350 Actuator Instruction Manual

Form 1387

June 2002

8

rod assembly. Rotate the zero (bias spring)

adjustment screw until the piston rod just begins to

move down. Change the input signal to the opposite

end of the input signal range and check the position

of the piston rod assembly. If the rod has moved less

than full travel, it indicates that the feedback spring

has too much tension and that the span (feedback

spring) adjustment screw is screwed into the spring

too far. If the rod has moved full travel, start moving

the input signal in the opposite direction to see

where the piston rod assembly starts to move. This

indicates if there is enough spring screwed onto the

span adjustment. After each adjustment of the span

(feedback spring) adjustment screw, the zero (bias

spring) adjustment screw must be adjusted for the

starting point (full up).

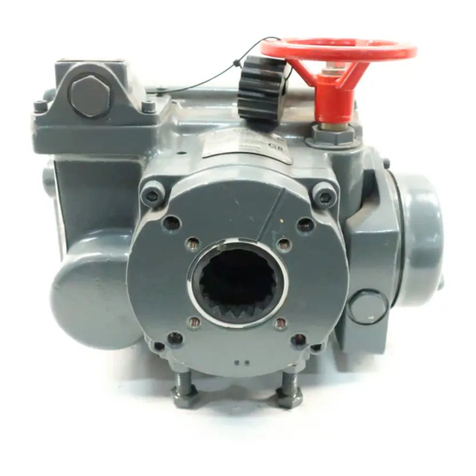

Bypass Valve and Handwheel

Operation

Bypass Valve

Before using a handwheel, open the bypass valve

(key 76, figure 7) so that fluid pressure will be

equalized on either side of the actuator piston.

Failure to equalize the pressures may make

handwheel operation difficult or impossible.

Note

If the actuator is equipped with

optional lock valves, the bypass must

be opened to allow handwheel

operation even if the motor has been

turned off.

To open the bypass valve, rotate the bypass valve

stem (key 77, figure 10), located on the side of the

actuator, counterclockwise. This rotation direction is

indicated by an arrow on the bypass plate (key 79,

figure 10). Rotate the stem only enough to open the

valve (2 to 4 turns). Further rotation might damage

the bypass plate (key 79, figure 10).

Handwheels for use with the Type 354 actuator are

covered in separate manuals. Refer to the Type

1076 handwheel or other handwheel instruction

manual as appropriate.

Bolt-On Handwheels

Bolt-on handwheels (see figure 13) are available in

either of two types, non-declutchable and

declutchable. The non-declutchable type is shown in

figure 13. With this type, there is no declutching

mechanism, but the design of the handwheel nut

allows unrestricted actuator travel when the

handwheel is positioned so that the pointer (key 160,

figure 13) is at the neutral position. The handwheel

can be used to open or close the valve if used with a

Type 350 actuator (see table 7).

To operate the non-declutchable handwheel,

open the bypass valve and rotate the handwheel

clockwise to close or counterclockwise to open the

valve. The non-declutchable handwheel can also be

used as a travel stop to limit either full opening or

closing of the valve. With the handwheel pointer at

the neutral position, travel is not restricted. As the

pointer is moved from the neutral position, the

handwheel mechanism will restrict travel in an

increasing amount. Moving the pointer from the

neutral position with clockwise handwheel rotation

will restrict opening of the valve (counterclockwise

rotation will restrict closing of the valve). The

handwheel cannot be used to restrict opening and

closing at the same time.

The declutchable bolt-on handwheel is similar to the

handwheel shown in figure 13 except that the lever

pin (key 153, figure 13) is replaced by a removable

engaging pin (not shown). Unrestricted actuator

travel is possible when the engaging pin is pulled out

(engaging pin is retained by a cotter pin) and the

handwheel is positioned so that the pointer (key 160,

figure 13) is at the neutral position. The declutchable

handwheel can be used to open, close, or throttle

the valve regardless of the actuator type.

To operate the declutchable handwheel, open the

bypass valve. Rotate the handwheel to align the

engaging pin holes in the levers (key 146, figure 13)

with the hole in the handwheel body (key 142, figure

13). Insert the engaging pin. Rotate the handwheel

clockwise to close or counterclockwise to open the

valve. Install the cotter pin to retain the engaging pin.

The declutchable handwheel cannot be used as a

travel stop.

If the actuator is moved from a valve having

push-down-to-close action to one having

push-down-to-open action or vice versa, a new

handwheel nut and screw must be installed to retain

counterclockwise-to-open handwheel action. Follow