3

1. DESCRIPTION

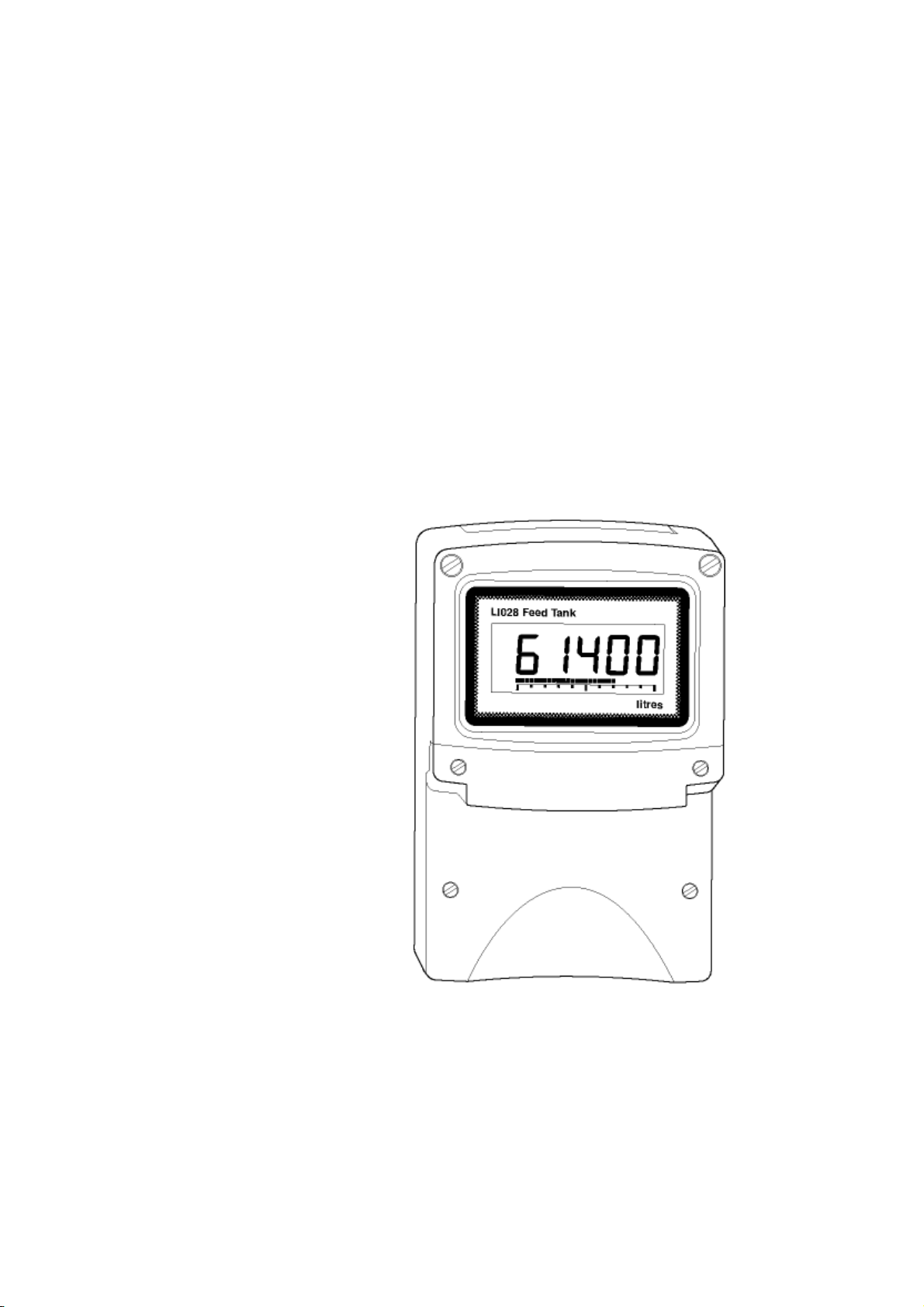

The BA614DF-F Fieldbus Indicator is a

FOUNDATION™ fieldbus instrument that can

display one fieldbus process variable on a five digit

LCD and 31 segment analogue bargraph. The

instrument is bus powered so no additional power

supply is required.

Communication Fieldbus Function

Protocol Block

FOUNDATION™ fieldbus Input Selector (1 x IS)

The Device Description files may be downloaded

from The Fieldbus Foundation or the BEKA

associates web site at www.beka.co.uk.

Housed in a robust IP66 glass reinforced polyester

(GRP) enclosure with a toughened glass window,

the BA614DF-F is surface mounting, or may be

pipe mounted using one of the accessory kits.

1.1 Documentation

This instruction manual describes system design

and installation of the BA614DF-F Fieldbus

Indicator. For commissioning information please

refer to:

FOUNDATION™ fieldbus

Fieldbus Interface Guide

for

Fieldbus Displays and

Fieldbus Indicators

which can be requested via the BEKA web site at

www.beka.co.uk

The instrument’s communication protocol is shown

on a label inside the terminal cover. The ‘-F’ order

code suffix also indicates the protocol but is not

shown on the instrument identification label.

2. SYSTEM DESIGN

The BA614DF-F Indicator is powered and

communicates via the fieldbus which is connected

to non-polarised terminals 1 and 2. As shown in

Fig 1 the instrument may be connected to any

fieldbus segment which can supply the additional

13mA required to power the instrument.

Fig 1 Fieldbus system

3. INSTALLATION

3.1 Location

The BA614DF-F Fieldbus Indicator is housed in a

robust IP66 glass reinforced polyester (GRP)

enclosure incorporating a toughened glass window

and stainless steel fittings. It is suitable for exterior

mounting in most industrial environments, including

offshore and wastewater treatment installations.

Please consult BEKA associates if high vibration is

anticipated.

The BA614DF-F enclosure is surface mounting.

Accessory kits described in sections 5.3 of this

manual enable the instrument to be mounted onto

a vertical or horizontal pipe.

The field terminals and the two enclosure mounting

holes are located in a separate compartment with a

sealed cover allowing the instrument to be installed

without exposing the display assembly.

The BA614DF-F earth terminal is connected to the

carbon loaded GRP enclosure. If this enclosure is

not bolted to an earthed post or structure, the earth

terminal should be connected to a local earth.

The BA614DF-F enclosure is supplied with a

bonding plate to ensure electrical continuity

between the three conduit / cable entries.