BOPP & REUTHER MESSTECHNIK FMD Series User manual

Bopp & Reuther

Messtechnik GmbH

Am Neuen Rheinhafen 4

67346 Speyer

Germany

Phone: +49 6232 657-0

Fax: +49 6232 657-505

www.bopp-reuther.de

A-EN-05809-00 Rev.A

11/2018

Page 1 of 20

Coriolis Dosing Mass Flow Meter Series FMD

Operating Manual

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 2 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

Table of Contents

Foreword ............................................................................................................................................................. 4

I. Transport, Delivery, Storage ............................................................................................................................ 4

II. Warranty ......................................................................................................................................................... 4

III. General Safety Instructions ........................................................................................................................... 4

1. Identification .................................................................................................................................................... 5

2. Area of Application .......................................................................................................................................... 5

3. Principle of Operation and System Design ..................................................................................................... 6

3.1 Measuring Principle .................................................................................................................................. 6

3.2 Design ....................................................................................................................................................... 7

4. Input ................................................................................................................................................................ 7

4.1 Measured Value ........................................................................................................................................ 7

4.2 Measurement Range ................................................................................................................................ 7

4.3 Status Signal ............................................................................................................................................. 8

5. Output ............................................................................................................................................................. 8

5.1 Output Signal ............................................................................................................................................ 8

6. Characteristic parameter ................................................................................................................................ 8

6.1 Reference conditions ................................................................................................................................ 8

6.2 Measurement error ................................................................................................................................... 9

6.3 Repeatability ............................................................................................................................................. 9

7. Operating Conditions ...................................................................................................................................... 9

7.1 Installation conditions ................................................................................................................................ 9

7.1.1 Installation instructions ....................................................................................................................... 9

7.1.1.1 General information .................................................................................................................. 10

7.1.1.2 Installation ................................................................................................................................. 10

7.2 Ambient Conditions ................................................................................................................................. 10

7.2.1. Ambient temperature ....................................................................................................................... 10

7.2.2 Storage temperature ........................................................................................................................ 11

7.2.3 Degree of protection ......................................................................................................................... 11

7.3 Process conditions .................................................................................................................................. 11

7.3.1 Media temperature ........................................................................................................................... 11

7.3.2 State of aggregation ......................................................................................................................... 11

7.3.3 Media pressure limit ......................................................................................................................... 11

7.3.4 Flow rate limit ................................................................................................................................... 11

7.3.5 Pressure Loss................................................................................................................................... 12

8. Construction details ...................................................................................................................................... 13

8.1 Design / Dimensions ............................................................................................................................... 13

8.2 Material ................................................................................................................................................... 14

8.3 Electrical Connection .............................................................................................................................. 14

9. Calculation pulse frequency ......................................................................................................................... 15

10. Certificates and approvals .......................................................................................................................... 16

Apppendix ......................................................................................................................................................... 17

A. Error diagnostics and fault rectification ........................................................................................................ 17

B. Maintenance, Cleaning ................................................................................................................................ 17

B.1 Maintenance, Cleaning .............................................................................................................................. 17

B.2 Repairs, hazardous materials ................................................................................................................. 18

C. Removal ....................................................................................................................................................... 18

D. Forms ........................................................................................................................................................... 19

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-EN-05809-00 Rev.A

Changes with reserve. Page 3 of 20

D.1 Declaration on contamination of products and components for contractor ........................................... 19

E. Certificates ................................................................................................................................................... 20

E.1EU - Declaration of conformity ........................................................................................................... 20

Operating manual Coriolis Dosing Mass Flow Meter, Series FMD

Page 4 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

Foreword

I. Transport, Delivery, Storage

Always protect devices against humidity, soiling, impacts and damages.

Delivery Inspection:

Check the delivery for completeness upon receipt. Compare the device data with the data on the delivery

note and in the order records.

Report any in-transit damage immediately. Damage reported at a later date shall not be recognized.

II. Warranty

Please refer the contractual terms and conditions relating to delivery for the scope and period of warranty.

Warranty claims shall be conditional to correct installation and commissioning in accordance with the

operating instructions of the device. The necessary installation, commissioning and maintenance work

should only be carried out by qualified and authorized personnel.

III. General Safety Instructions

1. Dosing flowmeters are reliable and high accurate measuring devices. They should only be used for

their intended purpose. Always observe the pressure and temperature limits stated on the type plate,

as well as all other technical data and safety information during device installation, start-up and

operation.

2. Always observe national and international regulations concerning the operation of devices and systems

under pressure.

3. Prior to installation, the operator has to ensure that the pressure bearing parts have not been damaged

during transportation.

4. The devices have to be installed, operated and serviced by qualified personnel. The operator has the

responsibility to ensure that the personnel have received sufficient and appropriate training. In cause of

doubt, please contact the manufacturer.

5. Only the measurement of liquids that provide for integrity of the materials used is allowed.

6. Symbols used

Warning!

Failure to observe this warning can lead to injury of persons or a security risk.

Attention:

Non-compliance can lead to faulty operation or damage to the device.

Operating manual Coriolis Dosing Mass Flow Meter, Series FMD

Page 5 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

1. Identification

Manufacturer: Bopp & Reuther Messtechnik GmbH

Am Neuen Rheinhafen 4

67346 Speyer

Phone: +49 6232 657-0

Fax: +49 6232 657-505

Product type: Direct mass flowmeter (Coriolis mass flowmeter)

Product name: FMD-Series Dosing Flowmeter

Version No. A-EN-05809-00Rev.A

2. Area of Application

The area of application of all the FMD dosing flowmeters is the measurement and the dosing of liquid

flows. They are used to dispense liquids with different properties. The focus is on the measurement

of non-conductive liquids with a low content of gas or solids. This equipment is also designed for the

purposes of measurement of oil, distilled water, or alkanes. As a result, they complete the range of

dosing flowmeters manufactured by Bopp & Reuther Messtechnik GmbH along with magnetic

inductive flowmeters and dosing oval gear flowmeters.

Due to the measuring principle, direct measurement of the mass of dosage is possible.

Coriolis Dosing Mass Flow Meter Series FMD provides the highest quality of dosing due to their

highly accurate measurement even at very short intervals of dosing.

The Series FMD is manufactured with nominal sizes DN10 and DN15. Depending on the type of

process connection, they can be used up to PN 40; the maximum operating temperature is 90 °C.

For cleaning and sterilization the devices can be subjected to SIP processes up to 140 °C.

As an accessory for the Coriolis Mass Flow Meter there is a compact controller with touch screen

and integrated PLC. So can be operated independently 4 dosing points.

With the help of such a compact controller, small filling and dosing systems can easily and

conveniently be put together.

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 6 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

3. Principle of Operation and System Design

3.1 Measuring Principle

Dosing flowmeters that use the Coriolis principle are classified as direct mass flowmeters. They

consist of two U-shaped measuring tubes, an actuator, and two sensors.

In operation, the two measuring tubes are stimulated to an antiphase oscillation. Without flow, both

sides of the measuring tubes vibrate equally and the sensors deliver in-phase signals.

When liquid flows through the measurement tubes, the inlet end of the tube decelerates and the

outlet end of the tube accelerates by the occurring Coriolis effect. As a result a phase difference in

the two sensor signals is generated, which is proportional to the mass flow.

Sensor signals without flow

Sensor signals with flow

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 7 of 20

3.2 Design

The Coriolis Dosing Mass Flow Meter Series FMD has a compact design and consists of the

following components:

Sensor:

The sensor consists essentially of two parallel measuring tubes. Sensors are mounted to these tubes

on the inlet side and the outlet side. Excitation leads to vibration of the measuring tubes. Additionally

a temperature sensor is installed. At the inlet and the outlet flow dividers are installed that distribute

the measured medium between the measuring tubes.

Transducer electronic:

The transducer electonic is connected to the sensor. The electronic receives the signals sent by the

sensor and calculates the measuring values. Pulses are generated in accordance with the flow and

sent to the control unit. The electronic expect a status signal of the control unit (see § 4.3).

4. Input

4.1 Measured Value

Mass flow

4.2 Measurement Range

Type Nominal

Diameter

Nominal Flow

[kg / min]

Pulse factor

[Imp/g]

FMD06 10 1 - 25 63,660

FMD08 15 2 - 45 28,293

The sensors are designed in such a way that at nominal flow (with water at 20 °C) a pressure drop of

approximately 1 bar occurs. The devices can easily be operated at higher flow rates. But it is

important to ensure that cavitation does not occur.

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 8 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

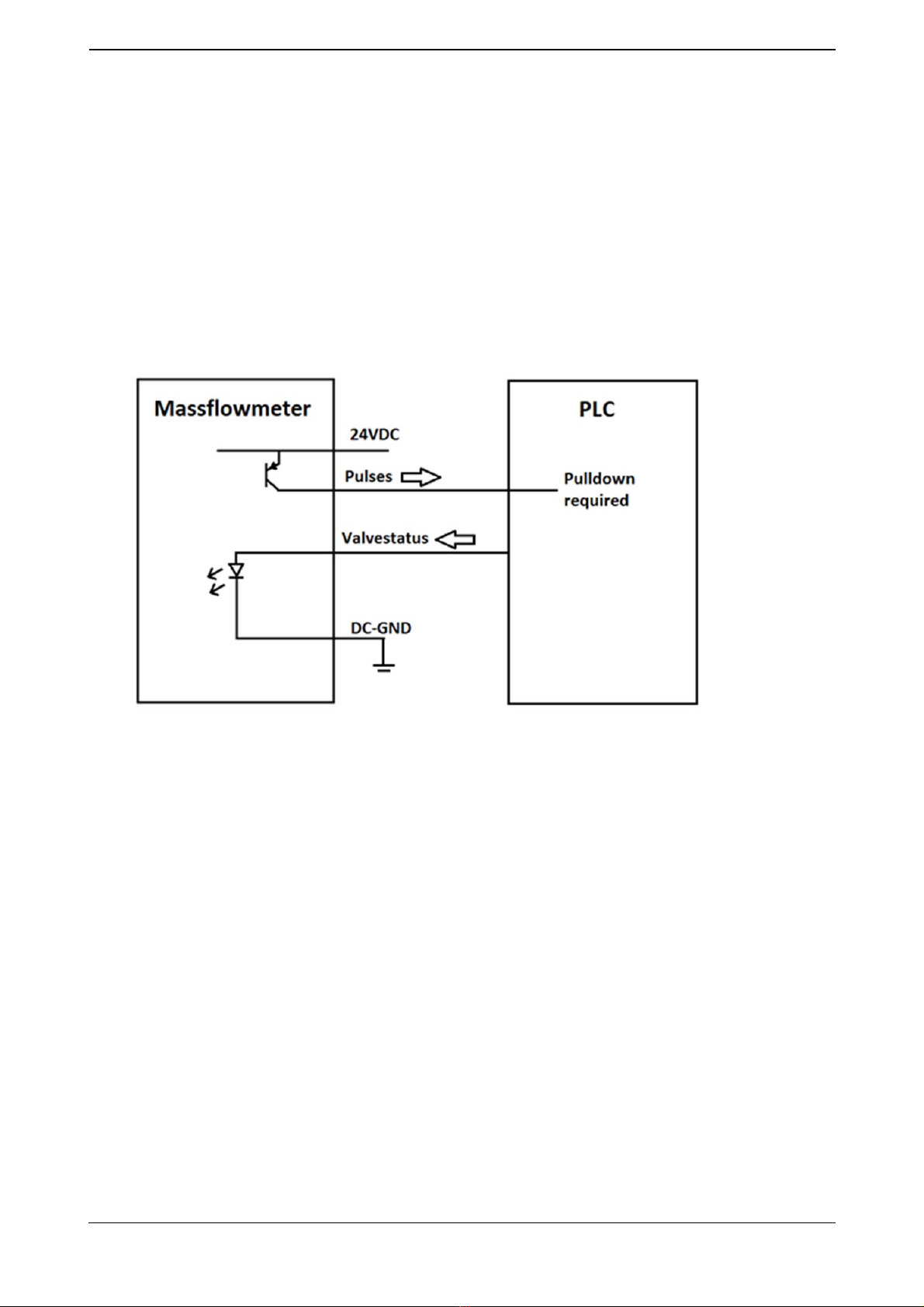

4.3 Status Signal

The dosing flowmeter requires a valve status signal from the control unit.

Pulses are generated only after the status signal is switched on/active. Even after the signal to close

the valve was given, pulses are generated until the flow completely stops. Pulses arriving after the

signal to close the valve are so-called overflow (trailing volume). This depends on the used valve and

can be accounted in the control unit to achieve precisely the required initial set.

5. Output

5.1 Output Signal

A pulse output is available for transmitting of the measured mass flow. The output pulses are active,

i.e., they don’t require an external power supply. Only an external pull-down resistor is necessary,

which, however, is already included in the input circuit of the majority of control units.

The pulse output Idle High.

The pulse-pause ratio is 1:1.

Pulse voltage corresponds to the supply voltage.

The maximum load of the output is 20 mA.

6. Characteristic parameter

6.1 Reference conditions

The dosing flowmeters are calibrated in accordance to the standard method of calibration with the

use of water.

Pressure: 1 bar, Temperature: 20-30 °C

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 9 of 20

6.2 Measurement error

The measuring accuracy was determined under reference conditions. Measuring times >= 10s.

±0.3% ±(0.01% * Nominal flow rate / instantaneous flow rate)

6.3 Repeatability

Repeatability as a function of dosing time

Dosing time [s] Standard deviation [%]

>5 0,05

>3 0,07

>1,5 0,1

>0,5 0,2

>0,25 0,5

7. Operating Conditions

7.1 Installation conditions

7.1.1 Installation instructions

Warning!

Before mounting and operating the device, carefully read and observe the installation

instructions.

Before mounting or assembling the device,

depressurize

and

cool down the

system

.

Error[%]

ErrorCurve

FlowRange[%]

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 10 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

7.1.1.1 General information

Only trained personnel who have been authorized by the system operator are allowed to perform

assembly, electrical installations, commissioning, maintenance and operation. You must have

read and understood the instructions and follow their instructions strictly.

The dosing flowmeters manufactured by Bopp & Reuter are precision mass flow meters and

require careful maintenance.

It is necessary to comply with the specified operating parameters, the order confirmation and the

configuration data sheet. If you want to use the device under differing operating conditions,

consult Bopp & Reuther Messtechnik GmbH indicating the factory number.

Installation of the dosing flowmeter must be implemented so that it is completely filled with liquid

even at rest.

To avoid measuring inaccuracies due to gas bubbles or contamination, preventive measures

must be taken.

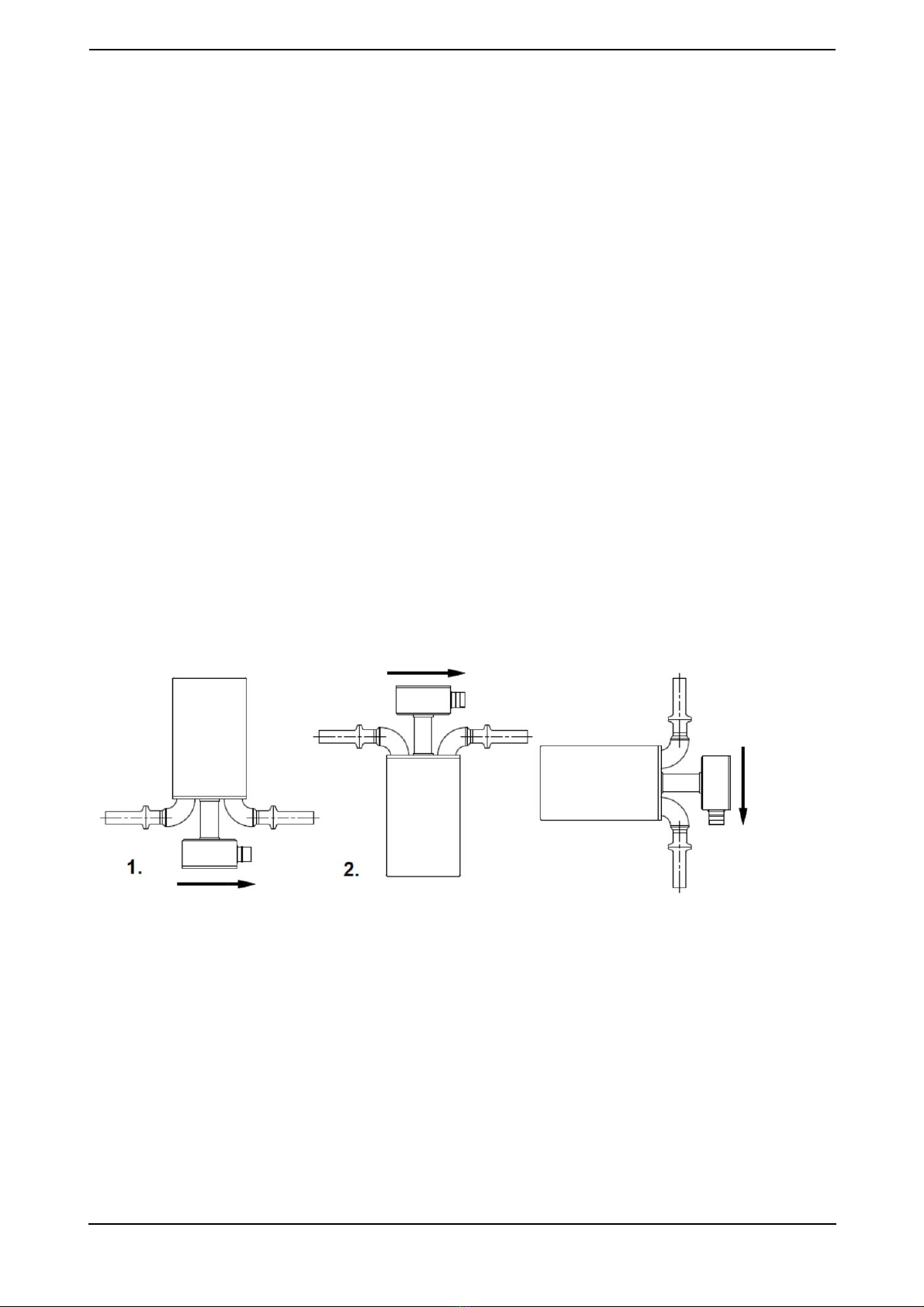

7.1.1.2 Installation

No inlet and outlet piping lines are required. The equipment must be installed in a way to prevent

accumulation of gases and solid particles inside.

1. For the liquids with solids of a greater density than the fluid, in a horizontal line.

2. For the liquids with gases or solids of a lower density than the fluid, in a horizontal line.

3. For all liquids in a vertical line.

The devices can be installed horizontally or vertically (see the drawing). It is necessary to ensure that

the measuring tubes are completely filled during operation. Vertical installation may require a cross-

sectional constriction in order to prevent spontaneous draining of the device during dosing.

7.2 Ambient Conditions

7.2.1. Ambient temperature

0 °C up to +50 °C

3.

Installation type 1 Installation type 2 Installation type 3

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 11 of 20

7.2.2 Storage temperature

-20 °C up to +70 °C (preferred temperature: 20 °C)

7.2.3 Degree of protection

IP67 IEC 529 / EN 60529

7.3 Process conditions

7.3.1 Media temperature

0 °C up to 90 °C

SIP up to 140 °C

7.3.2 State of aggregation

suitable for liquid media

7.3.3 Media pressure limit

depending on the process connections

7.3.4 Flow rate limit

FMD 06 FMD 08

25 kg / min 45 kg / min

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 12 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

7.3.5 Pressure Loss

1 bar at nominal water flow 20°C

PressureLoss

PressureLoss[mBar]

FlowRange[l/min]

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 13 of 20

8. Construction details

8.1 Design / Dimensions

G [mm] H, Height [mm] B, Width [mm] L, Length [mm]

FMD06 275 205 60

*

FMD08 320 240 60

*

*

Depends on the respective technological connection

DIN 32767 Tri-Clamp

L, Length [mm] Weight [kg]

FMD06 190 2

FMD08 220 3

DIN EN 1092 Flange

Length [mm] Weight [kg]

FMD06

FMD08 265 5.5

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 14 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

8.2 Material

Material / Material No. / ASTM

Sensor case X5CrNi18-10 / 1.4301 / 304

Measuring tube X6CrNiMoTi17-12-2 / 1.4571 / 316Ti

Flow divider X6CrNiMoTi17-12-2 / 1.4571 / 316Ti

Process connection X6CrNiMoTi17-12-2 / 1.4571 / 316Ti

Case of the transducer electronic AlMgSi1 / 3.2315 / -

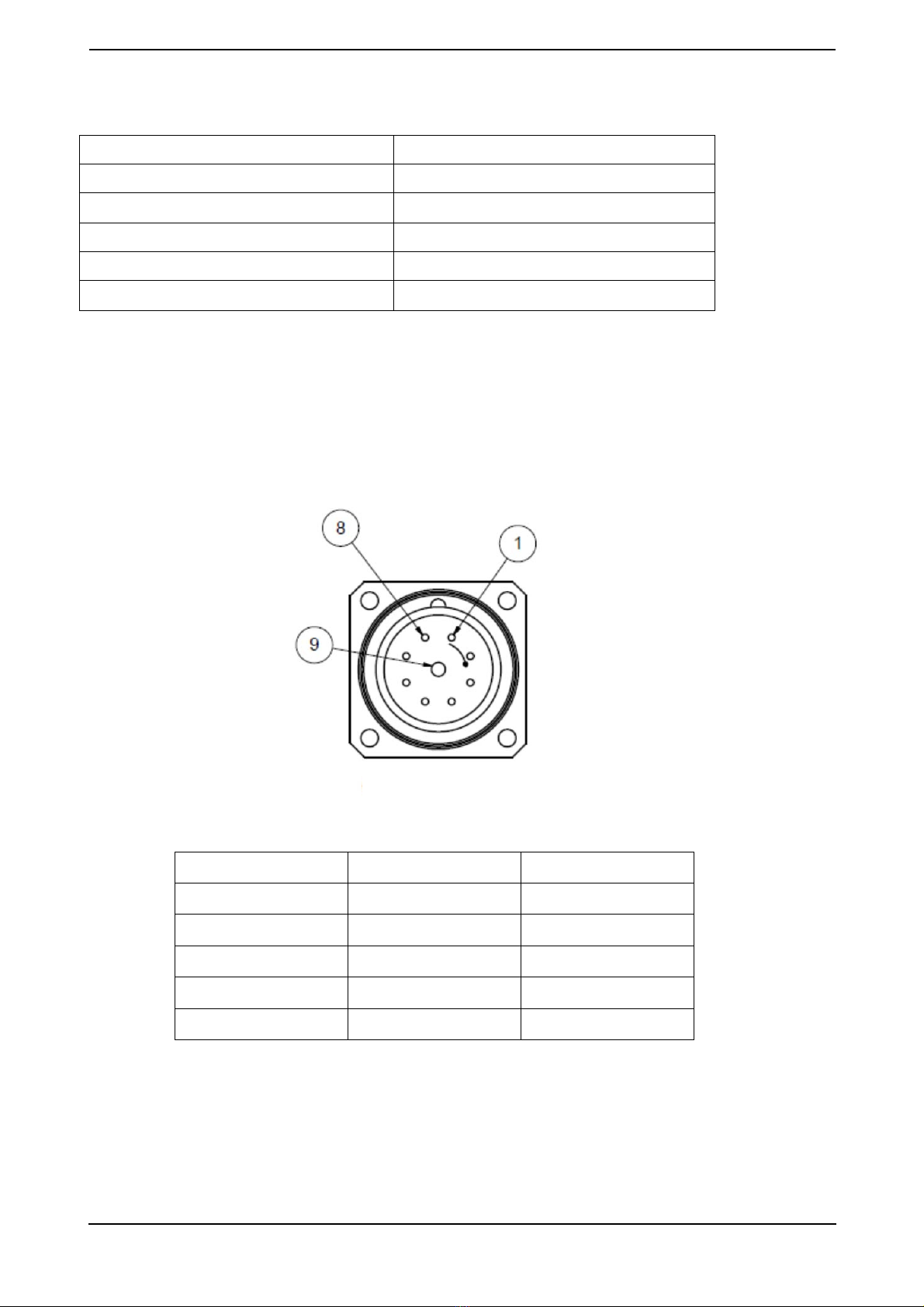

8.3Electrical Connection

The dosing flowmeter is equipped with a plug connector (type: RC-09 Phoenix Contact). The

appropriate interconnect cable is supplied ( 2-81-25826-005).

PIN Function Cable Color

3 Pulse White

5 Valve Status Brown

6 Power + Red

7 Power - Blue

other Do not connect Do not short-circuit

Plug connector

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 15 of 20

Power Supply Voltage

Rated voltage of 24V DC (12V DC - 36V DC)

Power Consumption

1.5W ~ 60 mA @ 24V DC

Inrush current: 0.5 A (<5 ms)

Pulse

Active pulse output (max. 20 mA; an external pull down resistor is required)

Valve Status

Valve status signal: 24 V DC / 2 mA (12V DC - 36V DC)

9. Calculation pulse frequency

Example for the FM06:

Flow rate: 9 kg/min = 150 g/s

Pulse factor: 63,330 Imp/g

Pulse frequency = flow x pulse factor

Pulse frequency = 150 g/s х 63,660 Imp/g = 9549 Imp/s (Hz)

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 16 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

10. Certificates and approvals

CE mark:

The measuring system fulfills the legal requirements of the EC Directives 2014/30/EU and

2011/65/EU including the amendments and supplements published to date. Bopp & Reuther

Messtechnik GmbH confirms the successful testing of the device by affixing the CE mark.

DIN EN ISO 9001 certified

Directive 2014/30/EU (EMC)

Electromagnetic compatibility according to DIN EN 61000-6-2, DIN EN 61000-6-3

EN 61326-1:2013-07 Electrical equipment for measurement, control, and laboratory use - EMC

requirements - Part 1: General requirements

EN 60529 Degrees of protection provided by enclosures (IP code)

Directive 2011/65/EU Restriction of Hazardous Substances

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 17 of 20

Apppendix

A. Error diagnostics and fault rectification

The dosing mass flow meter is maintenance-free. If a malfunction should occur or if a wrong

measurement is suspected, please contact Bopp & Reuther Messtechnik GmbH.

Warning!

When working on the electrical connections, the local regulations and all safety

instructions in this operating manual must be observed.

B. Maintenance, Cleaning

Warning!

The operating instructions must be read and observed before installation and

commissioning. The system must be

drained

,

depressurized

and

cooled

down

before mounting or dismounting the device.

Warning!

Make sure that you remove hazardous media from the meter properly!

B.1 Maintenance, Cleaning

Attention!

When cleaning the meter, make sure that the cleaning agent used does not attack the

meter.

The maximum permissible medium temperature for the measuring instrument must be

observed..

If the dosing mass flow meter is to be taken out of operation for a longer period of time, it must be

thoroughly cleaned.

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 18 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

B.2 Repairs, hazardous materials

The following measures must be taken before you repair the mass flow meter. Bopp & Reuther

einsenden:

In any case, please enclose the Declaration on contamination of products and components

with the description of the fault, the application and the chemical-physical properties of the

measuring medium (see appendix D for form)

Remove all adhering residues of the medium. This is particularly important if the medium is

hazardous to health, e.g. corrosive, toxic, carcinogenic, radioactive, etc.

We must ask you to refrain from returning the goods if it is not possible for you to completely

remove hazardous substances with absolute certainty.

The user will be invoiced for any costs incurred as a result of inadequate cleaning of the device for

possible disposal or personal injury (caustic burns, etc.).

In case of malfunctions of the dosing mass flow meter, please contact our customer service:

Bopp & Reuther

Messtechnik GmbH

Service

Am Neuen Rheinhafen 4

67346 Speyer / Germany

Phone : +49 6232 657-420

Fax: +49 6232 657-561

C. Removal

The device must also be removed properly and disposed of.

Warning!

The operating instructions must be read and observed before installation and

commissioning. The system must be

drained

,

depressurized

and

cooled

down

before mounting or dismounting the device.

Warning!

Make sure that you professionally remove media that are hazardous to health from the

meter and dispose of them properly!

Please note the relevant regulations:

the nationally valid regulations

material separation and recycling of equipment components

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Bopp & Reuther

Messtechnik GmbH

A

-DE-05809-00 Rev.A

Subject to change. Page 19 of 20

D. Forms

D.1 Declaration on contamination of products and components for contractor

You can fill out the form online on our homepage, or copy this page:

Coriolis Dosing Mass Flow Meter, Series FMD Operating Manual

Page 20 of 20 Subject to change. A-EN-05809-00 Rev.A Bopp & Reuthe

r

Messtechnik GmbH

E. Certificates

E.1 EU - Declaration of conformity

This manual suits for next models

2

Table of contents

Other BOPP & REUTHER MESSTECHNIK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Magnetrol

Magnetrol Smart EZ Modulevel Installation and operating manual

SEW

SEW 4338 mO instruction manual

Chauvin Arnoux

Chauvin Arnoux C.A 6528 quick start guide

Agilent Technologies

Agilent Technologies MXA Series Installation note

Signal Hound

Signal Hound USB-SA124B user manual

Novus

Novus N1500G operating manual

Raycus

Raycus RFL-P70QA User instruction

Keithley

Keithley 445 instruction manual

Lufft

Lufft C300 operating instructions

KROHNE

KROHNE SMARTPAT COND 5200 Supplementary instructions

Rohde & Schwarz

Rohde & Schwarz GSM400-MS operating manual

Teledyne

Teledyne TIENet 360 LaserFlow Ex Installation and operation guide