4

CALIBRATION – LEVEL

CALIBRATION USING PUSHBUTTONS TESTING on BENCH CALIBRATOR

NOTE: Default Error signal setting

from factory = 22 mA.

Direct action 4 to 20 mA at rising level:

1. Calibrate 4 mA/0 % level

Push = start calibration – loop will go to 22 mA.

Push = lock 4 mA value – red ZERO LED must be

ON.

Push = red ZERO LED turns OFF,after ± 5 s LED

flashes 1x to confirm the new 4 mA setting.

Note: DO NOT move level/push any buttons

before the LED has flashed. Restart the

procedure if any of these occurred.

2. Calibrate 20 mA/100 % level:

Establish liquid level at desired 20 mA level

Push = start calibration

Push = lock 20 mA value – red SPAN LED must

beON

Push = red SPAN LED turns OFF,after ± 5 s LED

flashes 1x to confirm the new 20 mA setting.

Note: DO NOT move level/push any buttons

before the LED has flashed. Restart the

procedure if any of these occurred.

3. In case 100 % level cannot be established:

Establish liquid level at highest possible level

Push = start calibration

Push = lock 20 mA value – red SPAN LED will turn

ON

Toggle /=untill loop signal corresponds with %

of actual level. Each two toggles

correspond with 0.1 mA

eg. 80 % level should match:

(20 mA – 4 mA) x 80 %+4mA = 16.8 mA

Push = red SPAN LED turns OFF,after ± 5 s LED

flashes 1x to confirm the new 20 mA setting.

Note: DO NOT move level/push any buttons

before the LED has flashed. Restart the

procedure if any of these occurred.

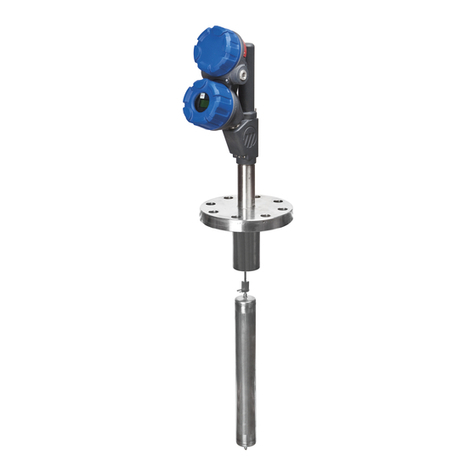

The EZ Modulevel bench calibrator is designed to test the

electronics of the unit. The bench calibrator can also be

used for calibration purpose but the calibration requires fine

tuning versus actual levels in the field.

Slide the electronic head over the open topped enclosing

tube, making sure that the white plastic washer is in

place.

1. Calibrate 4 mA/0 % level:

Slide the adjustment rod completely down into the

enclosing tube

Push = start calibration – loop will go to 22 mA.

Push =lock 4 mA value – red ZERO LED must be

ON

Push =red ZERO LED turns OFF,after ± 5 s LED

flashes 1x to confirm the new 4 mA setting.

Note: DO NOT move the adjustment rod/push

any buttons before the LED has flashed.

Restart the procedure if any of these occurred.

2. Calibrate 20 mA/100 % level:

Align the scale of the adjustment rod with the SG of

your medium

Push = start calibration

Push = lock 20 mA value – red SPAN LED will turn

ON

Push = red SPAN LED turns OFF,after ± 5 s LED

flashes 1x to confirm the new 20 mA setting.

Note: DO NOT move the adjustment rod/push

any buttons before the LED has flashed.

Restart the procedure if any of these occurred.

Ordering code: 031-6107-007

Adjustment rod

Red LED

100 % level,

20 mA output

Zero level, 4 mA output,

bottom of displacer

Desired

level range

(direct acting)

ZERO led

Span led

Error led

Pushbuttons LVDT

White plastic washer

must be installed

For non-Exi units:

Grip ring located

here on

process level

sensors

PC board

"O" rings

Stand

LVDT core

Base & junction

box

BENCH CALIBRATION DOES NOT COMPENSATE FOR ELAVATED TEMPERATURES -

SEE HAND HELD CALIBRATION PROCEDURE

Specific gravity needs to be set in function of selected unit (see partnumber) to establish 100 % level output:

E8x-J/M/A/D/Qxxx-Exx = align adjustment rod with real specific gravity

E8x-K/B/N/E/Rxxx-Exx = align adjustment rod with real specificgravity

multiplied by 2 (density = 0.3 - align with 0.6)

E8x-L/C/P/F/Txxx-Exx = align adjustment rod with real specific gravity

divided by 2 (density = 1.30 - align with 0.65)

IMPORTANT

NOTE: Reverse action: Maintain the same procedure as above described but calibrate 4 mA as 100 % level

(adjustement rod aligned with specific gravity) and 20 mA as 0 % level (adjustement rod entirely in LVDT core)