Boumatic StepMetrix Manual

StepMetrix™

(U.S. patent 6,699,207)

Installation, Operation Maintenance & Service Instructions

Instructional Content and Purpose

These instructions aim to aid those responsible (outlined und er

“Responsibilities”) for installing, operating , maintaining,

troubleshooting, and servicing this product.

Responsibilities

Procedures in these instructions are to be perfor med according to

applicable codes (state, local, and other) by the person(s) qualified

(licensed, if applicable) to do so—that is:

• Welding must be done by a qualified welder.

• High-voltage AC pow er wiring must be done by a qualified

(licensed) electrician in compli ance with the latest edition of

the ANSI/NFPA Standard 70, National Electrical Code, (USA)

or either LVD 2006/95/EC or EMC 2004/108/EC (Europe) and

in compliance with the local wiring codes as applicable.

• Other installation, major maintena nce, and service w ork must

be done by an authorized BouMatic dealer.

• Product/system checkout and troubleshooting steps are to be

performed by an authorized BouMatic dealer.

• Deviation from these instructions could affect product

performance or create a haza rdous situation. Under n o

circumstances will BouMatic be responsible for an y problems

caused in whole or in part by any deviation from the

procedures specified

in these instru ctions

without prior written

approval from

BouMatic.

• Operation steps ma y

be performed by the

owner/operator once

the dealer or

technician has

successfully finished the p roduct/system checkout. Th e

owner/operator is responsible for prop erly operating,

maintaining, and monitoring the product/s ystem to ensure that

it works properly.

P.O. Box 8050

Madison, WI, 53708-8050

USA

Telephone: (608) 222-3484

Fax: (608) 222-9314

Remicourt 31, Rue Jules Melotte

B 4350 Remicourt

Belgium

Telephone: +32 (0)19 544 266

Fax: +32(0)19 545 544

www.boumatic.com

Close compliance with the procedures herein is essential for the

owner to get maximum benefit from the product/system.

Disclaimers

No warranties are contained in th ese instructions. The division of

responsibilities, stated above, i s a general re minder of th ose

provisions in the applicable deal er contract and does not chang e

any agreement between BouMatic and the deale r. Information in

these instructions is not all-inclu sive and cannot cover all unique

situations.

Introduction ........................................................................................ 2

1. Preparation ..................................................................................... 2

1.1 Verifying Part and Tool Requirements ..................................... 2

1.2 Reviewing Installation Specifications ....................................... 2

1.2.1 StepMetrix Cow Traffic Guidelines.................................... 2

1.2.2StepMetrix Sensor Module Location .................................. 3

1.2.3 StepMetrix Controller Location.......................................... 3

1.2.4 Communication ................................................................. 3

1.2.5 Wiring................................................................................ 3

1.2.6 Dairy PC............................................................................ 4

1.2.7 Network Controller ............................................................ 4

1.2.8 SMX ISO ID Site Evaluation ............................................. 4

1.3 Reviewing Personal Safety Instructions................................... 5

1.3 Reviewing Personal Safety Instructions................................... 6

2. Installation....................................................................................... 6

2.1 Installing the StepMetrix with a BouMatic ID System............... 6

2.1.1 Installing the StepMetrix ID Antenna................................. 6

2.1.2 Installing the StepMetrix Sensor Module .......................... 7

2.1.3 Installing the StepMetrix Step-Up ..................................... 7

2.1.4 Installing the StepMetrix Step-Down................................. 7

2.1.5 Installing the StepMetrix Positioning Rails ........................ 8

2.1.5 Installing the StepMetrix Positioning Rails ........................ 9

2.1.5 Installing the StepMetrix Positioning Rails ........................ 9

2.1.6 Installing the StepMetrix Controller ................................. 10

2.1.7 Wiring the Power Supplies and StepMetrix Controller .... 11

2.1.7 Wiring the Power Supplies and StepMetrix Controller .... 11

2.1.7.1 Load Cell to StepMetrix Controller Connections...... 11

2.1.7.2 StepMetrix ID Connections ...................................... 15

2.1.7.3 Communication........................................................ 15

2.1.7.4 StepMetrix Controller Setup..................................... 15

2.2 Installing StepMetrix with ISO ID............................................ 15

2.2.1 Installing the StepMetrix Sensor Module ........................ 15

2.2.2 Installing the StepMetrix Step-Up ................................... 16

2.2.2 Installing the StepMetrix Step-Up ................................... 17

2.2.2 Installing the StepMetrix Step-Up ................................... 17

2.2.3 Installing the StepMetrix Step-Down............................... 17

2.2.4 Installing the StepMetrix Positioning Rails ...................... 17

2.2.5 Installing the StepMetrix ISO ID antenna ........................17

2.2.6 Installing the StepMetrix ISO ID Controller ......................18

2.2.7 Wiring the Power Supplies and StepMetrix ISO ID

Controller ...............................................................................19

2.2.7 Wiring the Power Supplies and StepMetrix ISO ID

Controller ...............................................................................19

2.2.7.1 Load Cell to StepMetrix ISO ID Controller

Connections .....................................................................19

2.2.7.2 Synchronization of HDX readers ..............................23

2.2.7.3 StepMetrix ISO ID Connections and Tuning ............23

2.2.7.4 Communication ........................................................23

2.3 StepMetrix System Configuration ...........................................23

2.3.1 Installing StepMetrix User Interface Software .................23

2.3.2 Unit Names......................................................................23

2.3.3 System Setup ..................................................................23

2.3.4 Dairy Setup ......................................................................23

2.4 StepMetrix Performance Tests ...............................................23

2.5 StepMetrix Calibration ............................................................25

2.5.1 Pre-Calibration Steps.......................................................25

2.5.2 StepMetrix Calibration Wizard .........................................25

3. Features ........................................................................................26

4. Operation .......................................................................................26

4.1 Understanding Basic StepMetrix Parts ...................................26

4.2 SMX™ Scores ........................................................................27

5 Troubleshooting .............................................................................28

6. Maintenance ..................................................................................32

6.1 StepMetrix Controller. .............................................................32

6.2 StepMetrix sensor module ......................................................32

7. Service...........................................................................................32

7.1 Load Cell.................................................................................33

7.2 ID Control ................................................................................33

7.3 Fan ..........................................................................................34

7.4 Hard Drive...............................................................................34

7.5 Load Cell Signal Conditioning Board ......................................34

7.6 Control Assembly ....................................................................34

7.7 Dealer Service Schedule.........................................................35

StepMetrix™ Installation Instructions 9E-864C

1

9E-864C StepMetrix™ Installation Instructions

2

Introduction

Lameness caused by injury or disease is a majo r

cause of fin ancial loss to the dairy owner. The

BouMatic StepMetrix system monitors hind leg

and hoof soundness in dairy cattle, providing

dairy operators early warning of hoof or l eg

problems that cause economic loss. StepMetrix

detects cows that are lame in the hind legs (the

most common form of lameness) a s they retur n

from the milking parlor. It can detect cows which

look sound, but have hoof problems and are sub-

clinically lame. StepMetrix enables “lameness

trend tracking” which assesse s lameness trends

within individual cows, groups and the herd.

StepMetrix calculates SMX™ scores of hin d

limbs every time a cow walks over t he

StepMetrix sensor module. The SMX score is a

numerical point system, unique to t he StepMetrix

system, indicating so undness or lameness.

StepMetrix provides an efficient, automatic

lameness detection system for mo nitoring cow

body condition and health. It dete cts early onset

of lameness, allowing early treatment. Early

detection helps to reduce the loss of milk

production and body weight, which are

associated with lamen ess. It can also provi de

useful information indicating the need f or

management changes for the cow, lot or herd.

1. Preparation

1.1 Verifying Part and Tool Requirements

To prepare, ensure that you have the follo wing

(depending on whether your Step Metrix installation

uses a Bo uMatic or ISO [Internatio nal Standards

Organization] ID antenna):

Product Parts Quantity per Single StepMetrix Unit

StepMetrix sensor module .................................................. 1

StepMetrix steps (step up + step down) ............................. 2

StepMetrix LH positioning rails ........................................... 2

StepMetrix RH positioning rails........................................... 2

StepMetrix controller........................................................... 1

StepMetrix packed parts ..................................................... 1

StepMetrix antenna ............................................................ 1

StepMetrix ID antenna shield.............................................. 1

StepMetrix software............................................................ 1

If something is missing, contact the

BouMatic Customer Service Department

immediately.

Dealer-Supplied Parts Quantity

2,3 Stranded wire, type TW insulated,

14 AWG (1.94 mm²) ....................................................a/r

2,3 Conduit fittings and fasteners......................................a/r

2,3 ¾” SCH40 PVC pipe, elbows, tees ...............................a/r

CAT 5E cable....................................................................a/r

Ethernet communication hub ............................................a/r

Dealer-Supplied Miscellaneous Parts Quantity

2,3 Wire nuts ......................................................................a/r

Cable ties ..........................................................................a/r

A small wooden screw driver or one with a plastic shaft ...a/r

Note: Abbreviation a/r means, “as required”

Notes

1. Part available from BouMatic Equipment catalog

2. Part must com ply with NEC; state, and/or local code

standards.

3. Parts must be CSA approved if installed in Canada

4. See subsection 1.2.4 for details explaining the n eed for this

part.

Other literature referenced in these instructions Section (§)

9P-476, Lighting Arrestor installation Instructions .......§1.2.5

9ES-768, ID Controller Installation Instructions…….......§1.9

9E-867, Ethernet Communications Instructions ............1.2.4

9E-892, SMX ISO ID Site Evaluation Instructions.......§1.2.8

1.2 Reviewing Installation Specifications

Plan the in stallation according to the following

guidelines:

1.2.1 StepMetrix Cow Traffic Guidelines

A training period is always necessary when

StepMetrix is first installed on a dairy. Cows will need

several consecutive passes over the platform befo re

they walk with a relaxed gait. The physical installation

of the StepMetrix is very important. If the device i s

installed in a steep return alleyway, co ws may move

too quickly across the platform, resulting in a l ower

percentage of cows receiving an SMX score. Whe n

this location is the only a vailable option, it may be

necessary to install a n additional short platform at

least 10’-15’ (3m – 4.5m) away from the entrance at

the StepMetrix to both sl ow the cows down as they

cross the platform and to keep sufficient space

between cows. Cows walking over the system with a

normal walking gait will maximize the benefits of t he

StepMetrix system.

Do not push cows through the StepMetrix or allow

them to bun ch up a s they cross the platform. Th e

cows must walk consistently over th e platform with

their normal walking gait for all milkings.

Research has shown that cow m ovement through

alleyways will be sped whe n solid white sidewalls are

installed. The alleyway areas should also have

excellent lighting to facilitate norm al cow movem ent.

The alleyway leading onto the StepMetrix should al so

have solid plastic walls. The shi elding should extend

for 5 to 10’ (1.5 – 3m) past the exit end of the

StepMetrix Step down platform. The plastic shielding

should be in stalled from approximatel y 1’ (30 cm ) of

the ground to a total of 5’ (1.5 m) off the floor. If gates

are used to narro w a co w movement alleyway, the

gates should also h ave the same white pla stic

shielding. The goal is for cows to see the rear end of

a herd-mate moving cal mly and sl owly through the

shielded alleyway, which will encourage them to walk

in the same calm, relaxed manner.

An additional technique to improve single file cow

movement is to install narrow rubber mats imbedded

at floor level to enco urage cows to mo ve in a singl e

file into the exit alleys. The ru bber flooring can be

wide at the e xit of the parlor and then narrow down

toward the entrance of the exit alley whe re the

StepMetrix is installe d. The goal i s to make it m ore

comfortable for the co w to be in sing le file at the

StepMetrix location.

1.2.2StepMetrix Sensor Module Location

• The StepMetrix sensor module must be installed

in an area where cows walk in a single file after

milking so that only one cow can walk on th e

sensor module at a time at their normal pace. The

breezeway or an exit all eyway of th e milking

parlor is an ideal location.

• The StepMetrix should be installed as far a way

from the mil king parlor as possible in order to

avoid groups of cows walking through the system

in a mass.

• The StepMetrix should be installed in a location

where the cows will leas t likely to be pushed

through the system. The cows must be allowed to

move through the syste m one at a time a t a

normal pace.

• The StepMetrix must be installed in a location

where all the cows ca n walk thro ugh the system

after every milking

• The sensor module must be installed so that

there are no sharp turns, high step s or othe r

obstacles at least 10 feet (3m) before and 10 feet

(3m) after the system.

• The sensor module must be in stalled in an area

with easy access to water for re gular cleaning.

Automated flushing is ide al for kee ping manure

cleaned from underneath the sensor module.

• If there is a footbath, it must be at lea st 20 feet

(6m) before the StepMetrix step up or 20 fe et

(6m) after the StepMetrix step-down.

• The sensor module must be in stalled with the

StepMetrix step up and StepMetrix step down in

place.

• Recommended StepMetrix installation locations

are shown in Figures 1-4.

• In order to get SMX™ scores from all of the cows

passing through the sensor module, every effort

must be ma de to avoid crowding of the cows

before the step up and after the step down.

• Depending on the layout of the dairy, more than

one StepMetrix may be required in order to collect

data from all of the cows.

• The floor must be leveled before installation of the

StepMetrix sensor module.

• The water draining systems should be such that

the sensor module is not submerged in the water

at any time.

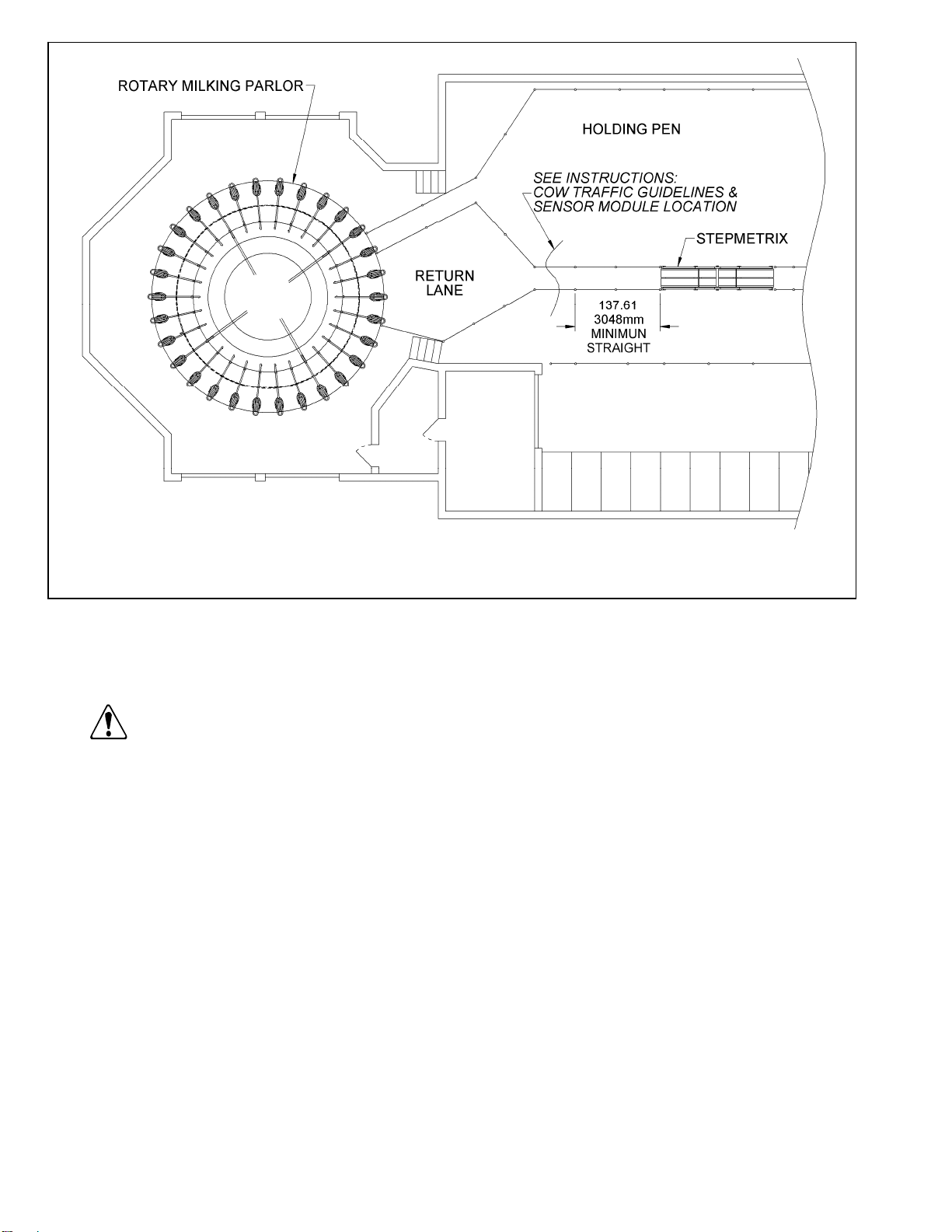

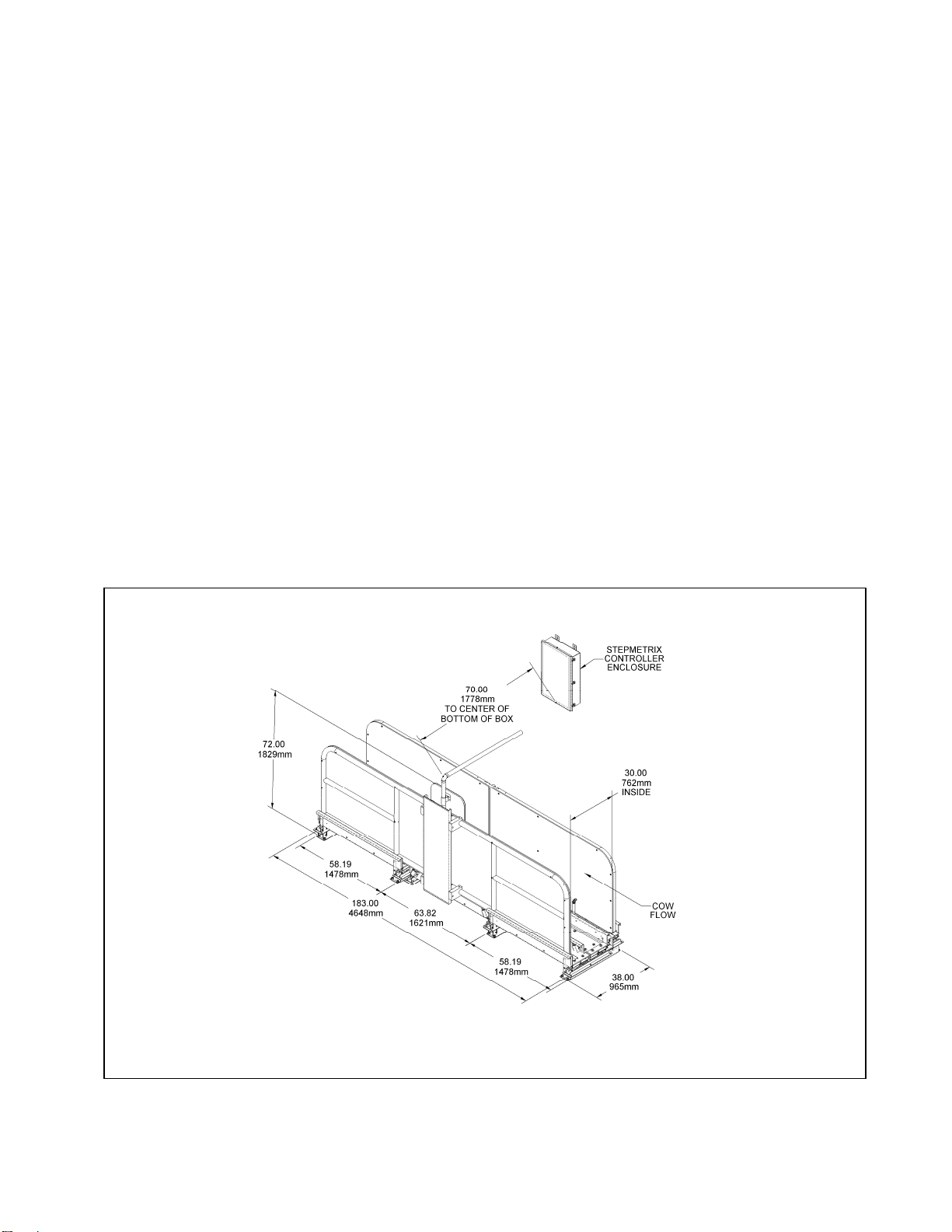

1.2.3 StepMetrix Controller Location

• The StepMetrix controller must be in stalled on

non-vibrating posts or a wall.

• The controller can be lo cated 8-10 fe et (2.4 to

3m) above ground level. It needs to be accessible

for troubleshooting.

• The controller must be installed within 58 inches

(1500 mm) of the top of the StepMetrix BM ID

antenna and within 70 inches (1800 mm) from the

ISO ID antenna furthest from the controller.

• The load cell cables must not be shortened.

Splicing the cables will adversely affect the

performance of the StepMetrix.

• The controller must be located on the same side

as the load cell conduit locations.

1.2.4 Communication

• A CAT 5E communi cation cable should run from

the controller(s) to the dairy PC.

• The CAT 5E cable must be run in conduit, and

must be no more than 300 feet (90 m) in length.

• A dedicated Ethernet connection to dairy PC from

a StepMetrix controller(s) is required.

• Refer to B ouMatic Ethernet Communications

Instructions 9E-867 for further details.

1.2.5 Wiring

• To operate properly, the controller requires 1 4

AWG (1.94 mm²) minimum input po wer stranded

wires to keep voltage drops to a minimum.

• Keep wiring as sho rt as possible for the best

protection against voltage drop.

• Wiring must be routed through conduit for

protection and aesthetic purposes (we

recommend the use of PVC conduit). AC and DC

wiring must not be route d together in the sam e

conduit.

StepMetrix™ Installation Instructions 9E-864C

3

9E-864C StepMetrix™ Installation Instructions

4

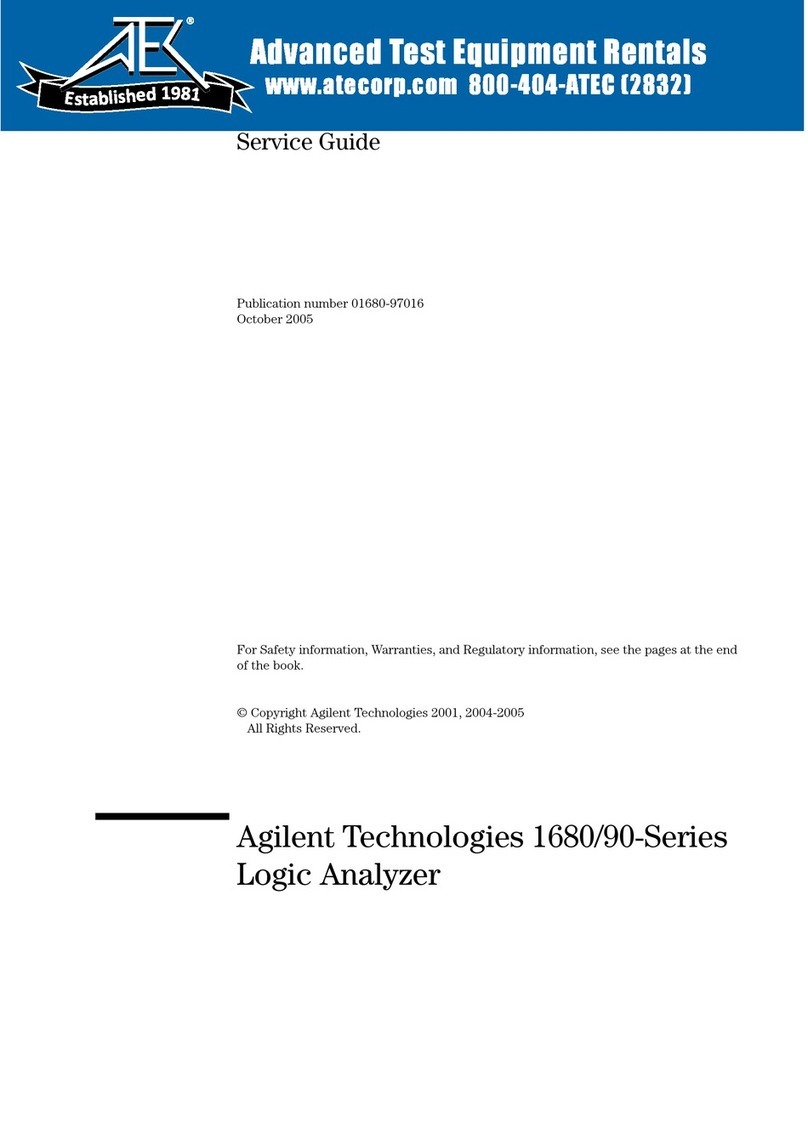

1. StepMetrix location in an adjoining building or passageway (ideal location) l864_1

If routed together, the AC wires will couple

transients onto the DC wires (that is, the DC wires

will pick up electrical noise). Communication and

DC cables can be run in t he same conduit. Such

noise could lead to poor or intermittent operation

of any cont roller served by the powe r supply.

Though no distance restrictions apply to conduits

for AC and DC wi res perpendicular to o ne

another, parallel conduit for AC and DC wi res

must be a mi nimum of 12 inches (305 mm) from

each other to prevent transients from coupling.

• Memory: 512 MB RAM

• Hard Drive: 10 GB Hard Drive

• Data Storage: 100 MB

• Network: Ethernet connector (Optional second

Ethernet connector for additional network)

• Backup Device: Secondary Hard Drive for full

backup

• DVD – R for data and program storage

• CDROM – R for program only

1.2.7 Network Controller

If the dairy fa rm is equipped with a Pro Vantage 2050

Network Controller, the dairy operator must have

Version 2.1.41 or higher of EZ cow software

• This product requires uninterrupted AC power to

operate properly. To ensure that it will not operate

intermittently, we recommend that a qualified (or

licensed, if applicable) electrician evaluate the

load on the farm and barn electrical service

entrance before you install and use the

product/system to ensure that it will have

adequate power.

1.2.8 SMX ISO ID Site Evaluation

• A site evaluation must be p erformed for

StepMetrix installations using ISO ID antennas.

Any needed corrective actions must be take n

before the installation of the StepMetrix.

• Before connecting power to the sy stem parts, a

lightning arrestor must be installed on AC power

lines, main pole, and p ower panels serving

BouMatic automation equipment. Refer to th e

Lightning Arrestor instructions, 9P-476.

• Refer to site evaluation instructions 9E-892 when

performing the evaluation.

1.2.6 Dairy PC

• Operating System: Windows 2000

• Processor: Intel Pentium III or AMD Athlon

• Monitor: SVGA Monitor, capable of resolution

1024x768 and 16-bit color depth

• Pointing Device: Mouse or equivalent

2. StepMetrix location, parlor with a dual return lane l864_2

3. StepMetrix location, single return lane l864_3

StepMetrix™ Installation Instructions 9E-864C

5

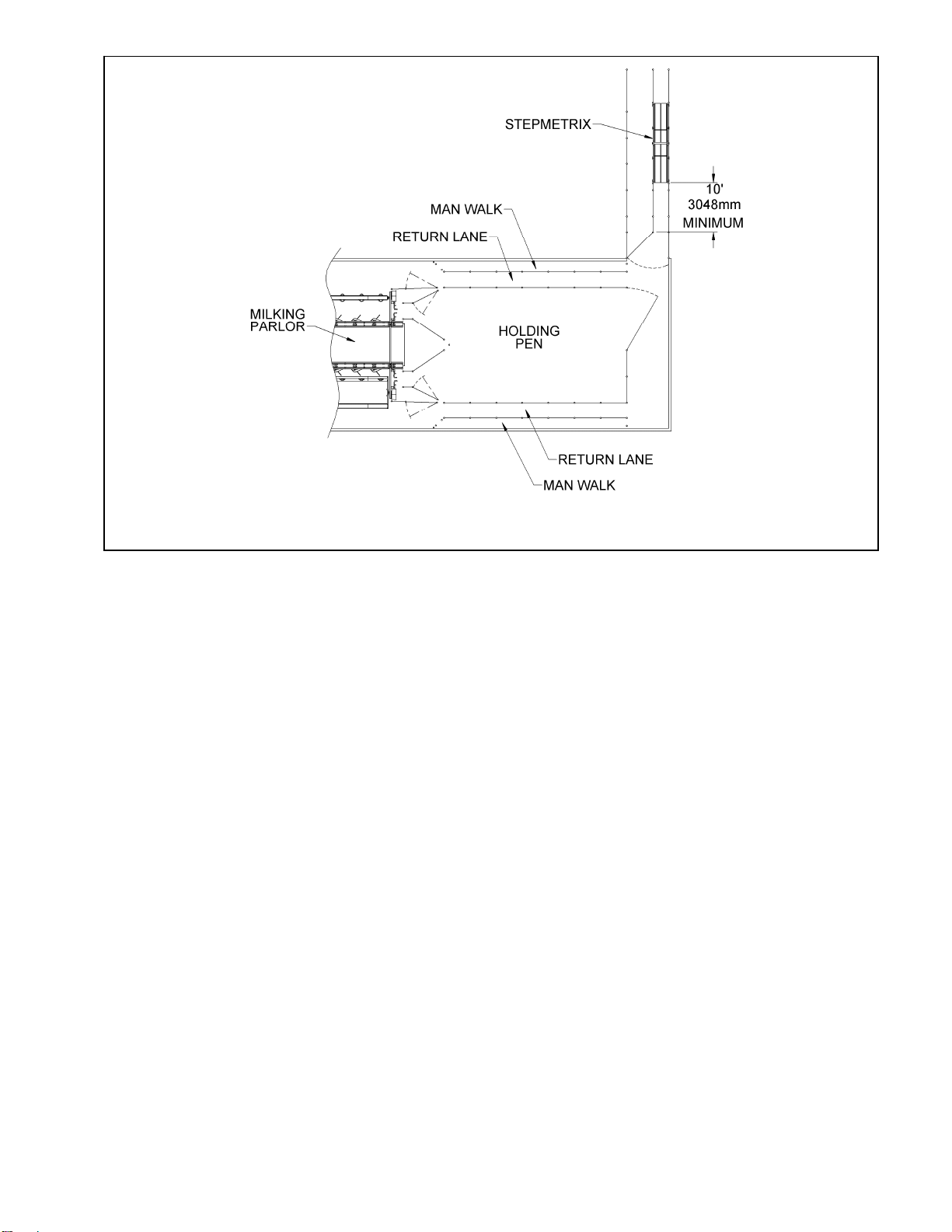

4. StepMetrix location, rotary parlor l864_4

1.3 Reviewing Personal Safety Instructions

To prevent possible bodily injury, foll ow the safety

instructions below and throughout this booklet.

— Warning ———————————⎯⎯⎯

9E-864C StepMetrix™ Installation Instructions

6

Turn off and lockout p ower to the po wer supply before

wiring the power for the St epMetrix. Failure to do s o could

cause serious injury or death.

2. Installation

The installation of the StepMetrix sy stem is a mult i-

step process. Follow installation steps as described in

the following sections.

— NOTE ———————————————————⎯⎯

• Review the instructions on page 1 under the

heading "Responsibilities" and perform only those

steps in this section that you are responsible for

performing.

• Review the personal safety message s and

installation specifications in Sectio n 1 and

instructions throughout this packet before starting

the procedure(s) in this section.

• Sides of the sensor module are defined as left

and right, as viewed from the direction of the cow

flow with respect to ¾” (19 mm) load cell conduit.

• Spacing of StepMetrix co mponents is critical for

best performance. Do not d eviate from

recommended dimensions

• It may be necessa ry to remove th e existing

railings in the installation area if the exit alleyway

is narrower than the recommended dimensions.

• The step assembly that is pla ced before the

sensor module will be referred as the StepMetrix

step up, while the ste p assembly that is pla ced

after the sensor module, will be referred as the

StepMetrix step down.

2.1 Installing the StepMetrix with a BouMatic

ID System

2.1.1 Installing the StepMetrix ID Antenna

— NOTE ———————————————————⎯⎯⎯

• The placement of the St epMetrix ID a ntenna and

StepMetrix controller determine the placement of th e

entire installation.

• The wire lengths of the load cell cables and ID antenna

cannot be ch anged; therefore the l ocation of th e

controller must be co nsidered before starting

installation.

• The StepMetrix ID a ntenna must be inst alled at the

center of, a nd perpendicular to, the sens or module.

The top of the ID anten na where the conduit emerges

must be no more than 5 8 inches (1473 mm) from the

center of the bottom of the StepMetrix controller.

1. Secure the ID antenna to the floor usi ng 4 concrete

anchors (see Figure 6).

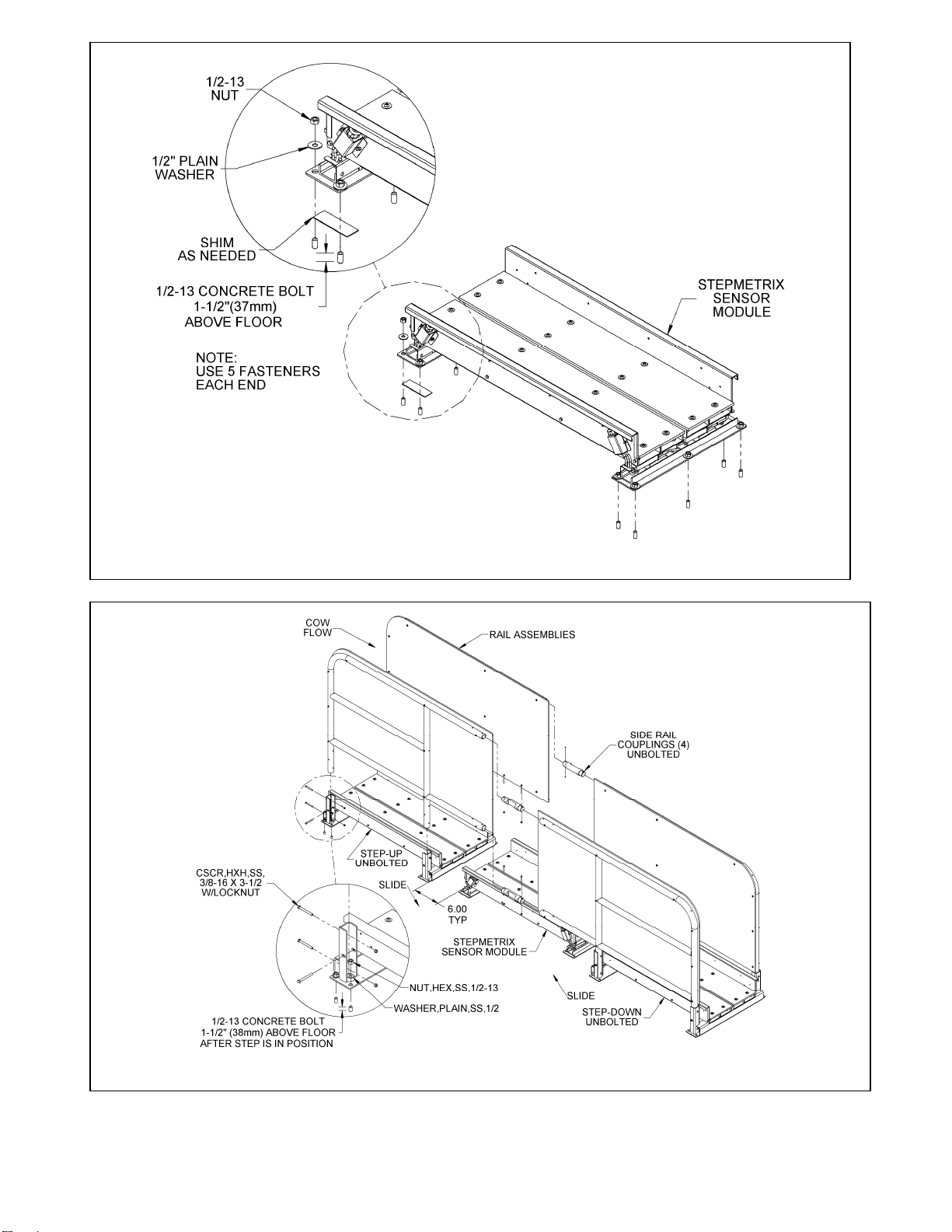

2.1.2 Installing the StepMetrix Sensor Module

1. Place the StepMetrix sensor module on the floor with

the conduits for the load cell cables on th e same side

as the conduit on the ID antenna.

2. Center the sensor module from side to side and end-to-

end in the StepMetrix ID antenna (see Figure 8).

3. Once sensor module is placed on the floor, walk on the

right and left sides of the se nsor module. If the sens or

module rocks, add sh ims underneath to stop the

rocking (see Figure 7). If the sensor module is fastened

to the floor without shimming to eliminate the rocking, it

will cause a twist in the sensor module that will hamper

the performance of the system and may cause

premature failure of the load cells.

4. Once the sensor module is neither rocking nor twisted,

fasten the sen sor module to the floor usin g concrete

anchors.

5. Walk on the sensor module after fastening the anchors

to make sure that the sensor module is not rocking.

2.1.3 Installing the StepMetrix Step-Up

1. Place the Ste pMetrix step-up on the flo or before th e

StepMetrix sensor module. Do not fasten the step-up to

the floor at thi s point. T he positioning rails need to be

assembled first (see Figure 9).

2.1.4 Installing the StepMetrix Step-Down

1. Place the StepMetrix step-down on the floor after the

sensor module.

2. Do not fasten the step-down to the floor at this po int.

The StepMetrix P ositioning rails must be assembled

first (see Figure 9).

5. The StepMetrix in place l864_5

StepMetrix™ Installation Instructions 9E-864C

7

9E-864C StepMetrix™ Installation Instructions

8

6. Mounting the StepMetrix™ ID antenna to the floor l864_6

7. Installin

g

the Ste

p

Metrix™ sensor module l864

_

7

8. StepMetrix sensor module dimensions and mounting locations l864_8

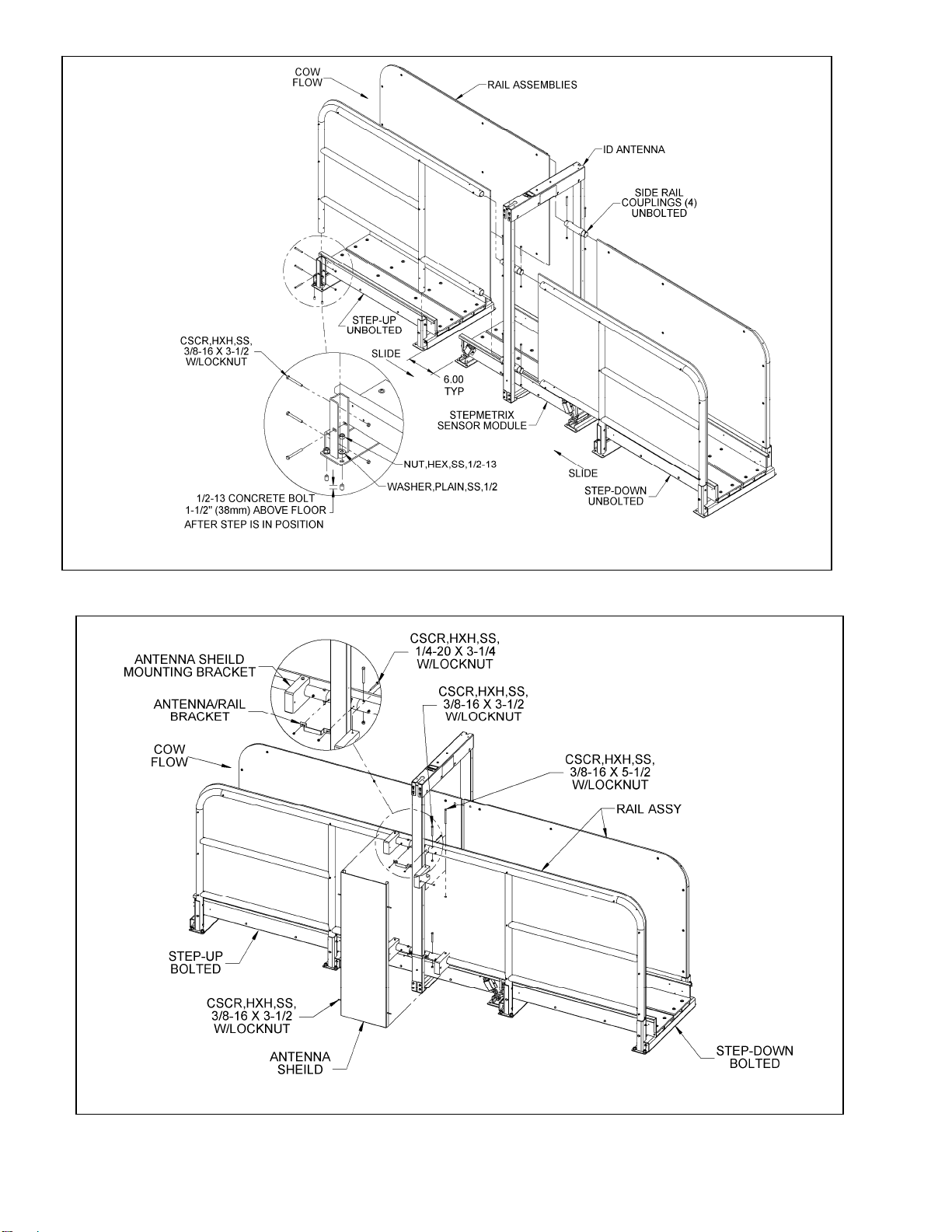

2.1.5 Installing the StepMetrix Positioning Rails

The StepMetrix positioning rails are used to center the

cows on the StepMetrix sensor module. To inst all

them, perform the following steps:

1. Place the p ositioning rails in the step up and step

down. Bolt the rails in place (see Figure 9).

2. Slide the step up and step down toward the s ensor

module, connecting the positioning rails together with

the plastic antenna supports as shown in Figure 9.

3. Position the step up and step down so there is a 1-inch

(25 mm) gap bet ween each step and t he sensor

module.

4. Walk on the step up an d step down to check for

rocking. If the step up or step do wn rocks place shims

underneath to prevent rocking.

5. Fasten the step up and the step down to the floor using

concrete anchors (see Figure 9).

6. Mount the antenna to the p ositioning rails using the

antenna rail bracket, as shown in Figure 10.

7. Attach the ant enna shield to the positioning rails us ing

the antenna shield-mounting bracket, as sho wn in

Figure 10.

2.1.6 Installing the StepMetrix Controller

— NOTE ———————————————————⎯⎯⎯

Route wiring through conduit for protectio n and aesthetic

purposes.

1. Select a location to mount the StepMetrix controller

where the ce nter of the bot tom of the b ox is no mor e

than 58” (1473 mm) from the t op of the Ste pMetrix ID

antenna where the flex conduit emerges. The controller

should be out of reach of cow traffic but accessible for

service.

2. Using suitable fasteners, mount the controller securely

to a stur dy structure or wall in a way that minimizes

vibration to the controller.

3. Connect the flex conduits from the Ste pMetrix ID

antenna and the se nsor module to the bottom of the

controller (see F igure 11).

StepMetrix™ Installation Instructions 9E-864C

9

9E-864C StepMetrix™ Installation Instructions

10

9. Installing the positioning rails, StepMetrix step-up and StepMetrix step-down l864_9

10. Attaching the antenna shield to the positioning rails l864_10

2.1.7 Wiring the Power Supplies and StepMetrix

Controller

—ATTENTION —————————————⎯⎯⎯⎯⎯⎯

Do not apply DC power to c ontrollers served by the power

supply until all connections have been made between the

power supply and the controller(s). If po wer is applied to a

controller before all connections have been made, the

power supply may become overloaded, causing a circuit

breaker to tri p or ot her power supply damage to res ult or

possibly causing damage to products served by the power

supply.

4. Wiring from the power supply to the controller box must

be run in conduit using 14 GA (2.5mm2) wire for the AC

Ground, DC Common, 12V and 24V.

5. Turn the voltage adjustment on the 12 V power supply

counter clockwise. This is done to re duce power

dissipation in the enclosure.

6. Connect the AC Ground, DC Common, 12V and 24V to

the terminal block in controller.

— NOTE ———————————————————⎯⎯⎯

The following colors are recommended

AC ground Green or green/yellow if required

by code

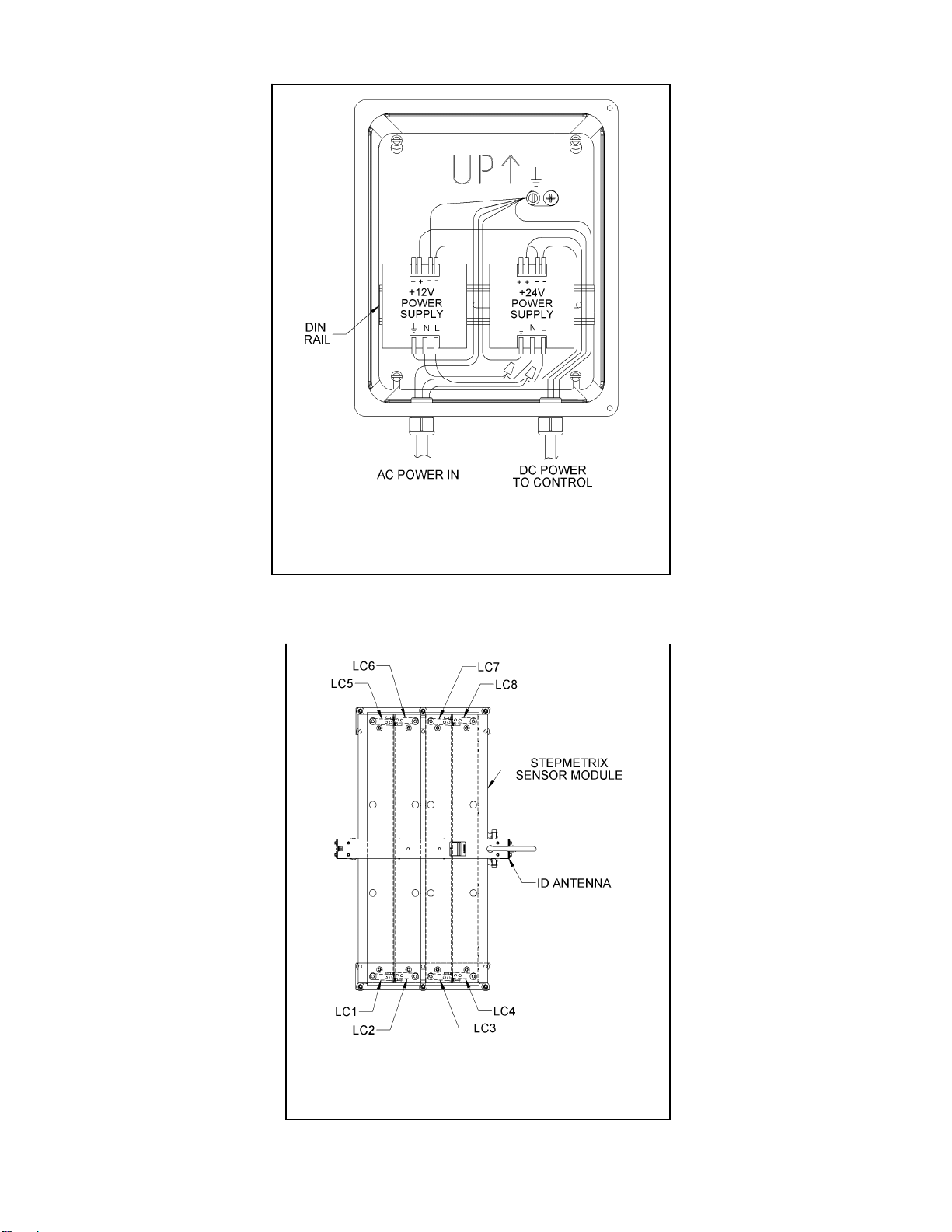

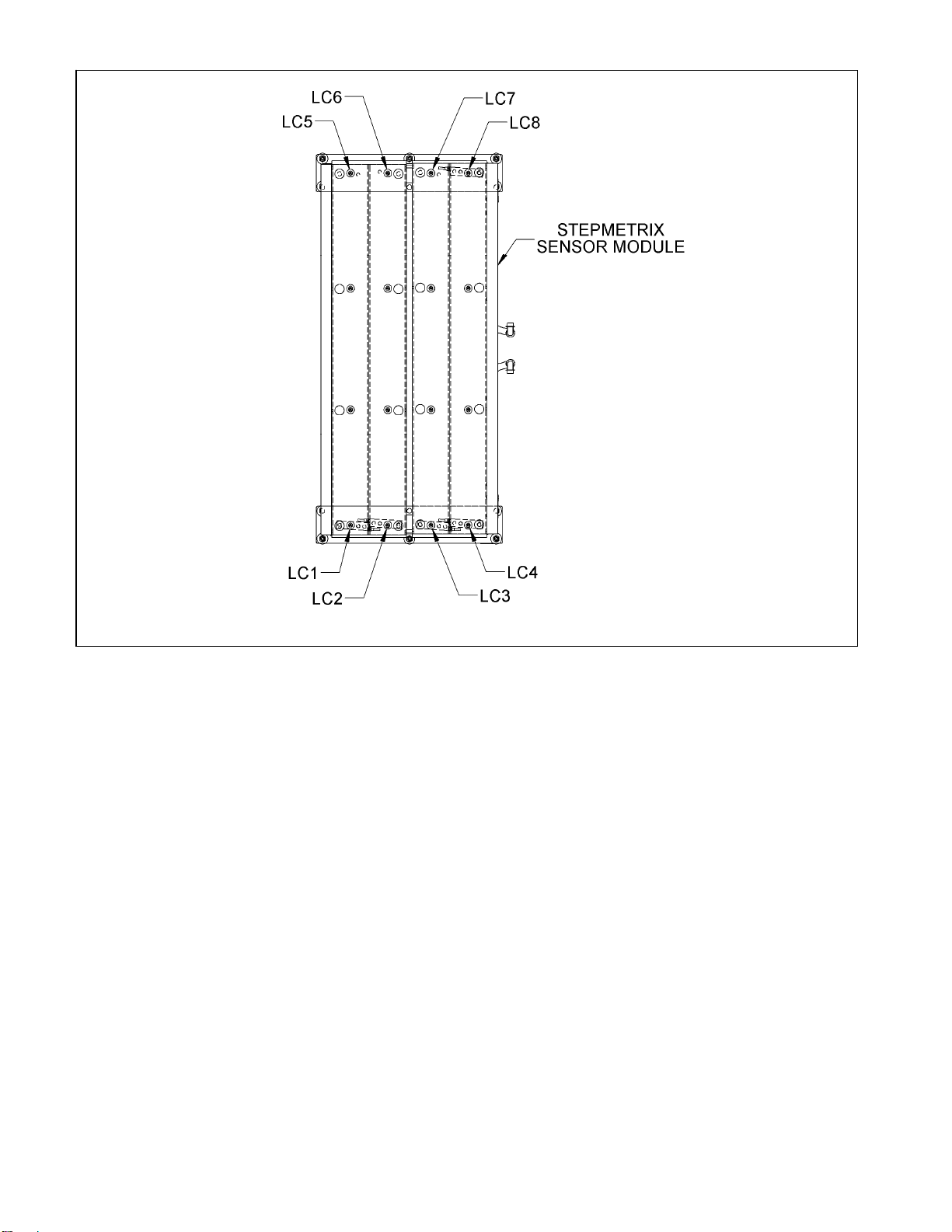

2.1.7.1 Load Cell to StepMetrix Controller Connections

• The load cells for the StepMetrix se nsor module

are numbered 1-8. They are numbered with

respect to the location of the ¾ ” (19 mm) conduit,

as shown in Figure 13.

DC common Black/white

+12 Volts DC Pink/white

+24 Volts DC Red/white

• Each load cell is connected to a connector on the

load cell signal conditioning board.

1. Mount the p ower supplies in the enc losure that’s

provided. Mount it in a dr y location no mo re than 5 0

feet (15 m) from the StepMetrix controller.

• The load cell signal conditioning board, located in

the StepMetrix controller, has fo ur 10-pin

connectors (J101 to J10 8), as shown in Figures

14 and 14a.

2. Connect the power supply to 220-240VAC, following all

applicable codes, as shown in Figure 12. • Connect individual load cell cables to the pins, as

shown in Figure 14a.

3. Connect DC Common between the 12V and 24V power

supplies. Use 14 GA (2.5 mm2) wire.

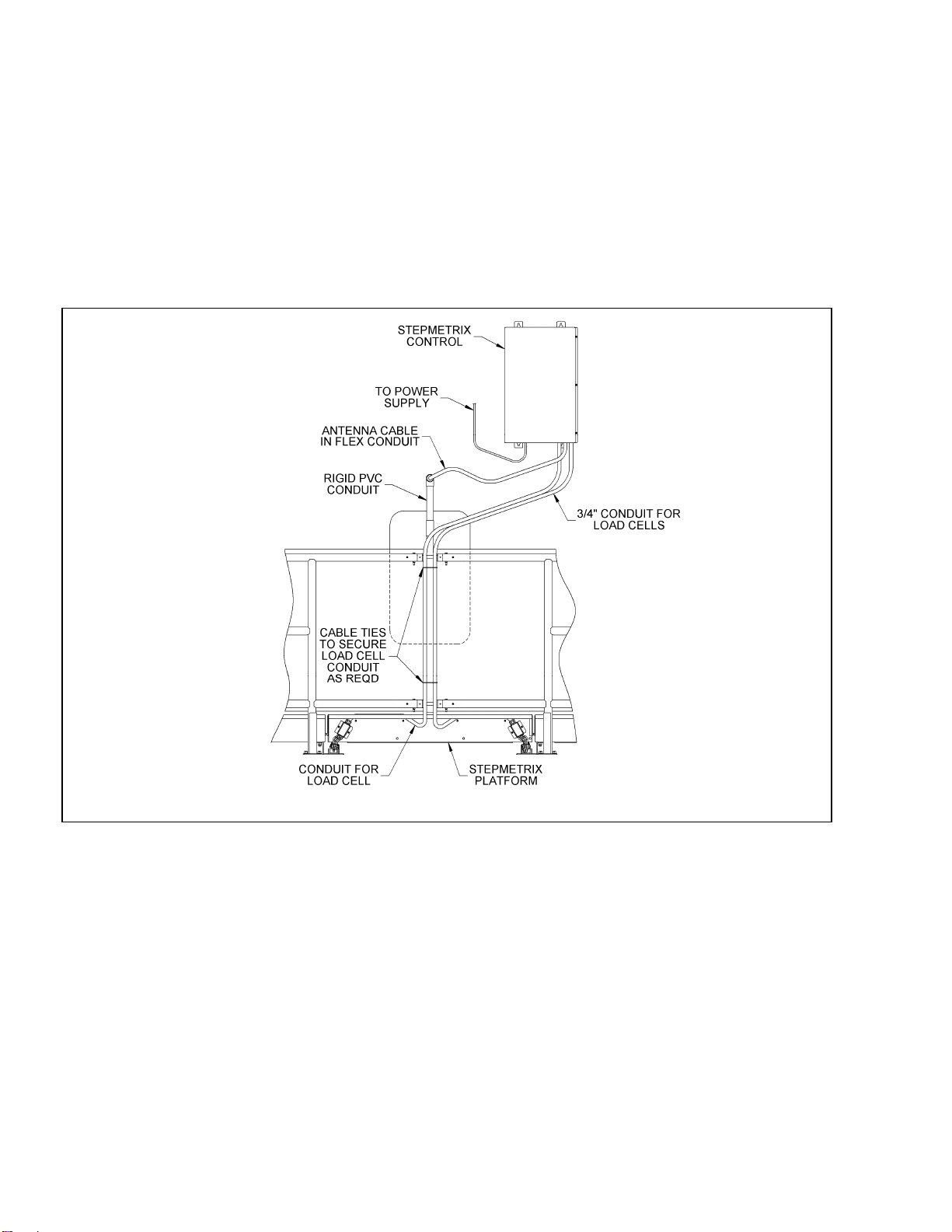

11. Installing the StepMetrix™ controller l864_11

StepMetrix™ Installation Instructions 9E-864C

11

9E-864C StepMetrix™ Installation Instructions

12

12. Wiring the power supply l864_12

13. Load cell locations l864

_

13

14. Wiring diagram label, P/N 3558769 l864_14

StepMetrix™ Installation Instructions 9E-864C

13

9E-864C StepMetrix™ Installation Instructions

14

14b. The control assembly l864_14b

14a. Load cell board l864_14a

2.1.7.2 StepMetrix ID Connections

Refer to I D controller instructions 9ES-768 when

installing the ID connections.

1. Connect the StepMetrix ID anten na receive and

transmit cables to the ID controller (see Figure 14).

2. The receive c able has small black, large black and

yellow wires. Connect the large black wire to pin 1, the

small black wire to pin 2, and the large yellow wire to

pin 3.

3. Connect the transmit cable, which has two black wires

bonded together, to the trans mit terminals of J1 in th e

ID controller.

4. Verify that there is a jumper wire from pin 2 to 5 of J5,

and that SW1is set to 1 and SW2 set to C.

2.1.7.3 Communication

For detailed networking instructions, refer to

BouMatic’s Ethernet Co mmunications instructions,

9E-867.

2.1.7.4 StepMetrix Controller Setup

1. Turn on power to the power supplies.

2. Tune the tra nsmitter on the ID co ntroller (Refer to I D

controller Instructions 9ES-768).

2.2 Installing StepMetrix with ISO ID

2.2.1 Installing the StepMetrix Sensor Module

1. Place the StepMetrix sensor module on the floor.

Locate the conduits for the load c ell cables on th e

same side that the Ste pMetrix controller will be

mounted.

2. Once the sensor module is placed on the floor, walk on

the right and left sides of th e sensor module. If the

sensor module rocks, add shims underneath to stop the

rocking (see Figure 16). If the s ensor module is

fastened to the floor without shimming to eliminate the

rocking, it will cause a twist in the se nsor module that

will hamper the performance of the s ystem and ma y

cause premature failure of the load cells.

3. Once the sensor module is neither rocking nor twisted,

fasten the sen sor module to the floor usin g concrete

anchors.

4. Walk on the se nsor module after fastening the anchors

to make sure that the sensor module is not rocking.

15. The StepMetrix™ with ISO ID system in place l864_18

StepMetrix™ Installation Instructions 9E-864C

15

9E-864C StepMetrix™ Installation Instructions

16

16. Installing the StepMetrix™ sensor module l864_19

17. Installing the positioning rails, StepMetrix step-up and StepMetrix™ step-down l864_20

18. Attaching the antenna shield to the positioning rails l864_21

2.2.2 Installing the StepMetrix Step-Up

1. Place the Ste pMetrix step-up on the flo or before th e

StepMetrix sensor module. Do not fasten the step up to

the floor at thi s point. T he positioning rails need to be

assembled first (see Figure 17).

2.2.3 Installing the StepMetrix Step-Down

1. Place the StepMetrix step-down on the floor after the

sensor module.

2. Do not fasten the step-down to the floor at this po int.

The StepMetrix p ositioning rails must b e assembled

first (see Section 2.2.4).

2.2.4 Installing the StepMetrix Positioning Rails

The StepMetrix positioning rails are used to center the

cows on the StepMetrix sensor module. To inst all

them, perform the following steps:

1. Place the p ositioning rails in the step-do wn and ste p

down. Bolt the rails in place (see Figure 17).

2. Slide the step -up and step-down toward the sensor

module, connecting the positioning rails together with

the plastic antenna supports as shown in Figure 17.

3. Position the step up and step-down so there is a 1-inch

(25 mm) gap bet ween each step and t he sensor

module.

4. Walk on th e step-up and step-down to check for

rocking. If the step up or step do wn rocks place shims

underneath it to prevent rocking.

5. Fasten the step-up and the step-down to the floor using

concrete anchors (see Figure 17).

2.2.5 Installing the StepMetrix ISO ID antenna

— NOTE ———————————————————⎯⎯⎯

The wire lengths of the load cell cables and ISO ID antenna

cannot be c hanged; therefore the location of the controller

must be considered before installation.

The StepMetrix ISO ID antenna must be i nstalled at the

center of, and parallel to, the positioning rails.

1. Position the ISO ID antenn a on p ositioning rails and

drill holes in t he ISO ID an tenna. Locate the hol es

within the area bordered by the groove in the antenna’s

surface, as s hown in Figure 18, detail A. T he antenna

must not be drilled outside this area. The top of the

antenna should be 72” a bove the floor. Drill h oles

through the plastic sheet of the p ositioning rails at the

center of the ID antenna. Mount the antenna using the

supplied hardware (see Figure 18).

StepMetrix™ Installation Instructions 9E-864C

17

9E-864C StepMetrix™ Installation Instructions

18

2. Install rigid PVC conduit (dealer supplied) to protect the

antenna cable from co w traffic and ro ute the cabl e to

the StepMetrix controller antenna (see Figure 18).

2.2.6 Installing the StepMetrix ISO ID Controller

— NOTE ———————————————————⎯⎯⎯

Route wiring through conduit for protectio n and aesthetic

purposes.

1. Select a location to mount the StepMetrix controller

where the ce nter of the bot tom of the b ox is no mor e

than 70” (1500 mm) from the top of the StepMetrix ISO

ID antenna. The controller should be out of reach of

cow traffic but accessible for service.

2. Using suitable fasteners, mount the controller securely

to a sturd y structure or wall in a way that allo ws the

least amount of vibration to the controller.

3. Connect the flex conduits from the Ste pMetrix ID

antenna and the se nsor module to the bottom of the

controller (see Figure 19).

19. Installing the StepMetrix™ ISO ID controller l864_22

20. Wiring the power supply l864_23

2.2.7 Wiring the Power Supplies and StepMetrix ISO

ID Controller

2. Connect the power supply to 220-240VAC, following all

applicable codes (see Figure 20).

—ATTENTION —————————————⎯⎯⎯⎯⎯⎯ 3. Wiring from the power supply to the controller box must

be run in conduit using 14 GA (2.5mm2) wire for the AC

Ground, 24 V and DC Common.

Do not apply DC power to c ontrollers served by the power

supply until all connections have been made between the

power supply and the controller(s). If po wer is applied to a

controller before all connections have been made, the

power supply may become overloaded, causing a circuit

breaker to trip or oth er power supply damage to result. It

may also cause damage to other products served by the

power supply.

4. Connect the AC Ground, DC Common, and 24V to the

terminal block in the controller.

2.2.7.1 Load Cell to StepMetrix ISO ID Controller Connections

• The load cells for the StepMetrix se nsor module

are numbered 1-8. T hey are numbered with

respect to the location of the ¾ ” (19 mm) c onduit,

as shown in Figure 21.

— NOTE ———————————————————⎯⎯⎯

The following colors are recommended:

AC ground Green or green/yellow if required

by code

• Each load cell is connected to a c onnector on the

load cell signal conditioning board.

DC common Black/white • The load c ell signal conditioning board, located in

the StepMetrix controller, has four 10-pin

connectors (J101 to J108), as shown in Figures 22

and 25.

+24 Volts DC Red/white

1. Mount the power supply in the enclosure that’s

provided. Mount it in a dr y location no mo re than 5 0

feet (15 m) from the StepMetrix controller. • Connect individual load cell cables to the pins, as

shown in Figure 22.

StepMetrix™ Installation Instructions 9E-864C

19

9E-864C StepMetrix™ Installation Instructions

20

21. Load cell locations l864_24

Table of contents

Other Boumatic Measuring Instrument manuals