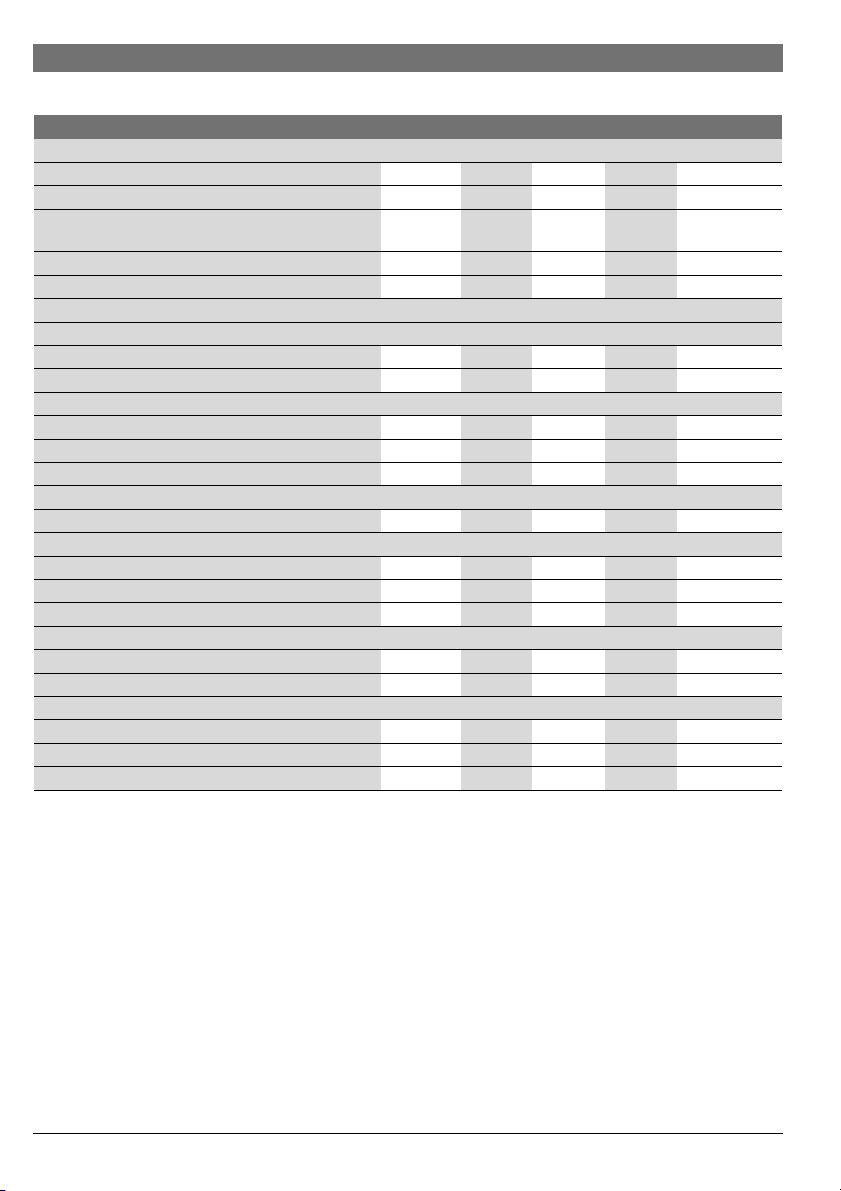

Bosch WR 11 G Series Technical Document

Other Bosch Water Heater manuals

Bosch

Bosch GWH 10-2 G Series Technical Document

Bosch

Bosch TR5000R Series User manual

Bosch

Bosch BC3200RA User manual

Bosch

Bosch C 1210 ESC Reference manual

Bosch

Bosch Greentherm T9800 SEO199 User manual

Bosch

Bosch Therm 8000 S GWHC 27 CTDE User manual

Bosch

Bosch PowerStar AE115 User manual

Bosch

Bosch Pro Tankless GWH-635-ES-N User manual

Bosch

Bosch TR5000R 24/27 EB User manual

Bosch

Bosch BC2600RA User manual

Bosch

Bosch TR1500TOR 5 T User manual

Bosch

Bosch GWH 1600 P NG User manual

Bosch

Bosch W 135 K B Series User guide

Bosch

Bosch T5600S 12 D 23 Operating and installation instructions

Bosch

Bosch TR4000 4 ET User manual

Bosch

Bosch RDE182141M User manual

Bosch

Bosch Tronic ES 030 Series Operating manual

Bosch

Bosch AQUA STAR 2400E NG User manual

Bosch

Bosch GWH-425-EF-N User manual

Bosch

Bosch Aquastar GWH 1600 H N User manual

Popular Water Heater manuals by other brands

Kenmore

Kenmore 153.582400 Use & care guide

STIEBEL ELTRON

STIEBEL ELTRON Eltronom SHU 5 S Operating and installation instructions

clage

clage E-Mini Series Operating and installation instructions

Toyotomi

Toyotomi Oil Miser OM-180 installation manual

Bradford White

Bradford White EF Series Service manual

Eccotemp

Eccotemp 40-H Use & care manual

Dimplex

Dimplex ECSd125-580 Installation and user instructions

Dux

Dux 32FCR6N installation manual

Noritz

Noritz N-132M Owner's guide and installation manual

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions