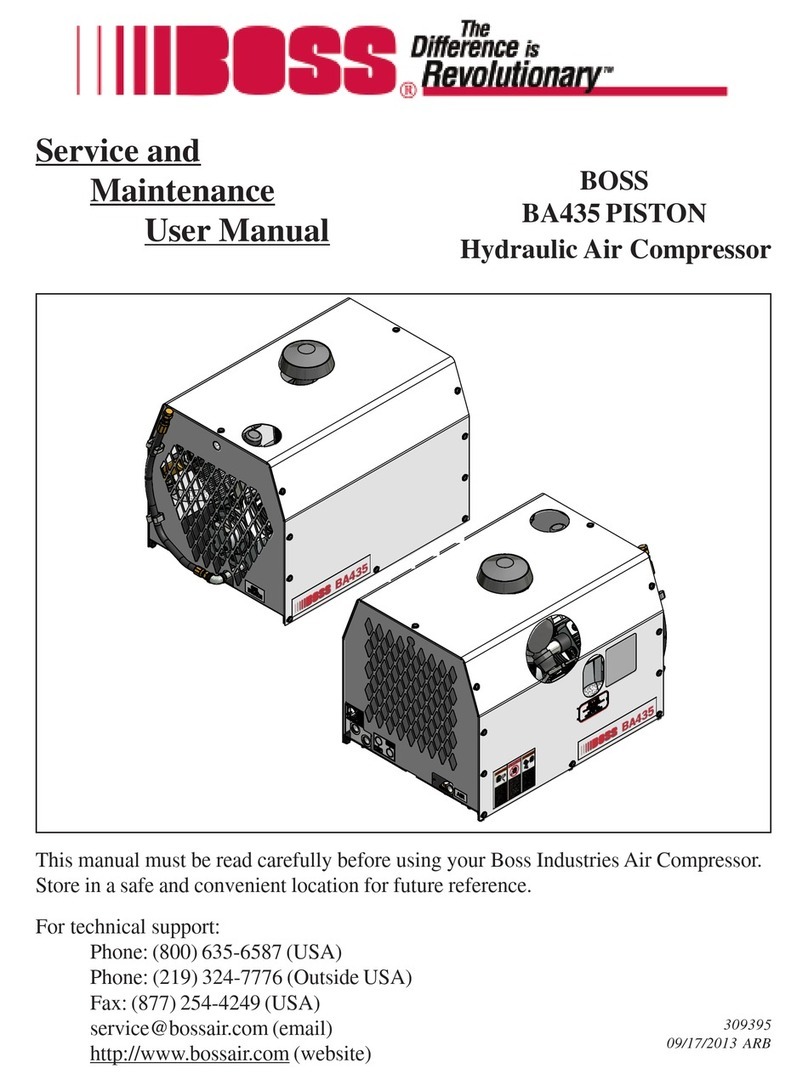

Boss Industries INFINITY 35 User manual

310928

8/23/2016 AEM

http://www.bossair.com

Product Manual

INFINITY 35

Hydraulically Driven Air Compressor

This manual must be read carefully before using your Boss Industries, LLC INFINITY 35. Store in a safe

and convenient location for future reference.

- 2 - 310928

- 3 - 310928

Contents

Welcome...............................................4

General Information.........................................4

Safety....................................................5

General Safety Overview.................................5

Safety Precautions...........................................6

Specifications......................................8

Specification Sheet..........................................8

Installation & Operation......................9

Mounting the Compressor................................9

Installation of Air Storage Tanks....................10

Installation of Wiring.......................................10

Connecting the Hydraulic Hoses....................11

Pre-Start-up Inspection Checks.....................11

Check All Fluid Levels....................................11

Machine Documentation................................11

Lifetime Warranty Registration.......................11

Shutdown Procedure.....................................12

Operating Conditions.....................................12

Operating Procedure......................................12

Maintenance.......................................13

Lifetime Warranty Information........................13

Recommended Spare Parts List....................13

Maintenance Chart.........................................14

Compressor Oil..............................................15

Compressor Oil Fill, Level, and Drain............16

Changing the Oil Filter...................................16

Changing the Air/Oil Coalescer......................17

Changing the Air Intake Filter........................17

Compressor Drive Belts.................................18

Troubleshooting................................19

Improper Discharge Pressure........................19

Sump Pressure Does Not Blow Down...........19

Oil Consumption.............................................19

Coalescer Plugging........................................20

High Compressor Discharge Temperature....20

Contacting Boss Industries, LLC....................20

Warranty.............................................21

- 4 - 310928

Welcome

General Information

Thank you for choosing the Boss Industries, LLC

INFINITY 35 Hydraulically Driven Air Compressor.

Before operating, carefully read this manual and

become well acquainted with your new machine.

Doing this will increase your safety and maximize

the life of the machine.

While this manual is written to be as accurate as

possible, Boss Industries, LLC strives to continually

improve the efficiency and performance of its

machines. As a result, sometimes there may be slight

differences between a given version of the manual

and the machine.

- 5 - 310928

Safety

General Safety Overview

- 6 - 310928

Safety

Safety Precautions

The following safety precautions are a general guide to safe operation of the equipment.

- 7 - 310928

Safety

Safety Precautions (continued)

- 8 - 310928

Specifications

Specification Sheet

COMPRESSOR SPECIFICATIONS

Model INFINITY 35

Type Hydraulically Driven Air Compressor

Output

Compressor RPM

Hyd Flow Hyd Pressure

Delivery

20 CFM @ 110 PSI 4400 8.2 GPM 1500 PSIG

25 CFM @ 110 PSI 5400 10.1 GPM 1500 PSIG

30 CFM @ 110 PSI 6400 12.0 GPM 1500 PSIG

35 CFM @ 110 PSI 7200 13.5 GPM 1500 PSIG

35 CFM @ 150 PSI 7300 13.7 GPM 1800 PSIG

35 CFM @ 175 PSI 7400 14.0 GPM 2100 PSIG

Operating Pressure

Range 80 - 175 PSIG

Ambient Operating

Temperature Range -20° - 110°F

Oil Capacity

(Compressor) 1 gallon

Air Service Connection 1/2” NPT

Overall Dimensions 28.89” L X 19.34” W X 21.82” H

Weight 200 lbs.

*CALCULATIONS PERFORMED @ 85% EFFICIENCY MECHANICAL AND 96% EFFICIENCY

VOLUMETRIC.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

- 9 - 310928

Installation & Operation

Mounting the Compressor

When mounting the compressor, care should be taken

to ensure that its location does not impede the

operation of other components on the vehicle. For

example, if your vehicle is equipped with a crane, you

must make sure the compressor will not interfere with

the swing of the crane. In addition, the compressor

should be installed in an area that permits cool

ambient air to enter the air filter and the hot air to

exhaust without recirculating into the machine. A

minimum of 12” of clearance is needed for the hot

discharge air from the cooler. A minimum of 10” of

clearance is required from the rear of the compressor

to allow for proper air intake. Cool ambient air is

drawn in from the rear of the machine. One last

consideration in the mounting should be the routing

of hydraulic hoses. Be sure these can be safely run

to the hydraulic manifold on the machine. The unit

should be secured to the vehicle with four 3/8” grade

8 bolts, flat washers, and loc washers. Ensure that

you have a sub structure that will support the weight

of the compressor. Be sure to follow all National

Vehicle Safety Standards.

- 10 - 310928

Installation of Air Storage Tanks

This rotary screw air compressor system is designed

to provide continuous volume and constant pressure

without the use of an air storage tank. Within a few

seconds of engagement, the compressor will produce

full volume and pressure needed to run corresponding

air operated equipment without waiting for air tanks

to fill.

Air storage tanks are not utilized as standard

equipment on vehicle mounted rotary screw

compressors. The installation of air storage tanks, if

not done properly, will hinder the performance of the

rotary screw compressor. Boss Industries, LLC

strongly discourages the use of an air storage tank as

standard equipment for vehicle mounted rotary screw

air compressors.

In the rare event air usage is required without

operating the vehicle, an air storage tank can be added

to your system. When adding an air storage tank, be

sure to follow all state and federal DOT regulations

regarding air storage tank usage.

Installation of Wiring

This unit is shipped from the factory with all

necessary internal wiring installed. The only

remaining wiring necessary is the wiring needed to

interface your vehicle/power source with the Boss

compressor. The unit is shipped with 1 end of a 4 pin

connector. They need to be connected as follows:

Pin A) Battery Power

Pin B) Power out to hydraulic system solenoid

through safeties

Pin C) Battery Ground

Pin D) 12VDC switched power for operation

Pin ‘B’ should be used to direct hydraulic flow to the

compressor. This wire can also be used with a relay

to signal the engine speed to increase if additional

hydraulic flow is required during compressor

operation. See one example below.

Installation & Operation

- 11 - 310928

HYD PRESSURE IN

-10 SAE

5/8" MIN HOSE ID

HYD RETURN OUT

-16 SAE

1" MIN HOSE ID

ELECTRICAL CONNECTION AIR OUTLET

1/2" FNPT

COMPRESSOR

OIL FILL

Installation & Operation

Connecting the Hydraulic Hoses

The hydraulic hoses to the compressor should be

connected directly to the hydraulic manifold with

appropriately sized fittings. The input line should be

made from a good quality high pressure (min. 3000

PSI) hydraulic hose 5/8" i.d. The return line can be

made from a medium pressure (min 1500 psi)

hydraulic hose 1" i.d. Care should be taken to see

that the hoses are not installed with kinks or bends

that inhibit flow of the hydraulic oil. Lack of flow

could result in damage to the motor and compressor.

Lastly, check to make sure hoses are not in contact

with sharp objects or edges that may fray, chafe, or

cut them over time. Secure all hoses with tie down

straps or clamps.

Pre-Start-up Inspection Checks

This inspection should be done prior to the

compressor test.

I. Check all assemblies, clamps, fittings, hose

connections, nuts, and bolts to ensure they are

properly tied and secured to the vehicle. This

is a very critical area of inspection. The

vehicle should not be moved until this

inspection has been completed.

II. Remove all tools, rags, and installation

equipment from the area.

III. Check all valves to ensure they are in correct

operating position.

IV. Vacuum all areas that have metal or plastic

shavings. Wipe all fingerprints off unit and

vehicle.

Check All Fluid Levels

Position the unit on a level surface so that proper

amount of fluids can be added.

I. Check the compressor oil level.

A. Add oil if needed.

B. Additional oil may need to be added after

test.

C. Top off oil level to half the sightglass

when finished with the test.

II. Check hydraulic system oil level.

Machine Documentation

Record all serial numbers for this installation.

A. Boss Industries, LLC Serial Number

_________________________________________

B. Compressor Serial Number

_________________________________________

C. Note any special applications relating to

specific installations.

_________________________________________

_________________________________________

Lifetime Warranty Registration

Every Boss Industries, LLC INFINITY 35 machine

comes standard with a lifetime warranty on the airend.

In order to activate the lifetime coverage, the

customer must register the machine on the following

website: www.bossair.com/lw

- 12 - 310928

Installation & Operation

Shutdown Procedure

I. Close service valve.

II. Disengage hydraulic flow to compressor.

III. Disengage hydraulic system.

Operating Conditions

The following conditions should exist for maximum

performance of the compressor:

●The machine should be as close to level as

possible when operating.

●Ambient temperature for operation should be

below 110°F (43°C). The machine may

experience high temperature shutdown above

this level.

Operating Procedure

I. Read this manual carefully before proceeding.

II. Verify the service valve is closed.

III. Engage hydraulic system.

IV. Allow hydraulic system to run on bypass for

3-5 minutes to warm-up.

V. Engage hydraulic flow to compressor.

VI. Allow compressor speed to stabilize before

opening service valve for use.

- 13 - 310928

Maintenance

Lifetime Warranty Information

In order to maintain the lifetime warranty status on

your INFINITY 35, the required maintenance

intervals listed on the following page must be obeyed.

Recommended Spare Parts List

PART

NUMBER DESCRIPTION

310438 Air Filter Element

80384 50-Hour Maintenance

Kit

80385 1-Year or 500-Hour

Maintenance Kit

- 14 - 310928

Maintenance Chart

The MAINTENANCE CHART lists serviceable items on this compressor package. The items are listed

according to their frequency of maintenance.

Maintenance

INTERVAL REQUIRED MAINTENANCE

EVERY 10 HOURS OR

DAILY

1. Check compressor oil level.

2. Check for oil and air leaks.

3. Check compressor air filter maintenance indicator. Clean or

change filter as required.

EVERY 50 HOURS OR

WEEKLY

1. Drain liquid from compressor sump. More frequent draining

may be required under high humidity conditions.

2. Inspect compressor mounting bolts.

*3. After first 50 hours install Boss P/N 80384 50-Hour

Maintenance Kit. Steps include changing oil and oil filter element.

Then follow yearly maintenance schedule.

EVERY 250 HOURS

OR 6 MONTHS

1. Check compressor shaft seal for leakage.

2. Check compressor air filter connections, fittings, and clamps.

EVERY 500 HOURS

OR 1 YEAR

1. Install Boss P/N 80385 1-Year or 500-Hour Maintenance Kit.

Steps include changing oil, oil filter element, air/oil coalescing

element, and air filter element.

2. Check airend pressure relief valve.

3. Clean cooler fins on all coolers.

- 15 - 310928

Maintenance

Compressor Oil

- 16 - 310928

Maintenance

Compressor Oil Fill, Level, and

Drain

Before adding or changing compressor oil, make sure

that the compressor is completely relieved of pressure.

The drain is located on the rear of the machine

towards the bottom of the airend. To drain the oil,

remove the cap from the oil drain hose and rotate the

valve to the open position to release all of the oil from

the compressor sump. When oil has been drained,

rotate the valve to the closed position and reinstall the

cap on the end of the hose.

Oil is added at the fill cap on the side of the machine.

The proper oil level is in the middle of the oil

sightglass when the unit is shut down and has had

time to settle. The machine must be level when

checking the oil. The fill neck is designed to prevent

overfilling; however, care must still be taken to ensure

the proper oil level. DO NOT OVERFILL. The oil

capacity is given in “Compressor Specifications”.

Changing the Oil Filter

The oil filter is a spin-on type element that is easily

replaced through the maintenance access panel. First,

remove the access panel from the right side (by the

pressure gauge) of the machine by removing the 2

bolts securing it. Inside the access panel will be 2

spin-on filter elements: the oil filter and the air/oil

coalescer. The oil filter will be on the left side and is

the smaller of the 2 filters. To remove the old

element, turn it counter-clockwise until it is loose and

then lift it off of the stem and out of the access panel.

It is normal for this filter to drip oil when it is

removed. You may need the assistance of a band

wrench to remove the old element, but new elements

should be installed by hand tightening only. Once

the old element is out, put a film of oil on the rubber

ring of the new element and place it onto the stem and

turn clockwise with your hands until it is tight. The

element should spin on very freely until the last full

turn. Make sure the threads are engaging properly if

it does not spin freely. Once the new element has

been installed, reinstall the access panel using the 2

bolts that were previously removed.

- 17 - 310928

Maintenance

Changing the Air/Oil Coalescer

The air/oil coalescer is a spin-on type element that is

easily replaced through the maintenance access panel.

First, remove the access panel from the machine by

removing the 2 bolts securing it. Directly inside the

opening you will find the air/oil coalescer. This is

the larger of the 2 spin-on elements. To remove the

old element, turn it counter-clockwise until it is loose,

and then lift it off of the stem and out of the access

panel. It is normal for this filter to drip oil when it is

removed. You may need the assistance of a band

wrench to remove the old element, but new elements

should be installed by hand tightening only. Once

the old element is out, put a film of oil on the rubber

ring of the new element and place it onto the stem and

turn clockwise with your hands until it is tight. The

element should spin on freely until the last full turn.

Make sure the threads are engaging properly if it does

not spin freely. Once the new element has been

installed, reinstall the access panel using the 2 bolts

that were previously removed.

Changing the Air Intake Filter

The air intake filter is a heavy-duty dry type high

efficiency filter designed to protect the compressor

from dust and foreign objects.

Frequency of maintenance of the filter depends on

dust conditions at the operating site. The filter

element must be serviced when clogged. A clogged

air filter element will reduce compressor performance

and cause premature wear of components.

To change the air filter element, first remove the

maintenance access panel from the machine by

removing the 2 bolts securing it. Make sure the

machine is not running when you perform this or any

other maintenance. Inside the access panel you will

find an air filter assembly with 2 latches. Disengage

each latch and pull the end cover off of the air filter

assembly. Inside you will find the air filter element.

Remove the air filter element by pulling and gently

twisting. Install the new filter element in reverse

fashion. Reinstall the air filter assembly end cover

and latch both latches to ensure a tight seal on the

element inside. Reset the air filter maintenance

indicator located on the air filter outlet. Once the new

element has been installed, reinstall the access panel

using the 2 bolts that were previously removed.

- 18 - 310928

Maintenance

Compressor Drive Belts

The 2-belt arrangement is sized for an average life of

1000 hours. This time frame can be increased or

decreased depending on the end user’s periodic

maintenance schedule. Drive belt tension should be

checked for adjustment after the first 10 hours of

operation and checked for adjustment every 100 hours

there after. Belt deflection is to be checked at

midpoint between both pulleys on one belt at a time.

Single belt deflection is to be 1/8” at 2.7 lbs.

minimum to 3.3 lbs. maximum.

The belt tension can be adjusted according to the

following procedure:

●Loosen 1/2” bolt that attaches the hydraulic motor

mounting bracket to the compressor base plate.

●Loosen 3/8” jam nut on the turnbuckle assembly.

●Loosen 3/8” nuts at the top and bottom eyebolts.

●Rotate turnbuckle nut clockwise to increase belt

tension and counterclockwise to decrease belt

tension.

●Tighten all nuts and bolts in reverse order.

- 19 - 310928

Troubleshooting

Improper Discharge Pressure

If discharge pressure is too low, check the following:

I. Too much air demand. (Air tools required

more air than the compressor can produce, air

tools are free wheeling without resistance.)

II. Service valve is wide open to atmosphere.

III. Leaks in service line.

IV. Restricted compressor inlet air filter.

V. Faulty control system operation (i.e. regulator

is sending a signal to close the inlet valve at

all times).

If discharge pressure is too high or the safety valve

blows, check the following:

I. Coalescer plugged or blocked.

II. Faulty safety valve.

III. Faulty regulator (regulator air pressure signal

is not getting to inlet valve).

If pressure relief valve blows at compressor idle,

check the following:

I. Inlet valve leaking or open.

II. Faulty regulator.

Sump Pressure Does Not Blow

Down

If after the compressor is shutdown, pressure does not

automatically blow down (this process should take

about 1 minute), check for:

I. Blow down valve may be inoperative.

II. Blow down valve exhaust port plugged. Blow

down valve should have a 3/64” orifice fitting

that is installed in the exhaust port.

Oil Consumption

Abnormal oil consumption or oil in service line can

be caused by the following:

I. Overfilling of oil sump.

II. Leaking oil lines or oil cooler.

III. Defective coalescer element.

IV. Compressor shaft seal leakage.

V. Discharge pressure below 65 PSI or above

150 PSI.

Relieving pressure too quickly after shutdown will

cause the oil to foam and spill out of the blow down

valve.

- 20 - 310928

Troubleshooting

Coalescer Plugging

If the coalescer element has to be replaced frequently

because it is plugging, it is an indication that foreign

material may be entering the compressor inlet or the

compressor oil is breaking down.

Compressor oil can break down prematurely for a

number of reasons:

I. Extreme operating temperature.

II. Negligence in draining condensate from oil

sump.

III. Using the improper type of oil or dirty oil.

High Compressor Discharge

Temperature

If the compressor shuts down on high temperature,

check the following:

I. Check compressor oil level. Add oil if

required.

II. Clean outside of oil cooler.

III. Clean oil system (cooler) internally.

IV. Check fan switch/relay harness. Fan should

be running at all times when compressor is

spinning.

Contacting Boss Industries, LLC

If you need assistance with any of the preceding steps,

or cannot find the solution to your problem, call the

Boss Industries, LLC Service Department.

Phone: (800)635-6587 (USA)

Phone: (219)324-7776 (Outside USA)

Fax: (877)254-4249

Email: [email protected]

Website: http://www.bossair.com

When calling for technical support, have the

following information available:

Machine Serial Number

Description of the problem

Table of contents

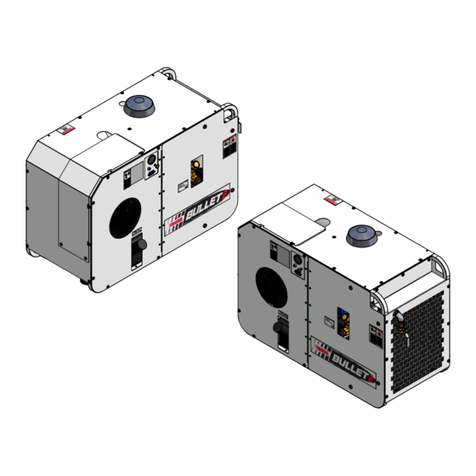

Other Boss Industries Air Compressor manuals

Popular Air Compressor manuals by other brands

Becker

Becker DT 4.25 Translation of the operating instructions

Craftsman

Craftsman 919.16558 owner's manual

XTline

XTline XT2002 user manual

Stanley

Stanley Fatmax TAB 200/10/24V Instruction manual for owner's use

Grizzly

Grizzly G0467 Parts Breakdown

Clarke

Clarke BOXER 14/150P Operation & maintenance instructions