BONMET SDL10A User manual

User Manual

For SD Series

Smart & Accurate

1

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Preface

Thank you for choosing BONMET‘s DC servo products.

This manual is a user guide that provides the information on how to install, operate and maintain

SD series DC servo drive. The contents of this manual include the following topics:

●Installation of DC servo drives and motors

●Configuration and wiring

●Trial run steps

●Control functions and adjusting methods of DC servo drives

●Parameter settings

●Inspection and maintenance

●Troubleshooting

●Application examples

Before using the product, please read this manual to ensure correct use. Users should thoroughly

understand all safety precautions (DANGERS and WARNINGS) before proceeding with the

installation, wiring and operation. If you still have any problem, please contact with the local

Bonmet sales representative. Place this user manual in a safe location for future reference.

2

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Safety Precautions

●To prevent electric shock, note the following:

DANGEROUS

·Before wiring or inspection, switch power off and wait for more than 10 minutes. Then,

confirm the voltage is safe with voltage tester. Otherwise, you may get an electric shock.

·Wiring must be carried by electrical engineer.

·Connect the servo drive and servo motor to ground.

·Operate the switches with dry hand to prevent an electric shock.

·The cables should not be damaged, stressed, loaded, or pinched. Otherwise, you may get an

electric shock.

●To prevent fire, note the following:

CAUTION

·Do not install the servo drive, servo motor and regenerative brake resistor on or near

combustibles. Otherwise a fire may cause.

·When the servo drive has become faulty, switch off the main power. Continuous flow of a

large current may cause a fire.

·When there is a signal faulty as a regenerative brake resistor is used, please switch the main

power off. Otherwise, a regenerative brake transistor fault may overheat the regenerative

brake resistor and cause a fire.

●Wiring Precautions

CAUTION

·Wire the equipment correctly and securely.

·Connect the output terminals (U, V, W) correctly.

·Do not connect AC power directly to the servo motor or servo drive.

●Operation and Adjustment Precautions

CAUTION

·Do not touch the radiator and the regenerative brake resistor as they are overheated.

·Do not set parameter value unduly. If so, system would be instable.

·Do not touch the rotating parts of the servo motor in operation. Doing so may cause injury.

●Others

CAUTION

·Do not attempt to remold the servo drive.

3

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

CONTENTS

Chapter 1

• • • • • •

Model and Specifications

Chapter 2

• • • • • •

Installation

Chapter 3

• • • • • •

Wiring

Chapter 4

• • • • • •

Display and Operation

Chapter 5

• • • • • •

Operation

Chapter 6

• • • • • •

Parameters

Chapter 7

• • • • • •

Communication

Chapter 8

• • • • • •

Protective Functions

4

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Chapter 1 Model and Specifications

1.1 Unpacking Check

After receiving the DC servo drive, please check for the followings in order to prevent mistake during purchase or

shipment:

●Check the following section about the model explanation of the servo drive and motor to ensure that the

product is what you have ordered.

●Rotate the motor shaft slightly by hand, a smooth rotation will indicate a good motor. However, a servo

motor with holding brake can not be rotated manually unless give power to the holding brake to release

the shaft.

●Inspect the unit to insure it was not damaged during shipment.

If any items are damaged or incorrect, please inform the distributor whom you purchased the product from or your

local BONMET sales representative.

1.2 Model Explanation

●Nameplate Explanation

Figure 1-1 Nameplate explanation

●Model Explanation

SD

L

10

A

XX

1

2

3

4

5

1.Product type: S(SD)- Series DC servo drive;

2.Power supply:48~80VDC

3.Nominal current:10A

4.Type code;

5.Software customized logo.

1.3 Product Features

●Definition of The Motor Rotation Direction

Positive direction(CCW)

Negative direction(CW)

Definition of the motor rotation direction:facing the motor shaft side, CCW (counterclockwise) direction is

positive direction, CW (clockwise) direction is negative direction.

Model

Input Power

Nominal Output

Serial Number

5

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

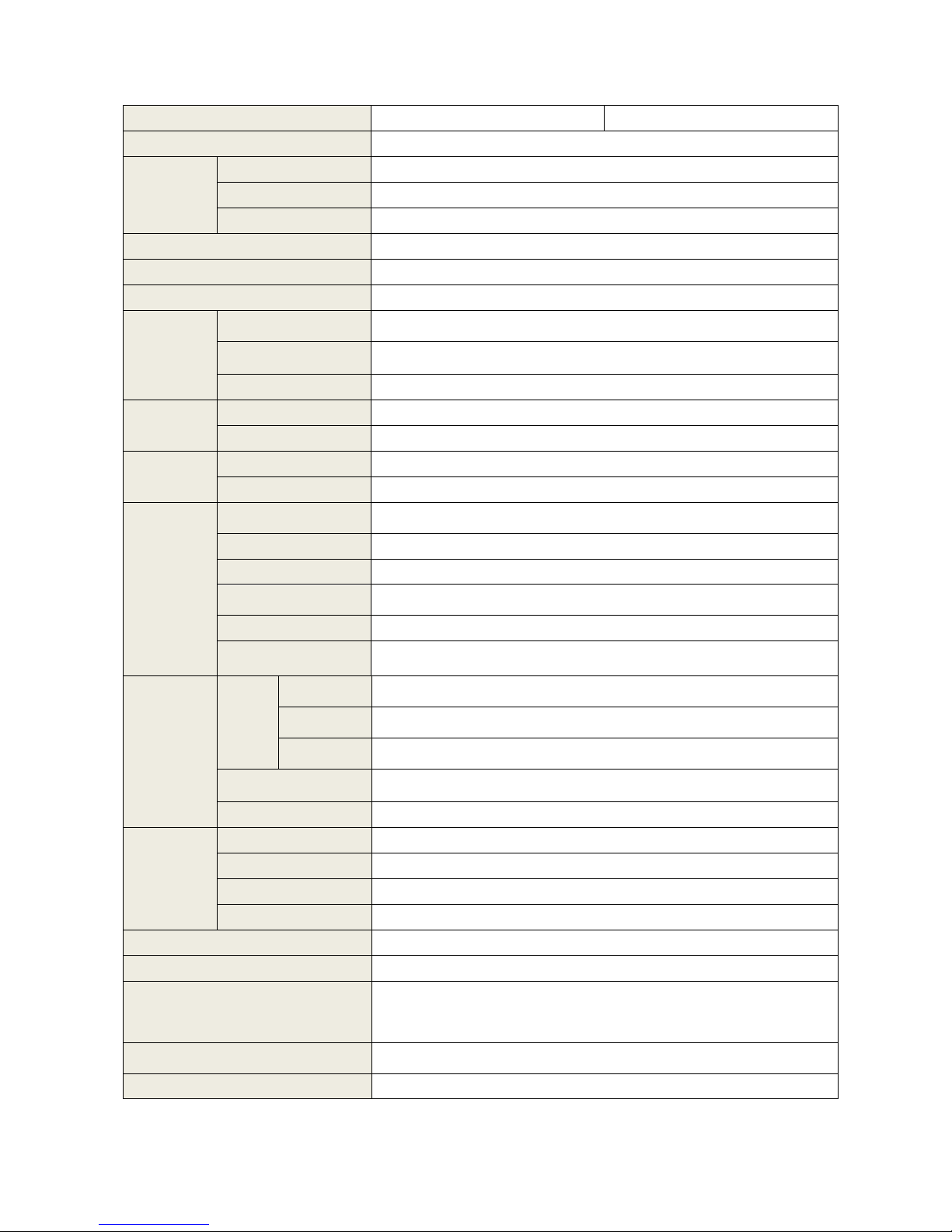

Model

SDL10A

SDL10B

Input Power Supply

DC 24V~85V

Environment

Temperature

Operation:0~40℃Storage:-40℃~50℃

Ambient Humidity

40%~80%( non-condensation)

Atmospheric Pressure

86~106kPa

Control Method

MOSFET

Control Mode

①Position control ②Speed control ③Torque control

Regeneration Brake

None

Speed

Characteristics

Speed Frequency

Response

300Hz or more

Speed Fluctuation Rate

±0.03 or less (Load 0~100%); ±0.02 or less (Power supply -15~+10%)

(Value corresponds to the nominal speed)

Speed Ratio

1:5000

Input Signal

Status Input Signal

Servo enable、Alarm clear

Command Input Signal

Analog torque / speed command input terminals、Pulse command input terminal

Output Signal

Status Output Signal

Servo alarm、Position complete output / speed reach output

Position Output Signal

Differential output for A、B、Z pulse, Open collector output for Z pulse

Position

Control

Maximum Input Pulse

Frequency

500KHz

Input mode

①Differential output ②Open collector output

Command mode

①Command/direction pulse ②CCW/CW pulse ③A/B pulse (set by parameters)

Command Smoothing

Method

Position command filter

Electronic Gear

1~30000/1~300000(Recommended value:50~1/50)

Torque Limit

①Set by parameters(CCW/CW)②16 speed command set by parameters

③Controlled by analog command

Speed

Control

Comma

nd mode

Internal

Command

16 speed command set by parameters,

Analog

Command

0~±10VDC(Default:10VDC corresponds 3000rpm)

Pulse

Command

0~500KHz(Default:500KHz corresponds 3000rpm)

Command Smoothing

①Analog low-pass filter order ②Increase / Decrease time constant ③Position

command filter

Speed Limit

Set by parameters

Torque

Control

Command mode

0~±10VDC(Default:10VDC corresponds 100% nominal torque)

Command Smoothing

Torque command filter

Speed Limit

Set by parameters

Torque Limit

Set by parameters(CCW/CW)

Communication

RS-232 port、RS-485 port

Bus Control Function

Mod bus

Monitoring Function

The percentage of motor torque, ,Motor speed, Motor accumulated travel pulse,

Torque command value, Speed command value,Accumulative command pulse,

Single-phase current, Absolute position of rotor, Position deviation pulse, Alarm

code, Input and output terminal signal status, etc.

Protective Function

Encoder signal abnormalities, Overload, Over current, Speed tolerance, Over

location etc.

Applicable Load Inertia

Less than five times of motor inertia

6

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Chapter 2 Installation

2.1 Notes for Installation

●Do not bend or strain the cables between servo drive and motor;

●When mounting the servo drive and servo motor, make sure to tighten all screws to secure the machine

in place;

●Motor shaft must be concentric with the axis of transmission;

●If the cable between drive and motor is longer than 10 meters, the cable must be thicken.

2.2 Installation Environment

●Please install the servo system in the place without oil mist, dust or electrical control cabinet (ensure the

temperature below 50℃, relative humidity below 80%. The long-term safety temperature below 40℃)

●Please install the servo system in the place without radioactive matters and combustibles.

●Take an anti-vibration measure to guarantee that the servo drive is free from vibration impact, ensuring

the vibration under 0.5G (4.9m/s2).

●Please install the servo system in the place without direct sunlight.

●Interferential equipment nearby would take great effects to the power wire and control wire which will

cause miss operation. For normal operation, a noise filter or any other anti-jamming measures is

necessary to be carried out. Leakage current would increase after installing a noise filter, therefore an

isolation transformer can be used to avoid this problem. Possessing a reasonable alignment and inhibit

measures is very important because the control signal wire is easy to be interfered.

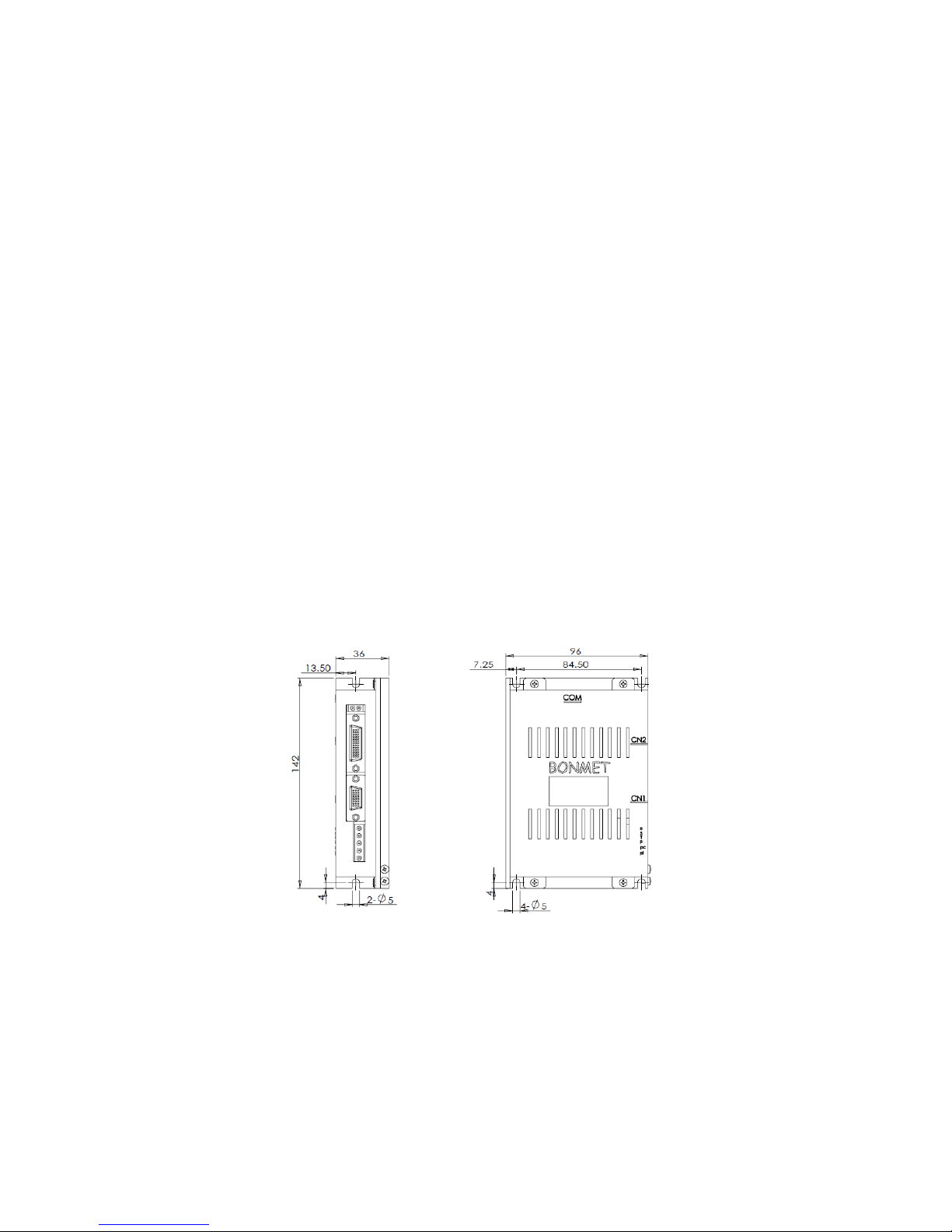

2.3 Dimensions(Unit: mm)

Figure 2-1 Dimension drawings

2.4 Installation Direction and Space

●The equipment must be installed in the specified direction. Otherwise, a fault may occur.

●Leave specified clearances between the servo drive and control box inside walls or other equipment.

●Leave a large clearance between the top of the servo drive and the internal surface of the control box,

and install a fan to prevent the internal temperature of the control box from exceeding the environmental

7

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

conditions.

●When using heat generating equipment such as the regenerative brake option, install them with full

consideration of heat generation so that the servo drive is not affected. Install the servo drive on a

perpendicular wall in the correct vertical direction.

Figure 2-2 installation schematic diagram for drives

Chapter 3 Wiring

2.5 Connections

3.1.1 Note

●All terminals and plugs must be screwed well, poor contact or disconnection could lead to accidents.

●In order to prevent error movement caused by noise, please install isolation transformers and noise filter.

●The equipment must be grounded.

●Do not put power lines and signal lines in a same conduit or their binding them together, the distance between

power lines and signal lines should be 30cm at least, otherwise it may cause interference.

●Please use the shielded twisted wire as signal cable.

●Do not switch power supply frequently. The maximum frequency should be no more than once per minute.

2.6 Connection

Control

Card

Power

48~80VDC Motor

Controler

≥

25

mm

≥

25

mm

≥

100

mm

≥

100

mm

Air flow

Air flow

≥

100

mm

8

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

2.7 Terminals

Terminal

Name

Function

+VDC、GND

Drive power terminal

Connect with 48~80VDC

U、V、W

Motor terminal

Connect with motor

CN1

Encoder Connector

Connect with encoder

CN2

I/O Connector

I/O port

COM

Communication Connector

Connect with PC or controller

2.8 Power Terminal

number

Name

Symbol

Description

1

Ground

GND

Connect with OV

2

Power

+VDC

Connect with 48~80V

3

Motor U、V、W terminal

U

Connect with motor power terminal

4

V

5

W

2.9 Encoder Connector CN1

Terminal

number

Name

Function

Symbol

I/O

Description

1

Power supply(5V)

+5V

The power supply and public ground of encoder. It is

necessary to use a parallel multi-cored wire to reduce

the pressure drop of wires.

13

Public ground

0V

7

Encoder CSL input

CSL

Type7

Connect with the electro-optic encoder CSL.

2

Encoder CSH input

CSH

Connect with the electro-optic encoder CSH.

6

Encoder CLKL input

CLKL

Type7

Connect with the electro-optic encoder CLKL.

1

Encoder CLKH input

CLKH

Connect with the electro-optic encoder CLKH.

8

Encoder DOL input

DOL

Type7

Connect with the electro-optic encoder DOL.

3

Encoder DOH input

DOH

Connect with the electro-optic encoder DOH.

4

Encoder A+ input

A+

Type7

Connect with the electro-optic encoder A+.

9

Encoder A- input

A-

Connect with the electro-optic encoder A-.

5

Encoder B+ input

B+

Type7

Connect with the electro-optic encoder B+.

10

Encoder B- input

B-

Connect with the electro-optic encoder B-.

14

Encoder Z+ input

Z+

Type7

Connect with the electro-optic encoder Z+.

15

Encoder Z- input

Z-

Connect with the electro-optic encoder Z-.

2.10 I/O Connector CN2

12345

1

2

3

45

10

11

12

13

1415

6

7

8

9

26 20

21

22

2324

25

1

2

3

45

19

6

78

9

17 1618 11

12

13

1415 10

9

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Control mode: Pstands for position control, Sstands for speed control, Tstands for torque control.

Terminal

number

Name

Terminal symbol

Function

Symbol

I/O

mode

20

Servo enable

ServoEn+

Type1

Servo enable input terminal.

ServoEn ON: Operation enabled;

ServoEn OFF: Operation disabled.

[Note 1]: Make sure the servo motor is quiescent before

―ServoEn OFF‖ turns to ―ServoEn ON‖

[Note 2]: Please wait for 50 ms before inputting any

command in the State of ―ServoEn ON‖.

19

ServoEn-

3

Alarm clear

AlarmClr+

Type1

Alarm clear input terminal.

AlarmClr ON: Clear the system alarm;

AlarmClr OFF: Maintain the system alarm.

[Note]: As the alarm code is less than 12, please cut off

the power supply and repair the drive.

12

AlarmClr-

5

Servo alarm

output

Alarm+

Type2

Output terminal of servo alarm.

ALM ON: Servo alarm output ON as there is no alarm;

ALM OFF: Servo alarm output OFF as there is any

alarm.

14

Alarm-

2

Command pulse

PLUS input

PulseInv+

Type3

P

External command pulse input terminal.

Note: pulse type is selected by parameter PN52.

①PN52=0, command pulse+ signal mode(default state);

②PN52=1, CCW/CW command pulse mode;

③PN52=2, 2-phase command pulse mode.

11

PulseInv-

1

Command pulse

SIGN input

SignInv+

Type3

P

10

SignInv-

24

Analog command

input

ASPEED+/

ATORQUE+

Type4

S、T

Command input terminal for external analog

torque/speed (difference mode), the impedance is 10kΩ,

the voltage is -10V~+10V.

25

ASPEED-/

ATORQUE-

26

Analog ground

AGND

The grounding line of analog input.

7

Encoder

Phase-A signal

PhaseA+

Type5

1. Encoder signal A, B, Z for difference drive output

(output through 26LS31, corresponding to RS422 );

2. Non-isolative output (non-insulation).

16

PhaseA-

8

Encoder

phase-B signal

PhaseB+

Type5

17

PhaseB-

9

Encoder phase- Z

signal

PhaseZ+

Type5

18

PhaseZ-

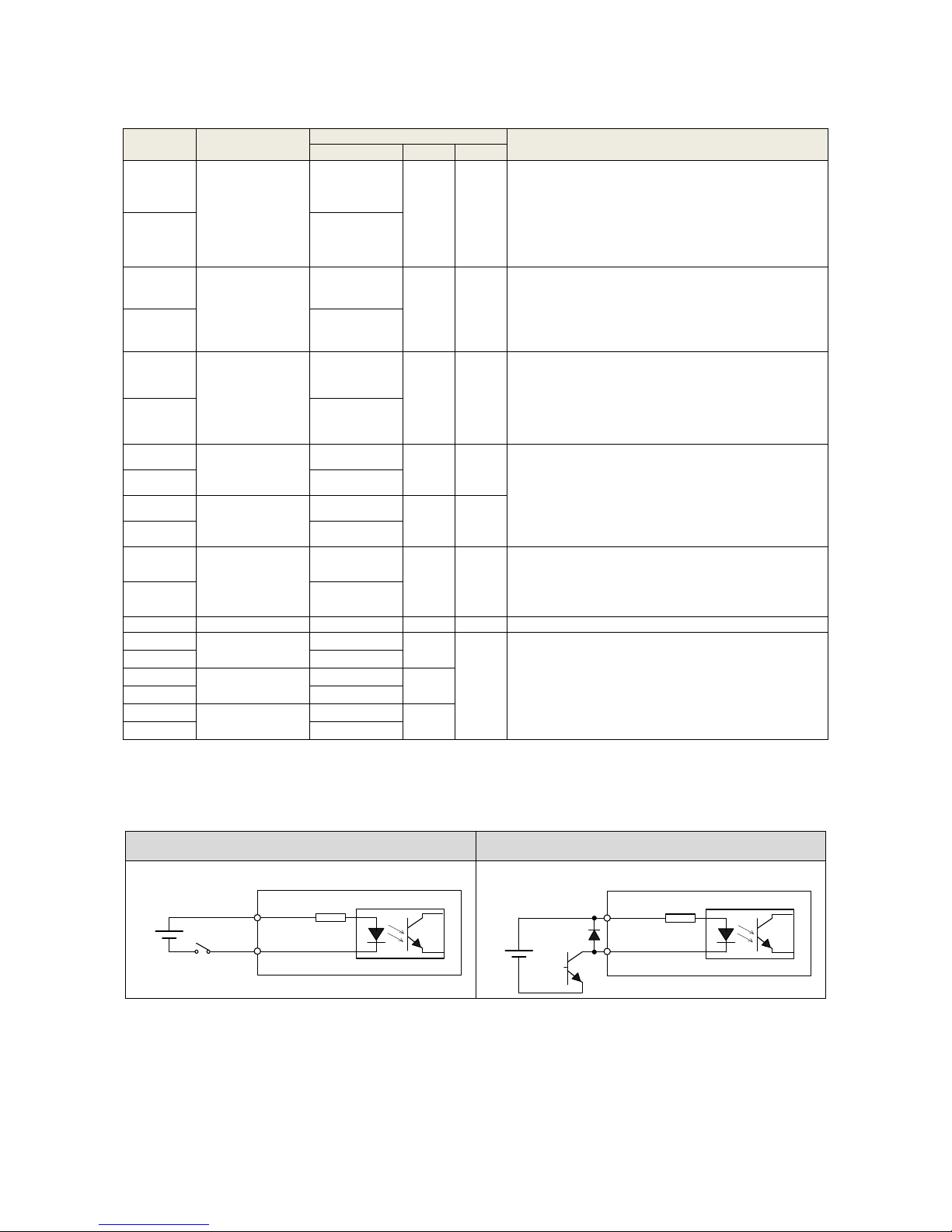

3.6.1 Wiring of Digital Input

Wiring of the relay circuit

Wiring of the open collector circuit

(1) Connect to contacts of switches and relays, or open collector output transistors.

(2) The power is provided by the user as the voltage range is DC12~24V and the current is more than 100mA.

Note: the internal circuit will be damaged if the power polarity is wrongly connected.

4.7K

VCCOM

ServoEn,etc

DC 12~24V

Servo drive

4.7K

VCCOM

ServoEn,etc

DC 12~24V

Servo drive

10

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

3.6.2 Wiring of Digital Output

Wiring of the relay circuit

Wiring of the Optocoupler circuit

Note: it is possible to connect a freewheeling diode in the wiring of relay circuit.

(1) The output circuit is composed of open collector transistor outputs in the Darlington connection, and connect

to relays or photo-couplers.

(2) The power is provided by the user as the voltage range is DC5 ~ 24V and the current is more than 50mA.

Note: the internal circuit will be damaged if the power polarity is wrongly connected.

(3) As driving the inductive load such as relay, you must connect a freewheeling diode in parallel.

Note: It would damage the serve drive as if the freewheeling is wrongly connected.

(4) There exists collector to emitter voltage, VCE (SAT) of approx. 1V at transistor-ON, due to the Darlington

connection of the output or. Note that normal TTL IC cannot be directly connected since it does not meet

VIL.

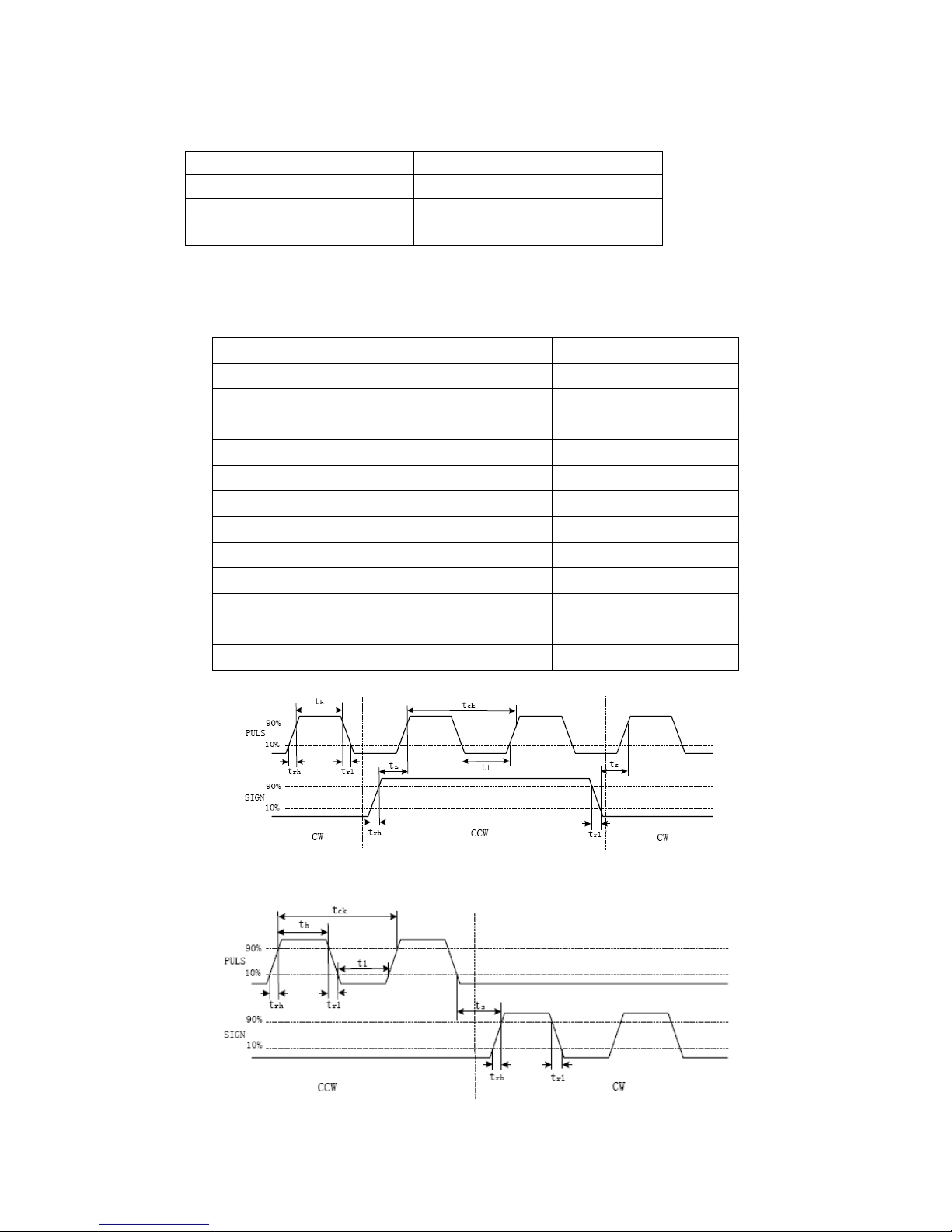

3.6.3 Wiring of Pulse Input

There are two kinds of pulse inputs, line drive input and open-collector input. The max. input pulse frequency is

500kpps.

BONMET servo drive support three kind of pulse mode (Set by Pn-52): ①Pulse + Direction; ②CW+CCW pulse;

③A/B phase pulse

●Line drive input

●Open-collector input

There are two kind of open-collector input: NPN type (like Mitsubishi, Omron, Panasonic) and PNP type (like

Siemens). The wiring of open-collector as below:

Wiring of NPN type pulse input

Wiring of PNP type pulse input

⑴Check the pulse input kind and make the wiring according to the drawing, otherwise it may cause the damage.

DC 12~24V

Servo drive

Relay

50mA as MAX.

output

Host controller Servo drive

PULS+

PULS-

SIGN+

SIGN-

Servo drive

PULS+

PULS-

SIGN+

SIGN-

Host controller

R

R

VCC

Servo drive

PULS+

PULS-

SIGN+

SIGN-

Host controller

R

R

VCC

11

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

⑵The Optocoupler supports max. to 15mA current. We need to add a current-limiting resistance as using

open-collector input.

Voltage of open-collector input

Value of current-limiting resistance

5V

Not need

12V

400

24V

1k

⑶The cable of pulse input should be twisted-paired and shielded to prevent from signal interference caused by

noise.

⑷The max. input pulse frequency is 500kpps, the relationship between pulse frequency and speed is a

proportional relationship as 500 kHz corresponds to 3000rpm.

Parameters

Differential drive input

Single-ended drive input

tck

>2μS

>5μS

th

>1μS

>2.5μS

tl

>1μS

>2.5μS

trh

<0.2μS

<0.3μS

trl

<0.2μS

<0.3μS

ts

>1μS

>2.5μS

tqck

>8μS

>10μS

tqh

>4μS

>5μS

tql

>4μS

>5μS

tqrh

<0.2μS

<0.3μS

tqrl

<0.2μS

<0.3μS

tqs

>1μS

>2.5μS

Sequence chart for pulse + direction

Sequence chart for CW+CCW pulse

12

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

Sequence chart for A/B phase pulse

3.6.4 Wiring of Analog Input

Analog voltage input

Potentiometer input

Note:"AO" means analog command.

(1) AGND must be connected to the ground (0V) of analog command;

(2) Max. permissible input voltage to each input is ±10V;

(3) It is suggested that using Shielded twisted pair as the analog input cable;

(4) Analog input drift is normal, you can use analog input drift compensation function to deal with it..

3.6.5 Wiring of Encoder Differential Output

Wiring of line receiver

Wiring of optocoupler

(1) Feeds out the divided encoder outputs (A, B and Z-phase) in differential through each line driver.

(2) Customer can use a line receiver (like AM26LV32). Install a terminal resistor (approx. 330Ω) between line

receiver inputs without fail. And connect ―EGND‖ to the ground (0V) of the receiver.

(3) Customer can use a optocoupler to receive the signals.

(4) These outputs are not insulated.

3.4

Servo drive

AO+

AO-

Host controler

+

-

+

-

AGND

10KΩ

AO+

AO-

Adjust voltage

by potentiometer

+

-

AGND

10KΩ

2KΩ(1/2W)

200Ω(1/2W)

200Ω(1/2W)

10V

10V

Servo drive

Servo drive

PhaseA+

PhaseA-

PhaseB+

PhaseB-

Host controler

PhaseZ+

PhaseZ-

Pin_1

Pin_2

Pin_3

Pin_4

Pin_5

Pin_6

R

EGNDPin_9

AM26LS31

AM26LV32 or other line receiver

R

R

Servo drive

PhaseA+

PhaseA-

PhaseB+

PhaseB-

Host controler

PhaseZ+

PhaseZ-

Pin_1

Pin_2

Pin_3

Pin_4

Pin_5

Pin_6

220Ω(1/2W)

220Ω(1/2W)

220Ω(1/2W)

EGNDPin_9

AM26LS31

Optocoupler

13

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

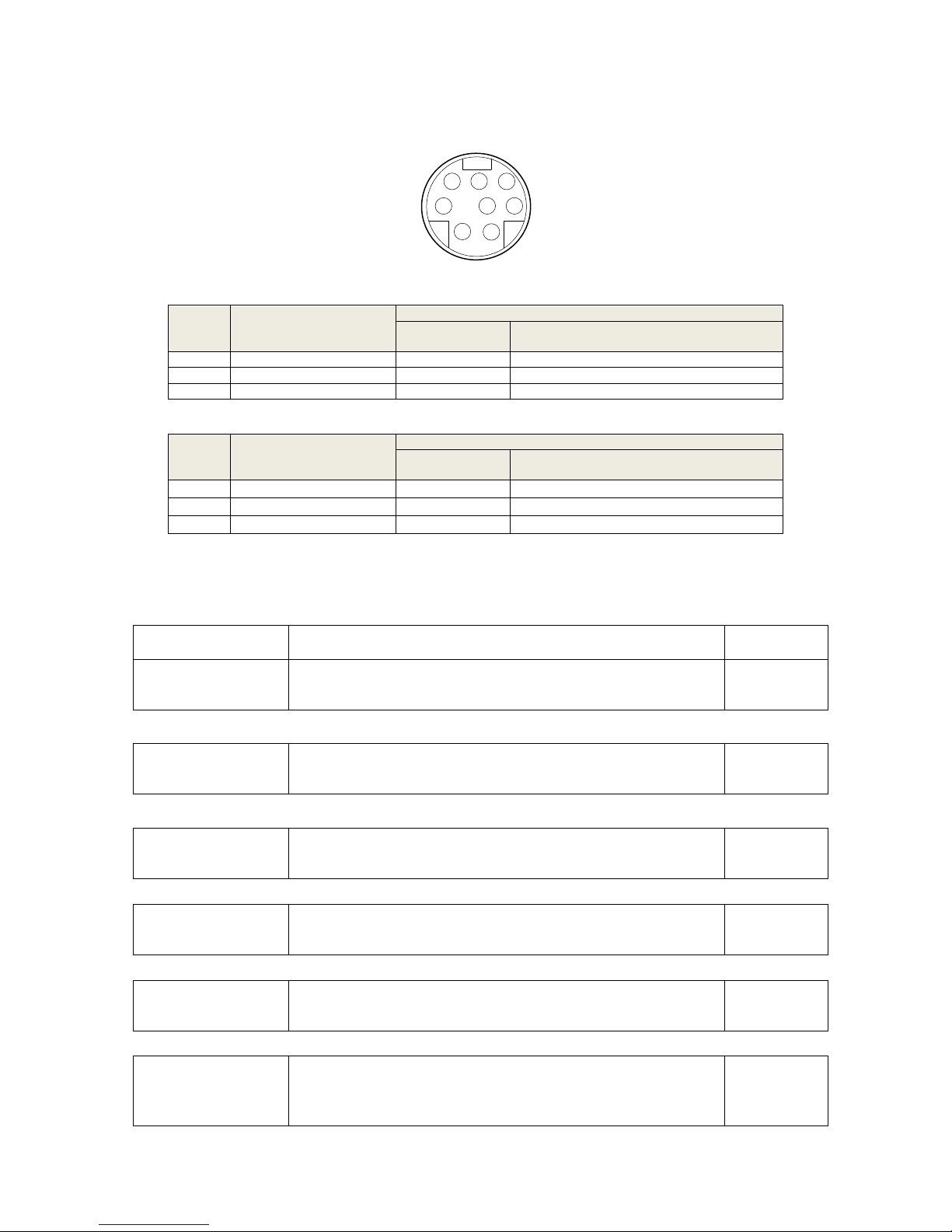

3.5 Communication Connector(CN3)

Serial-line terminal plug CN3

■RS-232

Termina

l

number

Name

Function

Symbol

Description

3

Receive data

RXD

Receive data signal.

5

Transmit data

TXD

Transmit data signal.

1

GND

GND

Inhibit signal earth.

■RS-485

Termina

l

number

Name

Function

Symbol

Description

7

Difference signal Data+

Data+

Data+ terminal

4

Difference signal Data-

Data-

Data- terminal

8

GND

GND

Inhibit signal earth.

Chapter 4 Operation

4.1 Operation steps

Item

Content

Reference

Installation

Please keep the motor shaft in a non-connection state, do not connect the motor

with mechanical system for servo action confirmation at first.

Chapter 2

↓

Wiring

Connect servo drive with power and peripheral device

Chapter 3

↓

Preparation before

operation

Please confirm all the necessary items before turn on the power. And check if

there is any alarm.

Chapter 4

↓

Action confirmation

Operate in speed mode to test the servo drive and servo motor without any load

on the shaft.

Chapter 4

↓

Parameters settings

Set parameters according to terms of use.

Chapter 5

↓

Trial operation

Connect motor with mechanical systems, turn on the power, and check whether

protective functions (such as emergency stop and stroke limit) are working.

Check operation at both low speed and high speed.

—

31 2

4 5 6

78

14

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

↓

Gain adjustment

Adjust the gain to get a good performance.

Chapter 4

↓

Normal operation

You can carry out normal operation now. If any faulty happens, please refer to

"Chapter 7 Protection."

Chapter 7

Preparing For Operation

Turning Power ON and Checking Indicators

■Checking Power Supply Voltage

·Check to be sure that the power supply voltage is 24~85VDC

■Checking Terminal Block Wiring

·The power supply inputs (+VDC、GND)must be properly connected to the terminal block.

·The servo motor‘s power line(U、V、W)must be properly connected to the terminal block.

■Checking the servo motor

·The Encoder Cable must be securely connected to the Encoder Connector at the motor side.

·The power lines at the servo motor must be securely connected.

■Checking the Control Connectors

·The Control Cable must be securely connected to the I/O Control Connector (CN2).。

·The ServoEn command must be OFF.

4.2 Software(Servofly)operation instructions

4.2.1 Communication

⑴Connect servo drive with PC through serial cable.

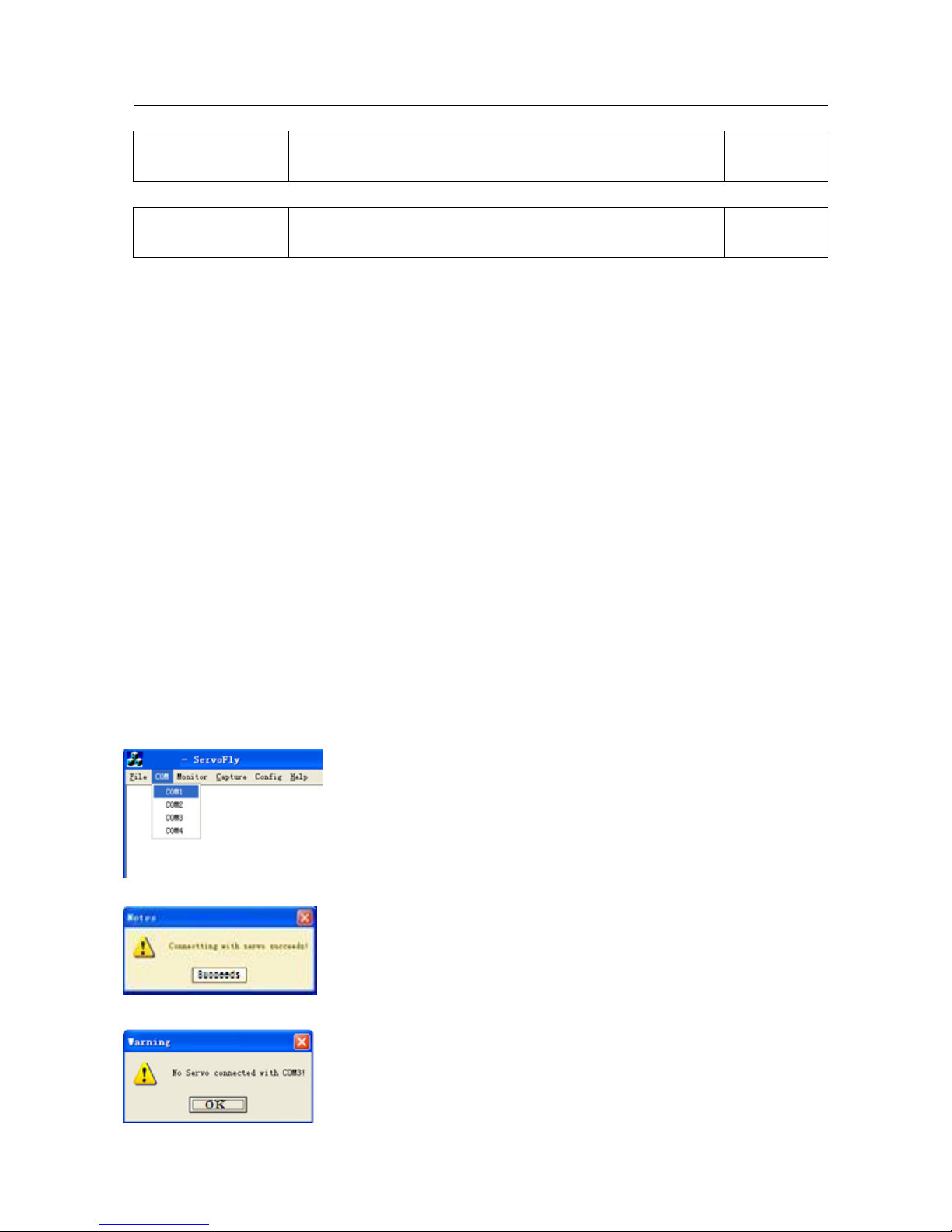

⑵Click “Servofly.exe‖and select the COM menu,click the defined COM port(can be modified by PC).

⑶The communication succeeds as the following dialog appears.

⑷The communication fails as the following dialog appears, please check the wiring.

15

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

⑸The communication fails as the following dialog appears, it indicates that the software version does not match,

please select Pn-0 to check the version information, and download the right software on our website.

4.2.2 Basic function

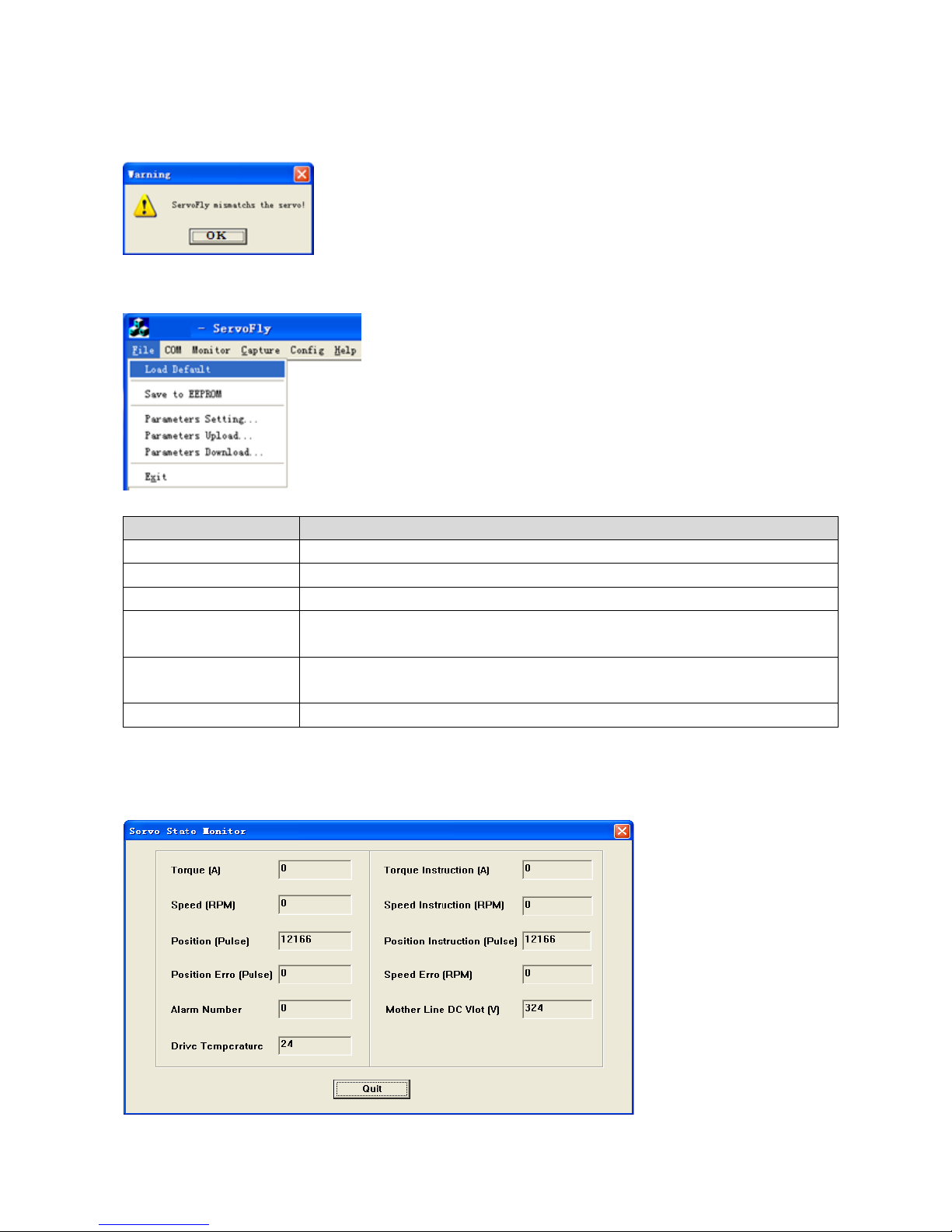

1. Customers can use the basic function of the software in the ―File‖menu.

2. Function

Item

Function

Load Default

Restore default parameters(equal with ―EE-Def‖ in panel operation)

Save to EEPROM

Save the current parameters to EEPROM

Parameters Setting…

Parameter setting

Parameters Upload…

Upload the parameters from servo drive to PC ( please name the parameter file as

“xx.par”, otherwise the operation would be invalid)

Parameters Download…

Download the parameters from PC to servo drive(please DO NOT use this

function.)

Exit

Exit the software

4.2.3 Monitoring function

1. Monitoring the servo state

⑴―Servo State‖ choice under the ―Monitor‖ menu is the monitoring choice of the servo state.

16

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

⑵Function

Item

Function

Torque(A)

Motor Q axis current(the value divided by 1.414 is motor current)

Torque Instruction(A)

Motor Q axis current command (the value divided by 1.414 is motor current

command)

Speed(RPM)

Motor speed(this is a real time value )

Speed Instruction(RPM)

Speed command

Position(Pulse)

Feedback pulse

Posiotn Instruction(Pulse)

Pulse command

Position Erro(Pulse)

Position deviation (pulse command minus feedback pulse)

Speed Erro(Pulse)

Speed deviation(this is a real time value)

Alarm Number

Alarm code(―0‖ means no alarm)

Mother Line DC Vlot(V)

Mother line DC voltage

Drive Temperature

The temperature of the heat sink inside part

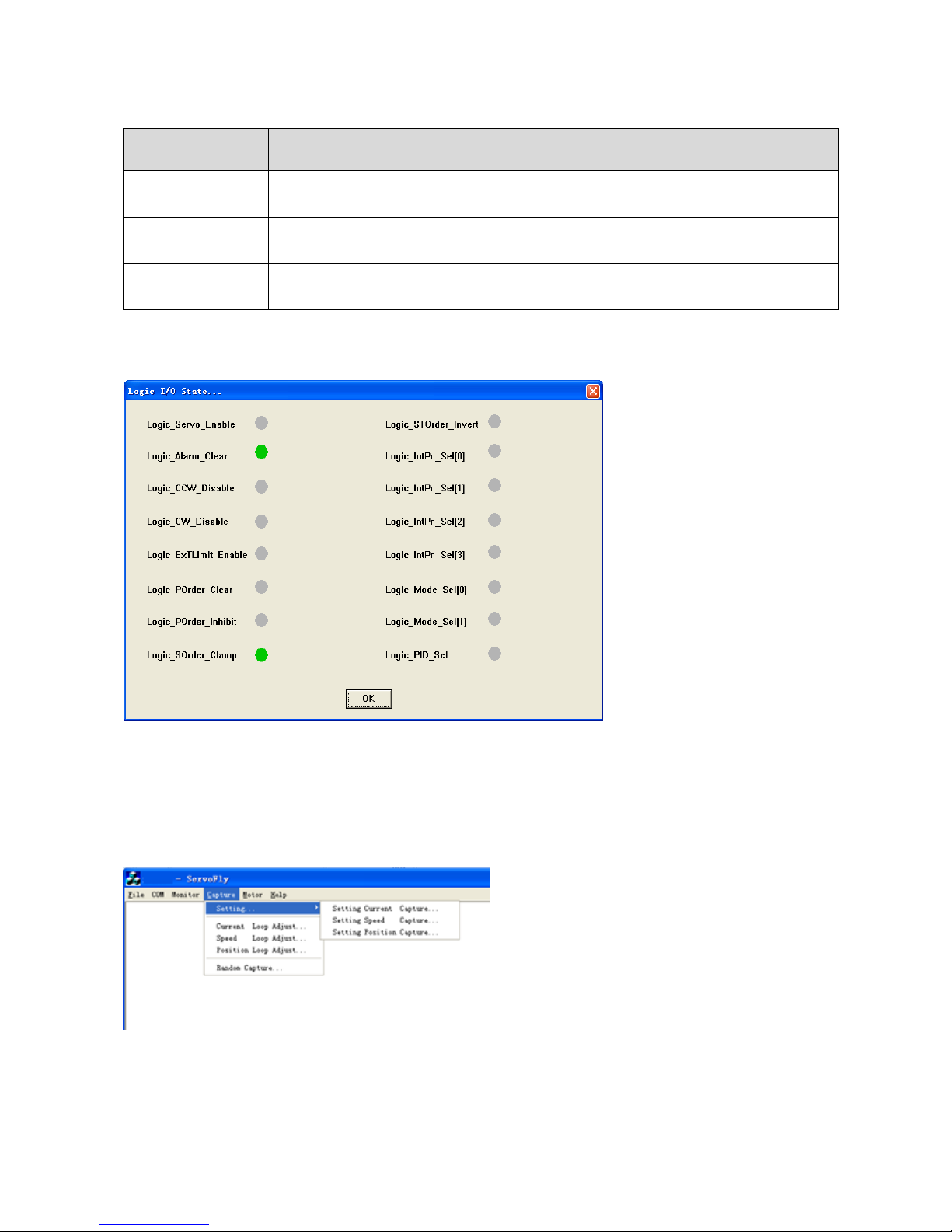

②Physical port status monitoring function

⑴The ―Physical State‖ item under the ―Monitor‖ menu is for the physical port status monitoring function.

17

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

⑵Function

Item

Function

CN2 Port Input

Monitor the digital input status, green light indicates “ON”and grey light indicates

“OFF”, please refer to chapter 3 for details of I/O connector

CN2 Port Output

Monitor the digital output status, green light indicates “ON”and grey light indicates

“OFF”, please refer to chapter 3 for details of I/O connector

CN1 Port Input

Encoder input signals, green light indicates “ON”and grey light indicates “OFF”,

please refer to chapter 3 for details of I/O connector

③Logical port status monitoring function

⑴The ―Logic State‖ item under the ―Monitor‖ menu is for the logical port status monitoring function.

⑵Function

Monitor the logical input status, green light indicates “ON”and grey light indicates “OFF”, please refer to

chapter 3 section 3.7 for details of logical input.

4.2.4 Oscillation control and running curve monitoring function

1. Oscillation control

In the picture, the items “Setting„”, “Current Loop Adjust„”, “Speed Loop Adjust„” and “Position

Loop Adjust„” are for oscillation control, this function is only for factory testing use, wrong operation may

cause damage, please DO NOT use this function.

18

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

2. Running curve monitoring function

―Random Capture‖ menu is for the running curve monitoring function, customers can check the current loop

curve, speed loop curve and position loop curve.

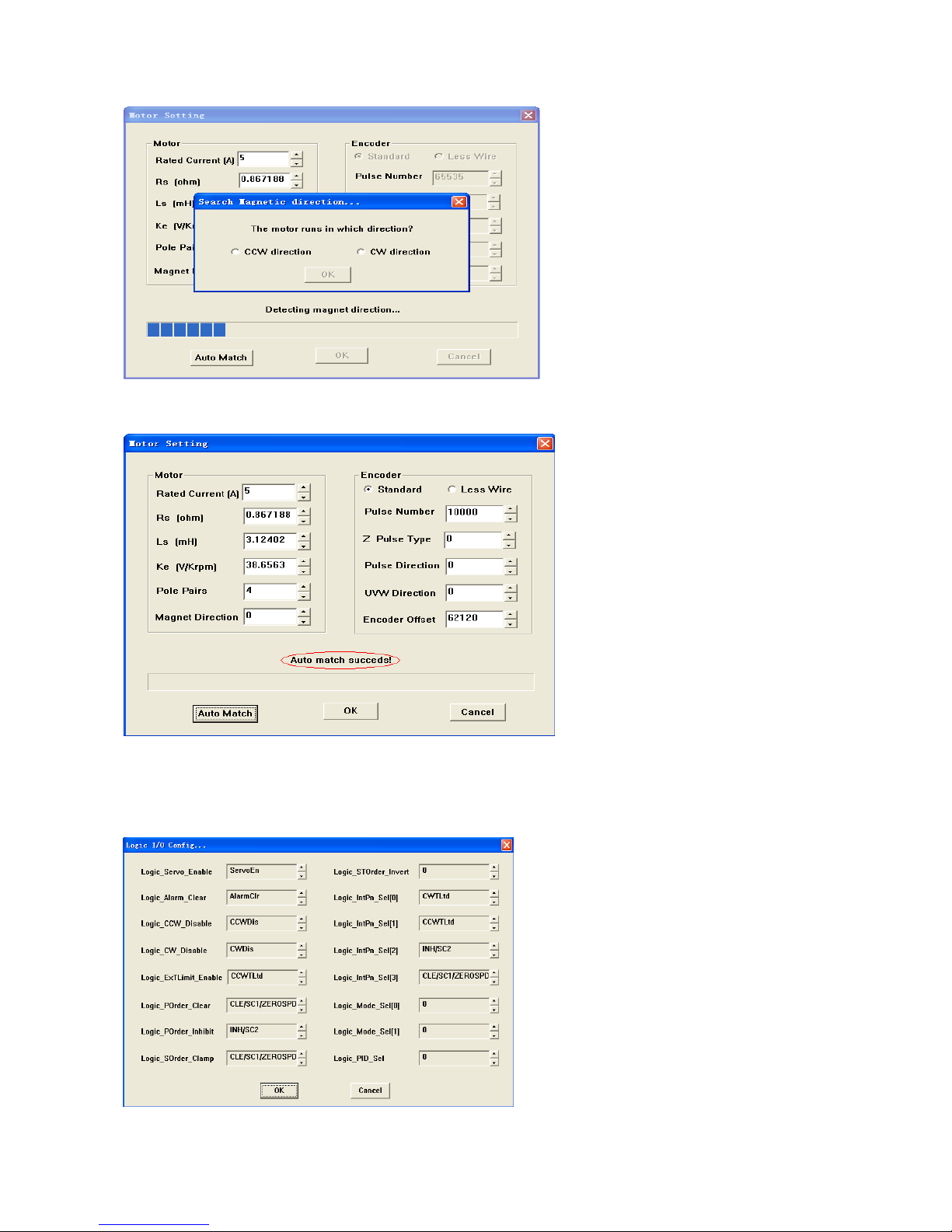

4.2.5 Config function

There are two items ―Motor Config…‖ and ―Logic I/O Config…‖ under the ―Config‖menu. The “Aux Encoder

Config…” item DOES NOT open to customers.

1. Motor parameters adaptive function

⑴Click ―Basic Information…‖ and the following dialog will appear:

⑵Fill in the basic data (please don‘t fill in other parameters)

Item

Function

Rated Current(A)

Motor nominal current

Rs(ohm)

Phase resistance

Ls(mH)

Phase inductance

Ke(V/Krpm)

Back EMF

Note:This operation must be carried out by electrical engineer and the above parameters must be effective,

otherwise it would cause mistake or damage.

⑶Adaption

Click ―Auto Match‖ to start the adaption operation, as the following dialog appears, select the right direction(face

the motor shaft, ―CCW direction‖indicates counterclockwise direction and ―CW direction‖indicates clockwise0

direction), and then click ―OK‖.

19

BONMET motion GmbH/www.bonmet.com/www.bonmet.de

The following dialog will appear as if the adaption is successful, please save the parameters to EEPROM and

power off, then power on again.

⑷If adption is not successful, maybe there is something wrong with the operation, please contact with out

technical staff.

2. Mapping function

⑴Click ―Logic I/O Config...‖ and the follow dialog will appear:

This manual suits for next models

1

Table of contents

Popular DC Drive manuals by other brands

Perception

Perception PEDAL DRIVE quick start guide

Lenze

Lenze L-force EYF A F04S06 Series Mounting instructions

Dynamatic

Dynamatic DCD-132 instruction manual

GFA

GFA ELEKTROMAT SI 6.160 FU-25,00 GA06/160MGDU installation instructions

YASKAWA

YASKAWA J1000 CIMR-JC series installation manual

Minarik

Minarik NRGD-4Q Series user manual

ABB

ABB ACS355 series Quick installation and start-up guide

Magnetek

Magnetek Impulse G+ series 4 quick start guide

Automationdirect.com

Automationdirect.com DURApulse GS10 quick start guide

EUCHIPS

EUCHIPS EUP200AD-1H12V-0 quick start guide

Masterflex

Masterflex I/P MFLX07591-20 operating manual

Aumuller

Aumuller KS15 Assembly instruction