Bornack O LIGHT User manual

User Manual

EN

0123 EN 362:2004/M

O LIGHT

|

INTENDED USE

The connector O LIGHT is part of

personal protective equipment (PPE) of

category III to prevent falls from heights.

The O LIGHT serves to connect several

parts of a securing system. The upper

and lower part of the O LIGHT are

connected to each other with screws.

The special design allows loads up to

kN despite the divisibility of the

connector.

Application temperature: - °C to

+ °C

All other uses are deemed improper. The

company BORNACK will not be liable for

any ensuing damages. The user bears

the sole risk.

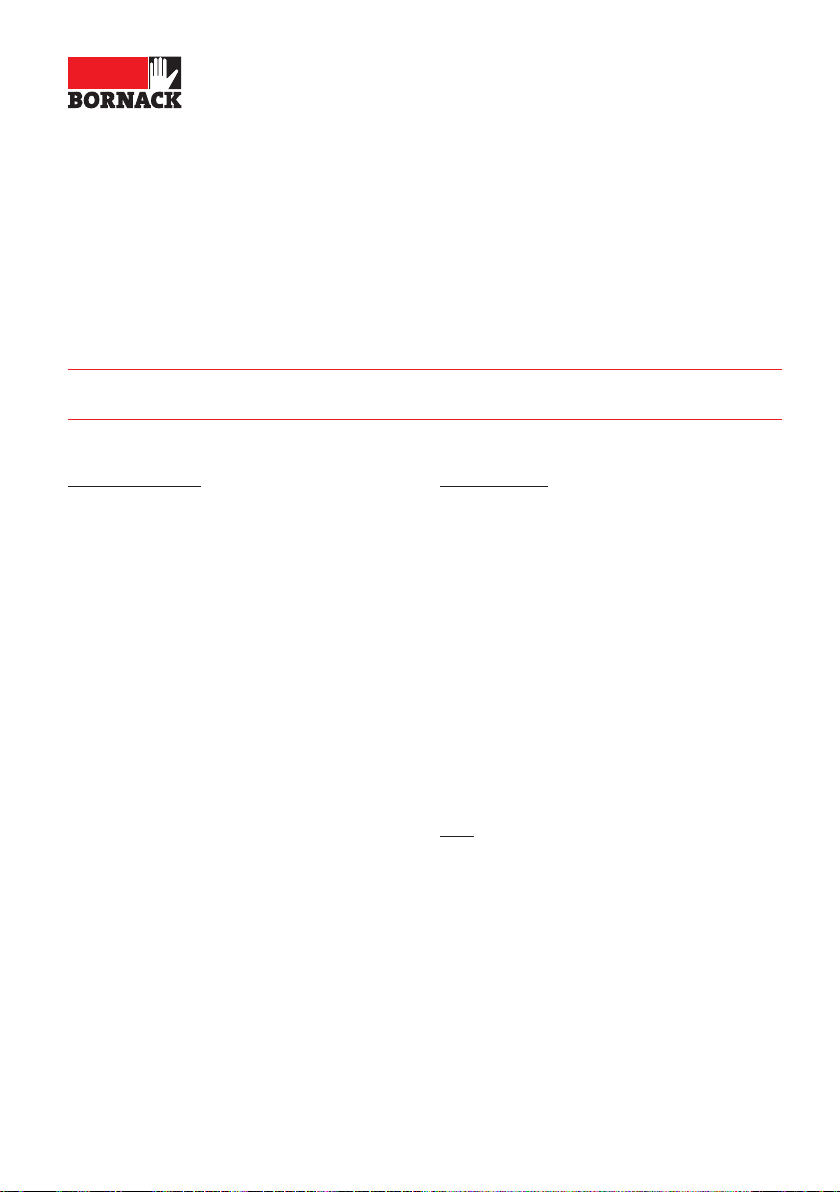

EQUIPMENT

• Ring-shaped connector made of

aluminium with a red upper part and

black lower part

• Fastener opening width: mm

• Inner diameter: mm

• Outer diameter: mm

• Diameter of the cross-section: mm

• stainless steel screws with O rings

made of rubber to ensure that the

screws fit tight

• Allen wrench SW mm

USE

• Connection of several parts of a

securing system

O LIGHT

Connector

Subject to technical changes

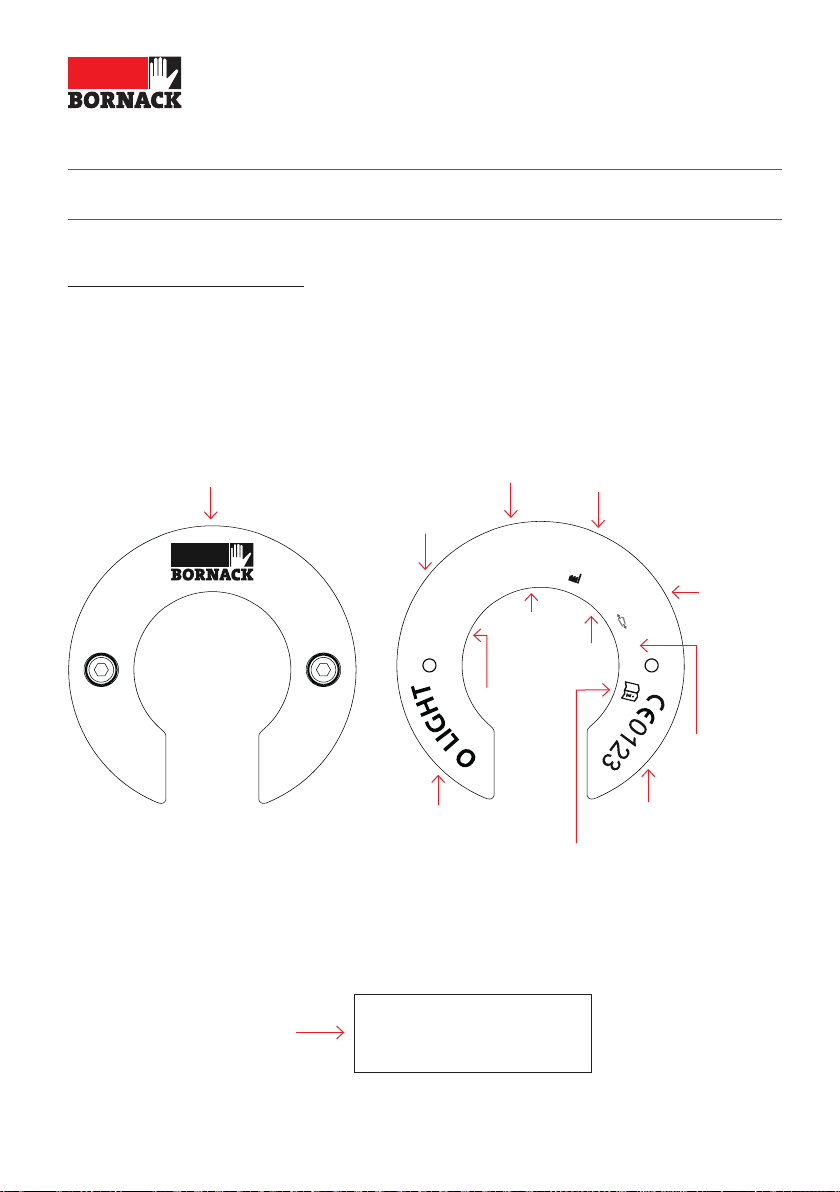

BRIEF DESCRIPTION

EN

Lower part (with marking)

Upper part

Screw

Screw

O-ring

Thread

Screw

Allen wrench

|

Always check before use!

• The personal protective equipment

(PPE) may no longer be used even in

the case of very minor faults.

• Faulty PPE components may only be

tested or repaired by BORNACK or in a

workshop authorised in writing by

BORNACK.

• Regular inspections are essential

because the safety of the user depends

on the eciency and durability of the

PPE.

• The user must have completely read

and understood the User Manual

before use.

VISUAL INSPECTION

• No deformations, cracks, grooves,

notches, wear or other damage.

• No soiling of the connector.

• O-rings are on the screws and are

undamaged.

• The last inspection by an expert was

carried out within the past months.

FUNCTION TEST

• Screws can be turned in and out easily.

INFORMATION BEFORE USE

EN

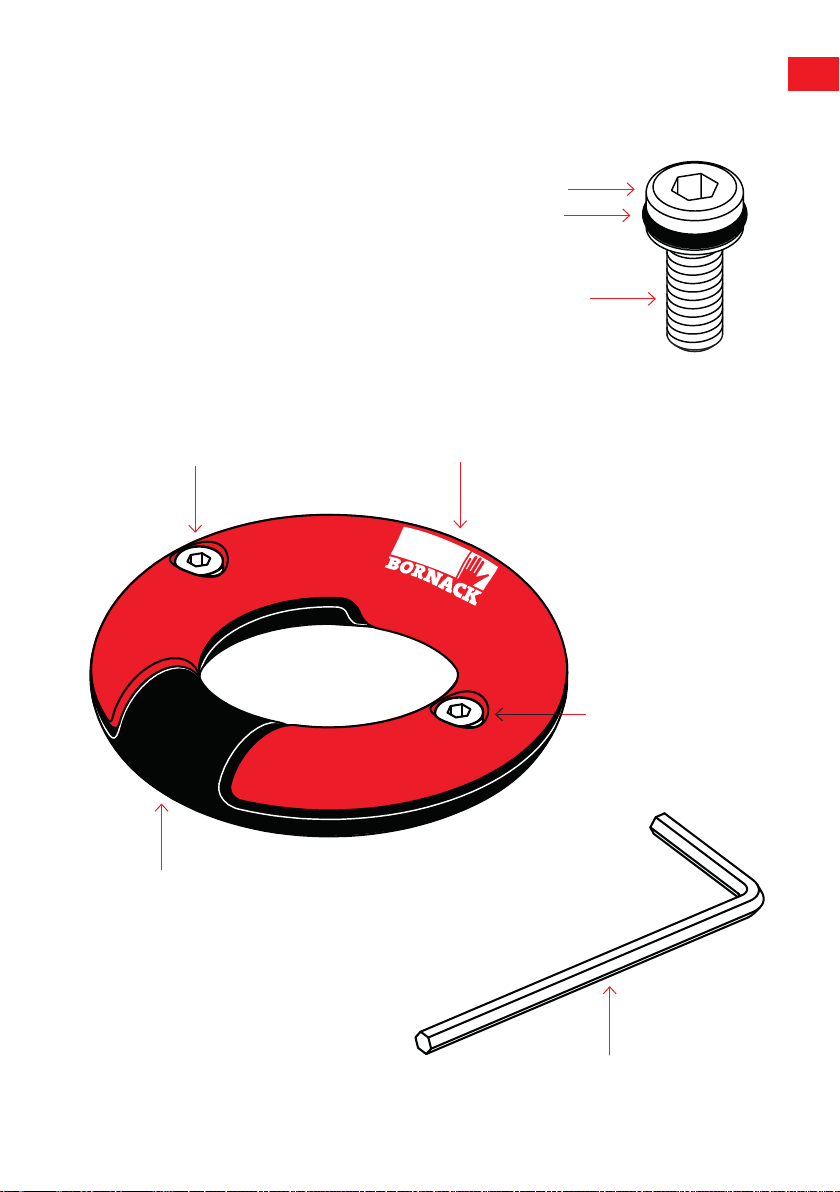

O LIGHT IN USE

OPEN AND CLOSE THE CONNECTOR

ELEMENT

A Unscrew the two screws in an

anticlockwise direction using an

Allen key.

B Dismantle the upper and lower

part of the O LIGHT.

C Slip the parts of the securing system

that need to be connected over the

lower part.

D Assembly of the upper and lower part.

CAUTION THREAT TO LIFE:

Always check that there are no objects

between the upper and lower part!

CAUTION THREAT TO LIFE:

If parts of the securing system cannot

be used in a way that allows the upper

and lower part of the O LIGHT to be

assembled correctly, the O LIGHT may

not be used to connect these parts!

E Ensure that the O-rings are positioned

correctly on the screws.

A

B

D

C

E

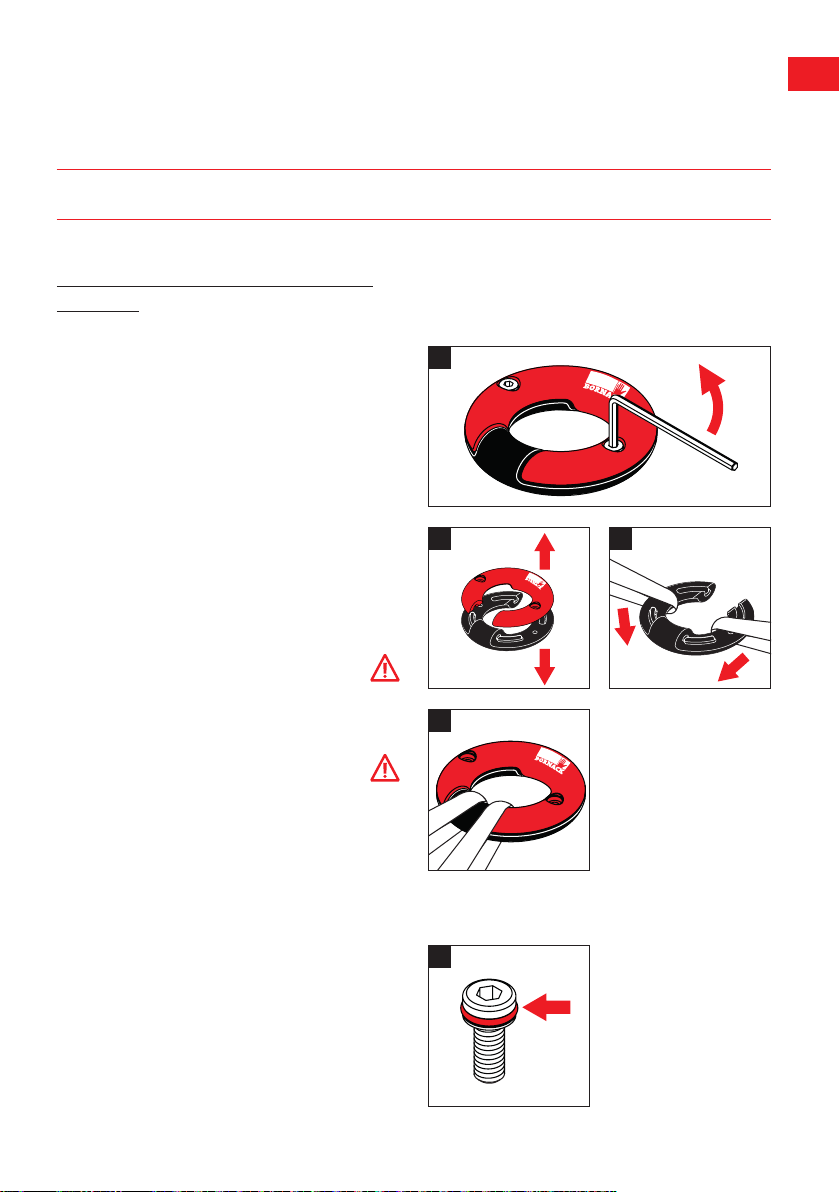

|

O LIGHT IN USE

F Screw in both screws using the Allen

key in a clockwise direction and

tighten up to . Nm.

CAUTION THREAT TO LIFE:

Only a connector that is assembled

correctly is able to withstand the stated

loads! Therefore, always carry out a

visual inspection and test the function

every time before use!

Check:

Do the screws sit tightly?

Are the screw heads lowered into the

upper part and do they not protrude?

The upper and lower part of the O LIGHT

sit tightly on each other and cannot be

taken apart or pushed against each

other?

CAUTION:

Even if the connector has been closed

for a longer period, the tightening

torque should be checked at regular

intervals.

2,0 Nm

F

EN

O LIGHT IN USE

LOAD DIRECTIONS

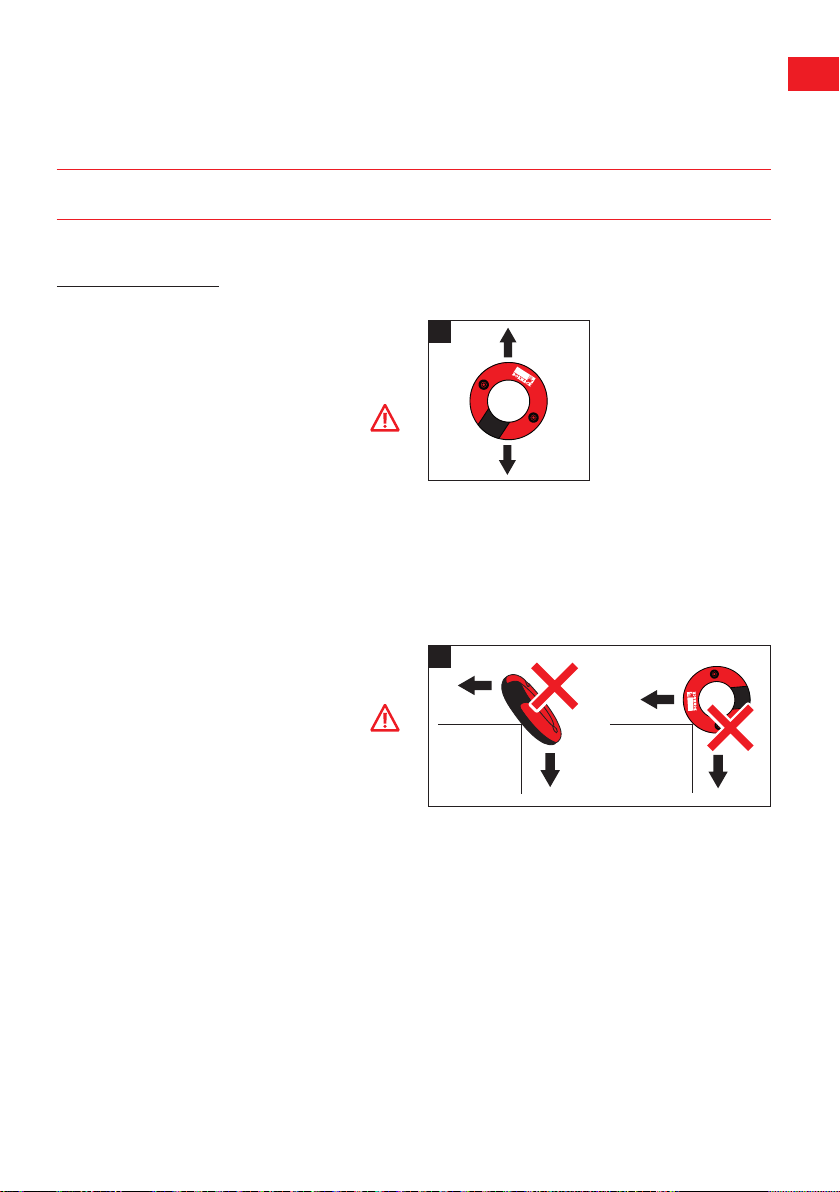

G Only use the connector so that it can

be aligned optimally in the load

direction.

CAUTION THREAT TO LIFE:

The connector has the stated

load-bearing capacity of kN in the

longitudinal direction (when

assembled correctly)! Other types of

force application can reduce the

load-bearing capacity and should

therefore be excluded!

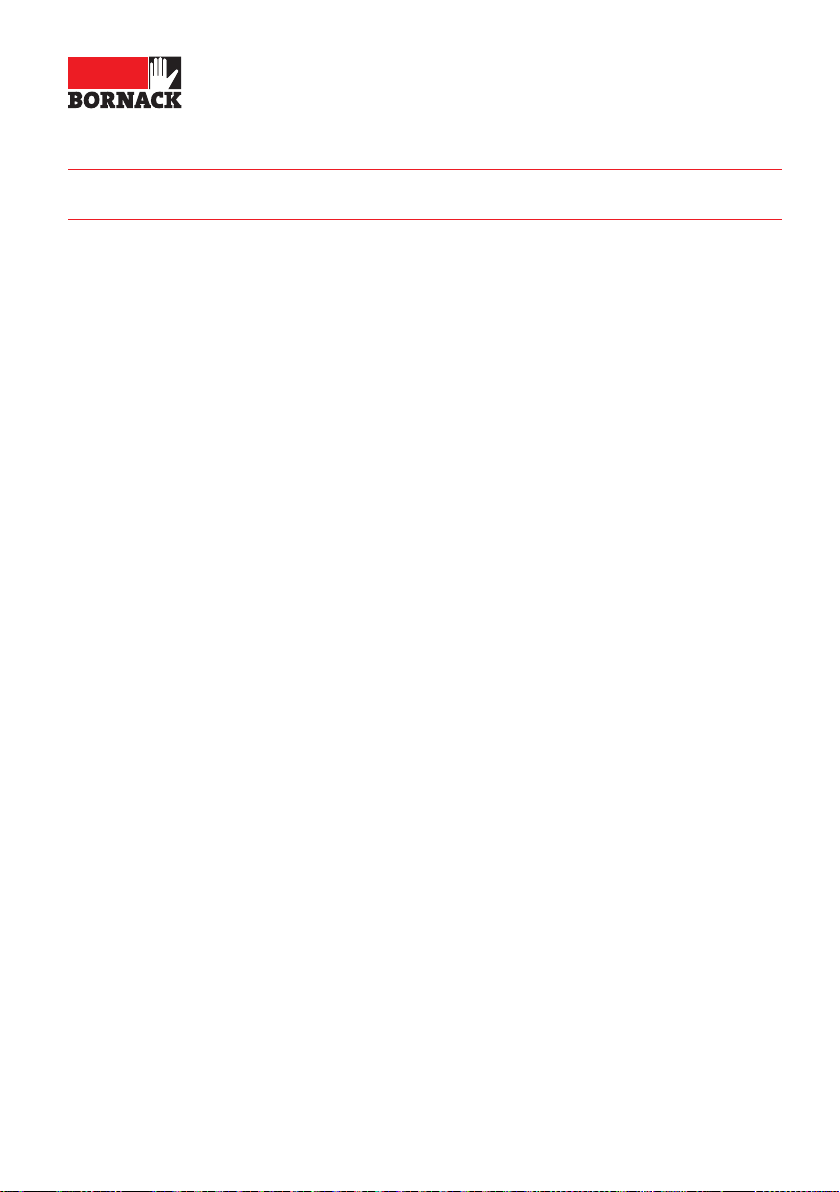

H Do not load connector element over

edges.

CAUTION:

Using the connector with wide

straps can reduce the strength of the

connector.

H

G

|

O LIGHT IN USE

ANCHOR POINTS

CAUTION THREAT TO LIFE:

Attachment points must be adequately

strong (observe EN )!

CAUTION THREAT TO LIFE:

When selecting the anchor point,

minimise the fall height and/or the free

fall!

USE IN ARRESTING SYSTEMS

I If the connector is used in an arresting

system, only a full body harness that

complies to EN may be used.

Observe the User Manual of the

full body harness.

CAUTION:

The length of the connector needs to be

taken into account when used in an

arresting system because this impacts

on the fall path.

I

EN

There is a risk to life if these safety

instructions are not observed!

• The personal protective equipment

(PPE) may no longer be used even in

the case of very minor faults.

• Damaged, fall-stressed, dubious

personal protective equipment or

safety devices must be immediately

withdrawn and not used. The

equipment may only be inspected by

an expert in compliance with DGUV

principle -, by BORNACK or by a

workshop authorised in writing by

BORNACK. This must be documented

in the test card.

• Independent modifications or repairs

are not allowed.

• •Rope protection is part of the

personal fall prevention equipment

and should be assigned to a specific

person.

• The personal protective equipment

may only be used by qualified staff

that are familiar with the material.

They must be proficient in handling

the personal protective equipment

and must have been briefed about the

possible risks associated with its use.

• In accordance with the accident

prevention guidelines (UVV), the users

of fall protective equipment (Category

III) must attend a theoretical training

course and a practical training course.

To this end, profit from the training

competence of the BORNACK training

centres info@bornack.de

• Accessories from other manufacturers

may only be used if approved by

BORNACK and may not impair the

function and safety of the protective

equipment.

• Clothing and shoes must be suitable

for the task at hand and the weather

conditions.

• Only use if fully fit and healthy. Health

impairments can jeopardise the safety

of the user when working at heights or

depths.

• If this PPE is used as an arresting

system (free fall is possible), only full

body harnesses that comply with

EN may be used.

• Calculation of the possible fall path, if

all necessary PPE components are used

correctly: (if necessary braking path

HSG) + surplus connector (situation-

dependent) + braking path energy

absorber (max. . m) + height of

D-ring (. m) + safety reserve . m.

• Before using, ensure adequate

clearance below the user to prevent

impact on a protruding object or the

ground.

SAFETY INSTRUCTIONS

|

• Protect PPE during storing, use and

transportation against the effects of

heat (e.g. welding flames or sparks,

burning cigarettes) and chemicals (e.g.

acids, alkalis, oils) and mechanical

impact (e.g. sharp edges).

• The combinability and protective

eect of the PPE must be checked for

each hazard situation (risk assess-

ment).

• If a casualty hangs motionless in a full

body harness for a longer time, blood

cannot flow back from the legs and/or

the flow may be interrupted. This can

lead to a suspension trauma, a

circulatory shock with serious to fatal

consequences.

• Before starting work, the responsible

person must draw up a plan of rescue

measures that defines how to rescue

casualties quickly and safely and

ensures first aid measures. Casualties

must be rescued within minutes.

BORNACK can help you draw up tailor-

made rescue plans and includes these

in the necessary training courses.

E-Mail Hotline: info@bornack.de

• The local safety guidelines (e.g. in

Germany, the DGUV Regulations

- and - issued by the

professional associations) and the

accident prevention guidelines for the

specific industry (UVV) must be

observed.

• Connectors with manual locking

fasteners should only be used if the

user does not hook it in and out very

frequently, e.g. several times during a

work day.

SAFETY INSTRUCTIONS

EN

OTHER

APPROVAL

Complies with the Directive (EU)

/ for PPE.

Type testing and production monitoring

by:

TÜV Süd, Product Service GmbH

Daimlerstr. , D- Garching

CE

Quality management system certified to

DIN EN ISO :.

Production monitoring by notified oce

in accordance with Category III.

REGULAR INSPECTIONS

• This personal protective equipment

must be inspected at least once a year

by an expert in compliance with DGUV

Principle -. The result must be

documented in the test card at the end

of this User Manual.

SALES

• The dealer must ensure that the User

Manual is supplied in the language of

the designated country. The respective

translation must be authorised by

BORNACK.

SERVICE

If you have any further questions about

this PPE or other BORNACK services,

such as:

• Risk analysis

• Rescue plans

• Training courses

• Expert inspections

• Technical inspections

• Maintenance + inspections

please send your question to our e-mail

hotline Hotline: info@bornack.de

We will be happy to help!

|

OTHER

MAINTENANCE

• If necessary, use small quantities of

silicon oil to protect the thread against

soiling. Mineral oils may not be used

on the O LIGHT because the O-rings of

the screws could become corroded.

Ensure that the oil does not come into

contact with textile PPE components.

• Maintenance may only be carried out

by a qualified expert in compliance

with DGUV Principle -. All

instructions in this user manual must

be strictly observed.

• Protective equipment that is clean and

well looked after will last longer!

CLEANING

• Dry damp personal protective

equipment in the air, not on artificial

heat sources. Dry metal components

with cloths.

• If disinfection is necessary, please

contact the e-mail hotline:

info@bornack.de

• If the personal protective equipment

comes into contact with saltwater,

keep it wet until it can be rinsed with

plenty of distilled water.

• Use compressed air to blow on the

unit if necessary.

LIFE SPAN

Metal parts are not subject to age-

related life span deadlines. The expert

makes a decision about these parts

based on his technical expertise.

For reasons of safety, intensive use and/

or extreme application conditions such

as sharp edges, chemical influences etc.

will reduce the usage period. The

company owner needs to take this into

account in the workplace risk analysis.

The test card at the end of this user

manual must be presented during the

regular expert inspections and be

completed by an expert.

For more details, please visit is available

online at www. bornack.de.

REPAIRS

• For reasons of liability, repairs may

only be carried out by BORNACK or in a

workshop authorised in writing by

BORNACK.

• Only original spare parts from the

manufacturer may be used.

EN

STORAGE

• Dry damp PPE before storage.

• Store in a dry place away from direct

sunlight.

• Do not store PPE near radiators.

Permanent exposure to temperatures

or more than + °C has a negative

impact on the strength of the

materials and shorten the life span.

• Do not allow PPE to come into contact

with aggressive substances (e.g. oils,

grease, acids, chemicals).

• Do not store PPE close to aggressive

substances (see above) because even

the vapours of aggressive substances

can have a negative effect on the

strength of the PPE. Small quantities

of silicone oil may be applied to the

thread of the O LIGHT. Always ensure

that textile PPE components do not

come into contact with the oil.

• Protected storage in the device case or

device bag.

TRANSPORT

• Protected transport in the device case

or device bag.

OTHER

|

OTHER

Manufacturer address

Packaging:

PRODUCT IDENTIFICATION

The following identification is on the product:

Eloxal rot

Eloxal schwarz

V

e

r

b

i

n

d

u

n

g

s

e

l

e

m

e

n

t

A

r

t

.

N

r

.

1

0

0

5

3

7

9

C

h

a

r

g

e

:

1

2

3

4

5

6

7

S

e

r

i

e

n

N

r

.

:

x

x

x

x

E

N

3

6

2

:

2

0

0

4

-

M

w

w

w

.

b

o

r

n

a

c

k

.

d

e

M

M

/

J

J

J

J

2

3

k

N

BORNACK GmbH & Co. KG

Bustadt 39

74360 Ilsfeld

Kennzeichnung auf

der Verpackung

Logo

Upper part:

Eloxal rot

Eloxal schwarz

V

e

r

b

i

n

d

u

n

g

s

e

l

e

m

e

n

t

A

r

t

.

N

r

.

1

0

0

5

3

7

9

C

h

a

r

g

e

:

1

2

3

4

5

6

7

S

e

r

i

e

n

N

r

.

:

x

x

x

x

E

N

3

6

2

:

2

0

0

4

-

M

w

w

w

.

b

o

r

n

a

c

k

.

d

e

M

M

/

J

J

J

J

2

3

k

N

BORNACK GmbH & Co. KG

Bustadt 39

74360 Ilsfeld

Kennzeichnung auf

der Verpackung

Eloxal rot

Eloxal schwarz

V

e

r

b

i

n

d

u

n

g

s

e

l

e

m

e

n

t

A

r

t

.

N

r

.

1

0

0

5

3

7

9

C

h

a

r

g

e

:

1

2

3

4

5

6

7

S

e

r

i

e

n

N

r

.

:

x

x

x

x

E

N

3

6

2

:

2

0

0

4

-

M

w

w

w

.

b

o

r

n

a

c

k

.

d

e

M

M

/

J

J

J

J

2

0

k

N

BORNACK GmbH & Co. KG

Bustadt 39

74360 Ilsfeld

Kennzeichnung auf

der Verpackung

Product type

Charge

Article no.

Lower part:

EN norm

Serial no.

Static

durability

Production

date

Contact

Observe/read the

User Manual

Product name CE-symbol and

Number of the

Testing oce

EN

EU DECLARATION OF CONFORMITY

|

The test list must be

completed in full by the

expert during the annual

inspection.

This test list does not

claim to cover all test

criteria and does not

relieve the expert from

his decision about the

overall condition.

TEST CARD

FOR ANNUAL MONITORING

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

. year

. year

. year

. year

. year

. year

. year

. year

. year

. year

Date Signature Next

Inspection Reason for inspection

Type product name: O LIGHT

Production date:

_________________________

Charge no:

______________

Serial no.:

_______

Purchase date:

__________________________

Date of first use:

_________________________

Life span ends at the latest:

_________________

EN

Please complete

year . . . . . . . . . .

No mechanical

damage?

No deformation?

No chemical soiling?

No corrosion

damage?

Screws and thread

undamaged?

Screws can be turned

in and out easily

Are O-rings on the

screws?

O-rings not porous/

damaged/worn?

Identification legible?

User Manual

available?

OK

Blocked

TEST CARD

FOR ANNUAL MONITORING

|

Notes:

EN

Notes:

BORNACK GmbH & Co. KG

Bustadt 39

74360 Ilsfeld

Germany

Tel + 49 (0) 70 62 / 26 90 0-0

Fax + 49 (0) 70 62 / 26 90 0-550

info@bornack.de

www.bornack.de

BORNACK Schweiz

Untere Brühlstr. 11

4800 Zofingen, AG

Switzerland

Tel + 41 (0) 62 / 886 30 40

info@bornack.ch

www.bornack.ch

FALLSTOP

Safety equipment for securing and

rescuing at heights and depths

SAFEPOINT

Permanently installed safety systems

for architects and industry

© BORNACK – Subject to technical changes

Reprinting or duplication, even of excerpts, is only permitted with written

consent

Status: 09/2018 GAL Nr. 000 172 anh

Table of contents

Popular Cables And Connectors manuals by other brands

BK TECHNOLOGIES

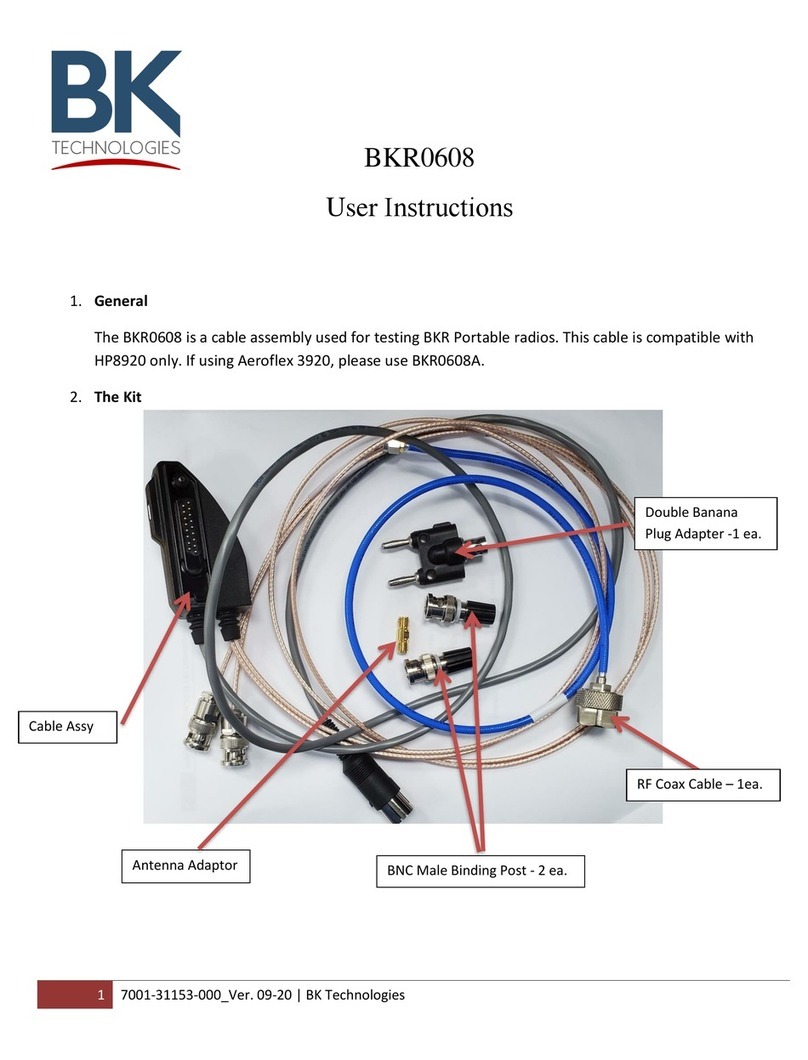

BK TECHNOLOGIES BKR0608 User instructions

Rean

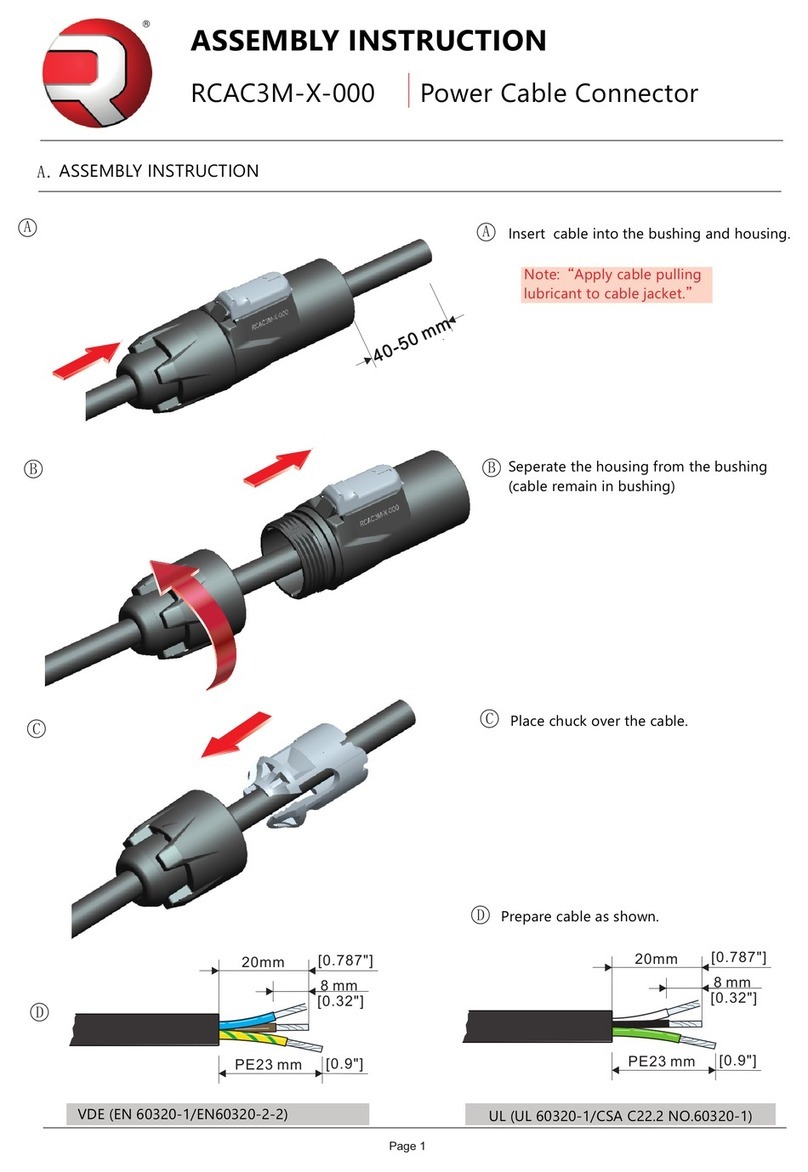

Rean RCAC3M-X-000 Assembly instruction

NETVIO

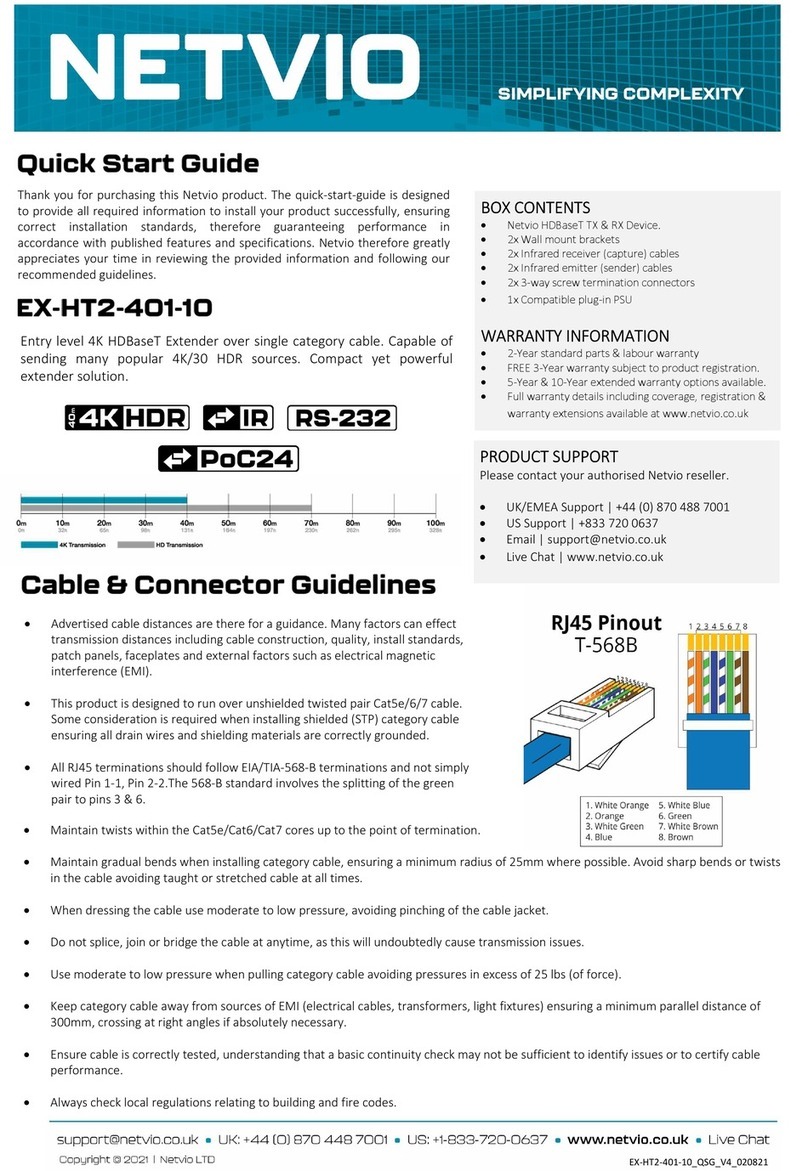

NETVIO EX-HT2-401-10 quick start guide

HUBER+SUHNER

HUBER+SUHNER QUICK-FIT 23 010 372 Assembly instruction

AOR

AOR LA400-RCK quick start guide

Comar Systems

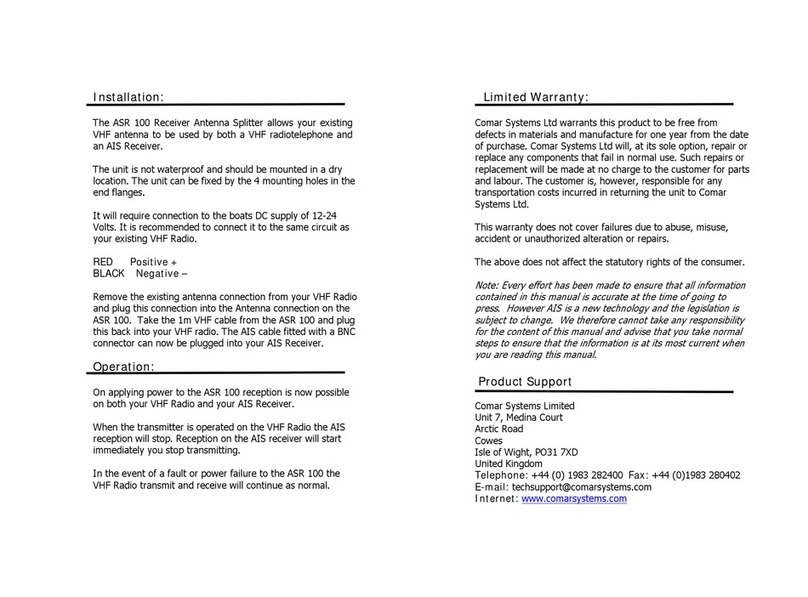

Comar Systems ASR 100 Installation and quick reference guide