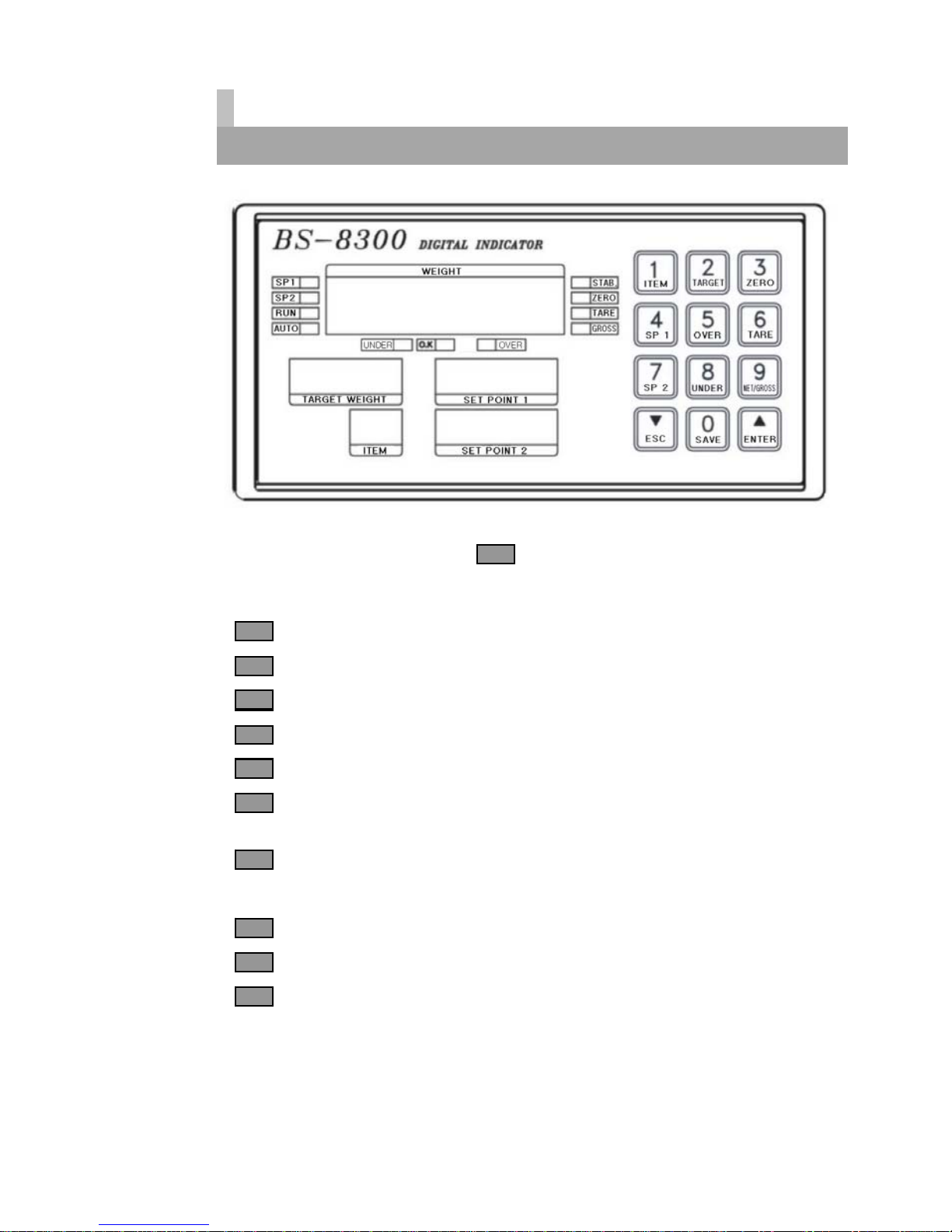

%"8]gd`Um@Uad

GD%@Uad: : It will lamp when 1step(90%) control works

GD&@Uad: : It will lamp when 2step(100%) control works

FIB@Uad: ON when the weighing is run.

GH56@9@Uad : ON when the weight is stable.

N9FC`Uad: ON when the current weight is 0 kg.

H5F9@Uad : ON when the tare weight is stored.

This Lamp will be switched to Net mode

;FCGG@Uad : ON when the current weight is GROSS weight.

When presetting a TARE, It will be a Lamp Function.

IB89F@Uad:

C"?@Uad:

CJ9F@Uad:

9

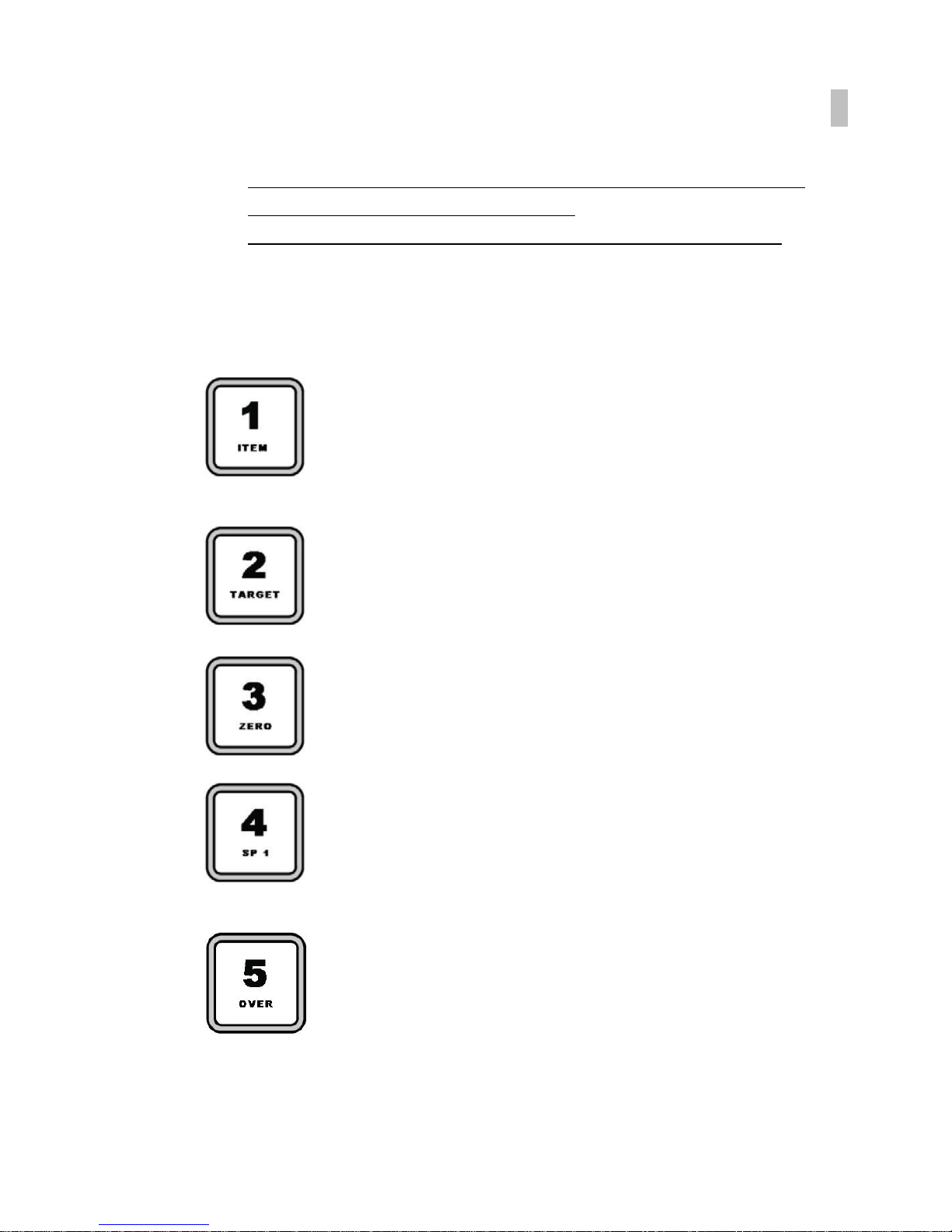

&"?YmVcUfX

* The Key operating can be permitted or prohibited by SETUP-F10

* When pushing the key, it sounds "OK".

* Each Key works either a single function or compound functions.

A compound function key will be a command key when it push first

and According to the command key, the fixed value works its function,

The key to finish a input data is ENTER Key.

ITEM Key : Usable to confirm or change the product part

* Can set up the data of each product from 1 No to 50 No.

- Confirmation ITEM : ITEM Key → ESC Key

- Changing ITEM : ITEM Key → Numeral Key →ENTER key

TARGET Key : Usable to confirm or change the target weight.

- Confirmation TARGET : TARGET Key → ESC Key

- Changing TARGET : TARGET Key → Numeral Key →ENTER key

ZERO Key : This key returns the display to the center of

ZERO when the weighing device is empty

- Changing ZERO : ZERO Key →ENTER key

SP 1 Key : Set Point 1(90%)weight.

-Confirmation SP1 : SP1 Key → ESC Key

-Changing SP1 : SP1 Key → Numeral Key →ENTER key

OVER Key : OVER weight.

-Confirmation OVER : OVER Key → ESC Key

-

Changing OVER : OVER Key → Numeral Key →ENTER key

10

TARE Key

1. Set-up of TARE Key

① Put a TARE on the weighing plate

② TARE Key → SET Key

2. Remove of TARE Key

① Remove TARE on the weighing plate

② Push TARE Key and push ENTER Key.

SP 2 Key : Set Point 2(100%) weight.

-Confirmation SP2 : SP2 Key → ESC Key

-Changing SP2 : SP2 Key → Numeral Key →ENTER key

UNDER Key : UNDER weight.

-Confirmation UNDER : UNDER Key → ESC Key

-

Changing UNDER : UNDER Key → Numeral Key →ENTER key

NET/GROSS Key

After setting TARE, Net Weight converts Gross weight,

or Gross weight converts Net Weight

* Available to convert setting TARE only.

SAVE Key

When recording each sated data

SAVE Key →ENTER key

ESC Key

This have 2way to use as follows .

1) When canceling it with input the setting value

2) Change the set Point 2 value

Decrease the first place value to 1.

11

ENTER Key

This have 2way to use as follows .

1) When canceling it with input the setting value

2) Change the set Point 2 value

Increases the first place value to 1.

12

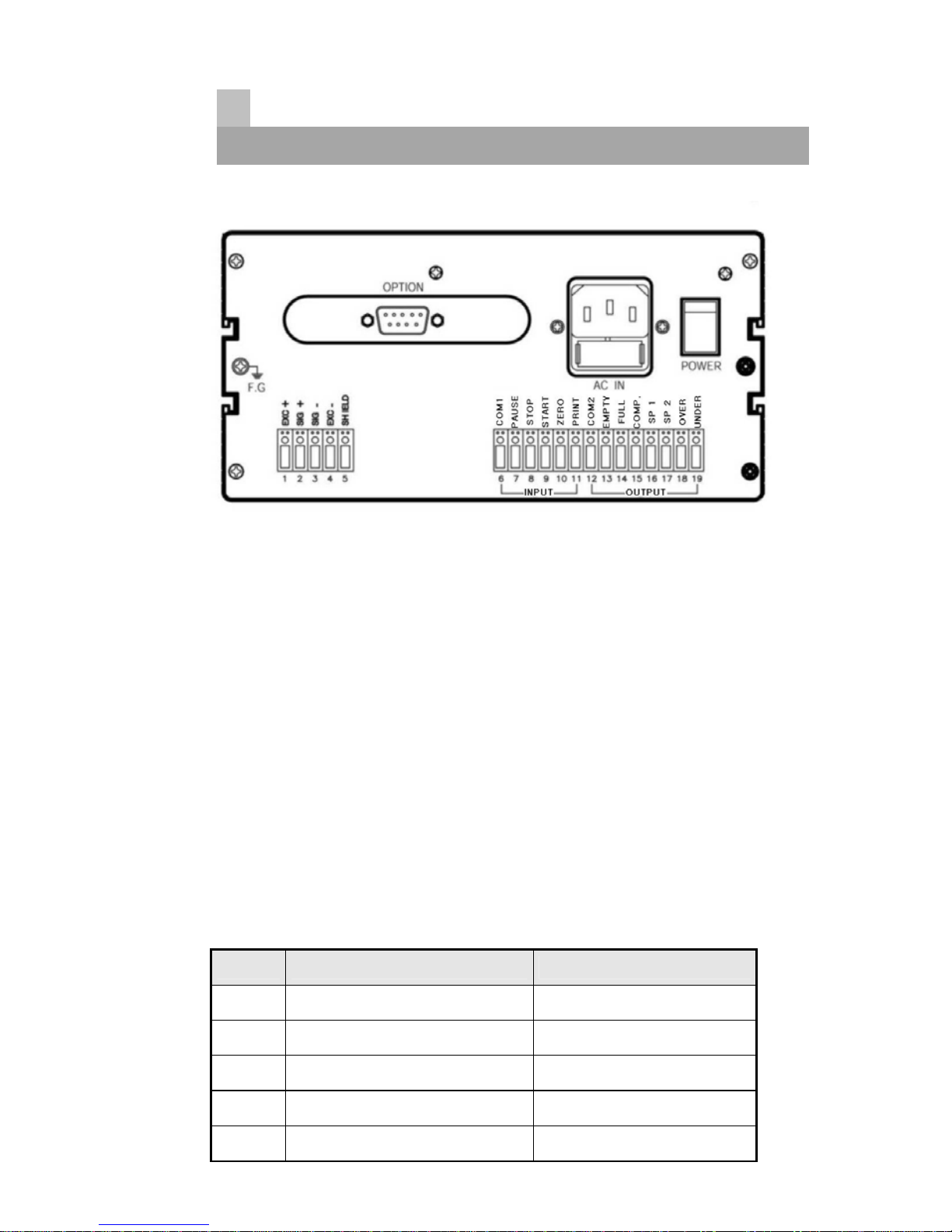

FYUfDUbY`

■ DCK9F : Power ON, OFF switch

It will be safe to use it after 10minuate for a precise measurements.

■ 57=B : Available to change AC110/220V with multiple.

Before setting up, please confirm the power voltage.

Please change the connect terminal of 110V/220V after

opening the cover

If you need to change. (It was settled with AC220V at the first)

Use a stable power supply AC110/220V ±10%, 50/60Hz

■ :IG9 : please use the standard approved .

FUSE AC250V, 0.5A (a glass tube with small type)

■ :"; : Please earth it for safe.

■ @C5879@@ Please connect the indicator connector with the wire of

load cell according to the color.

Pin no. SIGNAL

1 Load cell Input Voltage (+) EXC+ (Red)

2 Load cell output (+) SIG+ (Green)

3 Load cell output (-) SIG- (Blue)

4 Load cell Input Voltage (-) EXC- (White)

5 Shield SHIELD

13

EXC+

EXC-

SIG+ SIG-

SIG- (Blue)

EXC- (White)

SHIELD

SIG+ (Green)

EXC+ (Red)

1

2

3

4

5

The wire color of load cell according to a manufactures.

1

EXC+

2

EXC-

3

SIG+

4

SIG-

5

SHIELD

6CB;G<=B F98 K<=H9 ;F99B 6@I9 G<=9@8

CAS, TMI, AND RED WHITE GREEN BLUE SHIELD

BLH GREEN BLACK WHITE RED YELLOW

INTERFACE RED BLACK GREEN WHITE SHIELD

KYOWA RED BLACK GREEN WHITE SHIELD

P.T. RED BLACK GREEN WHITE SHIELD

SHOWA RED BLUE WHITE BLACK SHIELD

SHINKOH RED BLACK GREEN WHITE SHIELD

TML RED BLACK WHITE GREEN SHIELD

TFAC RED BLUE WHITE BLACK YELLOW

HUNTLEIGH GREEN BLACK RED WHITE SHIELD

※ Because wire color may be different according to a manufacture and

load cell models. Please refer for the data sheet of load cell.

14

=B!DIH : COM1, PAUSE, STOP, START, ZERO, PRINT

This key is to control a equipment from the outside .

Please connect between COM terminal and each input terminal .

Because the power of input terminal was connected with 12V voltage

From the inside.

* An electric current is about 10mA.

* Please make the minimum time to input a data with over 50mSEC.

■ CIH!DIH : COM2, EMPTY, FULL, COMP, SP 1, SP 2, OVER, UNDER

Connect between COM terminal and OUTPUT terminal

With the earth of no electric power.

Please use the output data For a signal only, don’t use it for working.

Max earth capacity : AC250V / 0.5A

=bghU``Uh]cb

15

☞ GENEANL RULES

- Avoid sudden Collision, vibration, temperature, water, wind

- Use a stable power supply 110V/220V ± 10% 50/60Hz

Set up voltage 220V

(Adjust the power voltage because the choice terminal of power is inside.)

- Connect and power off the switch when connecting the external

equipments.

- Ensure to earth Indicator to equipments

- Ensure to calibrate and set up it for operating.

* PARTS

- POWER CODE : 1EA

- FUSE : 1EA (PIPE TYPE 250V 0.5A SMALL TYPE)

- OPERATING MANUAL : 1EA

- A Stable Connector for Option installation.

▶ H9FA=B5@6@C7?

ઔ:IG9

FUSE : AC250V, 500mA

16

7U`]VfUh]cbacXY5WhiU`kY][\h

▣ What is Calibration?

Calibration is to adjust max weight, minimum division, decimal point

displayed to Indicator

To the actual weight worked by load cell.

☞ It should calibrated certainly when load cell or indicator will be

changed.

%"GD5B58>IGHA9BH

▣ what is span adjustment.

Span adjustment is to make the display value from "0" to max weight

consistent to the actual weight.

%!% <ckhcUWWYggh\YGD5B58>IGHA9BH

Turn on the power while pushing Key then, the display will

be "SEt. CAL."

Also, pushing

ENTER KEY on the below right. it will be displayed with "d xx"

("xx" means 1, 2, 5, 10, 20, 50, 100)

예) POWER OFF CONDITIONS

1. While pushing e Key ---------- Display is "SEt. CAL."

2. Pushing ENTER key ---------- Display is "d 2"

☞ "SEt. CAL." means SETUP & CALIBRATION mode

%!& 5jU]`UV`Y?Ymg

S&C MODE have 6way to adjust span. each step will be advanced with

ENTER key. Also, ESC key was used to return the prior conditions.

※ F.F : ENTER key

※ Review : ESC key

17

%!' 7U`]VfUh]cbAYbi%GhYdr*GhYd

1 Step : Minimum Division Set

2 Step : Maximum Capacity Set

3 Step : Setting Weight in span calibration

4 Step : Zero Calibration

5 Step : Span Calibration

6 Step : END

GhYd%

- Function : A]b]aia8]j]g]cbGYh

Range → 1~ 100

A step to set up a division value.

"d" means "Division" and "xx" means a division capable of displaying.

Also this value will be displayed as 1-2-5-10-20-50-100 by each key.

A step to set up a Decimal point is Function mode.

So, it will be go to the next step recording the position.

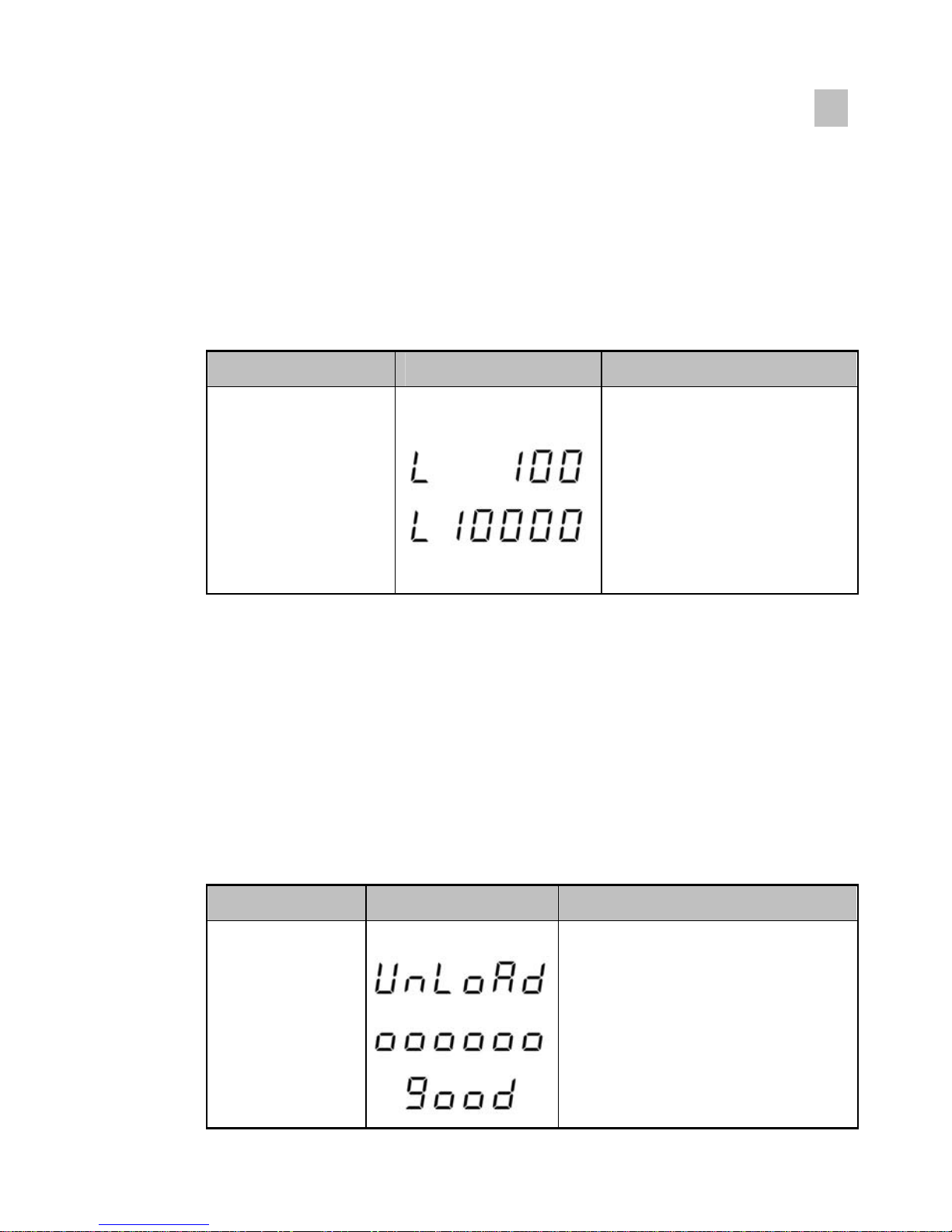

Key Display Description

“SAVE” key :

Increase

“ENTER” key :

Store and move

Into next menu

SEt.CAL. condition.

1 kg (Decimal point : 0)

0.01kg (Decimal point: 2)

☞ REF 1.The minimum division means the value of one division.

☞ REF 2. External resolution is obtained by division the min. division by the

maximum capacity. Set the resolution to be within 1/30,000.

18

GhYd&

- Function : AUl]aia7UdUW]hmGYh

Range → 1 ~ 99,999kg

A step to set up max. weight.

The display will appear "CAP."(Capacity) and discretion number

"C1000.0." (max. 5figure)

It can input the maximum weight as the end-user demands instead of

discretion number.

How to input is to push ENTER key after inputting discretion number.

♣ Don’t excess (A division ÷ Max. weight) with over 1/20,000

If accessing over 1/20,000,it will appear "Err 01".

Key Display Description

“ENTER” key :

Store and move

into next menu

Step 2 condition.

100 kg

10000kg

☞ REF 1. The maximum capacity means the maximum weight that scale

can measure.

GhYd'

- Function : GYhh]b[KY][\h=bGdUb7U`]VfUh]cb

Range → 1~ 99,999kg

The display discretion number "L1000.0." (span 5figure)

Please input the value of standard weight for span adjustment by

numeric key.

How to input is to push

ENTER

key after inputting discretion number.

This value of span standard weight must be equal to full capacity,

19

or over 10% of full capacity.

( In case of less 1/5,000 resolution ,the value of standard weight

must be over 10% of full capacity at least.)

( In case of over 1/5,000 resolution ,the value of standard weight

must be over 20% of full capacity at least.)

(Notice) If span capacity is set less 10% , indicator will display

error message.

Key Display Description

“ENTER” key :

Store and move into

next menu

Step 3

100 kg

10000kg

Setting Weight

☞ REF 1.

The weight shall be within the range of 10%~100% of maximum weight.

☞ REF 2.

The setting weight must be over the range of 10% of maximum weight.

☞ REF 3.

The setting weight over the maximum capacity.

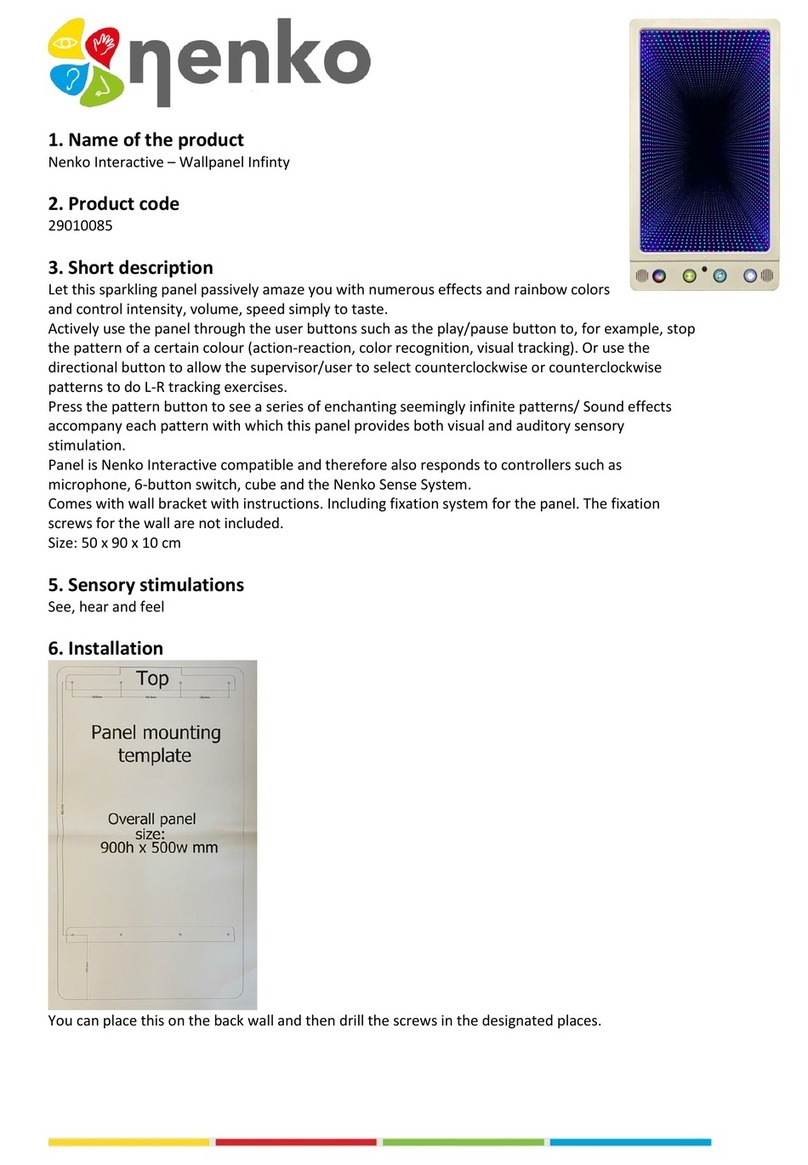

GhYd(

-Function : NYfc7U`]VfUh]cb

A step to check the zero conditions of Indicator.

After appearing "UnLoAd", please push ENTER key.

Please do it as the zero adjustment instruction.

Key Display Description

“ENTER” key :

Zero calibration

and move into

next menu

Step 4

Unload the tray and press

“ENTER”

key

Under zero calibration

Zero calibration is completed.

Table of contents

Other Bongshin Touch Panel manuals

Popular Touch Panel manuals by other brands

Emerson

Emerson GFK-3072D quick start guide

NENKO

NENKO Wallpanel Infinty quick start guide

Advantech

Advantech IPPC-8151S Series user manual

YASKAWA

YASKAWA VIPA HMI PPC021 CE manual

Extron electronics

Extron electronics TLP Pro 1725TG Setup guide

Extron electronics

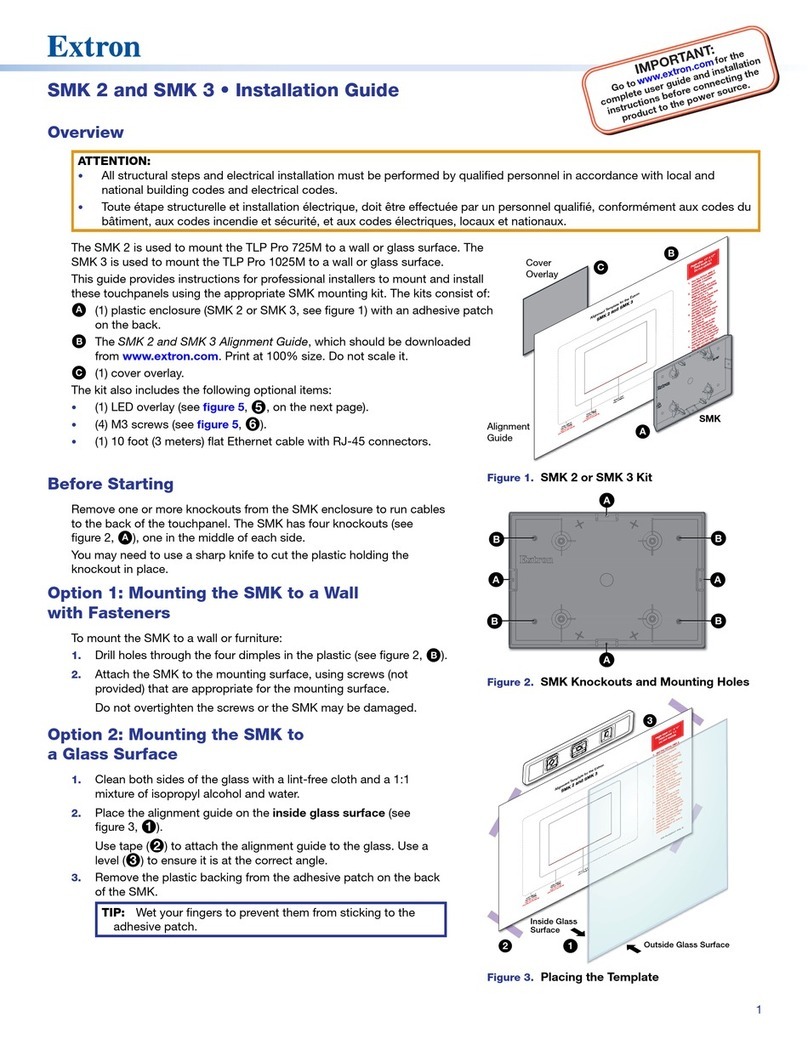

Extron electronics SMK 2 installation guide