SEW 4338 mO User manual

DIGITAL MILLIOHM METER

AND RESISTANCE TESTER

INSTRUCTION MANUAL

4338 mO

INDEX

1. INTRODUCTION.............................

2. SAFETY NOTES.............................

3. FEATURES.....................................

4. SPECIFICATIONS..........................

5. GENERAL.......................................

6. INSTRUMENT LAYOUT..................

7. MEASUREMENT.............................

8. MAINTENANCE..............................

9. FUSE REPLACEMENT...................

PAGE

1

2

3

4

5

6-10

10-12

13

14

-1-

1. INTRODUCTION

NOTE

This meter has been designed and tested According

to CE Safety Requirements for Electronic Measuring

Apparatus, IEC / EN 61010-1 and other safety

standards. Follow all warnings to ensure safe

operation.

WARNING

READ "SAFETY NOTES" (NEXT PAGE) BEFORE

USING THE METER.

CAT IV -Is for measurements performed at the

source of the low voltage installation.

CAT III -Is for measurements performed in the

building installation.

CAT II -Is for measurement performed on circuits

directly connected to the low voltage

installation.

-2-

2. SAFETY NOTES

●Read the following safety information carefully

Before attempting to operate or service the meter.

● Use the meter only as specied in this manual.

Otherwise, the protection provided by the meter

may be impaired.

●Rated environmental conditions :

(1) Indoor Use.

(2) Installation Category IV.

(3) Pollution Degree 2.

(4) Altitude up to 2000 meters.

(5) Relative humidity 80% max.

(6) Ambient temperature 0~40°C.

●Observe the International Electrical Symbols listed

below :

Meter is protected throughout by double

insulation or reinforced insulation.

Warning ! Risk of electric shock.

Caution ! Refer to this manual before using

the meter.

-3-

3. FEATURES

●Four terminal measurement for mΩ.

●4-wire method testing(mΩ): 1100.0mΩ / 11000mΩ.

● 2-wire method resistance testing: 110.00Ω /

1.1000kΩ / 11.000kΩ / 110.00kΩ / 1.1000MΩ /

11.000MΩ / 110.0MΩ.(auto ranging)

●Maximum resolution of 0.1mΩ.

●Large LCD (68×34mm).

●Relative mode / Auto-zero mode.

●Data hold function.

●MAX/MIN function.

●Power source: 1.5V "C" battery × 8

●Long battery life and stable power.

●Low battery indication.

●Lightweight, robust & compact.

●"O-Ring" sealed case.

●Safety Standard :

EN 61010-1 CAT IV 20V

EN 61326-1

-4-

4. SPECIFICATIONS

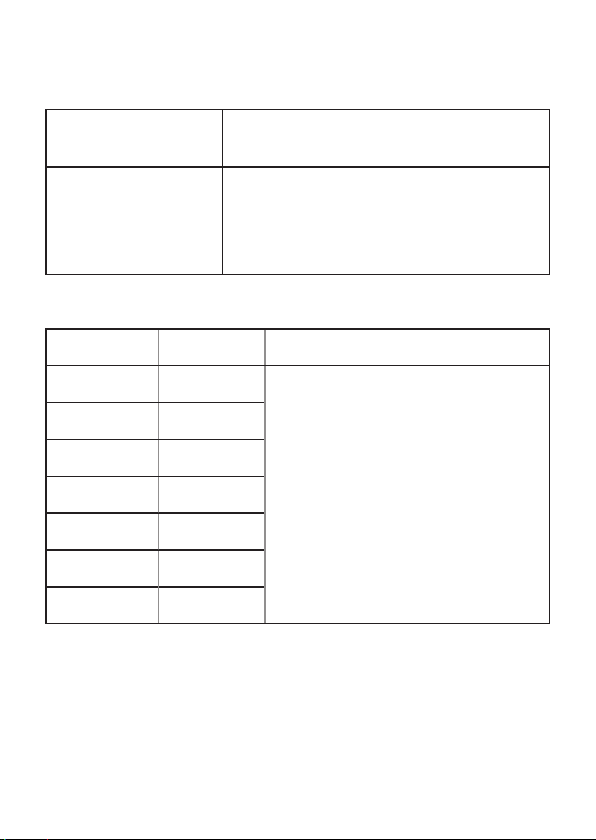

mΩ measurement (4-wire method)

Measuring ranges

(mΩ)

0~1100.0mΩ in steps of 100uΩ

0~11000mΩ in steps of 1mΩ

Accuracy

±0.8% of reading ±4 digits over the

operating temperature range

0°C ~ 40°C,

with the supplied test leads

Resistance measurement

Range Resolution Accuracy

110.00Ω 0.01Ω

0~2MΩ: ±(1.2%rdg+3dgt)

2~40MΩ: ±(2.0%rdg+4dgt)

40~110MΩ: ±(8.0%rdg+4dgt)

1.1000kΩ 0.1Ω

11.000kΩ 1Ω

110.00kΩ 10Ω

1.1000MΩ 100Ω

11.000MΩ 1KΩ

110.0MΩ 100KΩ

Auto-ranging

( )

2-wire method

-5-

5. GENERAL

●Protection fuse:

200mA/250V × 1

●Dimensions :

250(L) × 190(W) ×126(D)mm

●Weight :

Approx. 1848g (battey included)

●Power source :

1.5V "C" battery × 8

●Low Battery Indication :

"" sign appears on the display when the battery

voltage drops below accurate operating level.

●Accessories :

Instruction Manual

Test leads

Shoulder belt

Batteries

B

-6-

6. INSTRUMENT LAYOUT

(1) (5)(3)

(7)

(2)

(6)

(8)

(4)

(9)

(10)

(11)

MAX

MIN

HOLD

REL

TEST

TEST

ON

DIGITAL

MILLIOHM

METER

AND

RESISTANCE

TESTER

OFF

1100.0mΩ

11000mΩ

mΩ

(AUTO)

110MΩ

110.00Ω

LOCK

~

● Test Leads

● Special Resistance Test Lead

(Specialized for 2-wire resistance testing)

-7-

(1) C1 Termianl

This is the C1 terminal which is used for mΩ

measurement, for 1100.0mΩ and 11000mΩ

(4-wire testing).

(2) P1 Termianl

This is the P1 terminal which is used for mΩ

measurement, for 1100.0mΩ and 11000mΩ

(4-wire testing).

(3) P2 Termianl

This is the P2 terminal which is used for mΩ

measurement, for 1100.0mΩ and 11000mΩ

(4-wire testing).

This terminal is also the COM terminal for

resistance measurement, for 110.00Ω~110MΩ

(2-wire testing).

(1) C1 Termianl (7) TEST Button

(2) P1 Termianl (8) TEST ON LED

(3) P2 Termianl (9) REL Button

(4) C2 Termianl (10) HOLD Button

(5) Ω Terminal (11) MAX/MIN Button

(6) Function Rotary Switch

-8-

(4) C2 Termianl

This is the P2 terminal which is used for mΩ

measurement, for 1100.0mΩ and 11000mΩ

(4-wire testing).

This terminal is also the COM terminal for

resistance measurement, for 110.00Ω~110MΩ

(2-wire testing).

(5) Ω Terminal

This is the positive input termial for resistance

measurement, for 110.00Ω~110MΩ(2-wire

testing).

(6) Function Rotary Switch

The function rotary switch is for selecting different

functions.

(7) TEST Button

The TEST Button is only available for mΩ

measurement, which includes 1100.0mΩ and

11000mΩ. Press and turn the TEST button for

continuously testing. Remember to release the

TEST Button after the testing.

(8) TEST ON LED

When press the TEST button, the TEST ON LED

glows. When release the TEST button, the TEST

ON LED disappears.

-9-

(9) REL Button

In REL mode, the LCD displays DN+K-DN, where

DN=1,2,3,..., DNis the last value before REL is

pushed, and DN+K is the current value. If REL is

pushed again in REL mode, the meter displays

the reference value. The meter returns to normal

operation if REL is pressed and held for longer

than one second. Pressing HOLD in REL mode

makes the meter stop updating the reading on the

LCD.

(10) HOLD Button

HOLD mode makes the meter stop updating the

reading on the LCD. Enabling HOLD function

in automatic mode makes the meter switch to

manual mode, but the full-scale range remains

the same. HOLD function can be cancelled by

changing the measurement mode, or push HOLD

again.

(11) MAX/MIX Button

The meter displays the maximum or minimum

value of the input in MAX/MIN mode.

When MAX/MIN is pressed for the rst time, the

meter displays the maximum value.

When MAX/MIN is pressed again, the meter

displays the minimum value.

When MAX/MIN is pressed for the third time, the

meter displays current value. The meter returns

-10-

to normal operation if MAX/MIN is pressed

and held for longer than one second. Pressing

HOLD in MAX/MIN mode makes the meter stop

updating the maximum or the minimum value.

7. MEASUREMENT

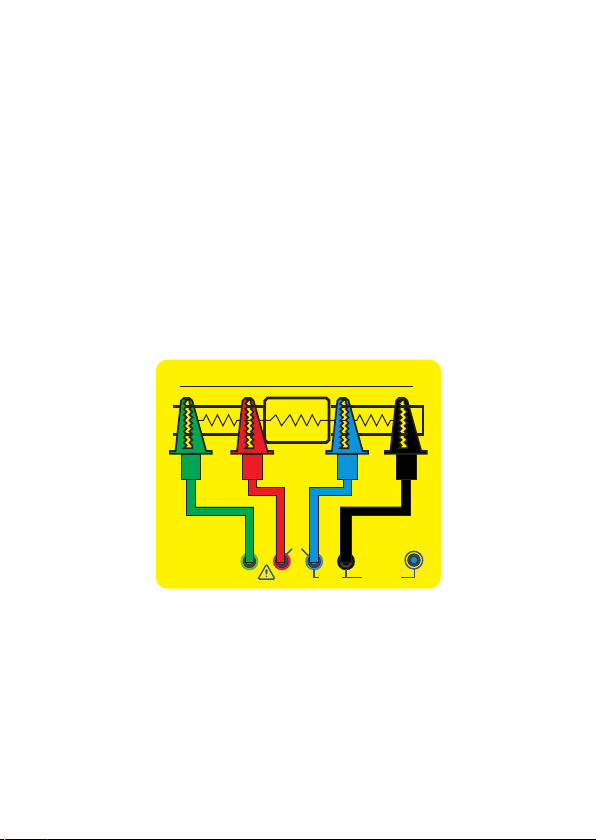

mΩ MEASUREMENT(4-wire method).

Use C1, P1, P2, C2 four terminals for 4-wire

mΩ measurement.

Connect green, red, blue, black test leads to C1, P1,

P2, C2 4 terminals.

Connect the test leads to the object or device for

measuring mΩ as Fig 1.

Turn the rotary switch to the position of 1100.0mΩ or

11000mΩ. Press the TEST button to do the

measurement, and get the mΩ reading on the LCD.

DC20V

MAX

RX

RB

RA

Compression

Joint

C1P1C2Ω

P2

0-110MΩ

COM 110MΩ

110.00Ω

~

4-wire method

Fig 1

-11-

When press the TEST button, the TEST ON LED will

glow red.

Please remember to release the TEST button after

mΩ testing, the TEST ON LED will disappear.

It's necessary to release the TEST button after

testing.

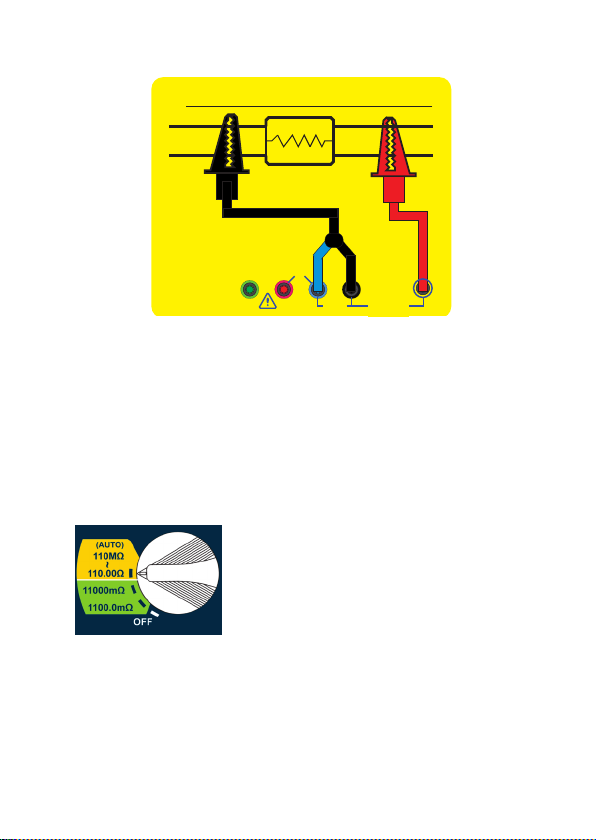

RESISTANCE MEASUREMENT(2-wire method).

Use P2, C2, Ω three terminals for 2-wire resistance

measurement.

★ The first step is to connect the special

resistance test lead to P2 and C2 terminals

before turning the rotary switch to the position

of 110.00Ω~110MΩ.

Connect the special resistance test lead to P2 and

C2 terminals as Fig 2, connect the red test lead to Ω

terminal as Fig 2.

TEST

ON

TEST

ON

-12-

Connect the special resistance test lead and the

red test lead to the object or device for measuring

resistance (110.00Ω/1.1000kΩ/11.000kΩ/110.00kΩ/1.

1000MΩ/11.000MΩ/110.0MΩ auto ranging).

Turn the rotary switch to the position of

110.00Ω~110MΩ(yellow area), then get the resistance

reading on the LCD.

It's not allowed to press the TEST button

when the rotary switch is at the position of

110.00Ω~110MΩ(yellow area).

It's not allowed to press the TEST button when do

the 2-wire method resistance measurement.

DC20V

MAX

RX

C1P1C2Ω

P2

0-110MΩ

COM 110MΩ

110.00Ω

~

2-wire method

Fig 2

-13-

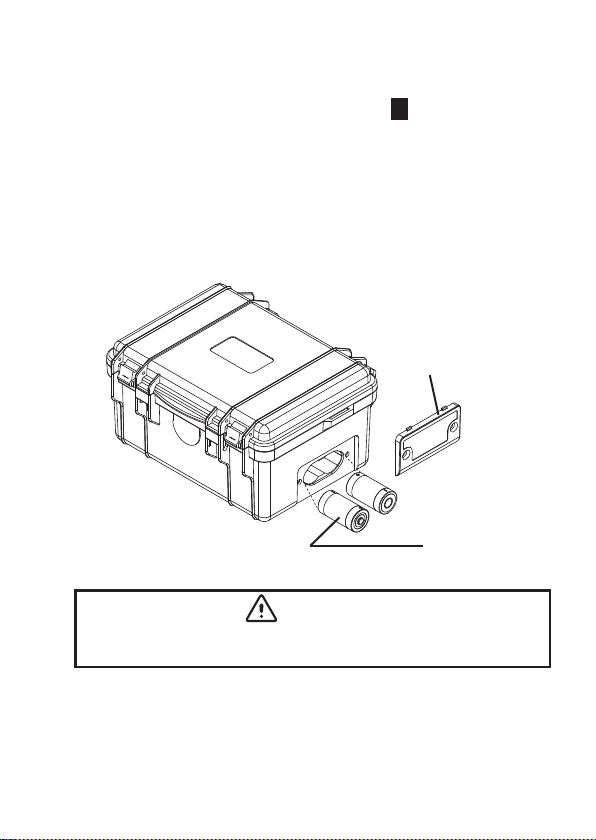

8. MAINTENANCE

Battery replacement :

When low battery warning symbol " B"appears,

change new batteries as follows :

(1) Disconnect the test leads from the instrument and

turn off the power.

(2) Unscrew the battery cover and replace with new

batteries(1.5V "C" battery × 8 ).

(3) Re-install the battery cover.

Cleaning and Storage :

WARNING

To avoid electrical shock or damage to the meter,

do not get water inside the case.

Periodically wipe the case with a damp cloth and

detergent. Do not use abrasives or solvents.

If the meter is not used for over 60 days, remove the

batteries for storage.

Batteries

(1.5V "C") × 8

Battery cover

–

+

-14-

9. FUSE REPLACEMENT

Open the meter case, replace with a new fuse

which has the same specication 200mA/250V,

5×20mm.

Due to our policy of constant improvement and development, we

reserve the right to change specications without notice.

Fuse 200mA / 250V

(5 × 20 mm)

Table of contents

Other SEW Measuring Instrument manuals