BOSSCO DN 15 User manual

CE-51AQ647/ED01

MADE IN ITALY

GAS PRESSURE REGULATOR

EN

EC approval according to EN 88-1, compliant with Regulation (EU) 2016/426

356

DN15 - DN 20 - DN 25

2

EN

INDEX

pag.

English ....................................................................................................................................................... 3

Drawings..................................................................................................................................................... 14

Dimensions (table 2) ....................................................................................................................................16

Regulation spring data (table 3)......................................................................................................................17

Diagram ......................................................................................................................................................18

3

EN

1.0 GENERAL INFORMATION

This manual shows you how to safely install, operate and use the device.

The instructions for use ALWAYS need to be available in the facility where the device is installed.

ATTENTION: installation/maintenance needs to be carried out by qualified staff (as explained in

section 1.3) by using suitable personal protective equipment (PPE).

For any information pertaining to installation/maintenance or in case of problems that cannot be solved with the instructions,

contact the manufacturer by using the address and phone numbers provided on the last page.

1.1 DESCRIPTION

Device which supplies a preset and constant “downstream” pressure value (P2) (within the intended operating limits) when the

inlet pressure (P1) and/or the flow rate (Q) changes.

It is fitted with:

• a spring to adjust the outlet pressure;

• safety membrane (with some exceptions);

• output pressure test nipple (with some exceptions) to control the outlet pressure (P2). On some models the pressure

test nipple is also present on the input;

Reference standards: EN 88-1 – EN 13611.

1.2 KEY OF SYMBOLS

ATTENTION: Attention

is drawn to the technical

details intended for

qualified staff.

DANGER:

In the event of

inobservance, this may cause damage

to tangible goods, to people and/or pets.

DANGER: In the event

of inobservance, this may

cause damage to tangible

goods.

4

EN

1.3 QUALIFIED STAFF

These are people who:

•Are familiar with product installation, assembly, start-up and maintenance;

•Know the regulations in force in the region or country pertaining to installation and safety;

•Are trained in first aid.

1.4 USING NONORIGINAL SPARE PARTS

•To perform maintenance or change parts (e.g. spring, filter element, etc.) ONLY manufacturer-recommended parts can be

used. Using different parts not only voids the product warranty, it could compromise correct device operation.

•The manufacturer is not liable for malfunctions caused by unauthorised tampering or use of non-original spare parts.

1.5 IMPROPER USE

•The product must only be used for the purpose it was built for.

•It is not allowed to use fluids other than those expressly stated.

• The technical data set forth on the rating plate must not, under any circumstances, be exceeded. The end user or installer is in

charge of implementing correct systems to protect the device, which prevent the maximum pressure indicated on the rating plate

from being exceeded.

•The manufacturer is not responsible for any damage caused by improper use of the device.

5

EN

2.0 TECHNICAL DATA

• Use : non-aggressive gases of the three families (dry gases)

• Ambient temperature (TS) : -15 ÷ +60 °C

• Operating inlet pressure range

:

200÷300 mbar

• Class : A (P2 ± 15%)

• Mechanical resistance : Group 2 (according to EN 13611)

• Rp threaded connections in line : (DN 15 - DN 20 - DN 25) according to EN 10226

• NPT threaded connections : request feasibility

• In compliance with : Regulation (EU) 2016/426 (Appliances burning gaseous fuels)

2.1 MODEL IDENTIFICATION

35501205: Rp 1/2 DN 15 P2: 16÷60 mbar

35501227: Rp 3/4 DN 20 P2: 16÷60 mbar

35501249: Rp 1 DN 25 P2: 16÷60 mbar

6

EN

3.0 COMMISSIONING THE DEVICE

3.1 OPERATIONS PRIOR TO INSTALLATION

•It is necessary to close the gas upstream of the device prior to installation;

•Check that the line pressure IS WITHIN the P1 range indicated on the label of the product and that IT IS NOT

HIGHER than the maximum value;

•Protective caps (if any) must be removed prior to installation;

•The pipes and inside of the device must be clear of any foreign bodies;

•IMPORTANT: to avoid possible pumping and/or disturbances in the gas flow, a straight pipe section equal to at least 5

DN must be installed (downstream of the regulator).

•IMPORTANT: install manual gas closing devices (e.g. ball valves) upstream and downstream of the regulator to protect

it from any pipe leak test;

•Make sure that the pipe thread is not too long, to prevent damaging the body of the device when screwing it on;

•If the regulator is not fitted with a filter, it is advisable to install an adequate filter upstream;

•With outdoor installation, it is advisable to install a protective roof to prevent rain from oxidising or damaging parts of the

device.

•According to the plant geometry, check the risk of an explosive mixture arising inside the piping;

•If the regulator is installed near other devices or as part of an assembly, compatibility between the regulator and

these devices must be evaluated beforehand;

•Provide a protection against impacts or accidental contacts if the device is accessible to unqualified personnel

.

7

EN

3.2 INSTALLATION (see example in 3.4)

•Assemble the device by screwing it, with the due seals, onto the plant with pipes and/or fittings whose threads are consistent

with the connection being attached.

•Do not use the neck of the top cover (3) as a lever to help you screw it on, but only use the specific tool;

•The arrow, shown on the body (5) of the device, needs to be pointing towards the application;

•The regulator is normally positioned before the application. Previously evaluate the possibility of installing the regulator as

shown in the installation example in 3.4, namely in an optimal position pos. a(see figures below);

•Should this not be possible, the following factors must be considered:

1. if installed as shown in pos. bthe maximum P2 value declared on the rating plate could be less by a few mbar.

2. if installed as shown in pos. cthe life span of the product could be shorter than the duration that could be obtained

if installed in the optimal position a;

3. if installed as shown in pos. d, besides that indicated for pos. cit is recommended to install a filter after the

regulator that protects it from debris that could enter from downstream from above (due to gravity);

a b dc

•During installation, avoid debris or metal residues from getting into the device;

•To guarantee mechanical tension-free assembly, we recommend using compensating joints, which also adjust to the pipe’s

thermal expansion;

8

EN

•If the device is to be installed in a gas train, it is the installer’s responsibility to provide suitable or correctly sized supports

to hold and secure the assembly. Never, for any reason whatsoever, leave the weight of the gas train only on the connections

(threaded or flanged) of the individual devices;

•In any case, after the installation check the tightness of the system, avoiding to subject the membrane of the regulator

(therefore, the downstream pipe section) to a pressure higher than 200 mbar;

3.3

INSTALLATION IN PLACES WHERE THERE IS THE RISK OF EXPLOSION (DIRECTIVE 2014/34/EU)

The device is not suitable for use in potentially explosive areas.

discharge in open air

internal thermal unit

external roof

piping

applicaon

12

8

9

10

345

6

77

3.4 GENERIC EXAMPLE OF AN INSTALLATION

1. Manual reset solenoid valve

2. Jerk ON/OFF valve

3. Gas filter

4. OPSO shut off valve

5. 356 BOSS pressure regulator

6. Relief valve

7. Pressure gauge and relative button

8. Gas detector

9. Remote jerk ON/OFF valve lever control

10. Expansion joint/anti-vibration mount

5 DN

9

EN

4.0 FIRST STARTUP

Before commissioning, verify that:

•all of the instructions on the rating plate, including the direction of flow, are observed;

•the small hole of the top cover (3) is not obstructed.

•IMPORTANT: The leak test of the piping must be performed while avoiding to subject the membrane of the

regulator (therefore, the downstream pipe section) to a pressure higher than 200 mbar. Use special manual gas

closing devices to prevent damaging the regulator;

•The pressurisation manoeuvre of the equipment must be carried out very slowly so as to avoid possible damage.

NOTE: the small hole of the top cover (3) must not be obstructed for any reason whatsoever otherwise the

regulator might not work;

•Open the downstream shut-off valve very slowly;

• Open the upstream shut-off devices (e.g. ball valves, solenoid valves, OPSO shut-off valve, etc.) very slowly;

•Wait until the downstream pressure stabilises at the calibration value P2 of the spring (indicated on the rating plate);

•Check the tightness of all the system gaskets and check the internal/external tightness of the regulator;

•Check the operation of the regulator.

4.1 - RECOMMENDED PERIODIC CHECKS

•Check the tightness of the flanged/threaded connections on the system;

•Check the tightness and operation of the regulator;

It is the responsibility of the final user or installer to define the frequency of these checks based on the severity of the service conditions.

10

EN

4.2 - ADJUSTING THE OUTLET PRESSURE

Before starting the system, make sure that the spring supplied with the regulator is suitable for the desired adjustment

pressure. The outlet pressure P2 (unless specifically requested) is factory set with the top cover (3) positioned as shown in

3.2 aand with the adjustment screw (2) set approximately at the minimum calibration value.

If the regulator is installed in different positions, check and reset the outlet pressure P2.

Adjust the outlet pressure as follows:

•Unscrew the cap (1);

• Unscrew the adjustment screw (2) and set it to the minimum calibration allowed (threaded end of the top cover (3));

•Start the system or make sure there is a minimum flow downstream of the regulator;

• To increase the pressure calibration downstream of the regulator, tighten the adjustment screw (2) to the desired value. Perform

the reading with a calibrated pressure gauge, installed downstream of the regulator to at least 5 DN (see example in 3.4);

•Screw the cap (1) back on and if necessary, seal it in that position using the appropriate seal holes (if present);

•Use pressure outlets (6) on the device only for zero flow or very low flow measurements.

4.3 - REPLACING THE SPRING

The step must be carried out without gas inside the regulator.

Replace the spring as follows:

•Unscrew and remove the cap (1) from the top cover (3);

•Completely loosen and take out the adjustment screw (2);

•Remove the spring (14) from the top cover (3) and replace it with the new spring;

•Tighten the adjustment screw (2) and after starting the system as shown in 4.0, set the outlet pressure to the desired value

as shown in 4.2;

•Screw the cap (1) back on and if necessary, seal it in that position using the appropriate seal holes (if present);

11

EN

5.0 MAINTENANCE

•Before carrying out any dismantling operation on the device, make sure that there is no pressurised gas inside.

To check the status of the filter element (7)*

• Loosen the fastening screws (8) and very carefully remove the bottom cover (10) from the body (5);

• Extract the filter element (7) and check its condition. Blow it and clean it and, if necessary, replace it (see figure on the

next page for the positioning);

• Check the conditions of the sealing O-Ring (11 ) of the bottom cover (10), and replace it if necessary;

• Make sure the sealing O-Ring (11 ) of the bottom cover (10) is inside the relevant groove before putting it back on;

• Reassemble the bottom cover (10) and secure it in its original position, being very careful not to “pinch” or damage the

O-ring during tightening.

IMPORTANT: make sure that the centre pin (4) is centred in the guide of the bottom cover (10);

• Tighten the screws gradually, following a “cross” pattern, until the torque (tolerance -15%) indicated in table 1 on page 15

is reached. Use a calibrated torque wrench to do this.

• Check the body/cover tightness;

NOTE: for internal inspections, it is recommended to:

• Also check the obturator’s integrity and, if necessary, replace the rubber seal (9);

• Replace the seals before reassembling.

* Only for versions equipped with an internal filters.

12

EN

Guides for

filter element

The filter element must

be placed inside these

guides

fig a: Cover without bottom cover

6.0 TRANSPORT, STORAGE AND DISPOSAL

• During transport the material needs to be handled with care,

avoiding any impact or vibrations to the device;

• If the product has any surface treatments (e.g. painting,

cataphoresis, etc) it must not be damaged during transport;

• The transport and storage temperatures must observe the

values provided on the rating plate;

• If the device is not installed immediately after delivery

it must be correctly placed in storage in a dry and clean

place;

• In humid facilities, it is necessary to use driers or heating

to avoid condensation.

• At the end of its service life, the product is to be disposed of

in compliance with legislation in force in the country where

this operation is performed.

7.0 WARRANTY

The warranty conditions agreed with the manufacturer at the

time of the supply apply.

For damage caused by:

• Improper use of the device;

• Failure to observe the requirements described in this

document;

• Failure to observe the regulations pertaining to installation;

• tampering, modification and use of non-original spare parts;

are not covered by the rights of the warranty or compensation for

damage.

The warranty also excludes maintenance work, the assembly

of parts of other manufacturers, making changes to the

device and natural wear.

13

EN

8.0 RATING PLATE DATA

The rating plate data (see example provided here) includes the following:

• Manufacturer’s name/logo and address

• Mod.: = device name/model followed

by the connection diameter

• P1 = Inlet pressure range at which product operation is guaranteed

• TS = Temperature range within which product operation is guaranteed

• P2 = Outlet pressure range

• CE-51AQ647/ED01 = certification pin number

• Cl. A = Tolerance on P2 ( A= ± 15% )

• Gr. 2 = Mechanical resistance group 2 in accordance with EN 13611

• EN 88-1 = Product reference regulation

• = Conformity with Regulation (EU) 2016/426 followed by Notified Body No.

• year = Year of manufacture

• Lot = Product serial number (see explanation below)

• U2002 = Lot issued in year 2020 in the 2nd week

• 1728 = progressive job order number for the indicated year

• 00002 = progressive number referring to the quantity of the lot

Mod.: DN 20 BOSS 356

CODE: 35501227

P1: 200-300 mbar TS: -15+60 °C

P2: 16-60 mbar

CE-51AQ647/ED01 CI.A Gr.2 EN 88-1

year: 2020 Lot: U2002 1728/00002

Lodge Way House, Lodge Way,

Harlestone Road,

Northampton NN5 7UG.

0051

14

EN

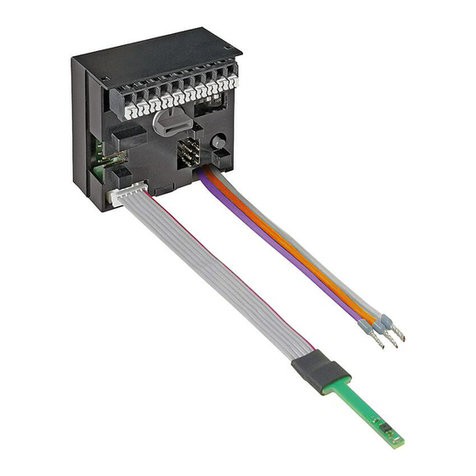

fig. 1

DN 15 - DN 20 - DN 25

15

EN

fig. 1

1. Closing cap

2. Adjustment screw P2

3. Top cover

4. Working membrane/centre pin

5. Body

6. Pressure test nipple (optional)

7. Filter element

8. Bottom cover clamping screws

9. Obturator

10. Bottom cover

11. Bottom cover sealing O-Ring

12. Top cover clamping screws

13. Safety membrane

14. Calibration spring

15. Seal (optional)

Table 1

Screw M5

Max. torque (N.m)

Galvanised

6

Stainless Steel 4,5

16

EN

Table 2

Overall dimensions in mm

Connections in line

A B=(D+E) C D E

Rp DN 15 - Rp DN 20 - Rp DN 25 120 153 94 40,5 111 , 5

The dimensions are provided as a guideline, they are not binding

17

EN

Table 3 -Flow rate range: 1-10 m3/h air

Regulation spring data

Spring code dimensions in mm (dx De x Lo x it) Connections Setting

(mbar)

P1 range

(mbar)

MO-0213 1,3x17x55x8

DN 15

13,7 ÷ 30 up to 100

MO-0210 1,3x17x70x11 20 ÷ 60 up to 100

MO-0213 1,3x17x55x8 16 ÷ 30 100÷200

MO-0210 1,3x17x70x11 20 ÷ 70 100÷200

MO-0210 1,3x17x70x11 16 ÷ 60* 200÷300

MO-0210 1,3x17x70x11 16 ÷ 60 300÷400

MO-0210 1,3x17x70x11 16 ÷ 60 400÷500

MO-0213 1,3x17x55x8

DN 20

13,7 ÷ 30 up to 100

MO-0210 1,3x17x70x11 20 ÷ 60 up to 100

MO-0210 1,3x17x70x11 16 ÷ 60 100÷200

MO-0210 1,3x17x70x11 16 ÷ 60* 200÷300

MO-0210 1,3x17x70x11 16 ÷ 60 300÷400

MO-0210 1,3x17x70x11 16 ÷ 60 400÷500

MO-0213 1,3x17x55x8

DN 25

13,7 ÷ 30 up to 100

MO-0210 1,3x17x70x11 20 ÷ 70 up to 100

MO-0210 1,3x17x70x11 16 ÷ 70 100÷200

MO-0210 1,3x17x70x11 16 ÷ 60* 200÷300

MO-0210 1,3x17x70x11 16 ÷ 60 300÷400

MO-0210 1,3x17x70x11 16 ÷ 60 400÷500

* Standard setting

it= total number of turns

18

EN

Capacity diagram of regulators without filter

dv = density relative to the air

Diagram calculated with P1 = 50 mbar and

regulator set out of service

dv = 0,65

dv = 1

dv = 0,47

dv = 1,67

1) methane

2) air

3) town gas

4) lpg

19

EN

NOTES

Mod. IT395.00 E

We reserve the right to any technical and construction changes.

Registered Office: Travis Perkins PLC, Lodge Way House, Lodge Way, Harlestone Road, Northampton NN5 7UG.

Telephone Number: 0116 245 5500

This manual suits for next models

5

Table of contents

Other BOSSCO Controllers manuals