Boste UDC102 User manual

1

PRODUCT

MANUAL

Boste BK Series

(UDC102 Undersink Dispenser Model)

2

Product

Manual

BK Series (UDC102 Models)

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . Page 3

2. Specifications . . . . . . . . . . . . . . . . . . . . . . . Page 4

3. Main Components . . . . . . . . . . . . . . . . . . . . . . . Page 5

4. Installation Guide . . . . . . . . . . . . . . . . . . . . . . . Page 7

5. Operation Guide . . . . . . . . . . . . . . . . . . . . . . . Page 8

6. Maintenance Guide . . . . . . . . . . . . . . . . . . . . . . . Page 9

7. Fault Diagnosis Guide . . . . . . . . . . . . . . . . . . . . . . . Page 10

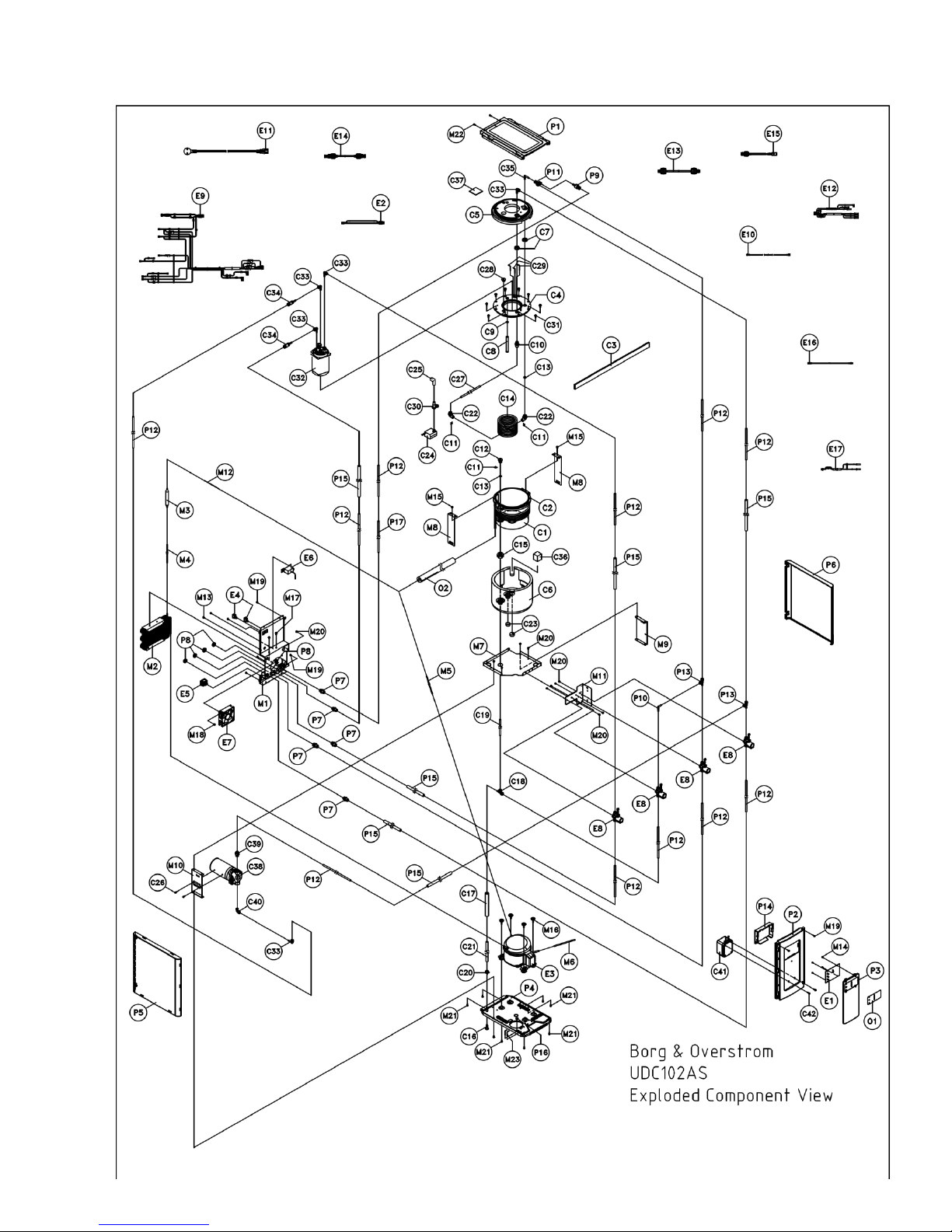

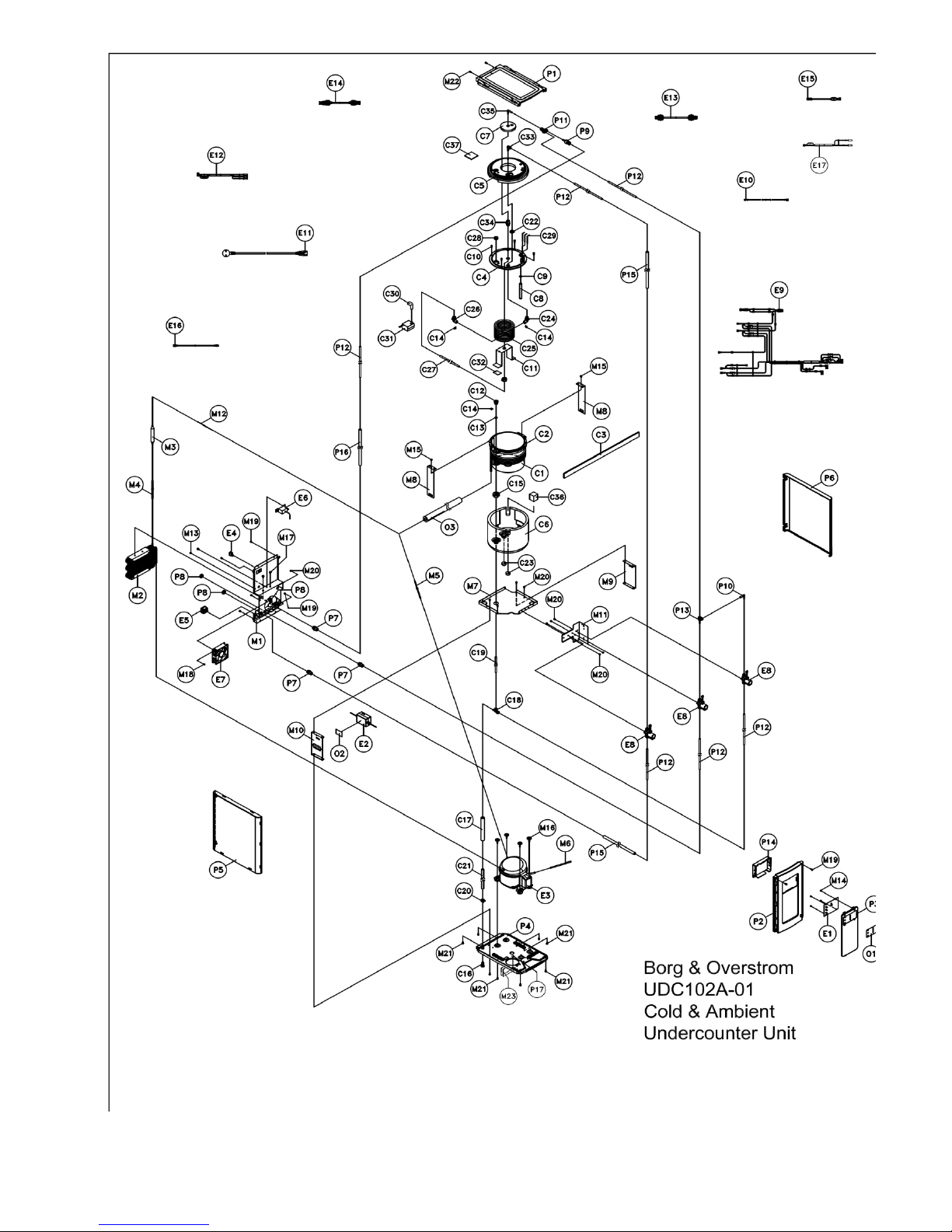

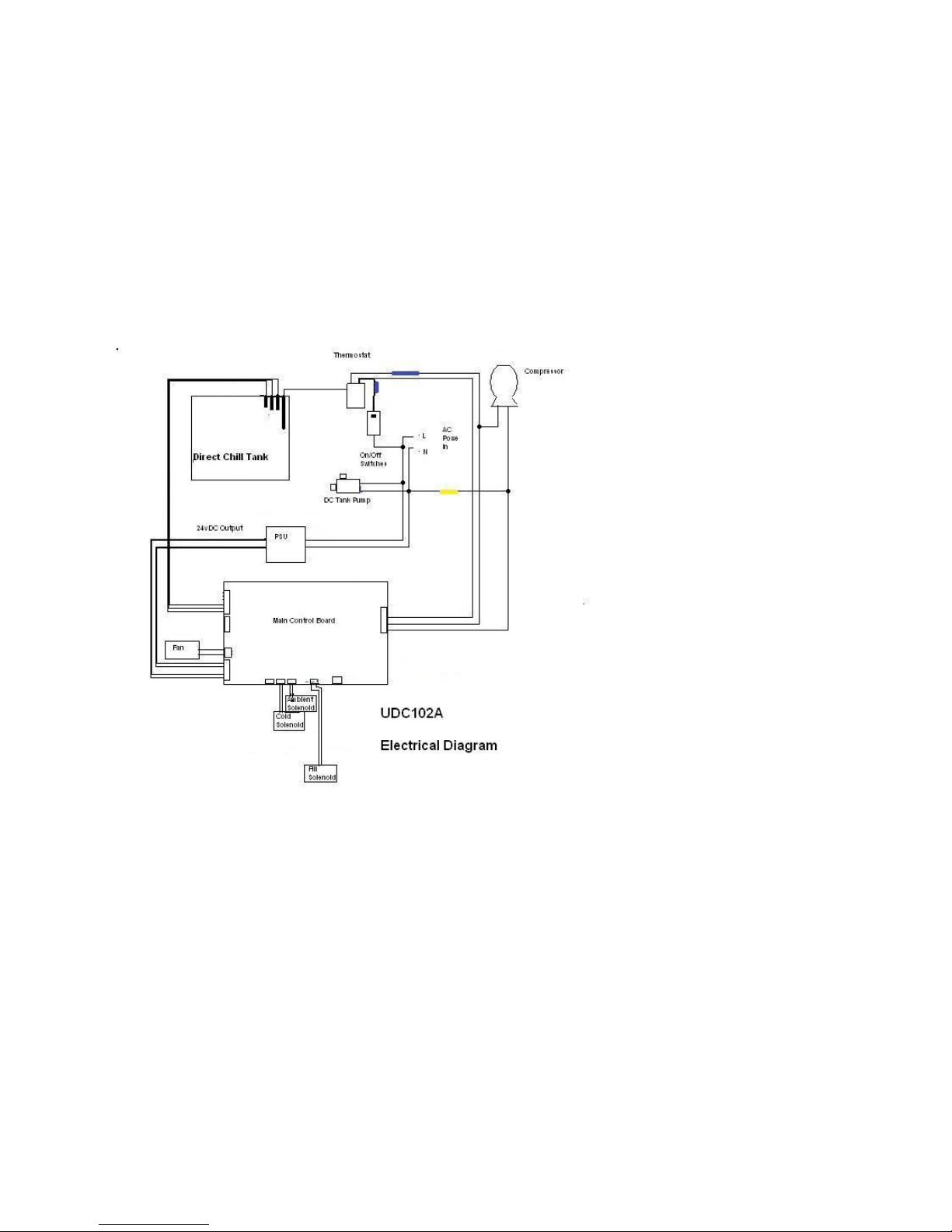

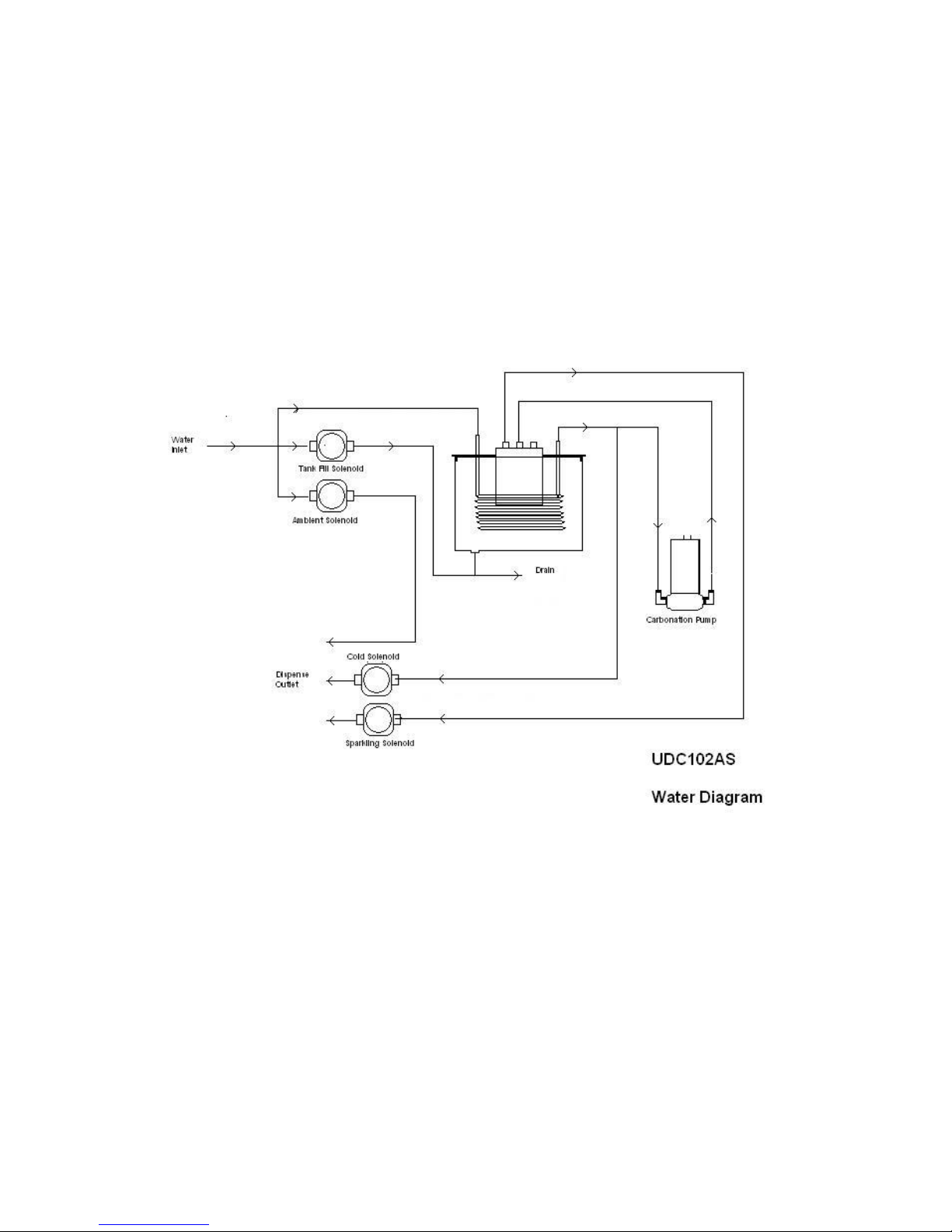

8. Diagrams & Parts Guide . . . . . . . . . . . . . . . . . . . . . . . Page 16

3

Introduction

Please Note: This Product Manual is intended for use by qualified Service Technicians only.

Use of the advice and material enclosed by the end-user could invalidate product warranty,

occupational insurances and present health and safety risks.

We strongly recommend that this Product Manual is not left with the dispenser or end-user but that

instead training is given regarding the simple function operations.

The Boste BK Series (UDC102 Model) is a range of undercounter water dispensers that are connected to the mains water

supply and dispense water through a proprietary swan-neck faucet that is mounted on a worksurface.

There are two models in the range:

BK5 –Cold & Ambient

BK9 –Cold, Sparkling & Ambient

Both models

models

have

robust steel framed cabinets

and

attr

activ

el

y

injection moulded

plastic front, side and top

panels.

An

IEC

Power Lead is

supplied

for

connection

to the

IEC

socket

found on the

rear

of all

models

(An

additional

Schuko

type is

supplied

for the

European

mark

et).

Both are Direct Chill cold water

dispenser

where water is used as the cooling

medium

in the Direct Chill tank.

This

is automaticall

y

filled and

controlled

by the level control

system

upon

installation.

This tank is then chilled via

the

outer

e

v

a

por

a

tion

coil of the capillary

controlled refrigeration compression sys

tem.

We

recommend

fitting a

Pr

essure

Reducing

V

a

l

v

e

is fitted to all

supplies

to

regulate

the

pressure

to 3.5 bar/355 kPa.

On the carbonated water model,

water is chilled as it

passes through

the coil

immediatel

y

before

dispense

or

being

pumped

under

pressure

into

the carbonator

which it fitted inside the

same

coil. The

carbonator

is also

level

controlled

and allows the

sparkling

eff

ect

to occur

through saturation

with CO2.

Dispense

is at inlet

pressure and controlled

via the solenoid

v

a

l

v

es.

The Cold

T

e

mperatur

e

is

thermos

taticall

y

controlled

via the

adjustment

screw on the back of the

machine. This

setting

is factory set and is not

necessary

to adjust in most

cases

The Cold Tank can be

drained

via the two Drain

Port

on the

rear

of the

machine.

The level control

system

also

incorporates

a leak

detection

device within the

cabinet

which

switches

the

machine

off in the event of

detecting wate

r

.

4

Specifications

COOLING SYSTEM

High efficiency compression system with capillary control.

Premium quality long life hermetic compressor. Compact

internal condenser –fan assisted for greater efficiency.

Environmentally friendly R134A refrigerant.

3.5 litre stainless steel chiller tank with level control containing

stainless steel cold water direct chill coil.

Stainless steel carbonator tank with independent level control

fitted inside coil.

High capacity, low voltage diaphragm pump feeding

carbonator on sparkling water machine option.

COLD TEMPERATURE

2°C to 11°C.

THROUGHPUT PER HOUR

18 litres cold < 12°C / 16 litres sparkling <12°C.

DISPENSE

Swan Neck Faucet with ergonomically designed and

situated light touch sensitive controls.

MAXIMUM RUNNING

POWER CONSUMPTION

85-100 watt. Cooling. (Additional intermittent carbonation

usage).

POWER REQUIREMENTS

230 volt/50Hz 16A supply required.

POWER SUPPLY

IEC Power FusedSocket.

WATER CONNECTION

Mains in (3.5bar max) - 1/4” Push Fit/Faucet - 6mm Push Fit .

CO2 CONNECTION

1/4” Push Fit.

UNDERCOUNTER

DIMENSIONS

(w x d x h) 230 x 360 x 390mm

WEIGHTS

BK5 (M102)

Unit only - 15.0 kg/Faucet - 1.3kg

BK9 (M102)

Unit only - 17.1 kg/Faucet - 1.3kg

Boste BK Series

5

Threaded Stem & Back Nut

Main Components

Undersink Unit

BK5 Cold & Ambient BK9 Cold, Sparkling & Ambient

1no UDC102A Undercounter Unit 1no UDC102AS Undercounter Unit

Complete with: Complete with:

1no 2.0m Power Cordset 1no 2.0m Power Cordset

1no 1.0m Faucet Connection Harness 1no 1.0m Faucet Connection Harness

1no CO2 Regulator with gauge

Electronic Swan Neck Faucet

1no Electronic Swan Neck Faucet 1no Electronic Swan Neck Faucet

Complete with: Complete with:

2 - Button Membrane Switch 3 - Button Membrane Switch

1.0m x 6mm Insulated Water Pipe 1.0m x 6mm Insulated Water Pipe

Also included: Also included:

2.0m x 1/4” Faucet Connection Pipe 3.0m x 1/4” Faucet Connection Pipe

1.0m Faucet Connection Pipe Insulation 2.0m Faucet Connection Pipe Insulation

2no ¼1/4” Stem Elbow 5no ¼1/4” Stem Elbow

1no 1/4” Y Fitting 1no 1/4" Cross Fitting

1no 1/4" Male Threaded Adaptor 1no 1/4" Male Threaded Adaptor

1no 6mm Female Threaded Adaptor 1no 6mm Female Threaded Adaptor

Mains Installation Kit & Filters:

These are supplied as extra items according to individual ordering requirements

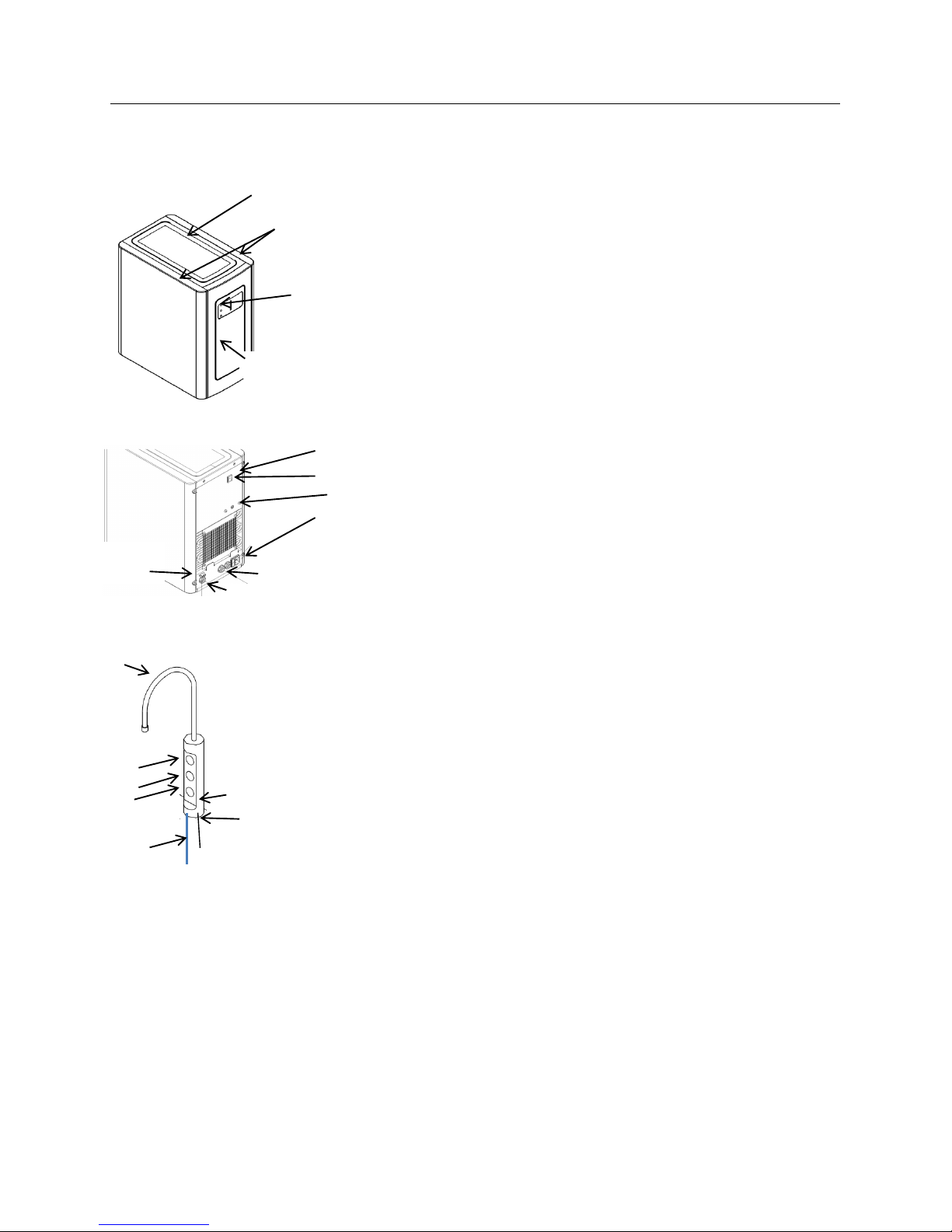

Top Panel

Side Panel

Front Panel

LED

Indication

Panel

On/Off Mode Switches

Power in

Thermostat

Water in & CO2 in

connections

Faucet

Connection

Water out connections

Swan Neck

Button

Switch

Panel

Ambient

Sparkling

Cold

Water Pipe

Elec

Connection

Back Panel

Boste BK Series

6

Installation Guide

1. Unpack both the undersink unit and the swan-neck faucet, checking the main components are present as per the

lists above. Dispose of the packaging in a responsible manner. Please note regarding any Mains Installation parts.

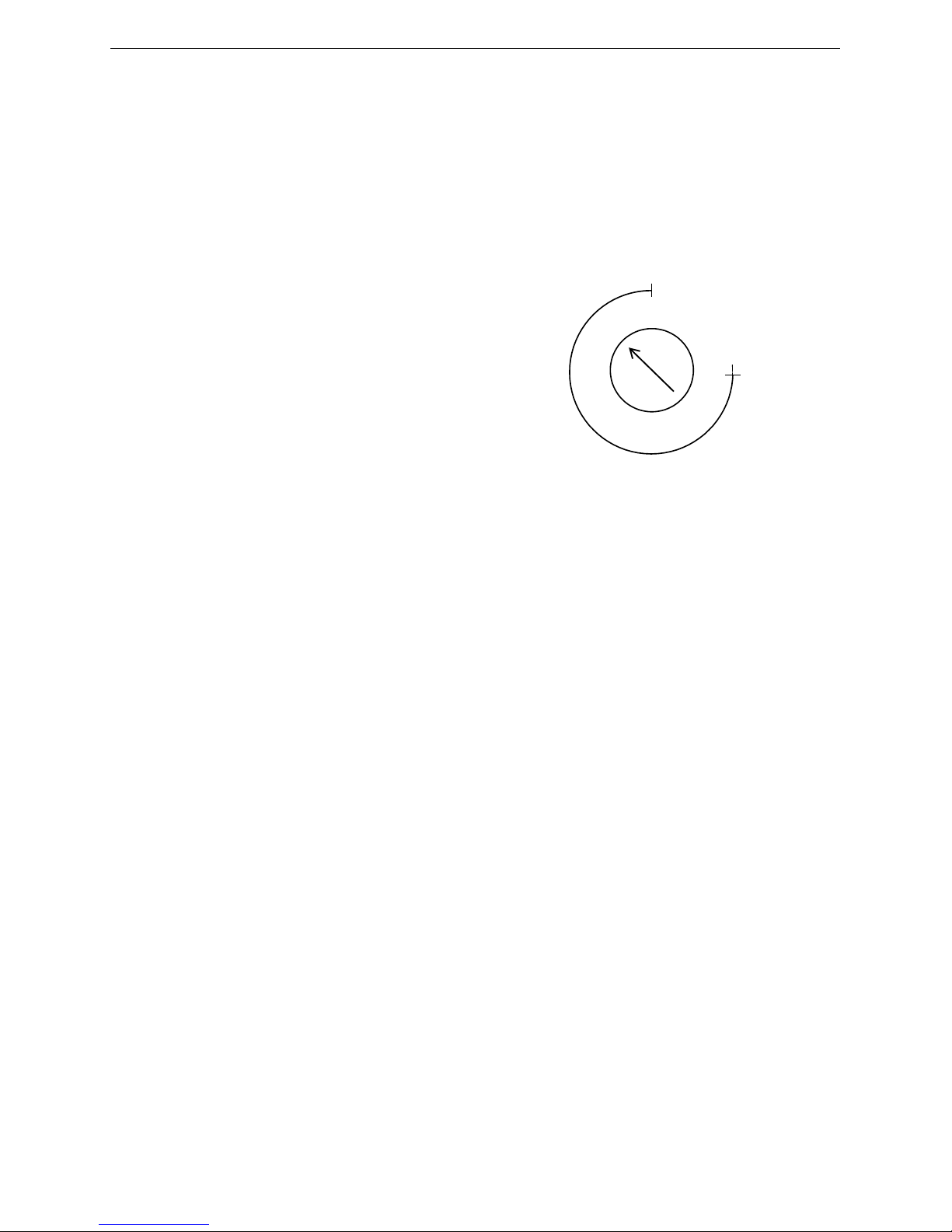

2. Check the thermostat set point of the undersink unit.

It should be preset to the following position:

-C

NB: Turn clockwise to

decrease

water

temperatur

e

3. Identify a suitable location for the unit. It should be positioned within 1.0m of the faucet, and within 2.0m of a

suitable services connections:

Water: Mains potable water –2.0bar recommended. Min 1.0bar

Electricity: 16A supply –Earth Leakage Protected.

Always install internally. Do not expose to dampness or moisture. There should be 150mm minimum behind the

unit, 25mm min each side and 100mm above. Always ensure there is adequate airflow around the unit.

Additional ventilation grills or extraction may be required.

When planning and providing for the connection to the services, always allow for easily accessible service

isolator fittings and for the position of an external water filter.

Allow also for the CO2 cylinder when installing a carbonated model.

4. Provide service connections as required.

5. Position the unit in place, ensuring it is level and stable.

6. Connect to the water supply. The maximum recommended inlet pressure is 3.5bar.We recommend fitting a check

valve, a pressure reducing valve and a „Waterbock‟ device. (These are available as part of our optional

Installation Kit). When fitting a Waterblock device we recommend a minimum setting of „2‟ be used. Pre-flush and

fit the filter in an accessible position and always allow adequate connecting pipe length to enable the unit to be

sufficiently moved for any future disconnection. Do not turn the water supply on at this stage.

7. Identify a suitable position for the swan neck faucet. A 33-35mm (max) hole is required. When positioning to

drain over an existing sink bowl, allow for the reach of the swan neck or otherwise the position of any optional

drip tray. Also allow for the height of the swan neck under any overhanging cupboard/shelf and for the space

needed for forming the needed hole. Relate the selected position to the undersink of the worksurface and check

for any obstructions. Allow sufficient space for fitting a back nut to the faucet stem.

8. Carefully form the needed hole, using the correct type of cutter for the worksurface material. Observe all local

occupational health and safety requirements.

9. Remove the back nut and washer from the faucet and carefully feed the connecting pipe tail and ribbon cable

through the hole formed in the worksurface. There is an integrated sealing O ring pre-fitted in the base of the

faucet but it may be necessary to apply a thin bead of silicone sealant also.

10. With the faucet membrane switch in the right position, carefully refit the back washer and nut. Take care not to

overtighten.

+C

Boste BK Series

7

2no

Adaptors

5no Stem

Elbow

Insulated Faucet Pipe

11. Connect faucet pipework as follows:

Cold & Ambient Model: Cold, Sparkling & Ambient Model:

-Fit Stem Elbows directly to water outlets on back of unit.

-Fit 30mm pieces of pipe to each.

-Fit Y or Cross Fitting.

-Fit 30mm piece of pipe

-Fit male threaded adaptor fitting

-Fit female threaded adaptor fitting

-Connect to insulated faucet pipe

12. (Sparkling Model only). Unpack CO2 Regulator and fit elbow fitting to spigot outlet. Check the control knob is oin

the fully closed position (anticlockwise). Carefully screw fit to a new, full CO2 single use cylinder ensuring the

small pressure relief vent in the stem is facing away from you or anyone else. Hand tighten securely. Connect to

the CO2 inlet on the back panel using the required length of ¼1/4” pipe. Stand cylinder in a suitable place.

13. Fit optional Drip Tray at this stage (if selected)

14. Turn on the water supply and check for any leaks.

15. Connect the IEC power cordset to the electricity supply. The Direct Chill system should now be heard to begin

filling. This may continue for a few minutes depending upon water pressure. (NB: Any immediate whining noise

from the DC pump should soon stop as the water level in the system rises).

16. Upon the filling cycle completing, proceed to flush the cold and the ambient water channels using these buttons on

the faucet control panel. We recommend that a minimum of 10lts is flushed through the unit*. (Cold approx. 8 lts

and Ambient approx. 2 lts). Switch on the Cooling Mode and allow up to 1 hr for the initial cooling cycle.

17. (Sparkling Model only). Switch on Sparkling Mode and allow the carbonation tank to fill. (The carboanntion pump

will run for approx. 15-20 secs). Upon completion, open the CO2 Regulator Knob and set initially to 5 bar. Flush

through approx. 10 lts of water using the sparkling button*. Depending on the inlet water pressure, you may have

to pause approx. every 500ml to allow the carbonation tank to refill. Reset the CO2 pressure to the required level.

We recommend 3-5bar (max) depending on individual requirements. Allow up to 1 hr for carbonation to develop.

*NB: The integrated leak prevention control will prevent any continuous dispense of >60 secs and could occur

while carrying out this prolonged dispensing. When it occurs the dispense will stop and a bleeping noise will

sound. To reset momentarily release the button and press again

2no Stem

Elbow

Y Fitting

Cross

Fitting

2no

Adaptors

CO2 Regulator &

Cylinder

Boste BK Series

8

Operation Guide

Operation of these models is very simple. According to the individual model, ambient and cold or ambient, cold and

sparkling water can be freely dispensed.

During normal operation the only LED indicators are those on the

the front panel of the Undercounter Unit

Cold & Ambient Model Cold, Sparkling & Ambient Model

Top: Power on Sparkling Mode on

Middle: Cooling Mode on Cooling Mode on

Bottom: Cooling cycle on Cooling cycle on

To dispense water simply press and hold the appropriate button for the duration of the required dispense:

Cold & Ambient Model Cold, Sparkling & Ambient Model

Top: Ambient Ambient

Middle: N/A Sparkling

Bottom: Cold Cold

No other user operation function or adjustment is required

Please Note:

The integrated leak prevention control will prevent any

continuous dispense of >60 secs and could occur while

carrying out this prolonged dispensing. When it occurs the

dispense will stop and a bleeping noise will sound. To reset

momentarily release the button and press again

Boste BK Series

9

Maintenance Guide

Minimal routine maintenance is required. Every 6 months maximum a sanitisation procedure is

recommended as follows:

1. Turn off incoming

mains

water, briefly

press cold/ambient (not sparkling) dispense

button(s) to

release internal

water

pressure

from

the

machine

and remove filte

r

.

2. Add 100 ml of a

proprietary sanitisation

fluid to a clean and empty service filter

cartridge/dosing

device

and

connect

into

machine.

Always

ensure

to use a

reputable branded sanitisation

fluid for effective

action.

Please

note: We

recommend

using a 3% Hydrogen Peroxide

concentration base sanitising

fluid of

r

eputabl

e

manufacture

to the

appropriate

dilution ratios as

supplied

with the

product

or typically 1:30 max.

(Str

onger

concentrations

will

require larger

dilution

ra

tes).

Please remember

that most

sanitisation

fluids (including ozone) contain an active

caustic/alkaline

agent.

Always use

re

sponsibl

y

and with care

remembering

that due to its

alkaline nature unnec

e

s

sary

concentrated/prolonged contact

with any

materials,

including

metals,

can

cause damage.

Always rinse

all

contact surfaces

after use with clean

wate

r

.

3. Turn on incoming water, allow service

cartridge/doser

to fill and then draw off at

least

1 litre of water for

the

machine

to ingest the

solution.

Leave solution for 10

minutes

inside

machine

for

sanitisation

to take eff

ect.

During this time

thor

oughl

y

clean the

machine

e

x

ternall

y

. For this we

recommend

the use of

pr

oprietary

disposable sanitisation

wipes. Pay

particular attention

to the

dispense

faucet and the push button

c

ontr

ols.

Remember

to include the drip tray.

If

a

W

a

s

t

e

Overflow System is fitted, this may benefit from flushing

thr

ough

with

a

small amount

of dilute

sanitisation fluid.

4. After a

satisfactory

period of time, flush the

machine

with at

least

10 litres of clean water to clear any

trace

of the

sanitisation

fluid. Optionally use test

strips

to

check.

5. Turn off water and remove the service

filter/doser

and fit a new filter of

reputable

quality and suited to the

site

conditions.

We

recommend pre-flushing

the new filter to

reduce

any risk of any loose media in the

filter

entering

the solenoid valves and

pos

s

ibl

y

causing

a

malfunction.

Retain the service

cartridge/doser

for

re

use.

6. Turn on incoming water supply and carefully

ensure

the

thorough sanitising

of the

outside

of the

machine is

completed. Reconnect

power and

reset

any

service/filter

life

monitors

ac

c

o

r

dingl

y

.

Ensure

any hot tank inlet

is

reconnected

and the tank is

purged

of air before switching

heater

on

again.

ALWAYS ENSURE ANY RESIDUAL AIR HAS BEEN PURGED FROM ALL DISPENSE CHANNELS

AND ALL

IS

OPERATIONAL BEFORE

LEAVING.

Boste BK Series

10

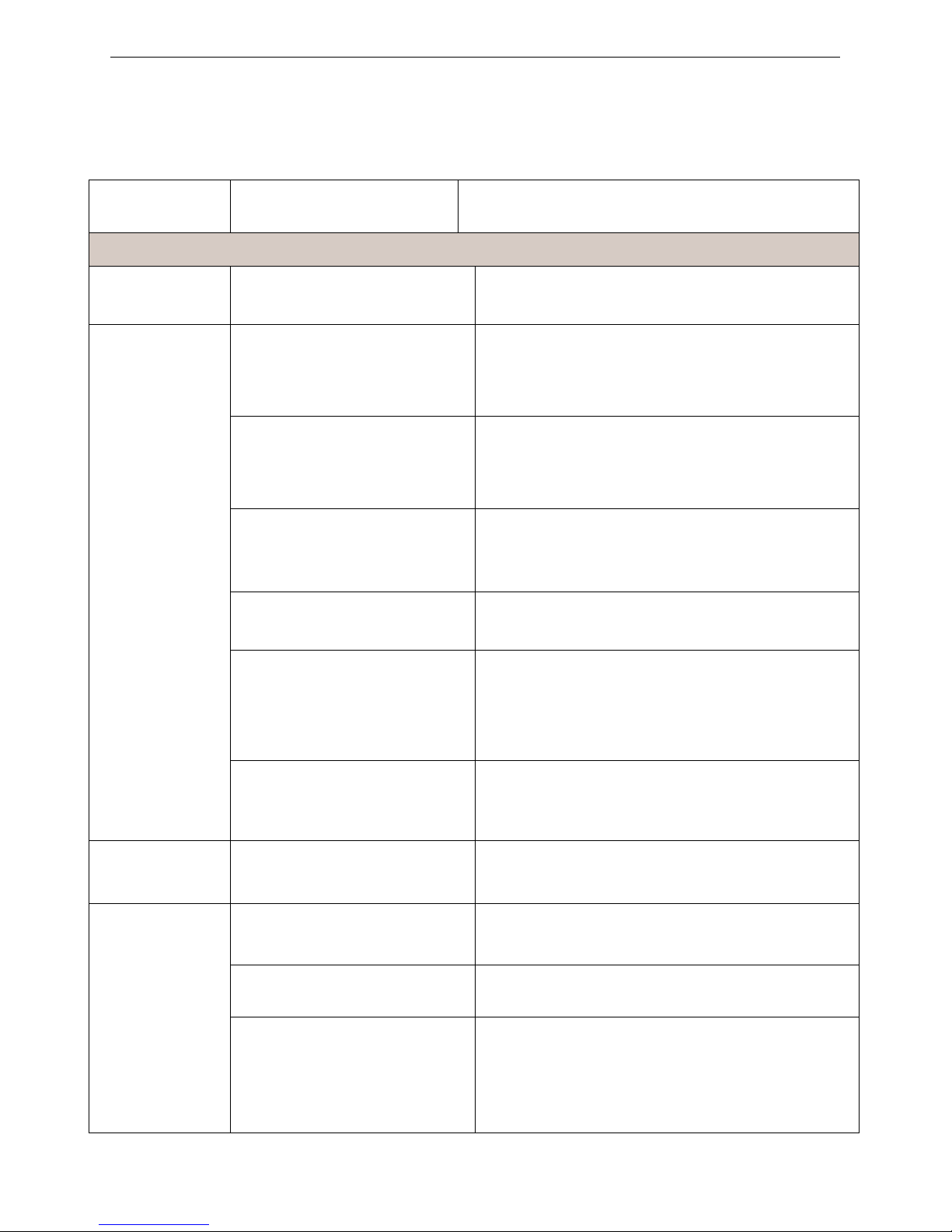

Fault Diagnosis

No Water

Dispenses

Pr

obl

em/

Report

Possible Cause

Suggested Action

No Water

Dispenses

From

Ambient

Valve

Water Supply

turned

off

Check all

T

a

ps/v

al

v

e

s/

filters

on

incoming

supply are fitted and are

turned on.

No

Electricity/Power Suppl

y

Check power cord

connected

and live

and

machine

is

switched on.

“Waterblock” tripped off

Reset “Waterblock” ( and check for cause

of leakage)

Faulty dispense control panel

membrane switch

Check and replace if required

Faulty Solenoid

V

a

l

v

e

V

a

l

v

e

clicking but no

water-Check

if hole in

centre

of

washer

is

cl

ea

r

.

Check valve action. Carefully

dismantle

v

a

l

v

e

and clean out

/part replace/complete

r

eplac

e

as

needed.

V

a

l

v

e

not

clicking-Check

voltage

output

when

operated.

If

no output

replace PCB.

If

there is output, replace

solenoid coil/whole

valve

coil/whole valve

as

sembl

y

c

ompl

e

te.

Leak

detector

has

disabled

dispense operation.

Check for

internal leakage, ensure probes

are

dry and

r

eset.

From Cold

V

a

l

v

e

Fir

s

tl

y

all as for

Ambient

Ta

p

Carry out

checks

and

actions

as for

ambient

tap.

Chiller tank frozen

-

F

aulty

Thermos

tat/Incorrect Setting

Thaw out, check and

replace

thermostat or reset

temperature

set

point.

Chiller tank F

r

ozen-faulty

air

pump

Thaw out, check

operation

and

replace

Air

pump

id necessary.

Boste BK Series

11

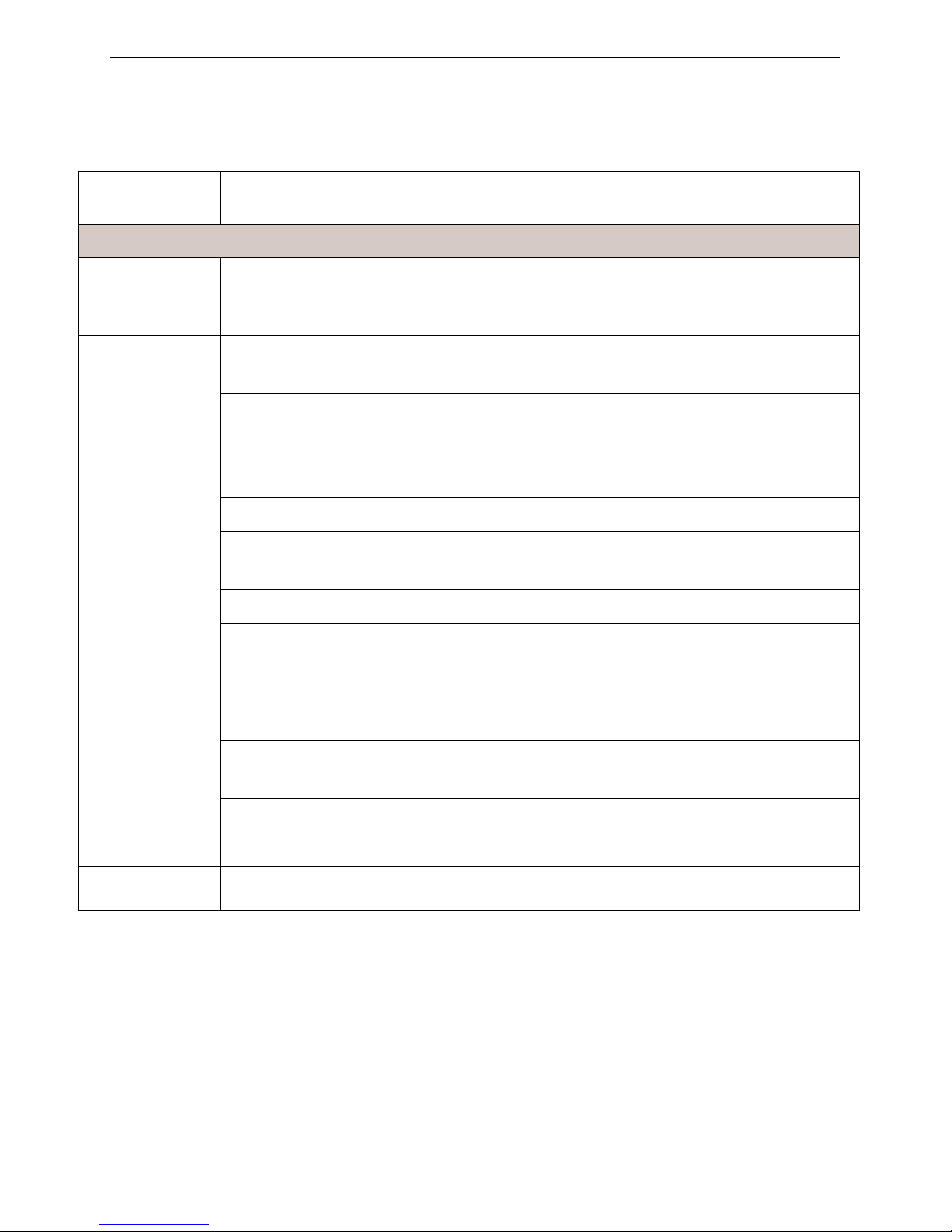

No Water

Dispenses continued

No Water

Dispenses

continued

From

Ambient

or Cold

V

a

l

v

e

Button not being

pr

es

sed

enough

Press

button firmly

Faulty c o ntr ol s P C B –no

v ol tag e ou tpu t .

Replace PCB –Check for 24 VDC outputs if necessary.

From

Sparkling

Valve

Carbonation System switched

off.

Check switch on back of the machine

Fir

s

tl

y

as for Ambient

and

or Cold

Dispense

Carry out the

checks

and

actions

as

f

o

r

Ambient

Dispense

Low or no CO2 pressure.

Check and

replace

cylinder as

nec

e

s

sary

Pump not

oper

ating

Check

carbonator

level Control Sys

tem.

Check

probes connected/leads attached.

Check

power supply to

pump.

Carbonator Tank over

pressurised with CO2

Switch Sparkling System off, shut off CO2 supply and

release CO2 from carbonator. Switch Sparkling system on,

then check pump operation.

If normal, open CO2 supply after pump has stopped.

Pump Feed Valve not opening

Check valve function:

If no input DC voltage, check rectifier and level control

module.

If input but no function, check valve coil.

Replace parts as needed.

Boste BK Series

12

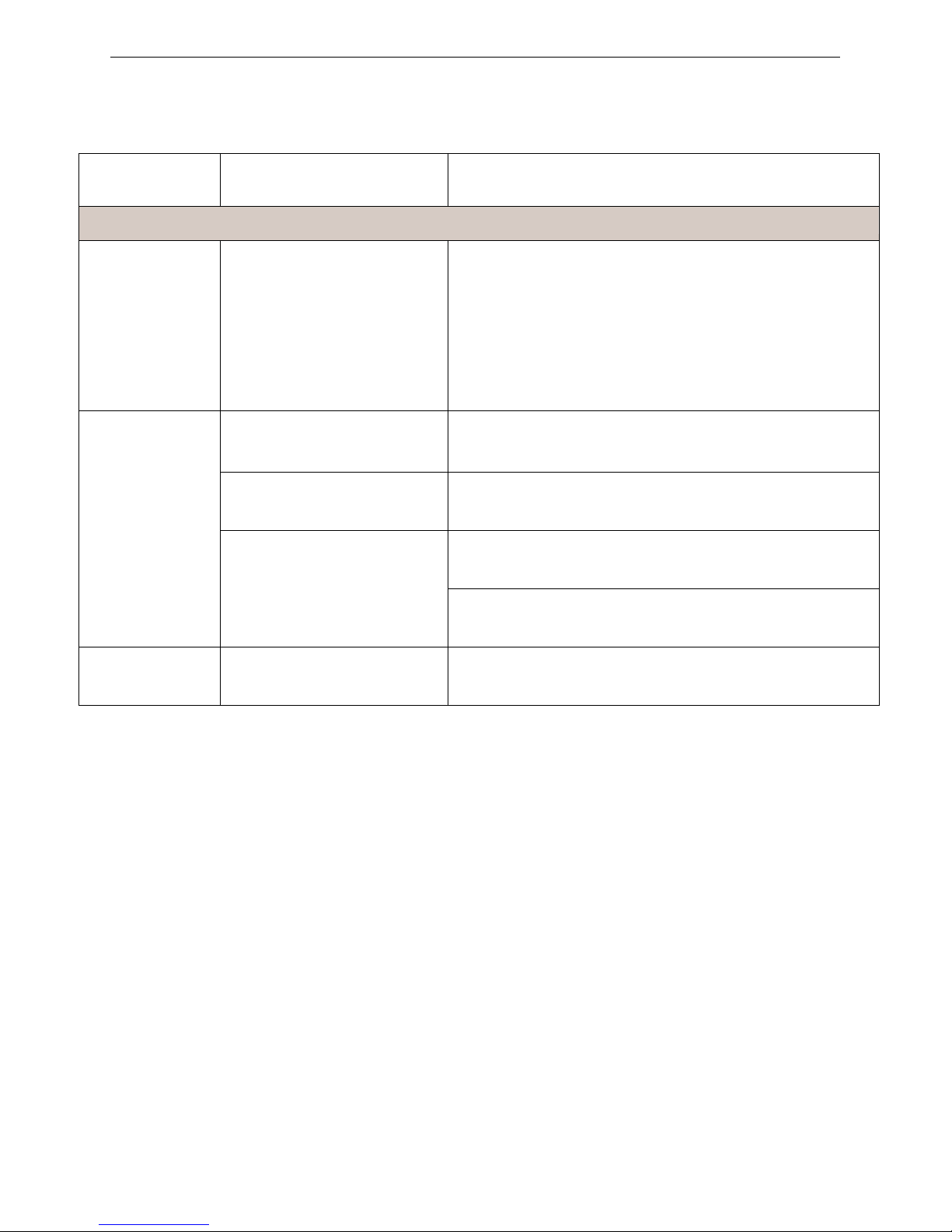

Water Dispenses but not correct Temperature

Pr

obl

em/

Report

Possible Cause

Suggested Action

Water

Dispenses

But Not Correct

T

emper

atur

e

Ambient

W

ater

too warm

Low

usage

and / or fed

from

water supply pipe in

warm

ducting.

Advise

user replacing

e

x

ternal

causes and

solutions.

Cold water

not

Cold

Cooling and or

Sparkling

System switched

off.

Check switch

positions on the back of the machine as

nec

e

s

sary

.

Compressor

runs and

switching off

(cool/warm to

touch) -

Thermostat

set

too

high.

Decrease

Cold

Thermostat

set

point.

Faulty

Thermos

tat.

Replace Thermos

tat

Compressor

runs but

not

Switching off (Hot to

touch).

Contact Aftersales Support.

Refrigeration

pr

obl

e

m.

Contact Aftersales Support.

Compressor

not

running

at

all.

Check voltage path through the machine.

No electricity power

suppl

y

.

Check power cord

connected

and live,

and

machine

is

switched on.

Compressor

only

hums

slightly/

briefl

y

.

Check and

replace

r

e

lays.

Relays l

oose.

Check and refit

r

e

lays.

Compressor

F

aulty.

Contact Aftersales Support.

DC Tank Empty

Check water level and replace level control module in

fill valve as needed.

Boste BK Series

13

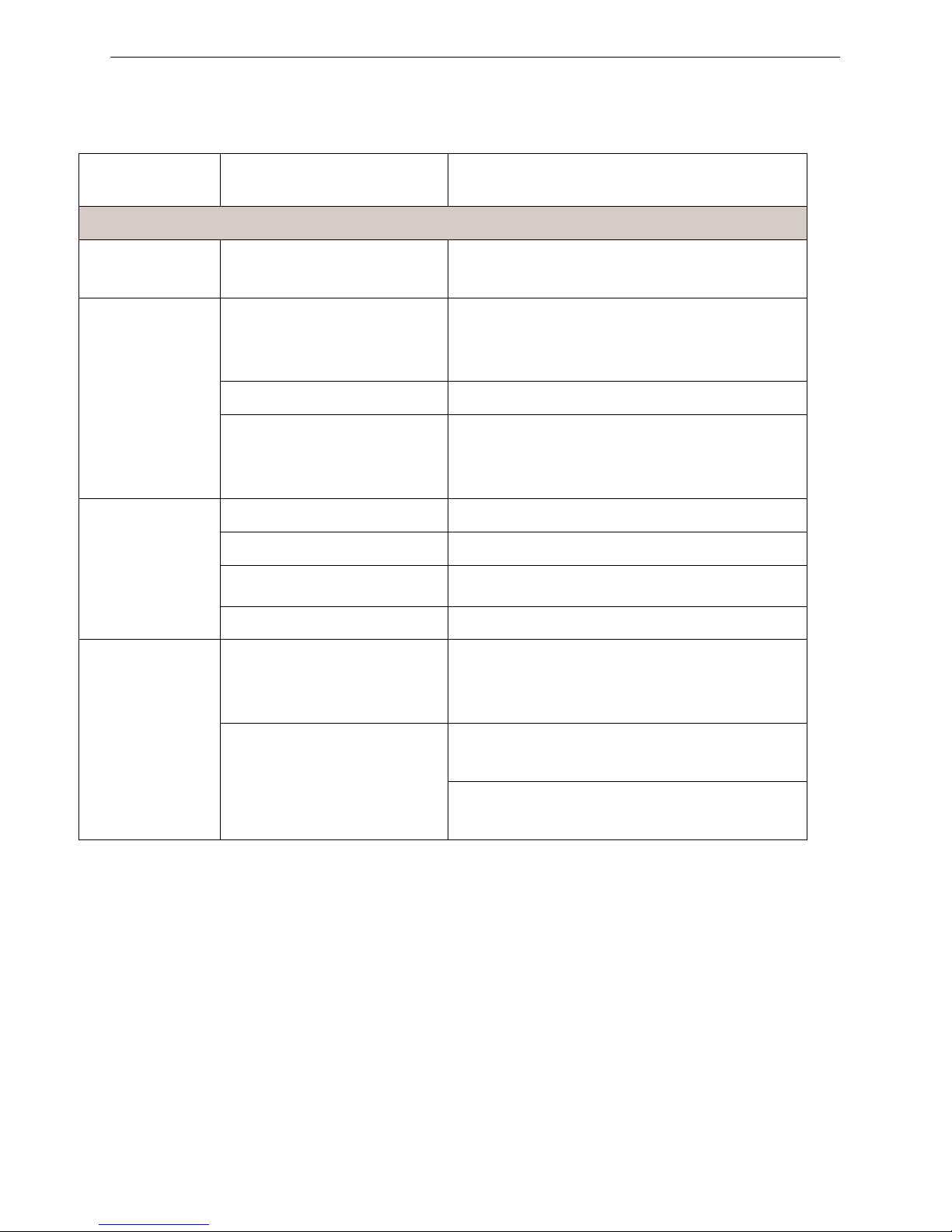

Water Leaks

Pr

obl

em/

Report

Possible Cause

Suggested Action

Water

Leaks

Water lying

on

top edge of

lower

door

panel and /

or

bottom of

Cabinet.

Overflowing Waste Container

.

Empty Waste Container and check drain pipe is not

blocked.

Water lying in

bottom of

machine

Faulty W a ter S y s te m Level

Sensor.

Check

operation and replace batteries if needed.

Leak in supply inlet

pipe-

work and / or filte

r

.

Locate and

repair acc

o

r

dingl

y

.

Leak from

machine water

pipe work

fittings.

Locate and

repair acc

o

r

dingl

y

.

Check

pressure

and fit

pressure

r

educing

valve if

needed.

DC tank over overfilling

Check level control module and fill valve function.

Boste BK Series

14

Miscellaneous

Pr

obl

em/

Report

Possible Cause

Suggested Action

Misc

ellaneous

Bleeping

Noise

Waste Container full/Internal

water leak.(If fitted)

Empty Waste Container. Check and

reset Leak Detector.

No

LED function

Lights

No electricity to

Machine.

Check power supply and

reconnect

as

necessary

(Also check out other

symptoms

as

described

separa

tel

y).

Check Fuse in

IEC

Sock

et.

Replace

if

nec

e

s

sary

.

Faulty C o n tr o l PCB

(Machine working

normall

y

otherwise).

Replace Control PCB.

Machine

shak

es

on

Start-Up

Compressor Starting.

Level

Surf

a

c

e

.

No action

needed.

This is quite

normal.

Uneven

Surf

a

c

e

.

Level up

machine

using adjustable feet.

Missing Fixings.

Replace missing fixings.

Tripping

out

El

ectricity

suppl

y

Machine in high humidity

envir

onment.

Discuss possible repositioning with

cust

ome

r

.

Electrical

circuitry

f

aults.

T

e

s

t,

identify and

address

acc

o

r

dingl

y

.

See

Electrical Diagr

ams.

(Contact Azure Aftersales for

further

advice).

Boste BK Series

15

Miscellaneous continued

Pr

obl

em/

Report

Possible Cause

Suggested Action

Slow but Continuous Water

Dispense

From

Ambient

or Cold

W

ater

Valve

Low incoming

W

ater

pr

es

sur

e.

Consider re-plumbing to

alternative suppl

y

if

pos

s

ibl

e or boosting the inlet supply

pressure.

From

Sparkling

Water Valve

Low/no CO2

Pr

es

sur

e.

Check

Regulator

and/ or

replace

cylinde

r

.

Intermittent Water

Dispense

From

Ambient

or Cold

W

ater

Valve

Trapped air in pipe

w

o

rk

(especially where water

pressure

is low or

after

filter

change).

Hold button on to purge air out. (This

c

ould

take

se

v

e

r

al

minutes

where pressure

is low).

Use filter function if available.

Button Not being

pr

es

sed

enough.

Press

button firmly N.B. This could

be

caused

by a

surrounding

cold

envir

onment

making the action

s

tiff

e

r

.

Faulty C o n tr o l PCB

Replace Control PCB.

From

Ambient

or Cold

W

ater

V

a

l

v

e

and

hammering

noise

Fluctuating

mains water

pressure situation.

Contact Azure r

egar

ding

special

replacement washers

av

ailabl

e

.

Continuous Water

Dispense

From

Ambient/

Cold

or

Sparkling

Water Valve.

Button

jammed

on/faulty.

Replace Control

PCB and or/ button Panel as

needed.

Debris blocking hole in

diaphragm washe

r

.

Dismantle

V

a

l

v

e

and clean out

.

Faulty solenoid valve.

Check valve and replace if needed.

Boste BK Series

16

Diagrams & Parts Lists

17

Table of contents

Popular Water Dispenser manuals by other brands

Bartscher

Bartscher 190990 instruction manual

Greenway Home Products

Greenway Home Products GWD5500WBC Use & care guide

Katadyn

Katadyn Siphon operating instructions

Follett

Follett 7UC100A Installation, operation and service manual

Stalgast

Stalgast DVA LT Series Instruction leaflet

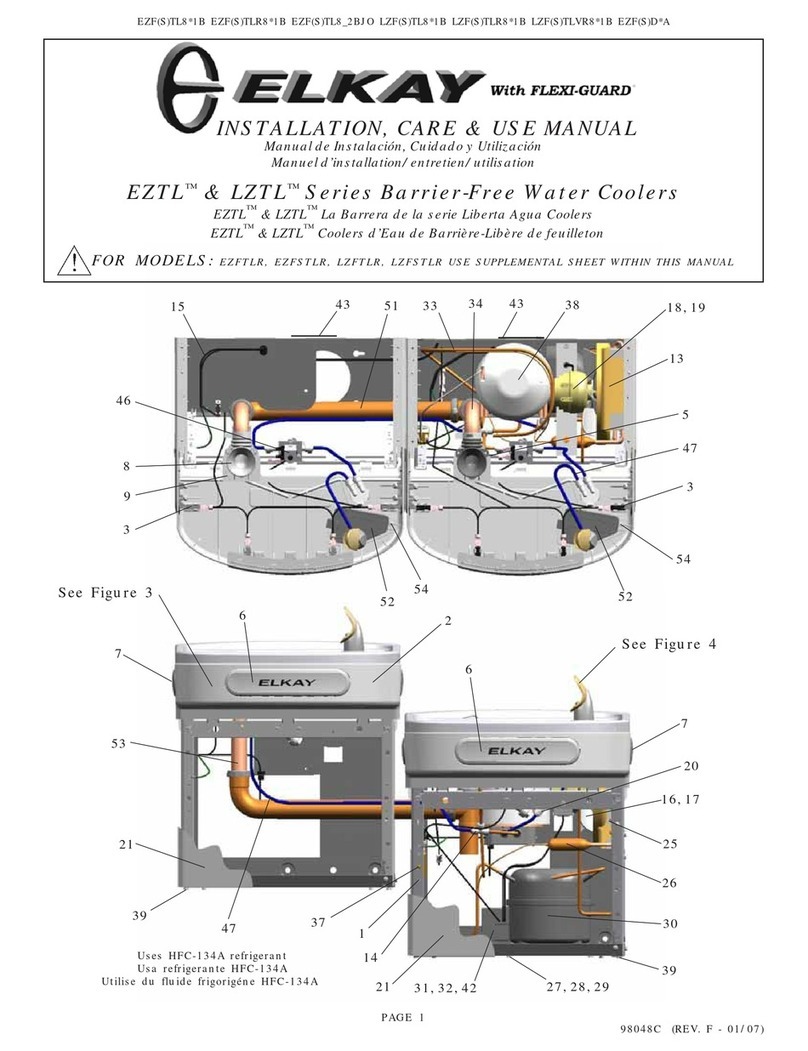

Elkay

Elkay LZTL Series Installation, care & use manual