Boqballe L-Trail User manual

Operator's Manual

L-Trail + M -Trail GB

3

M45W, M35W

M45, M35

L20W

L20

=

=

=

=

Table of Contents

Safety ....................................................................................................................................................... 4

Safety and protection ......................................................................................................................................................................4

Legend ............................................................................................................................................................................................5

Liability .................................................................................................................................................... 6

Main settings ........................................................................................................................................... 7

Principle sketch ...................................................................................................................................... 8

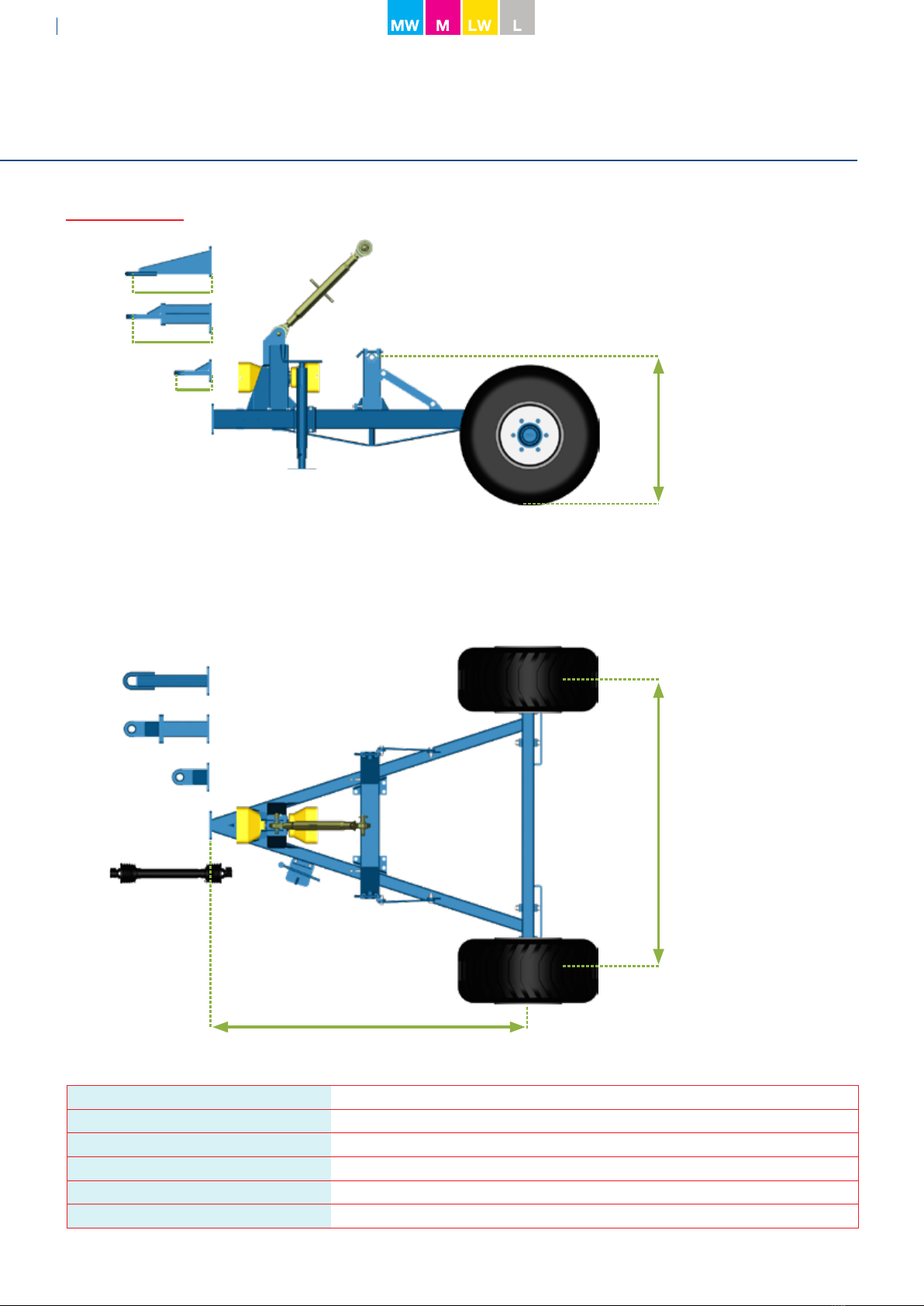

L20 / M35-Trail ................................................................................................................................................................................8

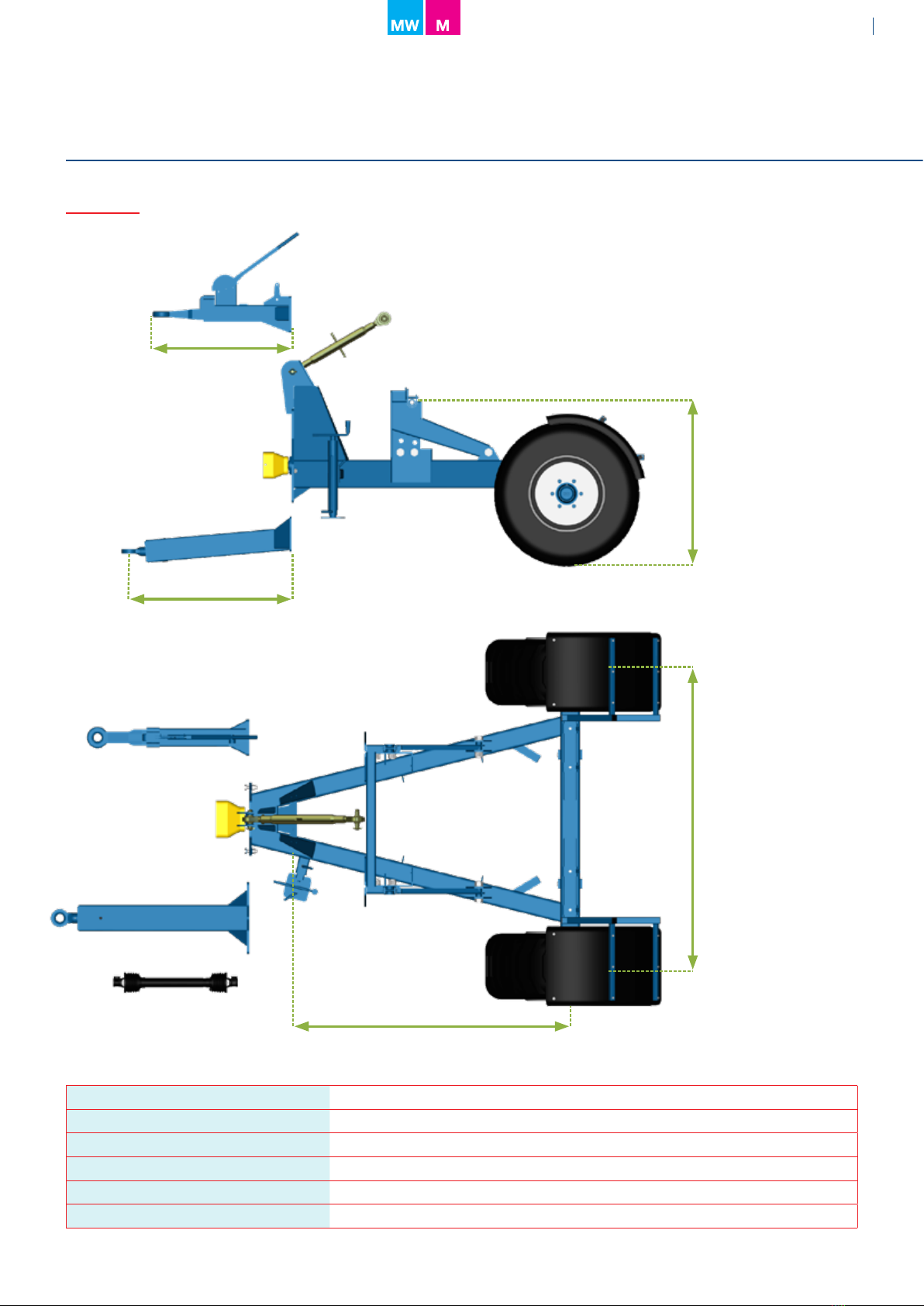

M45-Trail .........................................................................................................................................................................................9

Setting and Service .............................................................................................................................. 10

M45-Trail - height adjustable implement carrier ...........................................................................................................................10

M45-Trail - tightening of construction ...........................................................................................................................................10

L20 / M35-Trail and M45-Trail - wheel track adjustment ...............................................................................................................10

L20 / M35-Trail and M45-Trail - wheel hub and wheel bolts .........................................................................................................10

L20 / M35-Trail and M45-Trail - PTO Tractor ................................................................................................................................11

L20 / M35-Trail and M45-Trail - adjustment of wheel hub ............................................................................................................11

Corrosion ............................................................................................................................................... 12

EC-Declaration of conformity .............................................................................................................. 13

Colour codes

4

●Read Operator’s Manual and safety rules before starting.

●Read Operator’s Manual for the PTO shaft.

●Do not leave the tractor cabin without stopping the PTO system of the tractor!

●Turn o tractor engine and all electrical controlling devices during maintenance and other intervention on the

spreader

●Ensure that bystanders maintain a sucient safety distance from the spreader as long as the tractor engine is

on.

●Do not enter the spreader when the tractor engine is on.

●Do not wear loosely tting clothes that could become entangled with moving parts.

●Wear personal protective equipment when necessary or when required by the manufacturer of the fertiliser.

●Stay under the spreader is prohibited.

●Never go between spreader and tractor when engine is started.

●Never enter the spreader using the ladder when the spreader is not mounted to a tractor. The spreader might tilt

over due to unstable weight distribution.

●Safety distance for ying material must be observed.

●Never go behind the spreader with rotating spreading discs.

●Avoid contact with rotating parts.

●Never put hand/object into the hopper with rotating spreading discs.

●Avoid contact as long as parts are moving.

●Never clean the spreader with rotating spreading discs.

●When parking the spreader ensure that the hopper is empty and the ground is solid and horizontal.

Safety and protection

Safety

5

Dieser Dünger-

streuer erfült

die europäische

Umweltnorm

EN 13739-1

This fertiliser spreader

fulfils the European

environmental standard

EN 13739-1

Ce distributeur d'engrais

répond à la norme

environnement

EN 13739-1

Denne gødnings-

spreder opfylder

den europæiske

miljønorm

EN 13739-1

For vort miljø

Für unsere Umwelt

Pour notre environnement

For our environment

xxxx

Legend

Read Operator’s Manual and safety rules before starting.

Never go under a raised spreader.

Never go between spreader and tractor when engine is started.

Never use the ladder when the spreader is not mounted on a tractor.

Safety distance for ying material must be observed.

Never go behind the spreader with rotating spreading discs.

Avoid contact with rotating parts.

Never put hand/object into the hopper with rotating spreading discs.

Avoid contact as long as parts are moving.

Never clean the spreader with rotating spreading discs.

Do not spray water in this area.

Noise level measured inside a closed tractor cabin (level depends on tractor brand and model).

Lashing points for loading and unloading the spreader

Do not step on.

Not designed for boarding purposes.

EN13739-1

Max. loading capacity.

Do not exceed.

Type: Model

No.: Serial number

Year: Manufacturing year

Safety

6

Liability

Liability

You are fully responsible for the setting of the spreader. The spreader must be set according to the fertiliser in use.

Be aware that the fertiliser batch tested in the BOGBALLE A/S test facilities may dier from the fertiliser delivered

to you even if with the same specications.

BOGBALLE A/S cannot be held responsible for any kind of personal injury, crop damage, after eects etc.

7

Main settings

Main settings

If the spreader is mounted on M-Trail or other carriages – the distance from the ground to the spreading discs is

increased from 75 cm, typically up to 100 cm to 140 cm.

Example

Height : 110 cm

Spread width : 24 metres

Spread chart : +4°

Tilt angle M-Trail : (+4° -2°) = +2°

Spread width H: 100 - 140 cm. (see gure 1)

Tilt angle- reduction (according to Spread chart)

12 - 18 metres -4°

20 - 36 metres -2°

40 - 42 metres 0°

H

Top of the crop

Figure 1

8

Principle sketch

Net weight 500 kg

Payload max. 4.000 kg

Gross weight max. 4.500 kg

Tyres 400/60-15,5: 4,7 bar

3-point linkage Cat. II / ISO 730/l

Max. driving speed 25 km/h

L20 / M35-Trail

20 cm

20+30 cm

50 cm

95 cm

Min. 170 cm - Max. 200 cm

195 cm

9

Principle sketch

Net weight 1.000 kg

Payload max. 5.000 kg

Gross weight max. 6.000 kg

Tyres 400/55-22,5: 3,5 bar

3-point linkage Cat. II / ISO 730/l

Max. driving speed 25 km/h

M45-Trail

95 cm

120 cm

Min. 110 cm

Max. 118 cm

Min. 180 cm - Max. 210 cm

200 cm

10

▲

Setting and Service

L20 / M35-Trail and M45-Trail - wheel track adjustment

L20 / M35-Trail and M45-Trail - wheel hub and wheel bolts

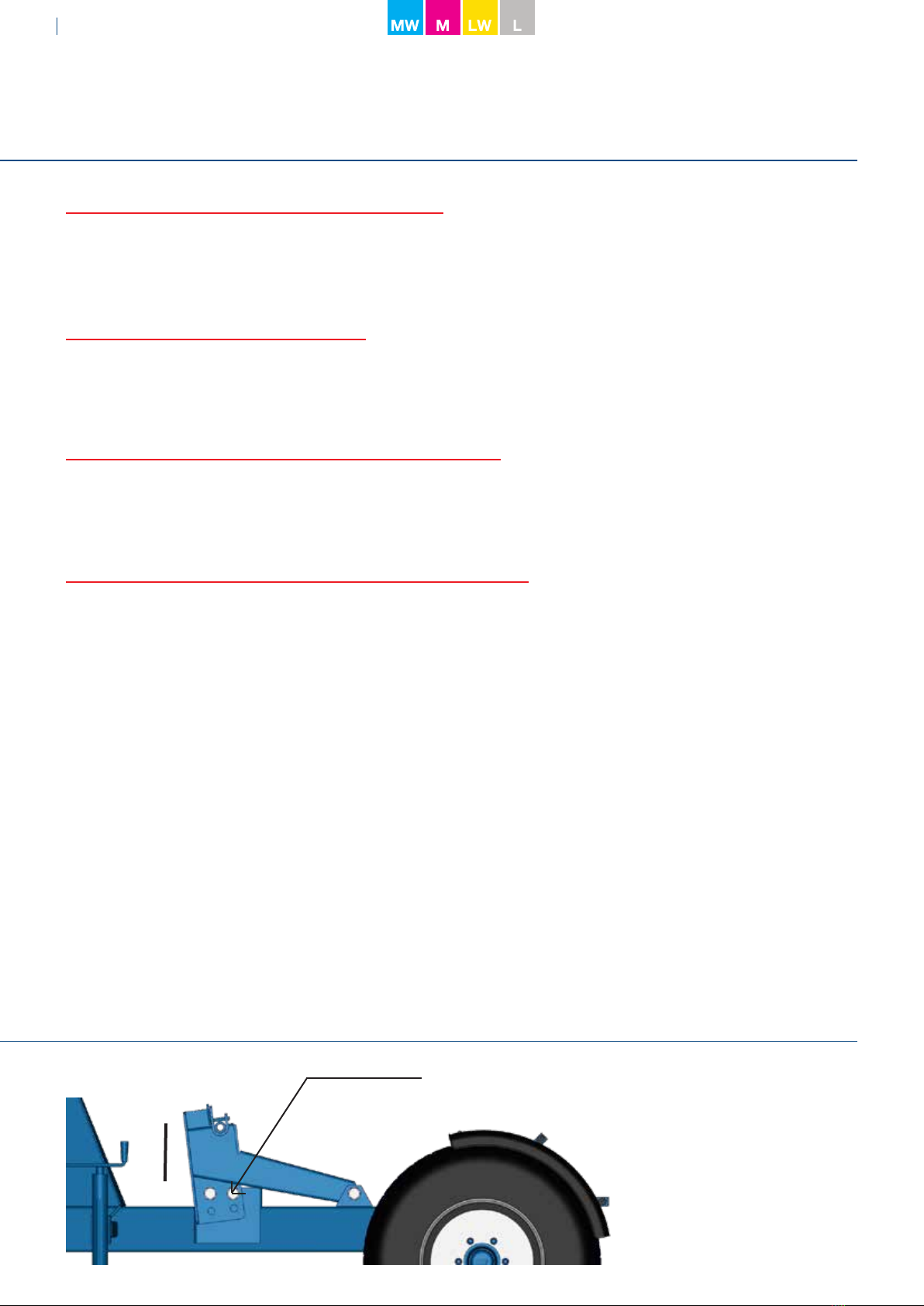

M45-Trail - tightening of construction

2 + 2 pcs. M30

Figure 1

M45-Trail - height adjustable implement carrier

The system makes it possible to optimise the spreader height in proportion to the M45-Trail (see gure 1).In cases

where the spreader must be tilted negative (-) the spreading vanes can collide with respectively the guards and

the wheels. If this is the case the lifting system must be raised to a minimum distance of 10 cm between guards /

wheels.

The 2 + 2 pcs. of M30 bolts MUST be tightened at 1200 Nm (see gure 1).

It is recommended to tighten up the construction after 2-3 working hours.

Stepless setting individually on respectively right and left wheel.

●After 2-3 working hours, tighten up the construction at 350 Nm.

After 8-10 working hours:

●Tighten up the 6 wheel bolts on each wheel at 250 Nm.

●Remove the cap from the wheel hub and tighten up the hub at 250 Nm.

11

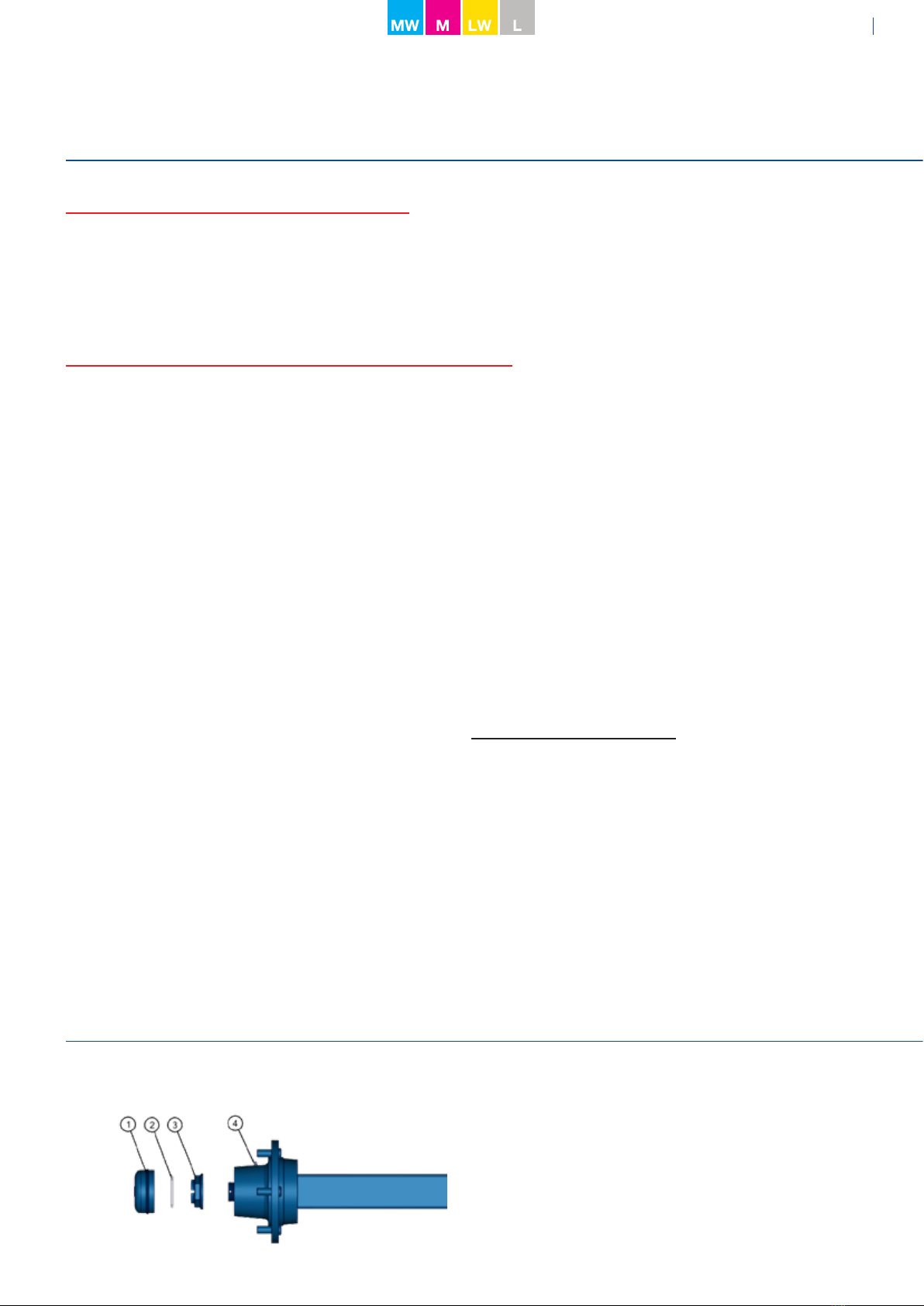

Figure 1

Setting and Service

L20 / M35-Trail and M45-Trail - adjustment of wheel hub

In case of clearance adjust the lock nut as follows (see gure 1):

●Dismantle the hubcap (1).

●Remove the split pin (2) from the lock nut (3).

●Tighten the lock nut until the clearance is equalised (3).

●Check that the wheel is free running without resistance. A slight clearance is preferred - opposite bearing

resistance.

●Fit a NEW split pin (2) greese and assemble the hub.

The wheel hub must be greased every 50 hours.

Grease nipple (4)

L20 / M35-Trail and M45-Trail - PTO Tractor

●A standard PTO shaft can maximum resist an angle turning of 25º

●A wide angle PTO shaft can maximum resist an angle turning of 80º

If there is a need for turning angles higher than 25º - The carriage must be tted with a wide angle PTO shaft.

Servicing and adjusting the clearance in the taper roller bearings on the wheel hub. It is important to check and

adjust the clearance every 50 hours of use.

After every 50 hours:

●Position the Trailer on a level and stable surface and lift the wheel clear of the ground - free to rotate.

●Place a lever between the tyre and the ground and by lifting and lowering the lever, verifying that that there is no

clearance in the hub.

12

Corrosion caused by insucient cleaning and protection

is not covered by warranty!

Remember always to grease the entire spreader in a corrosion protective

oil. It is not sucient just to wash the spreader, as dried-in fertiliser dust

will absorb water and escalate corrosion.

Mineral fertiliser is extremely corrosive and often with a high content of

nitrogen and sulphur, which combined with water generate sulphuric acid.

Remember to:

• Cover/oil the spreader carefully before using it the rst time.

• Oil seals up joints and connections between components – to pre-

vent fertiliser dust from getting in and building up between the various

spreader parts.

• Wash and grease/oil the spreader after every use.

• Store your spreader indoor

Corrosion

13

Bogballe, 2019-09-01

Manufacturer:

BOGBALLE A/S

Bogballe

DK-7171 Uldum

Phone +45 7589 3266

Fax +45 7589 3766

Declares that machine:

Under carriage for Centrifugal fertiliser spreader:

L20-Trail / M35-Trail / M45-Trail

Is made in conformity with:

Directive of 17th May 2006 conc. mutual approximation of the laws of the member states on machines (2006/42/

EØF), with special reference to the enclosure II, A and enclosure I of the directive, conc. essential safety and health

claims in connection with construction and manufacture of machines.

International/national standards:

DS/EN ISO 12100

DS/EN ISO 13857 1st edition - 2008.03.26

DS/EN 349

ISO 500, 1st edition - 2004.02.01

DS/EN ISO 4254-1 :2015

DS/EN ISO 4254-8 :2018

EC-Declaration of conformity

14

Notes

15

Notes

FIND MORE INFORMATION ON

www.bogballe.com

0431-GB 06-20 V01

This manual suits for next models

1

Table of contents

Other Boqballe Farm Equipment manuals