Bonnet EQUATOR User manual

Other Bonnet Oven manuals

Bonnet

Bonnet PRECIJET+ 6 GN1/1 User manual

Bonnet

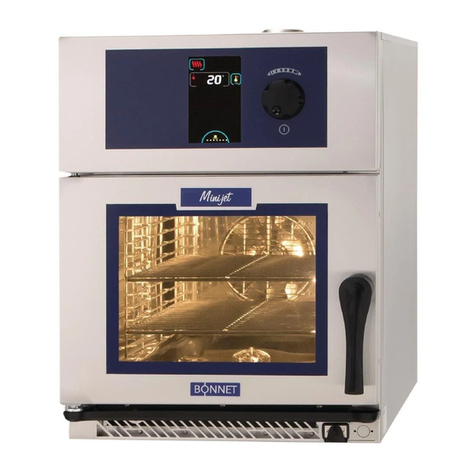

Bonnet MINIJET ELECTRIC User manual

Bonnet

Bonnet Maestro C412A14 User manual

Bonnet

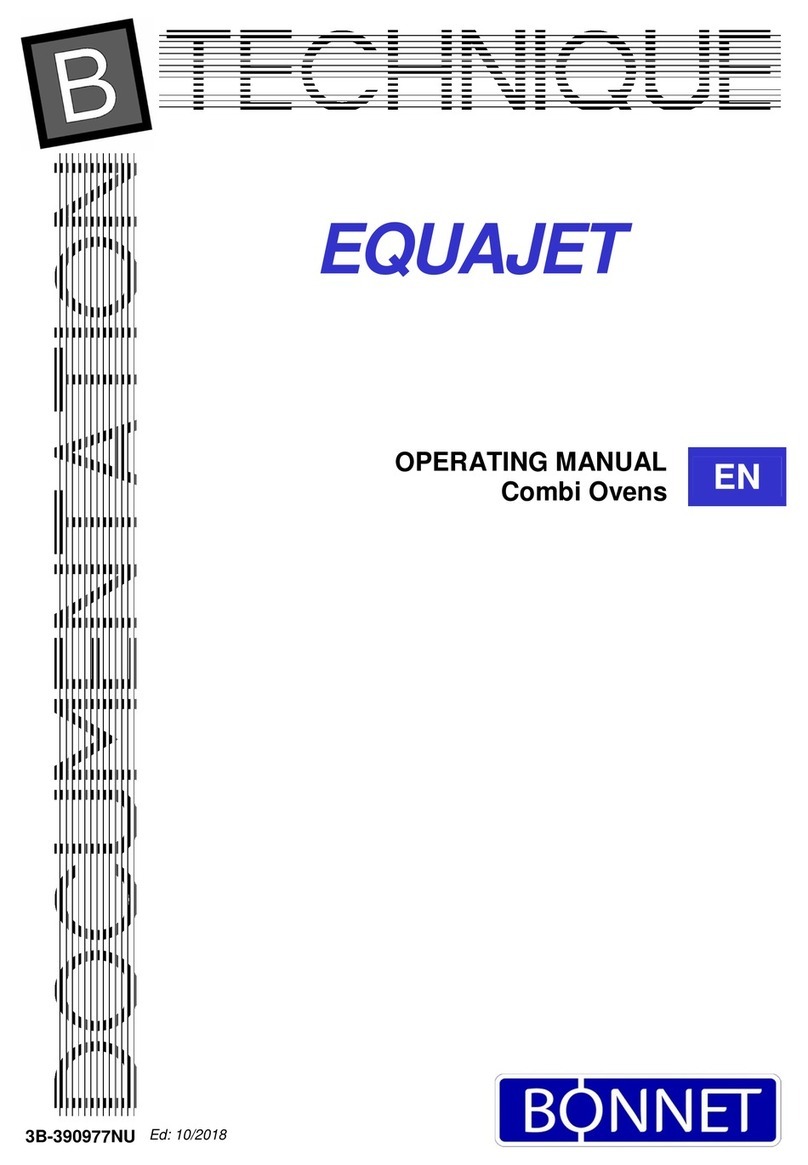

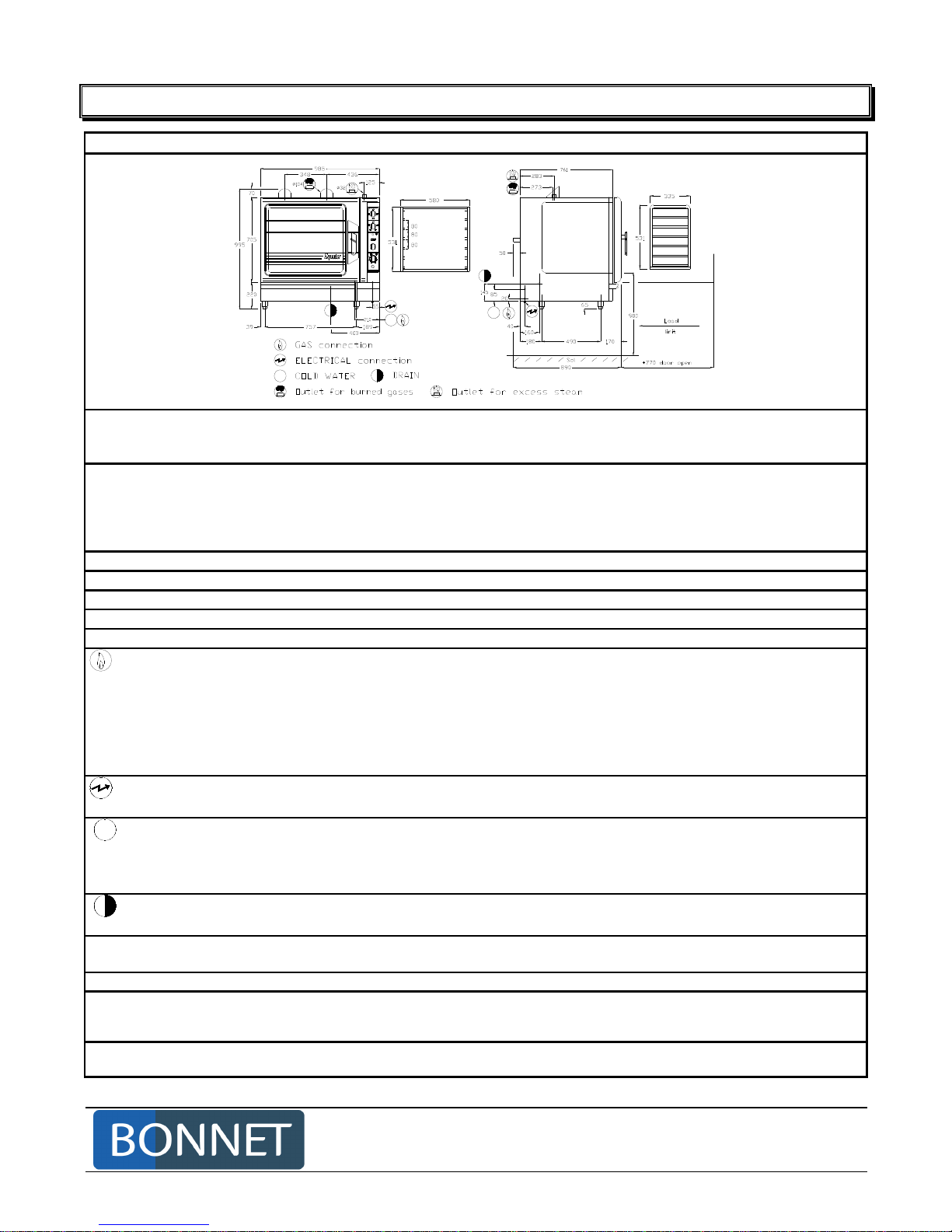

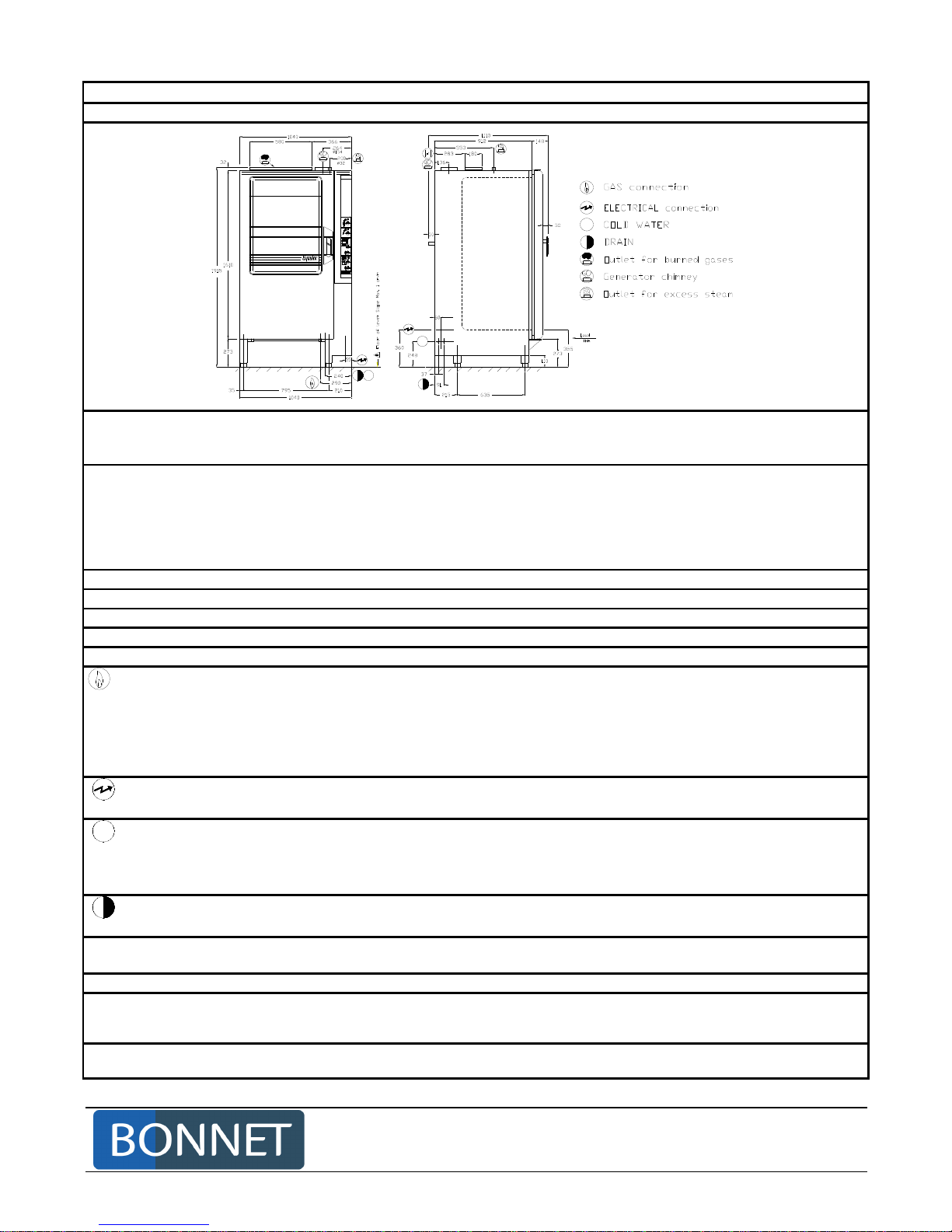

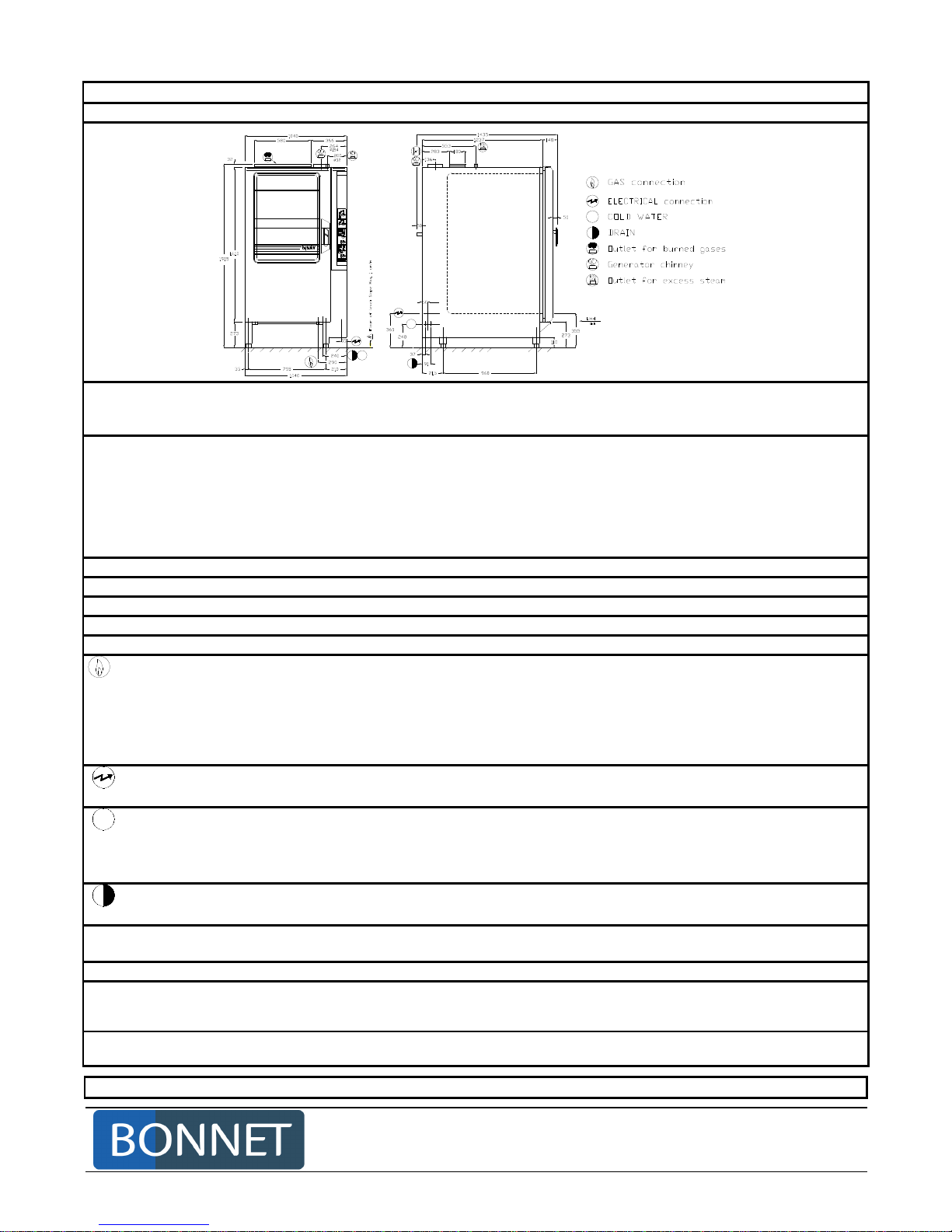

Bonnet EQUAJET User manual

Bonnet

Bonnet MINIJET B1MJ061E User manual

Bonnet

Bonnet Equator 6 Series User manual

Bonnet

Bonnet MINIJET ELECTRIC User manual

Bonnet

Bonnet PRECISIO User manual

Bonnet

Bonnet EQUATOR User manual

Bonnet

Bonnet EQUAJET User manual