GA 12.137/2.02 - 05/2002

Description

7

1.3 Technical specifications

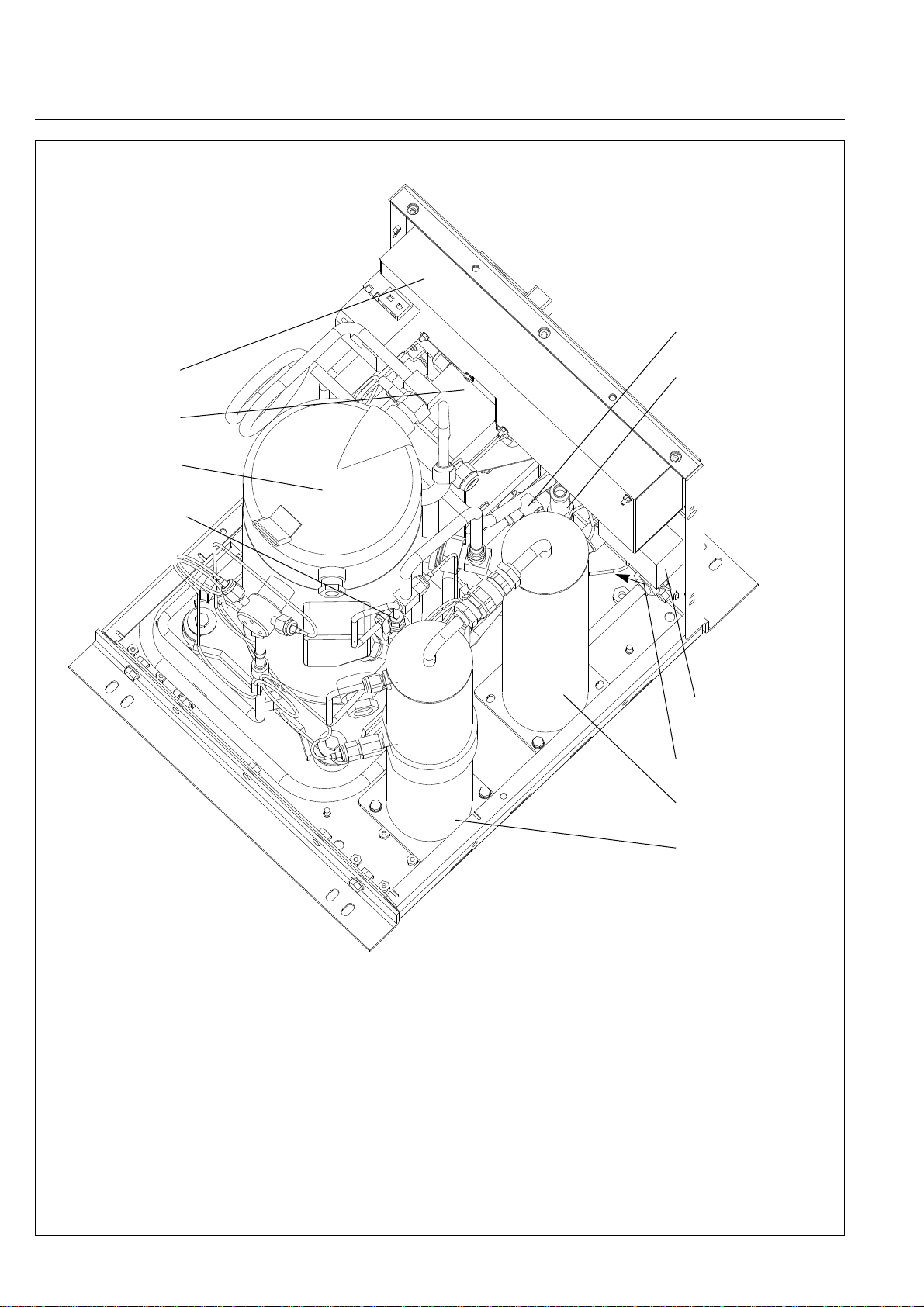

Compressor unit COOLPAK 6000-1

————————————————————————

Helium fill pressure to be set at the system,

at room temp.

at 50 Hz 15-1 bar

218-15 psig

1.5-0.1 MPa

at 60 Hz 14-1 bar

203-15 psig

1.4-0.1 MPa

Factory set Helium filling pressure 15-1 bar

218-15 psig

1.5-0.1 MPa

Operating pressure in the high-pressure

circuit at 50 and 60 Hz 20±2 bar

and with connection of a RGD 5/100 290±29 psig

2.0±0.2 MPa

Coolant data see Section 2.4

Ambient conditions for transportation

and storage see Section 3.4.1

Mains power supply,

50 Hz, 3-ph, each ± 10 % 380/400 V

60 Hz, 3-ph, each ± 10 % 480 V

Delivered from the factory wired for 400 V

Cold head motor type select (see Section 2.5)

factory set to 3-phase (rotary) current

Motor protection switch factory set to 14 A

Electrical power drawn at operation temperature

at 50 Hz 6.0 - 6.5 kW / 20,500 - 22,200 BTU/h

at 60 Hz 6.5 - 6.9 kW / 22,200 - 23,600 BTU/h

Electrical power drawn at start-up

with warm cold head

at 50 Hz 8.2 kW / 28,000 BTU/h

at 60 Hz 8.7 kW / 29,700 BTU/h

Operating current at operation temperature

at 50 Hz 9.5 - 10.5 A

at 60 Hz 9.0 - 10.0 A

Operating current at start-up

with warm cold head

at 50 Hz 13.7 A

at 60 Hz 12.0 A

Control voltage for the remote control + 24 V DC

Supply voltage for the cold head 240 V AC

Fuses (5x) 0.315 AT (slow blow)

5x20 mm glass tube

DIN 41662, IEC 127-2/III

IEC rating for circuit breaker in the mains supply 20 A

Helium connectors: self-sealing

couplings1) 1/2“ m

Noise level2), at a distance of 1 m 53 dB(A)

Weight 95 kg / 210 lbs

Equipment type Industrial safety standard class I

The safety standard for the device when installed in

accordance with these instructions, with the line power

and cold head connector lines attached IP 30

1.4 Order information

Cat.-No.

Compressor unit COOLPAK 6000-1 892 35

Adsorber CACP 6000 893 52

Mains power cords

4xAWG 12, Plug Han 3 HvE/conductor ferrules

2.5 m long, cable turns to the right at

power module 200 81 194

0.7 m long, cable turns to the left at

power module 200 16 178

Flexlines

One pair each with self-sealing couplings

at both ends f1)

FL 4.5 (1/2“,1/2“), 4,5 m long (15 feet) 892 87

FL 9.0 (1/2“,1/2“), 9 m long (29.5 feet) 892 88

FL 2.0 ELBOW (1/2“ m /1/2“ f), 2 m long 893 66

FL 13.5-SF (1/2“ f,1/2“ f), 13.5 m long (45 feet) 893 67

FL 11.3 (1/2“ f,1/2“ f), 11.3 m long (37 feet) 893 68

FL 15.0 ELB (1/2“ f,1/2“ f), 15 m long (49 feet) 893 69

Installation accessories

with self-sealing couplings, Helium filling

pressure at room temperature (16-1) bar (232 psig)

90°elbows, 1/2“ m /1/2“ f 891 73

Insulating adapter, 1/2“ m / 1/2“ f 891 76

Line coupler, 1/2“ m / 1/2“ m 891 71

CRYO SERVICE SET, case with tools for

maintenance work at all cold heads and

compressor units 890 93

Electric extension cable for the

cold-head power cord, 4.5 m long 893 74

1) f=female / inside threads; m=male / outside threads “Aeroquip

series 5400“ or compatible designs.

2) As per DIN 45 635, Part 1, corresponding to ISO 6081-1986,

ISO 11203