2

Table of Contents

Troubleshooting Guide Overview ....................................................................................................1

Table of Contents .......................................................................................................................... 2-

Section 1, Bass Box Only Procedures....................................................................................... 4-21

Section 1 Contents............................................................................................................................4

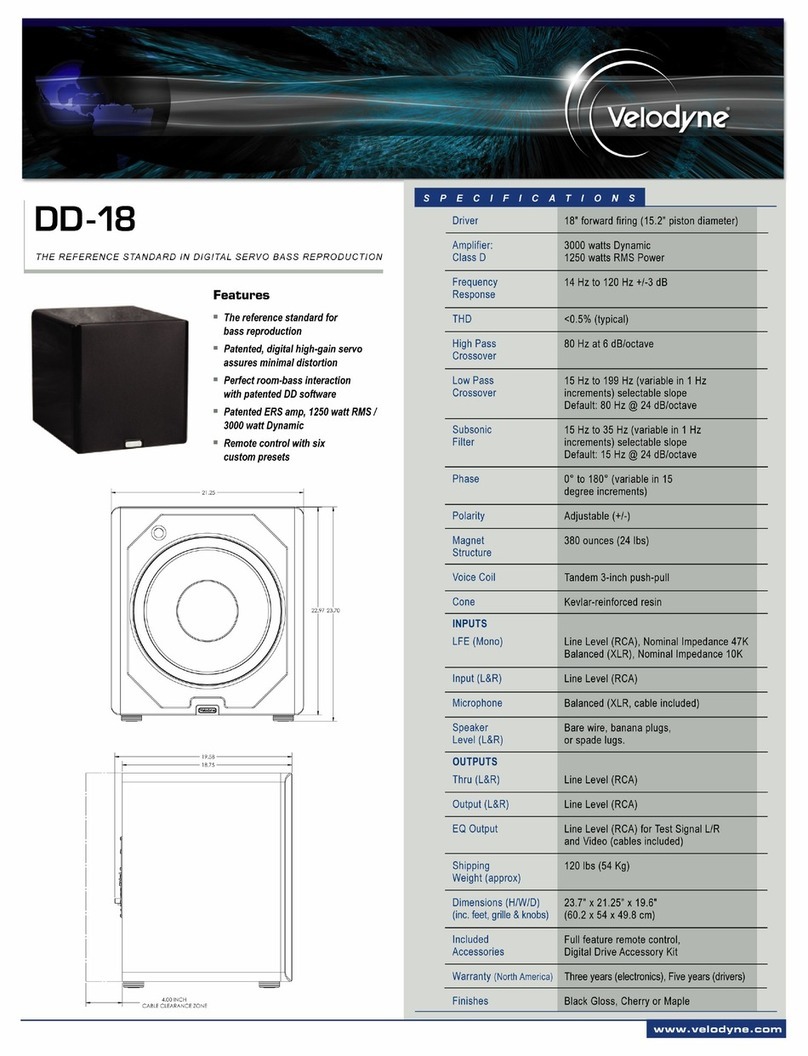

Test Set-up Parameters and Equipment .........................................................................................5

Bass Box Only Troubleshooting Procedures..................................................................................5

Bass Box Only Test Procedures .................................................................................................. 6-7

Figure 1. Scope Photo of Boot Prompt at J5 Pin 11..........................................................................7

Amplifier PCB Hook-Up Procedures ......................................................................................... 8-11

Figure 2. Cable for Amplifier Output Connection at J701 ..................................................................8

Figure 3. Output Wire Connection View at J701 ...............................................................................8

Figure 4. Input Wire Connection View at J700 ..................................................................................9

Figure 5. Triac Jumping View on DSP PCB .....................................................................................10

Amplifier Test Procedures ..............................................................................................................12

DSP PCB Troubleshooting Procedures ................................................................................... 1 -19

Figure 6. Codec to DSP, Digital Audio Signal Path ..........................................................................17

Figure 7. Micro to/from DSPs..........................................................................................................17

Figure 8. DSP PCB Test Point Locations Layout Diagram, Solder Side ..........................................19

Scope Photos ............................................................................................................................ 20-21

Figure 9. Codec (U100) Scope Photo, Mute Condition ...................................................................20

Figure 10. Microcontroller (U202) Scope Photo, Power Up ............................................................21

Figure 11. Microcontroller 8 MHz cloc at U202 pin 39...................................................................21

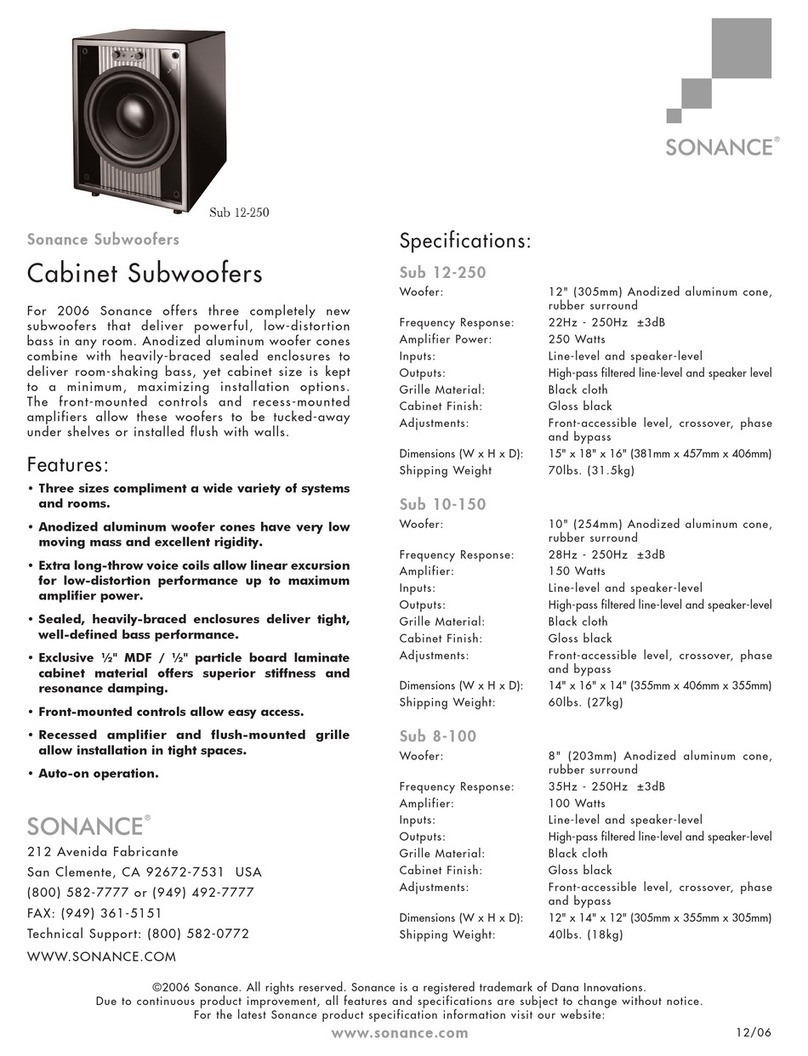

Section 2, Bass Module with Head Unit Procedures.............................................................. 22-41

Section 2 Contents..........................................................................................................................22

Normal System Operation Description .........................................................................................2

Test Setup Procedures ...................................................................................................................24

Connection of Bass Module Using a CD-5/CD-20 Music Center.................................................24

Bass Box Troubleshooting Procedures................................................................................... 25-

Figure 12. Scope Photo of Boot Prompt at J5 Pin 11......................................................................26

Figure 13. Codec to DSP, Digital Audio Signal Path........................................................................ 2

Figure 14. Micro to/from DSPs ........................................................................................................ 2

DSP PCB Troubleshooting.............................................................................................................. 4

Figure 15. DSP PCB Test Point Locations Layout Diagram, Solder Side ........................................ 4

Scope Photos ............................................................................................................................ 5-41

Figure 16. Codec (U100) Scope Photo, Un-mute Condition ........................................................... 5

Figure 17. Codec (U100) Scope Photo, Mute Condition ................................................................. 6

Figure 18. Microcontroller (U202) Scope Photo, Power Up ............................................................ 7

Figure 19. SPDIF Signal at U100 pin 42 ......................................................................................... 8

Figure 20. Microcontroller 8 MHz cloc at U202 pin 39................................................................... 8

Figure 21. Codec 11.2896 MHz Cloc ............................................................................................ 9

Figure 22. 40 MHz DSP cloc ......................................................................................................... 9

Figure 23. 3.3V Switching Power Supply Signals............................................................................40

Figure 24. Power Up Condition at U202 Pin 25...............................................................................40

Figure 25. Transmit Frame Sync .....................................................................................................41

Figure 26. Serial Data Cloc ...........................................................................................................41

Figure 27. Audio Data .....................................................................................................................41

Section , Computer Aided Troubleshooting .......................................................................... 42-64

Section Contents..........................................................................................................................42

Test Setup Parameters and Equipment.........................................................................................4

Test Setup Procedure .....................................................................................................................4