8/128 About this documentation

Bosch Rexroth AG, CytroBox, RE 51057-B/11.19

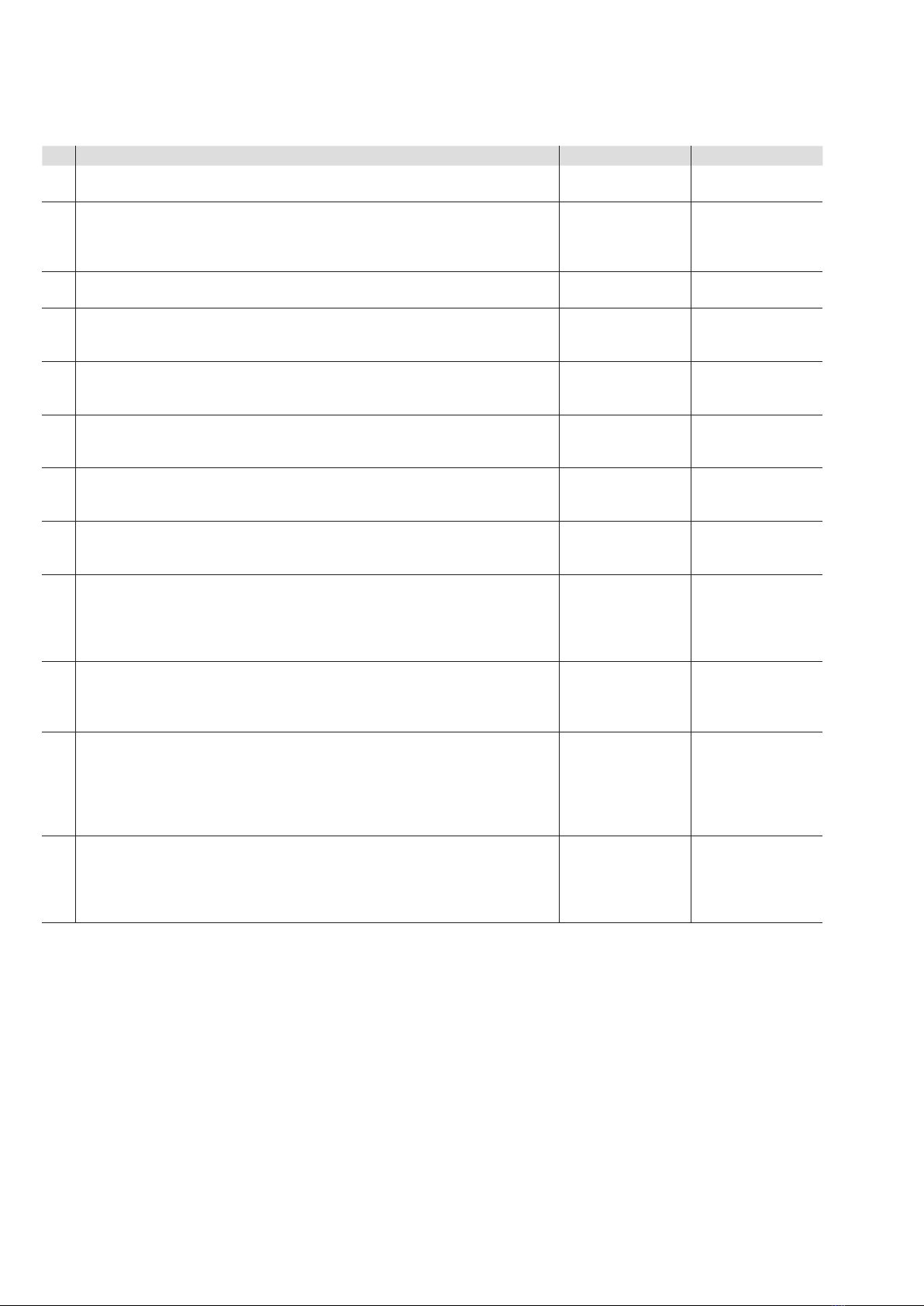

Table 1: Required and amending documentation

Title Document number Document type

Sytronix, SvP 7020 IMC, variable-speed pump drives

Includes information on the electric drive system.

R911377187 Operating

instructions

Axial piston units A10FZO, A10VZO and A10FZG, A10VZG;

Series 10 for variable-speed drives

Includes technical data, operating conditions, performance limits and project

planning information

91485 Datasheet

General operating instructions for axial piston units

Includes amending information on datasheet 91485.

90300-B Operating

instructions

IndraDyn S, synchronous motors MS2N

Includes information for the operating, service and maintenance personnel and

basic instructions on installation, operation and maintenance of the motors.

R911347580 Operating

instructions

Rexroth IndraDrive, drive controllers, power sections HCS03

Includes information on the installation and operation of the drive controllers,

power sections HCS03 in short.

R911327655 Instructions for use

Rexroth IndraDrive, drive controllers, power sections HCS03

Includes information on the installation and operation of the drive controllers,

power sections HCS03.

R911339023 Operating

instructions

Rexroth IndraDrive, control sections CSB02, CSE02, CSH02, CDB02

Includes information on the installation and operation of the control sections

CSB02, CSE02, CSH02 and CDB02.

R911338961 Project planning

description

IndraDrive, MPx-20, functions

Describes all functional properties of variants MPB-20, MPM-20, MPC-20 and

MPE-20.

R911345607 Application

description

Rexroth IndraDrive, integrated safety technology "Safe Torque Off"

(as of MPx-16)

Includes information on the assembly and maintenance, on the correct and

safe operation and on the decommissioning of the integrated safety technology

"Safe Torque Off" of the IndraDrive drive technology.

R911332633 Application

description

MS2N synchronous servo motors

Explains the product properties, application possibilities, application conditions

and operating limits of the motors, includes the data of the available motors and

gives advice on product selection, handling and operation.

R911347582 Project planning

instructions

Rexroth IndraDrive, IndraDrive with PROFINET, example with

Siemens SIMATIC S7

This documentation explains the commissioning of the following drives:

IndraDriveC, IndraDrive M and IndraDrive Cs with PROFINET communication.

Theconnection to the drive for commissioning is established via a SIMATIC

control system by Siemens.

R911341342 Commissioning

instruction

Rexroth IndraDrive, IndraDrive with EtherCAT, example with Beckhoff TwinCAT

This documentation explains the commissioning of drive controllers of the

following drive families: IndraDrive C, IndraDrive M, IndraDrive Mi and IndraDrive

Cs with EtherCAT communication in connection with the external control TwinCAT

by Beckhoff.

R911341344 Commissioning

instruction