1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the con-

sequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of fail-

ure to observe action and information given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-obser-

vance:

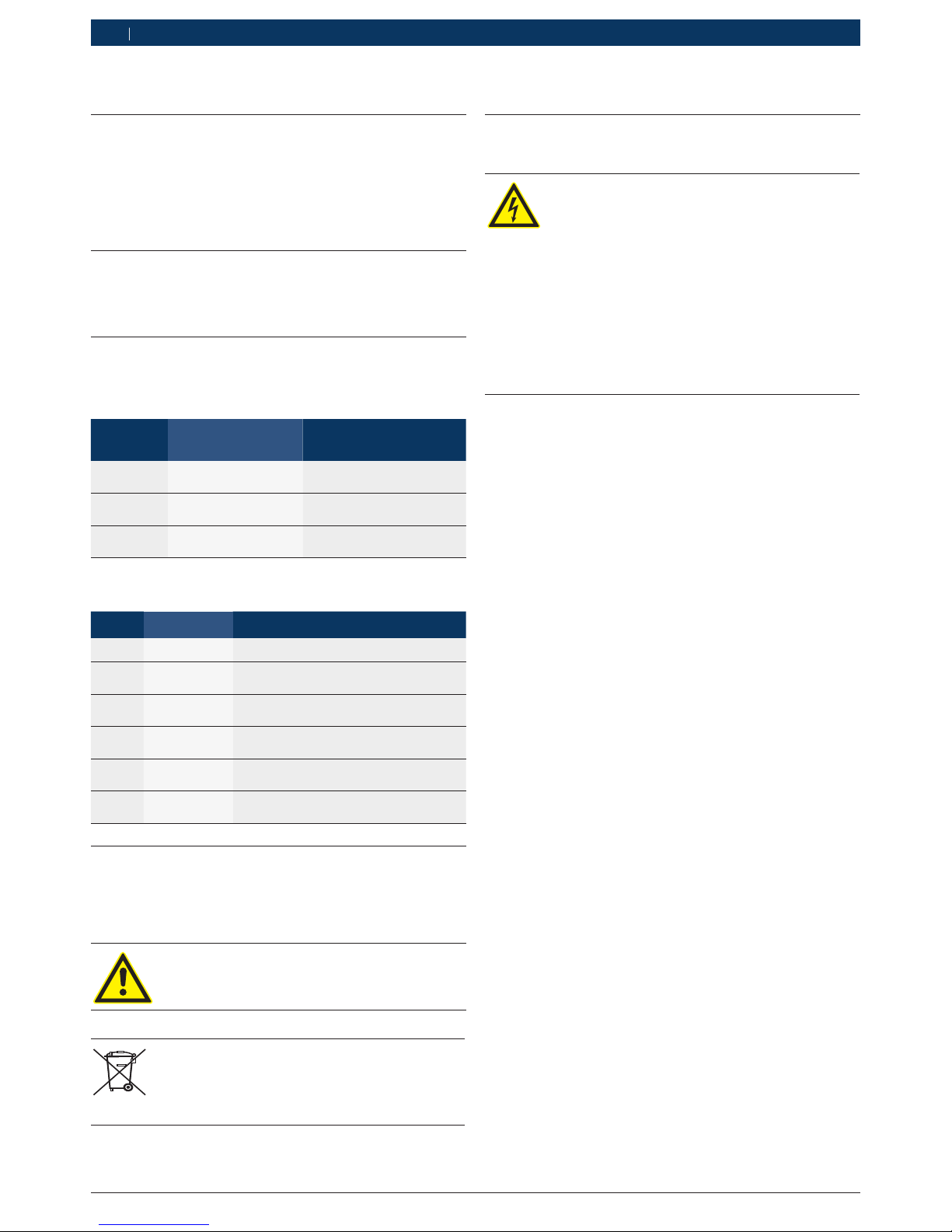

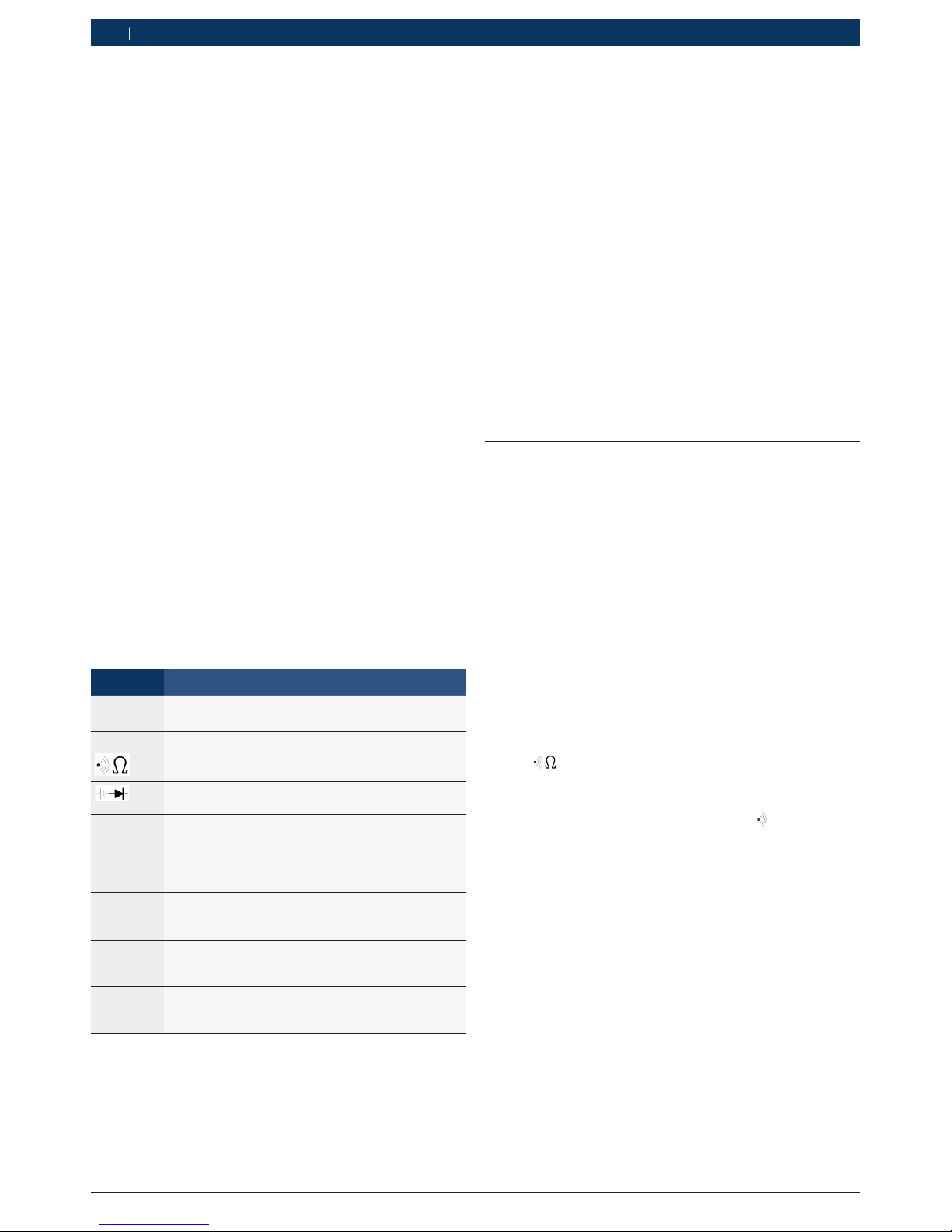

Key word Probability of

occurrence

Severity of danger if in-

structions not observed

DANGER Immediate impend-

ing danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

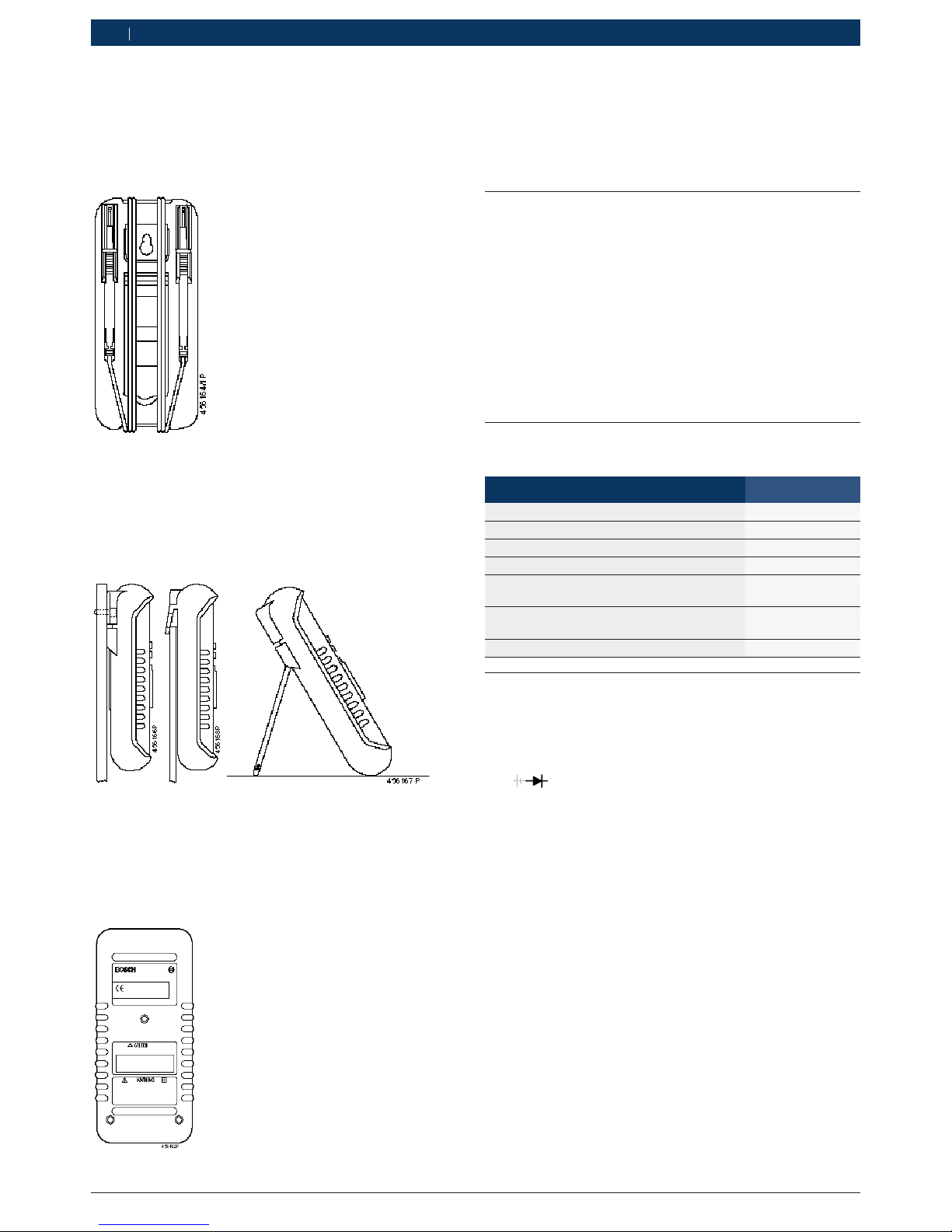

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible inter-

mediate result.

"Final result There is a visible final result on com-

pletion of the instruction.

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible.

Instructions for your personal safety and

for the protection of equipment/vehicle

components

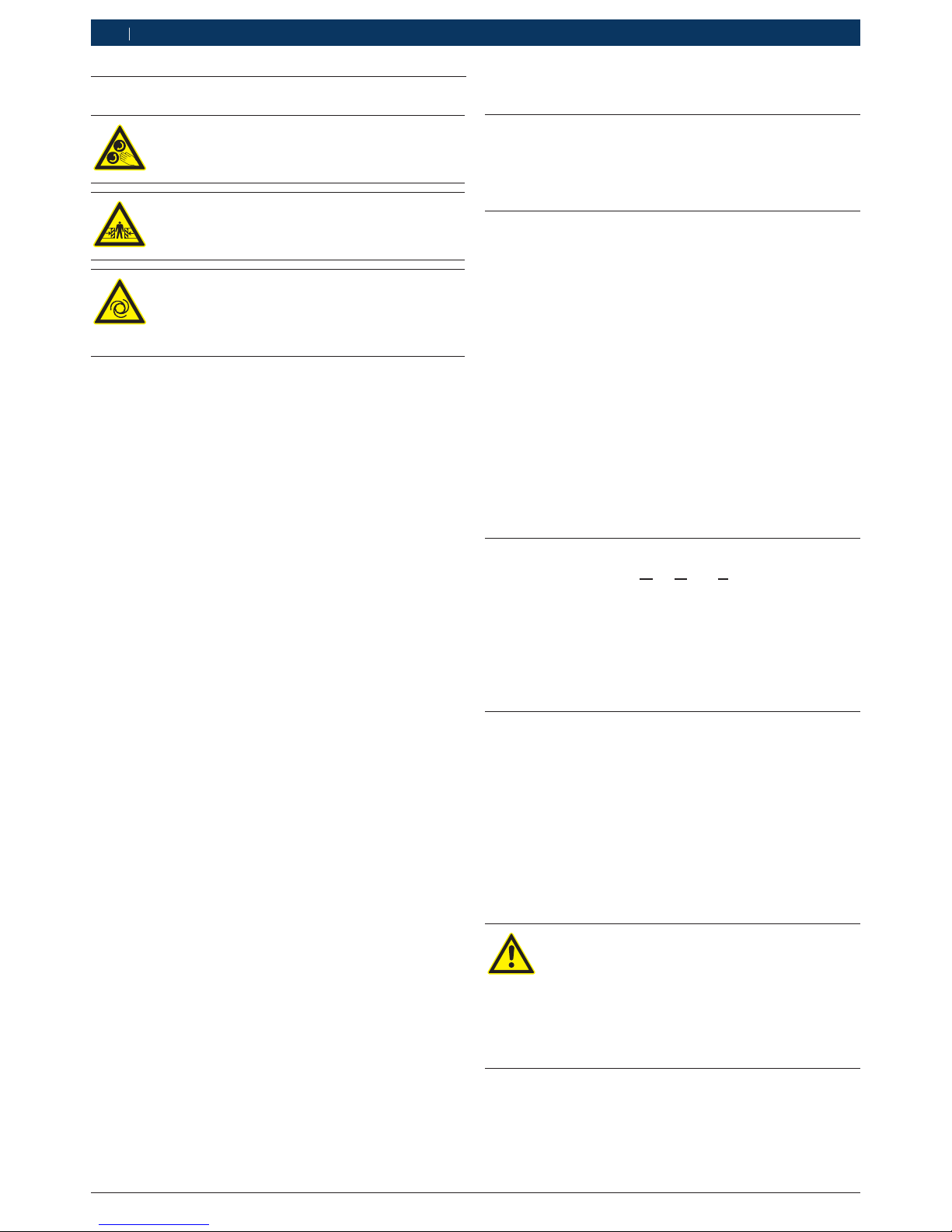

2. Safety instructions

2.1 Risk of electric shocks

2.1.1 Low voltages, high voltages

Hazardous voltages occur in both the lighting

system and the electrical system of a motor

vehicle. If contact is made with live parts

(e.g. with the ignition coil), there is a risk of

electric shock from flashover voltages caused

by damaged insulation (e.g. ignition cables

which have been attacked by martens). These

apply to the secondary and primary sides of

the ignition system, the wiring harness with

connectors, lighting system (Litronic) as well

as connection to the vehicle.

Safety measures:

¶Only connect to a properly grounded outlet.

¶Only the enclosed or a tested power supply cable is

to be used.

¶All extension cables must be fitted with shock-proof

contacts.

¶Do not exceed the voltage limits as specified on the

connection cables.

¶Any cables with damaged insulation must be re-

placed.

¶Before connecting it to the vehicle, first connect the

product to the lighting mains and switch on.

¶Before switching on the ignition connect the (B-)

cable to engine ground or the battery (B–) terminal.

¶Always switch off the ignition before performing any

work on the electrical system of the vehicle. Inter-

vention includes, for instance, connection to the

vehicle, replacement of ignition system components,

removal of equipment (e. g. alternators), connection

of equipment to a test bench.

¶Wherever possible, tests and settings should always

be caried out with the ignition switched off and the

engine stationary.

¶If tests or settings are carried out with the ignition

switched on or the engine running, care must be

taken not to touch any live parts. This applies to all

connection cables and leads as well as to connec-

tions of equipment to test benches.

¶Test connections must always be made using suit-

able connectors (e.g. Bosch testing cable set or

vehicle-specific adapter cables).

¶Make sure that all test connections are properly

plugged in and secure.

¶Before disconnecting the (B-) cable from the engine

ground or battery (B–), switch off the ignition.

¶Never open the enclosures.

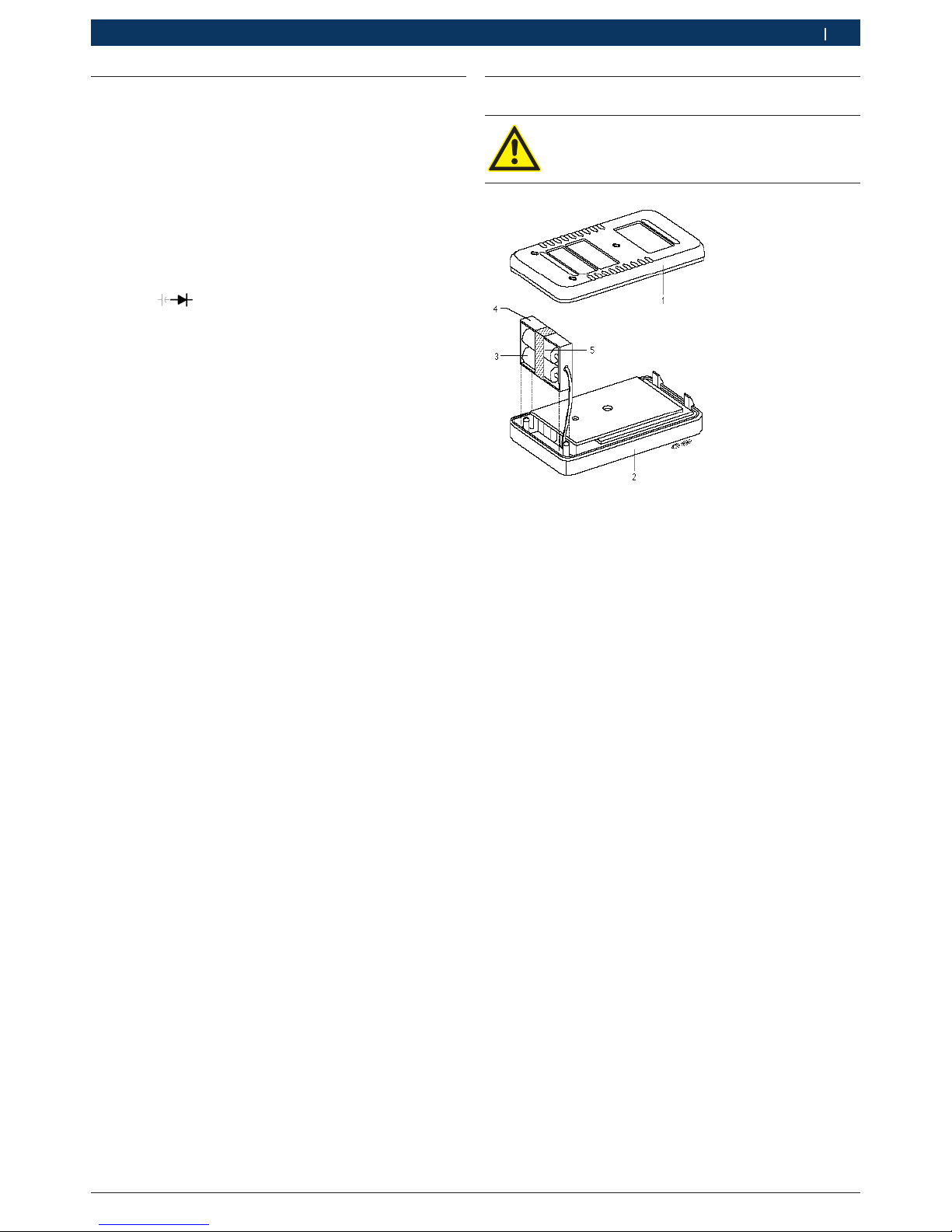

Disposal

Dispose of used electrical and electronic

devices, including cables, accessories and

batteries, separately from household waste.