Boonton Electronics 71A, 71AR User manual

OPERATING INSTRUCTIONS

MODELS

71A & 71AR

capacitance/Inductance

Meter

•

o

~

co

....

...

FINE

...

...•.

C

~

AOJ

@)

TEL:

201-887-5110

TWX:

710-986-8241

BOONTONIIII

ROUTE

287

AT

SMITH

ROAD

!=~~~~'!~~~~

PARSIPPANY,

N.

J.-

07054

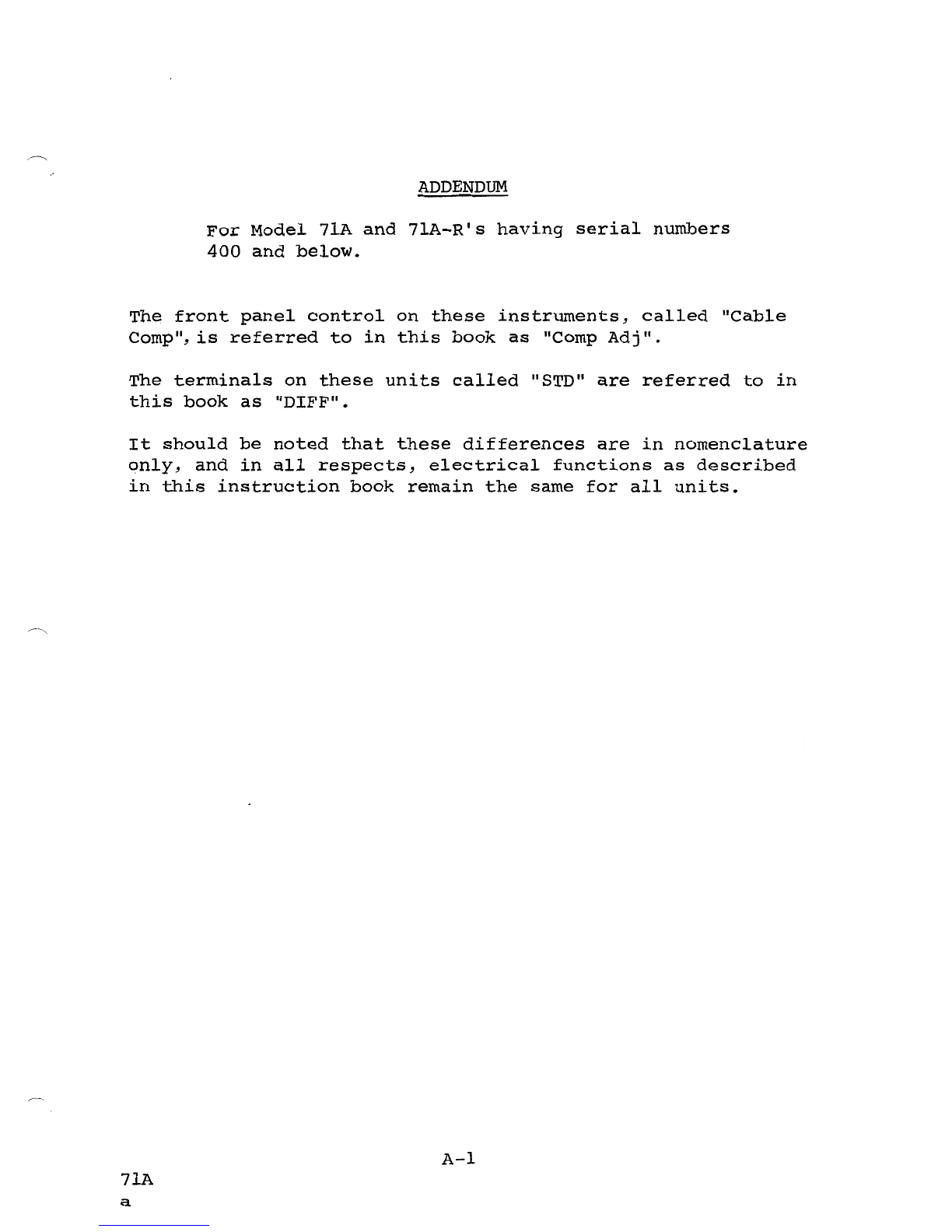

ADDENDUM

For

Model

7lA

and

7lA-R

' s

having

serial

numbers

400

and

below.

The

front

panel

control

on

these

instruments,

called

"Cable

Comp",

is

referred

to

in

this

book

as

"Comp

Adj".

The

terminals

on

these

units

called

"STD"

are

referred

to

in

this

book

as

"DIFF".

It

should

be

noted

that

these

differences

are

in

nomenclature

only,

and

in

all

respects,

electrical

functions

as

described

in

this

instruction

book

remain

the

same

for

all

units.

A-I

71A

a

Table

of

Contents

Page

1-1

Section

I

Specifications

Section

II

General

Description

2-1

2.1

General

Description~

Model

71A

2-1

2.2

General

Description~

Model

71AR

2-1

2.3

Location

of

controls

and

Adjustments~

Model

71A

2-2

2.4

Location

of

Controls

and

Adjustments~

Model

7lAR

2-3

2.5

Explanation

of

Controls

and

Adjustments

2-4

Section

III

Operating

Instructions

3-1

3.1

Initital

Installation

3-1

3.2

Capacitance

Measurements

3-3

3.3

Local

Capacitance

Measurements

3-3

3.4

Remote

Capacitance

Measurements

3-6

3.5

Increasing

Capacitance

Measuring

Range

3-10

3.6

Differential

Capacitance

Measurements

3-10

3.7

Extending

the

Range

of

the

C ZER0

Control

3-11

3.8

DC

Bias

for

Capacitance

Tests

3-11

3.9

Capacitance

Test

Signal

3-12

3.10

Capacitance

Calibration

Procedures

3-12

3.11

Inductance

Measurements

3-17

3.12

Connection

for

Inductance

Measurements

3-17

3.13

lnductance

Zero

Check

3-17

3.14

DC

output

3-18

3.15

IlMETER-OFp

lI

Switch

3-19

List

of

Replaceable

Parts

Following

Section

III

Schematics

Endfold

List

of

Figures

Figure

2-1

Location

of

Controls

and

Adjustments,

Model

71A

2-2

Figure

2-2_

Location

of

controls

and

Adjustments,

Model

7lAR

2-3

Figure

3-1

Correction

for

Series

Inductance

of

Connecting

Cables

3-9

71A

i

Table

of

Contents

(cont'd)

Figure

3-2

Circuit

for

Applying

High

Voltage

DC

Bias

to

Capacitance

Specimens

3-13

Figure

3-3

Connection

Errors

for

Inductance

Measurements

at

1

MHz

3-20

ii

71A.

b

SECTION I

Specifications

C~acitance

Measurements

{Three-terminal}

Range:

0

-to

1000

pF

in

7

Ranges;

lowest

range,

1

pF,

fs

Accuracy:

0.5%

of

reading

+

(0.5%

+

~

%)

fs

+

0.01

pF

Resolution:

0.25%

Inductance

Measurements

{Two-terminal}

Range:

0

to

1000

~H

in

7

ranges;

lowest

range,

1

~H

fs

L *

Accuracy:

0.5%

of

reading

+

(0.5%

+

~

% +

5b~lo)

fs

+

0.01

~H

( *

Where

L~H

=

Inductance

of

the

test

specimen)

Resolution:

0.25%

Test

Signal

Freguency:

1

MHz~

crystal

controlled

.

Level:

Capacitance

measurements,

15

mV;

Inductance

measurements,

less

than

1

mV

DC

Bias

(For

Capacitance

Measurements

Only)

External

bias

up

to

+200

V @

250

rnA

may

be

applied

at

rear

terminals;

bias

circuit

protected

from

overload

by

250

rnA

fuse

DC

Analog

Output

Level:

0

to

100

mV

or

0

to

300

mV

depending

on

full

scale

numerics;

also

:> 1 V

fs

for

loads

:>

10

MO

Linearity:

0.1%

of

reading

+

0.005%

fs

Response

Time:

10

milliseconds

(approx)

Primary

Power

117

or

234

V

(+10%),

50/60

cps:

40

watts

Physical

Dimensions

Model

7lA:

7

1/4/1

w x

10

1/4/1

d

xlI"

h;

weight

12

Ibs;

packed

for

shipment,

16

Ibs.

Model

71AR:

7"

x

19"

(panel

size);

depth

in

rack,

9";

weight,

14

Ibs;

packed

for

shipment,

21

lbs.

1-1

7lA

c

SECTION

II

General

Description

2.1

Model

7~

The

Model

71A

provides

instant,

direct-reading,

three-terminal

capacitance

measurements

and

two-terminal

inductance

measure-

ments

at

1 MHz.

The

measuring

capabilities

of

0

to

1000

pF

and

0

to

1000

~

are

each

covered

in

7

ranges

in

a

1-3-10

sequence.

The

internally

supplied

1

MHz

test

signal

is

crystal

controlled.

The

instrument

operates

with

low

test

levels

as

required

for

many

semiconductor

measurements.

Terminals

at

a

rear

panel

permit

application

on.

an

externally

supplied

dc

bias

up

to

±200

volts

to

the

test

specimen

on

capacitance

measurements

only.

Bias

cannot

be

provided

for

inductance

measurements.

A

linear

dc

output

is

available

at

rear

panel

terminals

which

is

proportional

to

the

meter

reading.

This

output

extends

the

range

of

application

beyond

laboratory

measurements

to

include

production

testing

as

well

as

a

variety

of

control

functions.

2.2

Model

7lAR

The

Model

7lAR

provides

the

performance

characteristics

of

the

Model

7lA

in

rack-mounting

form.

In

every

respect

its

electrical

specifications

are

identical

to

those

of

the

bench

unit.

In

addition,

the

Model

7l-lA

Standard

Capacitor

is

incorporated

in

the

Model

7lAR

and

is

switched

into

service

by

a

front

panel

selector.

** *

For

the

location

and

explanation

of

all

controls

and

adjust-

ments

of

the

Models

71A

and

71AR,

see

pages

2-2

through

2-7.

2-1

7lA

c

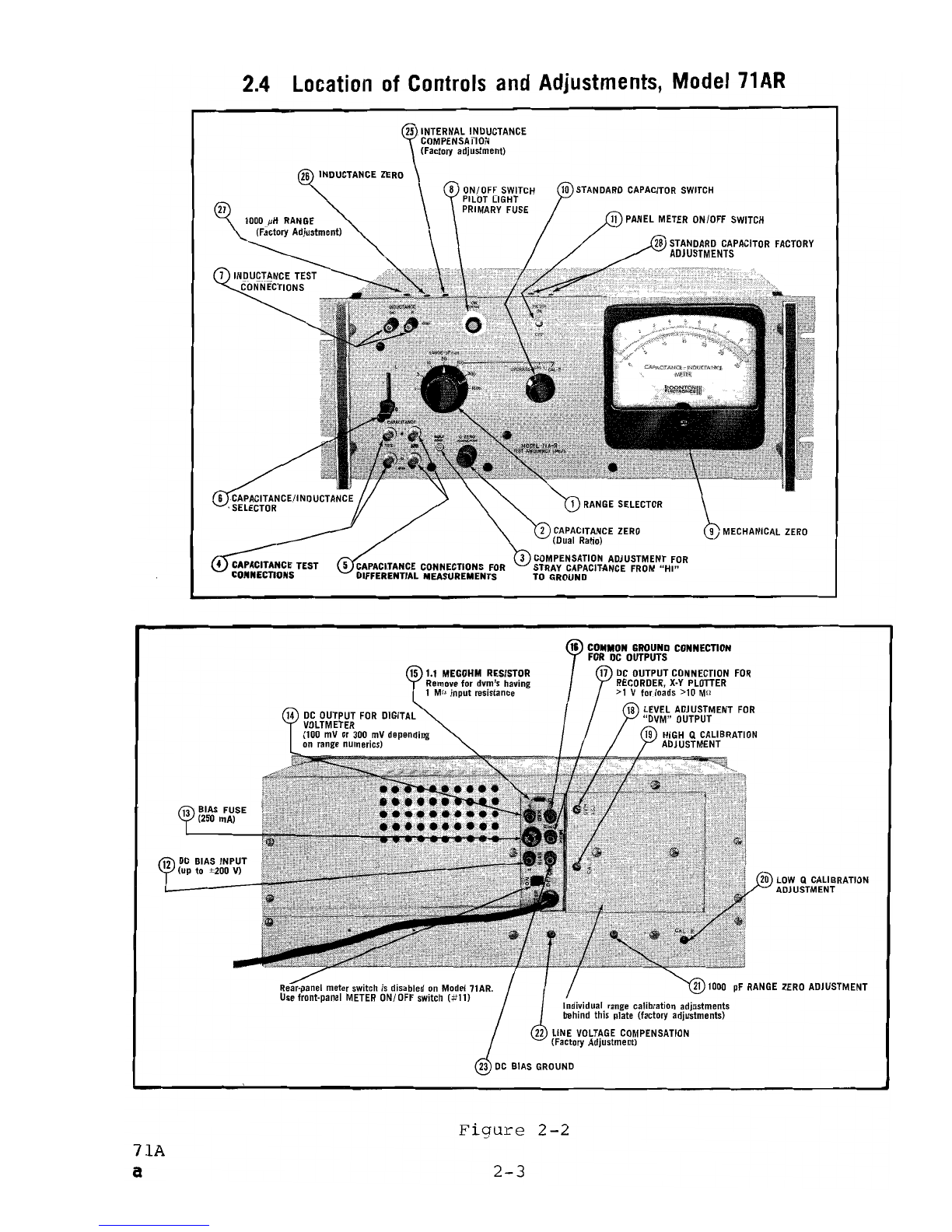

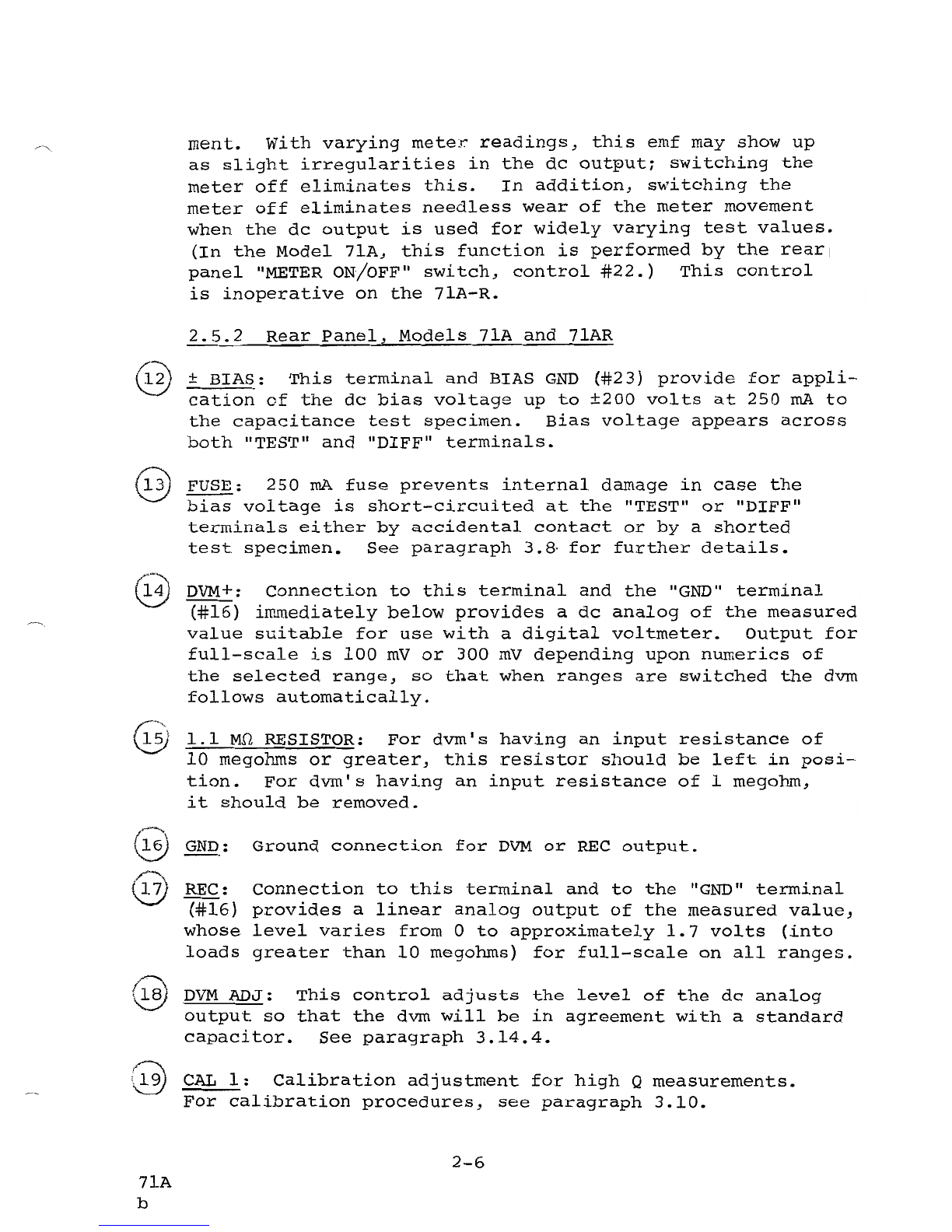

2.4

Location

of

Controls

and

Adjustments,

Model

71

AR

26

INDUCTANCE

ZERO

STANDARD

CAPACITOR

SWITCH

27

15

t.l

MEGOHM

RESISTOR

Remove

for

dvm's

having

1 Ma

input

resistance

DC

OUTPUT

FOR

DIGITAL

VOLTMETER

(100

mV

or

300

mV

depending

on

range

numerics)

12

DC

BIAS

INPUT

(up to ±200 V)

COMMON

GROUND

CONNECTION

FOR

DC

OUTPUTS

17

DC

OUTPUT

CONNECTION

FOR

RECORDER,

X·Y

PLOTTER

>1

V fnrJnads >10 M!l

LEVEL

ADJUSTMENT

FOR

"DVM"

OUTPUT

19

HIGH

Q

CALIBRATION

ADJUSTMENT

LOW

Q

CALIBRATION

ADJUSTMENT

21

lODD

pF

RANGE

ZERO

ADJUSTMENT

Individual

range

calibration

adjustments

behind this plate (factory adjustments)

LINE

VOLTAGE

COMPENSATION

(Factory Adjustment)

Figure

2-2

71A

a

2-3

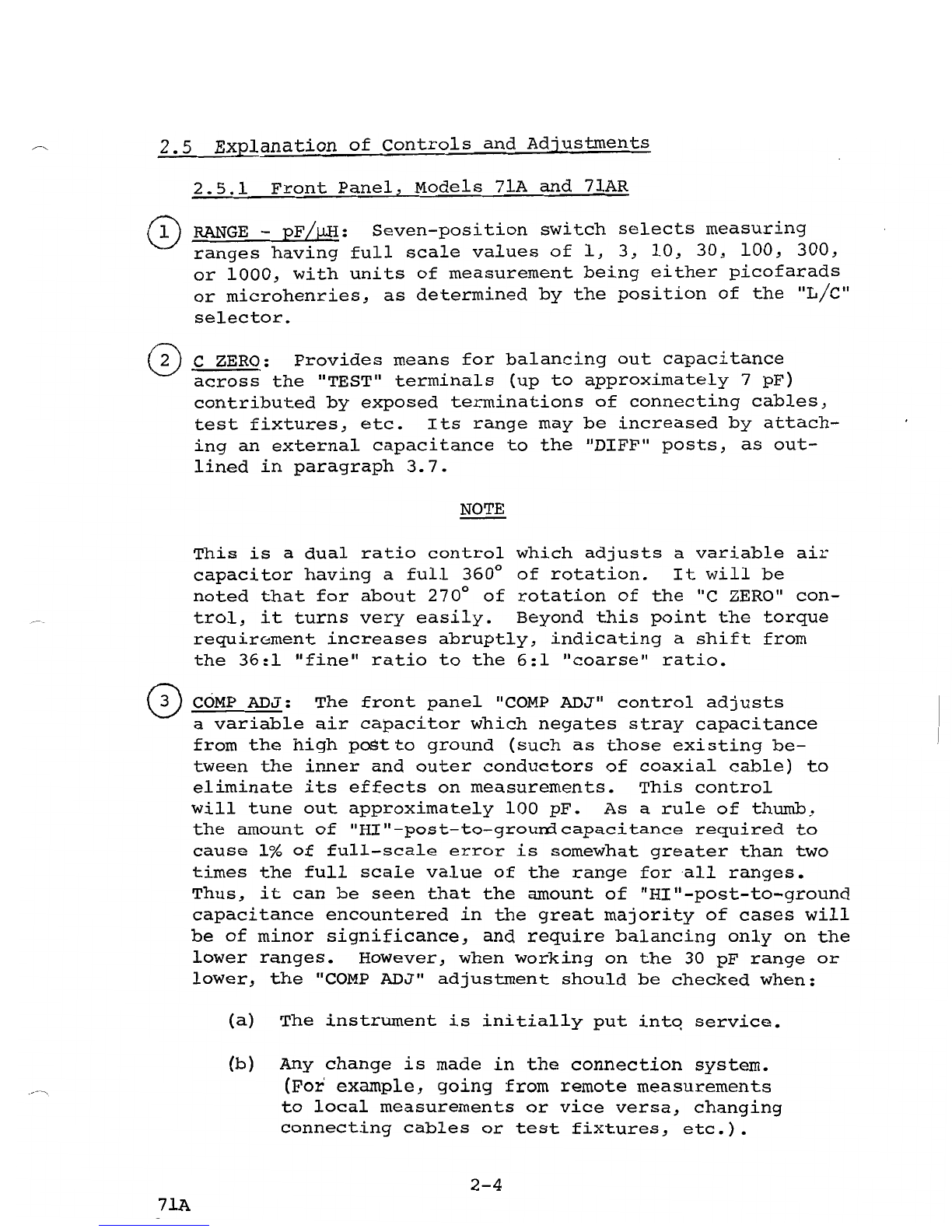

2.5

Explanation

of

Controls

and

Adjustments

2.5.1

Front

Panel,

Models

7lA

and

71AR

RANGE

-

pF!~:

Seven-position

switch

selects

measuring

ranges

having

full

scale

values

of

1,

3,

10,

30,

100,

300,

or

1000,

with

units

of

measurement

being

either

picofarads

or

microhenries,

as

determined

by

the

position

of

the

"L/C"

selector.

C ZERO:

Provides

means

for

balancing

out

capacitance

across

the

"TEST"

terminals

(up

to

approximately

7

pF)

contributed

by

exposed

terminations

of

connecting

cables,

test

fixtures,

etc.

Its

range

may

be

increased

by

attach-

ing

an

external

capacitance

to

the

"DIFF"

posts,

as

out-

lined

in

paragraph

3.7.

NOTE

This

is

a

dual

ratio

control

which

adjusts

a

variable

air

capacitor

having

a

full

360

0

of

rotation.

It

will

be

noted

that

for

about

270

0

of

rotation

of

the

"c

ZERO"

con-

trol,

it

turns

very

easily.

Beyond

this

point

the

torque

requirGment

increases

abruptly,

indicating

a

shift

from

the

36:1

"fine"

ratio

to

the

6:1

"coarse"

ratio.

COMP

ADJ:

The

front

panel

"COMP

ADJ"

control

adjusts

a

variable

air

capacitor

which

negates

stray

capacitance

from

the

high

postto

ground

(such

as

those

existing

be-

tween

the

inner

and

outer

conductors

of

coaxial

cable)

to

eliminate

its

effects

on

measurements.

This

control

will

tune

out

approximately

100

pF.

As

a

rule

of

thumb,

the

amount

of

"HI"-post-to-grourrlcapacitance

required

to

cause

1%

of

full-scale

error

is

somewhat

greater

than

two

times

the

full

scale

value

of

the

range

for

all

ranges.

Thus,

it

can

be

seen

that

the

amount

of

"HI"-post-to-ground

capacitance

encountered

in

the

great

majority

of

cases

will

be

of

minor

significance,

and

require

balancing

only

on

the

lower

ranges.

However,

when

working

on

the

30

pF

range

or

lower,

the

"COMP

ADJ"

adjustment

should

be

checked

when:

(a)

The

instrument

is

initially

put

intq

service.

(b)

Any

change

is

made

in

the

connection

system.

(For

example,

going

from

remote

measurements

to

local

measurements

or

vice

versa,

changing

connecting

cables

or

test

fixtures,

etc.).

2-4

7lA

(c)

-Measuring

a

standard

capacitor.

(d)

Testing

a

specimen

having

markedly

different

"HI"-to-ground

capacitance

than

those

tested

previously

with

a

given

connection

system

(as

caused

by

considerable

differences

in

internal

construction,

encasing,

or

terminations).

~

CAPACITANCE

TEST:

BNC

connectors

for

the

test

specimen.

Measurements

may

be

made

either

locally

or

remotely

by

means

of

coaxial

cables.

CAPACITANCE

DIFF:

A

given

capacitance

connected

to

the

"TEST"

terminals

produces

an

accurately

calibrated

up-scale

reading.

Attaching

the

same

capacitance

to

the

"DIFF"

post

causes

a

comparable

down-scale

reading.

These

connections

are

useful

for

such

functions

as

making

differential

capaci-

tance

measurements,

extending

the

measuring

range

upwards,

or

extending

the

range

of

the

"c

ZERO"

control.

There

are

certain

limitations

on

the

use

of

the

"DIFF"

posts

which

are

detailed

in

paragraphs

3.5, 3.6,

and

3.7.

~

L/c:

This

switch

selects

a

condition

for

measurement

of

either

inductance

or

capacitance.

INDUCTANCE:

Test

terminals

for

inductance

measurements.

Measurements

should

be

made

directly

at

the

terminals.

Use

of

even

short

test

leads

should

be

avoided,

if

possible.

<:~

ON

(PUSH):

The

main

power

switch

(push

for

on,

pull

for

.

off)

i

the

translucent

red

button

serves

as

the

pilot

light.

This

assembly

also

contains

the

primary

power

fuse,

which

may

be

removed

by

rotating

the

black

ring

counterclockwise

and

withdrawing

the

fuse

holder.

~

MECHANICAL

ZERO:

This

adjusts

the

meter

pointer

to

a

mechanical

zero.

It

should

be

checked

with

the

instrument

switched

off.

I

I

@ OPERATE/CAL

l/CAL

2

(Model

7lAR

only):

For

measuring,

th~s

selector

is

left

in

the

lIOPERATElI

position.

Set

the

"CAL

1"

and

"CAL

2",

it

switches

in

the

internal

100

pF

standard

capacitor

for

high-Q

and

low-Q

calibration

checks,

respec~ively.

(See

paragraph

3.10.4.)

METER

ON/OFF

(Model

71AR

only):

There

is

no

interaction

between

the

indicating

meter

and

the

dc

output

except

for

a

small

counter-emf

from

the

moving

coil

of

the

meter

move-

2-5

7lA

mente

with

varying

meter

readings,

this

emf

may

show

up

as

slight

irregularities

in

the

dc

output:

switching

the

meter

off

eliminates

this.

In

addition,

switching

the

meter

off

eliminates

needless

wear

of

the

meter

movement

when

the

dc

output

is

used

for

widely

varying

test

values.

(In

the

Model

71A,

this

function

is

performed

by

the

rear!

panel

"METER

ON/OFF"

switch,

control

#22.)

This

control

is

inoperative

on

the

71A-R.

2.5.2

Rear

Panel,

Models

71A

and

71AR

±

BIAS:

This

terminal

and

BIAS

GND

(#23)

provide

for

appli-

cation

of

the

dc

bias

voltage

up

to

±200

volts

at

250

rnA

to

the

capacitance

test

specimen.

Bias

voltage

appears

across

both

"TEST"

and

"DIFF"

terminals.

FUSE:

250

rnA

fuse

prevents

internal

damage

in

case

the

bias

voltage

is

short-circuited

at

the

"TEST"

or

"DIFF"

terminals

either

by

accidental

contact

or

by

a

shorted

test

specimen.

See

paragraph

3.8·

for

further

details.

®

DVM+:

Connection

to

this

terminal

and

the

"GND"

terminal

(#16)

irrmediately

below

provides

a

dc

analog

of

the

measured

value

suitable

for

use

with

a

digital

voltmeter.

Output

for

full-scale

is

100

mV

or

300

mV

depending

upon

numerics

of

the

selected

range,

so

that

when

ranges

are

switched

the

dvm

follows

automatically.

~

1.1

Mn

RESISTOR:

For

dvm's

having

an

input

resistance

of

10

megohms

or

greater,

this

resistor

should

be

left

in

posi-

tion.

For

dvm's

having

an

input

resistance

of

1

megohm,

it

should

be

removed.

GND:

Ground

connection

for

DVM

or

REC

output.

REC:

connection

to

this

terminal

and

to

the

"GOO"

terminal

(#16)

provides

a

linear

analog

output

of

the

measured

value,

whose

level

varies

from

0

to

approximately

1.7

volts

(into

loads

greater

than

10

megohms)

for

full-scale

on

all

ranges.

DVM

ADJ:

This

control

adjusts

the

level

of

the

de

analog

output

so

that

the

dvm

will

be

in

agreement

with

a

standard

capacitor.

See

paragraph

3.14.4.

CAL

1:

Calibration

adjustment

for

high

Q

measurements.

For

calibration

procedures,

see

paragraph

3.10.

2-6

71A

b

CAL

2:

Calibration

adjustment

for

low

Q

measurements.

For

calibration

procedures,

see

paragraph

3.10.

1000

pF

ZERO:

Zero

adjustment

for

1000

pF

range.

Once

set

on

initial

installation,

this

control

will

rarely

need

re-

adjustment.

However,

since

the

setting

of

this

control

is

vital

to

proper

operation

for

either

capacitance

or

induc-

tance

measurements,

it

is

recommended

that

it

be

checked

periodically.

(See

paragraph

3.1.4,

(f)

&

(g)

for

procedure.)

Line

Voltage

Compensation:

Factory

adjustment

to

assure

insensitivity

to

line

voltage

changes

from

105

to

125

V,

ac.

GND:

Ground

connection

for

dc

bias

input.

METER

ON/OFF,

Model

71A

only):

There

is

no

interaction

between

the

indicating

meter

and

the

dc

output

except

for

a

small

counter-emf

from

the

moving

coil

of

the

meter

move-

ment.

With

varying

meter

readings,

this

emf

may

show

up

as

slight

irregularities

in

the

dc

output~

switching

the

meter

off

eliminates

this.

NOTE:

In

the

Model

71A.R

this

function

is

performed

by

front

panel

switch

#11.

While

this

swi~ch

is

present

at

the

rear

of

the

Model

71AR,

it

is

disabled.

2.5.3

Model

7lA

z

Left

side~

Model

7lAR,

Top

INTERNAL

INDUCTANCE

COMPENSATION:

This

factory

adjustment

compensates

for

inductance

of

internal

wiring.

Pre-set

at

the

factory,

this

control

does

not

require

readjustment.

L ZERO:

This

control

provides

a

means

for

zeroing

the

in-

strument

on

the

1

~H

range

in

accordance

with

the

procedure

outlined

in

paragraph

3.13.

1000

WH

CALIBRATION:

This

control

provides

means

for

in-

dividually

calibrating

the

1000

~

range~

it

is

pre-set

at

the

factory

and

does

not

require

readjustment.

Adjustments

for

the

internal

100

pF

standard

capacitor.

These

are

set

at

the

factory

and

do

not

require

readjustment.

2-7

7lA

b

L SECTION

III

Operating

Instructions

3.1

Initial

Installation

3.1.1

Unpacking

On

unpacking~

inspect

the

instrument

for

possible

damage

in

transit.

If

the

instrument

is

damaged~

contact

your

local

Sales

Engineering

Representative

or

the

factory

(see

title

page

for

factory

address)

for

further

instructions.

If

no

damage

is

found~

the

instrument

may

be

put

into

service

by

the

following

procedure:

3.1.2

Mechanical

Zero

Adjustment

with

the

instrument

unpowered

and

in

a

normal

operating

position~

check

to

see

that

the

indicator

needle

rests

at

zero.

If

not~

set

to

zero

by

adjusting

the

mechanical

zero

control

on

the

meter

housing.

3.1.3

Turn-on

Procedure

and

Warm-up

Plug

the

instrument

into

a

source

of

117

V (±10%)

50/60

HZ

power

and

push

the

front

panel

ON

button.

(Note:

The

translucent

red

center

button

of

the

ON

switch

also

serves

as

the

pilot

light.

This

switch

is

turned

off

by

pulling

the

outer

black

disk

outward.

It

should

be

noted

that

this

switch

also

serves

as

the

fuse

holder.

(To

remove

the

fuse~

turn

the

switch

off~

twist

the

black

ring

counterclockwise~

and

withdraw

the

assembly.)

The

instrume~t

may

be

operated

approximately

30

seconds

after

turn-on.

However~

for

maxi-

mum

accuracy~

a

warm-up

of

approximately

a

half-hour

should

be

allowed.

3.1.4

Initial

Installation

Checks

and

Adjustments

3.1.4.1

General

Before

the

instrument

is

put

into

service,

there

are

several

initial

checks

which

should

be

made~

and~

if

necessary,

adjustments

perfor.med:

3.1.4.2

(a)

Allow

an

initial

warm-up

of

a

half

hour.

(b)

Set

the

Llc

selector

to

C.

3-1

71A

c

(c)

With

the

instrument

on

the

1

pF

range~

and

no

specimen

connected

to

the

"TEST"

terminals,

set

the

indicator

to

about

75%

of

full

scale

using

the

front

panel

"c

ZERO"

control.

(d)

Adjust

the

front

panel

"COMP

ADJ"

control

for

a

peak

reading.

(Readjust

the

"c

ZERO"

control

to

keep

indications

on-scale

if

necessary)

.

(e)

Having

achieved

a

peak

reading~

return

the

indicator

to

zero

using

the

"c

ZERO"

control.

(f)

Switch

to

the

1000

pF

range~

and

observe

the

zero

position

of

the

indicator.

If

required~

set

to

zero

using

the

"1000

pF

ZERO"

at

the

rear

panel.

(g)

Switch

one

range

at

a

time

back

to

the

1

pF

range,

observing

the

zero

position

of

the

indicator

for

each

range.

If

the

zero

posi-

tion

shifts

appreciably

for

any

range,

re-

peat

steps

(c)

through

(g).

When

properly

adjusted,

the

zero

position

should

be

con-

stant

for

all

ranges.

NOTE

Once

properly

set,

the

"1000

pF

ZERO"

rarely

needs

readjustment.

However~

since

its

set-

ting

is

essential

to

the

proper

operation

of

the

instrument

for

either

capacitance

or

inductance

measurement,

it

is

advisable

to

check

it~

following

steps

(f)

and

(g)

above,

at

fairly

frequent

intervals.

(h)

Stretch

a

short

length

of

#22

copper

wire

between

the

"INDUCTANCE"

terminals.

(j)

Switch

the

"L/C"

switch

to

the

"L"

posi-

tion.

The

indicator

should

rest

one

minor

division

up-scale

from

zero.

If

not~

ad-

just

for

this

reading

using

the

"L

ZERO"

control

(the

center

adjustment

on

the

left

side

of

the

instrument).

3-2

71A

d

3.2

capacitance

Measurements

With

the

front

panel

IIL-C

II

selector

in

the

"C

II

position~

the

Models

71A

and

71AR

measure

the

"direct"

capacitance

of

the

test

specimen.

(The

instruments

ignore

stray

capacitance

from

the

"LO"

post

to

ground.

Up

to

about

100

pF

of

capaci-

tance

from

the

"HI"

post

to

ground

can

be

nulled

by

adjust-

ment

of

the

"COMP

ADJ"

control.

As

a

result~

the

Models

71A

and

71AR

measure

only

the

capacitance

appearing

between

the

"HI"

and

"LO"

terminals.)

The

measurements

may

be

made

either

at

the

"TEST"

terminals

or

remotely

by

connecting

the

specimen

or

test

fixture

via

'

coaxial

cables

to

the

"TEST"

terminals.

By

use

of

both

the

"DIFF"

and

"TEST"

terminals

differential

capacitance

measure-

ments

may

be

made

within

certain

limitations.

3.3

Local

Capacitance

Measurements

3.3.1

Connections

for

Local

Measurements

While

the

capacitance

connectors

of

the

Models

7lA

and

7lAR

are

intended

primarily

for

attachment

of

coaxial

cables~

tests

may

readily

be

made

locally

by

connecting

the

speci-

men

directly

to

the

te~inals.

A

pair

of

Type

UG-1090/U

or

comparable

BNC-to-binding-post

adapters

are

particularly

convenient

for

this

purpose~

although

for

quick

measurements

the

leads

of

the

component

may

be

simply

inserted

in

the

center

receptables

of

the

BNC

terminals.

NOTE

If

any

length

of

coaxial

cables

is

used

for

connection~

even

if

they

are

only

a

few

inches

in

length~

the

measurement

is

considered

not

local~

but

is

remote

and

the

instructions

of

paragraph

3.4

apply.

3.3.2

Checks

and

Adjustment

Prior

to

Making

Local

Measurements

There

are

three

controls

whose

adjustment

should

be

checked

before

measuring

at

the

terminals

of

the

Model

71A

or

71AR:

(a)

"1000

pF

ZERO"

(b)

"COMP

ADJ

II

(c )

"C

ZERO"

3-3

71A

d

3.3.2.1

111000

pF

ZERO"

Adjustment

The

111000

pF

ZERO"

control

is

located

at

the

rear

panel.

Its

setting

is

checked

by

switching

to

the

1000

pF

range

and,

with

no

specimen

attached

at

the

IITEST

If

terminals,

observing

the

rest

position

of

the

pointer.

If

it

does

not

read

zero,

follow

the

adjustment

procedure

outlined

in

paragraph

3.1.4,

(f)

and

(g).

3.3.2.2

IICOMP

ADJ

II

Peaking

Adjustment

Prior

to

measuring

at

the

IITEST

II

terminals,

the

IICOMP

ADJ"

peaking

adjustment

should

be

performed

as

follows:

(a)

Attach

any

terminal

adapters

or

connectors

to

be

used

for

subsequent

measurements

to

the

IITEST

II

terminals

and

set

the

"RANGE"

selector

to

the

1

pF

range.

(b)

Adjust

the

"c

ZERO"

control

for

a

reading

of

approximately

75%

of

full

scale.

(e)

Adjust

the

IICOMP

ADJ

II

control

for

a

maximum

reading.

(Readjust

the

"c

ZERO"

control

to

keep

deflections

on

scale

if

required.)

(d)

After

peaking,

zero

the

pointer

using

the

lie ZERO"

control.

Once

adjusted,

the

"COMP

ADJ

II

control

need

not

be

re-

adjusted

(although

periodic

checking

during

extended

periods

of

operation

is

advisable)

unless

some

change

in

either

the

method

of

connection

or

the

nature

of

the

test

samples

substantially

affects

the

stray

capacitance

from

the

"HI"

post

to

ground.

In

such

cases,

readjust-

ment

pf

the

"COMP

ADJ"

control

is

required.

The

above

"COMP

ADJ"

adjustment

procedure

will

suffice

for

the

majority

of

measurements

at

the

terminals

for

all

ranges.

However,

to

obtain

the

greatest

possible

accuracy

when

measuring

high

Q

(>10)

components

on

the

1,

3,

10

or

30

pF

range,

and

when

the

test

sample

has

significant

capacitance

from

the

IIHI JI

post

to

ground,

the

following

procedure

should

be

follows:

(a)

Attach

whatever

terminal

adapters

or

connectors

are

to

be

used

in

subsequent

measurements

to

the

"TEST"

posts

and

connect

a

specimen

typical·of

3-4

7lA

those

to

be

measured.

If

no

connectors

are

to

be

used,

insert

the

leads

of

the

specimen

in

the

center

conductors

of

the

"TEST"

posts.

(b)

Set

the

"RANGE"

selector

to

the

lowest

range

on

w.mch a

reading

of

approximately

75%

of

full

scale

is

possible.

(On

the

lower

ranges

the

"C ZERO"

control

may

be

of

help

in

obtaining

this

reading.)

(c)

Adjust

the

"COMP

ADJ"

for

peak

reading.

(Readjust

the

tIC

ZERO"

to

keep

deflections

on

scale

if

necessary.)

(d)

Disconnect

the

specimen

from

the

low

post,

leav-

ing

any

terminal

adapters

to

be

used

for

subse-

quent

tests

in

position;

zero

the

pointer

with

the

"c

ZERO"

control.

3.3.2.3

IIC ZERO"

Adjustment

The

front

panel

"c

ZERO"

adjustment

is

checked

by

switching

to

the

1

pF

range.

with

the

"COMP

ADJ"

control

properly

peaked

and

no

specimen

across

the

test

terminals,

observe

the

rest

position

of

the

pointer.

If

necessary,

the

pointer

should

be

brought

to

zero

using

the

front

panel

control.

Any

terminal

adapters

to

be

used

in

subsequent

measurements

should

be

left

installed

for

this

adjustment.

with

"100

pF

ZERO"

and

"c

ZERO"

controls

properly

set,

the

instrument

will

be

correctly

zeroed

for

all

ranges,

assuming

the

"COMP

ADJ"

control

is

properly

adjusted.

It

is

advisable

to

check

the

1

pF

zero

position

periodi-

cally

during

the

course

of

operation,

particularly

if

working

on

the

1

or

3

pF

ranges.

NOTE

The

front

panel

"c

ZERO"

control

is

a

dual

ratio

control

which

adjusts

a

variable

air

capacitor

having

a

full

360

0

of

rotation.

It

will

be

noted

that

the

"C

ZERO"

control

turns

very

easily

for

about

270

0

of

rotation.

At

this

point

the

torque

requirement

increases

abruptly,

indicating

a

shift

from

the

36:1

"fine"

adjustment

to

the

6:1

"coarse"

adjustment.

3-5

71A

3.4

Remote

Capacitance

Measurements

3.4.1

Connections

for

Remote

Measurements

A

test

specimen

or

a

test

fixture

m~cted

to

the

"TEST"

terminals

by

coaxial

cables.

RG-62

is

particularly

recommended

for

this

purpose

because

0

its

low

capacitance.

To

minimize

errors

in

measurement

resulting

from

the

series

inductance

of

the

coaxial

cable,

the

length

of

each

of

the

two

cables

should

be

less

than

approximately

5

feet

on

the

1,

3,

and

10

pF

ranges,

with

shorter

lengths

on

higher

ranges.

Figure

3-1,

which

indicates

correction

factors

for

cable

inductance,

may

be

used

as

a

guide

in

selecting

prac-

tical

cable

lengths.

3.4.2

Initial

Adjustment

for

Remote

Measurements

There

are

three

controls

whose

adjustment

should

be

checked

before

making

remote

measurements

with

this

instrument:

(a)

"1000

pF

ZERO"

(b)

"COMP

ADJ"

(c)

rIC ZERO"

3.4.2.1

"1000

pF

ZERO"

Adjustment

The

"1000

pF

ZERO"

control

is

located

at

the

rear

panel.

Its

setting

is

checked

by

switching

to

the

1000

pF

range

and,

with

no

specimen

attached

at

the

"TEST"

terminals,

observing

the

rest

position

of

the

pointer.

If

it

does

not

read

zero,

follow

the

adjustment

procedure

outlined

in

paragraph

3.1.4,

(f)

and

(g).

3.4.2.2

"COMP

ADJ"

Peaking

Adjustment

Prior

to

measuring

remotely,

the

"COMP

ADJ"

peaking

adjust-

ment

must

be

performed

as

follows:

(a)

Connect

the

coaxial

cables

and

test

fixture

(if

any)

to

be

used

in

subsequent

measurements

to

the

"TEST"

terminals.

Set

the

range

selector

to

the

1

pF

range.

(b)

Adjust

the

"e ZERO"

control

for

a

reading

of

approximately

75%

of

full

scale.

3-6

7lA

(c)

Adjust

the

"CaMP

ADJ"

control

for

a

maximum

reading.

(Readjust

the

"e

ZERO"

control

to

keep

deflections

on

scale

if

required).

(d)

After

peaking~

zero

the

pointer

using

the

"c

ZERO"

control.

Once

adjusted~

the

"CaMP

ADJ"

control

need

not

be

re-

adjusted

for

some

time

(although

periodic

checking

during

extended

periods

of

operation

is

advisable)

unless

some

change

in

either

the

connection

system

or

the

nature

of

the

test

samples

substantially

effects

the

stray

capacitance

from

the

"HI"

post

to

ground.

In

such

cases~

readjustment

of

the

"CaMP ADJ"

control

is

required.

The

above

"CaMP

ADJ"

adjustment

procedure

will

suffice

for

the

majority

of

remote

measurements.

However,

to

obtain

the

greatest

possible

accuracy

when

using

the

l~

3~

10

or

30

pF

range,

and

when

the

specimen

has

sig-

nificant

capacitance

from

the

"HI"

post

to

ground,

the

following

procedure

should

be

followed:

(a)

Attach

the

coaxial

cables

and

test

fixture

(if

any)

which

are

to

be

used

in

subsequent

measure

ments

to

the

"

..

TEST"

posts

and

connect

a

specimen

typical

of

those

to

be

measured.

(b)

Set

the

"RANGE"

selector

to

the

lowest

range

on

which~

using

the

"C ZERO"

control~

a

reading

of

approximately

75%

of

full

scale

is

possible.

(c)

Adjust

the

"CaMP

ADJ"

for

peak

reading.

(Re-

adjust

the

"c

ZERO"

to

keep

deflections

on

scale

if

necessary.)

(d)

Disconnect

the

cable

at

the

low

post

and

zero

the

pointer

with

the

lie

ZERO"

control

(see

paragraph

3.4.2.3

below).

3.4.2.3

"C

ZERO"

Adjustment

The

front

panel

"e

ZERO"

adjustment

is

checked

by

switch-

ing

to

the

1

pF

range.

with

the

"CaMP ADJ"

control

properly

peaked

and

no

specimen

across

the

test

terminals

observe

the

rest

position

of

the

pointer.

If

necessary,

the

pointer

should

be

brought

to

zero

using

the

front

panel

"e ZERO"

control.

(The

coaxial

cables

and

test

3-7

71A

fixture

to

be

used

in

subsequent

measurements

should

be

attached

for

this

adjustment.)

with

the

111000

pF

ZERO"

and

"c

ZERO"

controls

properly

set,

the

instrument

will

be

correctly

zeroed

for

.all

ranges,

assuming

the

"COMP

ADJ

II

control

is

properly

adjusted.

It

is

advisable

to

check

the

1

pF

zero

position

periodi-

cally

during

the

course

of

operation,

particularly

if

working

on

the

1

or

3

pF

ranges.

NOTE

The

front

panel

IIC

ZERO"

control

is

a

dual

ratio

control

which

adjusts

a

variable

air

capacitor

having

a

full

360

0

of

rotation.

It

will

be

noted

that

the

"C

ZERO

II

control

turns

very

easily

for

about

270

0

of

rotation.

At

this

point

the

torque

requirement

increases

abruptly,

indicating

a

shift

from

the

36:1

IIfine

ll

adjustment

to

the

6:1

"coarse"

adjustment.

If

it

is

found

that

the

"c

ZERO"

range

is

inadequate

to

zero

out

the

external

capacitance,

its

range

may

be

extended

as

outlined

in

paragraph

3.7.

3.4.3

Errors

in

Capacitance

Measurements

Resulting

from

Series

Inductance

of

Connecting

Cables.

The

measured

capacitance,

Cm,

of

a

specimen

may

differ

from

the

true

capacitance,

Ct,

as

a

result

of

the

series

inductance

of

connecting

cables,

and

the

inductance

of

the

specimen.

The

error

will

be

noted

as

an

apparent

increase

in

capaci-

tance

value

in

accordance

with

the

following

expression:

Where

L =

the

combined

series

inductance

in

micro-

henries

of

BOTH

lengths

of

connecting

coaxial

cable

and

the

inductance

of

the

sample

(generally

small

with

respect

to

the

cable

inductance).

The

correction

chart

of

Figure

3-1

indicates

typical

cor-

rections

to

be

subtracted

from

the

mea$ured

value

for

a

pair

of

l-foot

cables

of

RG-62/U

at

1

MHz

for

test

values

3-8

71A

d

Table of contents

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments CO260 user manual

PCB Piezotronics

PCB Piezotronics P357B03 Installation and operating manual

Saveometer

Saveometer 2652 user guide

Alpha Moisture Systems

Alpha Moisture Systems DS1200-PDT user manual

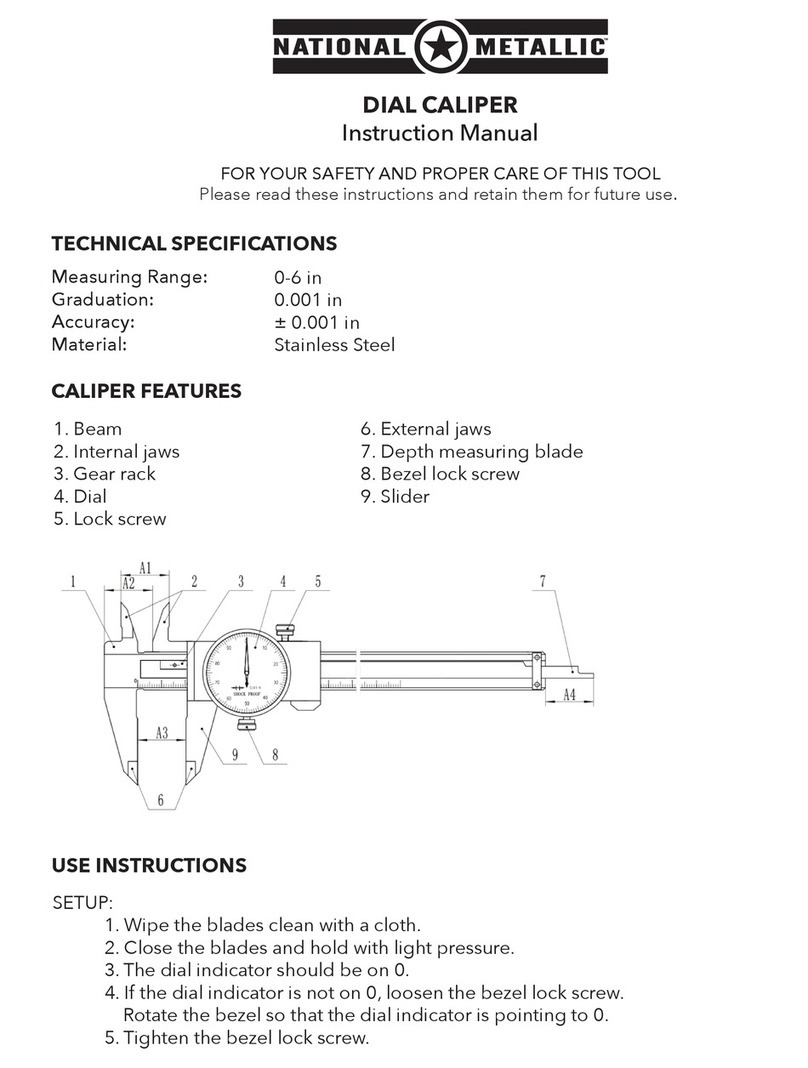

National Metallic

National Metallic DIAL CALIPER instruction manual

PT

PT PT200P Operator's manual