Belzona 2141 User manual

Belzona 2141

FN10051 (ACR-FLUID ELASTOMER)

INSTRUCTIONS FOR USE

www.belzona.com Publication No. 43-03-20

1. TO ENSURE AN EFFECTIVE MOLECULAR

WELD

1.1 METALLIC SURFACES

a) Remove all loose surface contamination and degrease with

Belzona®9111 (Cleaner/Degreaser) or any other effective cleaner

which does not leave a residue e.g. methyl ethyl ketone (MEK).

b) Select an abrasive to give the necessary standard of cleanliness

and a minimum depth of profile of 3 mils (75 microns). Use only an

angular abrasive.

c) Blast clean the metal surface to achieve the following standard of

cleanliness:

ISO 8501-1 Sa 2½ very thorough blast cleaning

American Standard near white finish SSPC SP 10

Swedish Standard Sa 2½ SIS 05 5900

d) After blasting, metal surfaces should be coated before any

oxidation of the surface takes place.

SALT CONTAMINATED SURFACES

Metal surfaces that have been immersed for any periods in salt

solutions e.g. sea water, should be blasted to the required

standard, left 24 hours to allow any ingrained salts to sweat to the

surface and then washed prior to a further brush blast to remove

these. This process may need to be repeated to ensure complete

removal of salts. The soluble salt contamination of the prepared

substrate, immediately prior to application, should be less than

20mgs/m².

1.2 FLEXIBLE SURFACES (e.g. rubbers)

NOTE: Belzona®9111 can draw processing oils and waxes to the

surface of some rubbers, particularly when new, which then impairs

adhesion of Belzona®2141.

Test for this on a small area. If, on rubbing with a rag moistened

with Belzona®9111, a greasy film appears, the surface should not

be degreased, but simply abraded.

Undercut fine edges with a sharp knife and scuff the surface with a

rotary wire brush or suitable roughing tool.

1.3 EXISTING BELZONA SURFACES.

a) When using Belzona®2141 to overcoat a surface which has been

treated with Belzona®1111 or Belzona®1311, the Belzona product

must first be allowed to fully cure and the surface abraded, followed

by conditioning as below.

b) Application of Belzona®2141 over Belzona®1221 can be carried

out up to 4 hours after the application of Belzona®1221 without the

need of any surface treatment other than removal of contamination.

When overcoating Belzona®1221 after this time, the surface

should be abraded, followed by conditioning as below.

c) When applying the Belzona®2141 system over a Belzona coating

such as Belzona®1341 (not NSF Grade) or Belzona®5811 the

coating may be overcoated by Belzona®2941 once hard and

within its overcoat time without further surface preparation. Once

beyond the coatings overcoat time it must be flash blasted to

produce a minimum 25 micron profile before conditioning.

CONDITIONING

All surfaces must be Conditioned before applying Belzona®2141.

Metal surfaces, Belzona®1000 series and Belzona®5811 apply

Belzona®2941

Rubber and other non-metallic surfaces apply Belzona®2911 or

Belzona®2921.

Apply a thin, even coat of Belzona®Conditioner onto the surface.

A brush should be used as a stipple.

Practical coverage rate

Belzona®2941 19.8 sq.ft. (1.83 sq.m) per unit, on metallic

substrates.

Belzona®2911 and Belzona®2921, 13 sq.ft. (1.25 m²) per unit, on

smooth substrates. On well roughened rubber substrates this could

be reduced by as much as 50%.

The Belzona®Conditioner must be completely touch dry before

overcoating with Belzona®2141. This will depend on the prevailing

temperature, relative humidity, ventilation and substrate. At 68°F

(20°C) and 50% relative humidity, the touch dry state will be

achieved after the times given when applied to a steel surface.

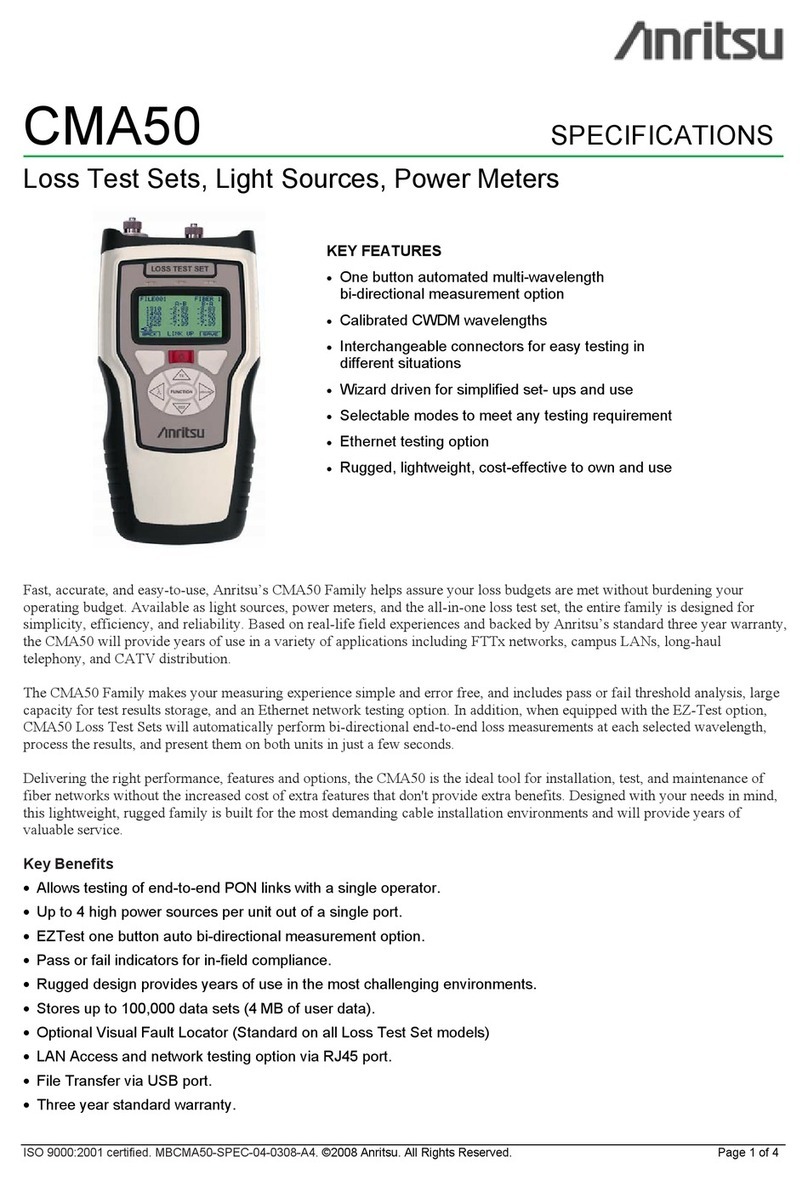

Conditioner

Touch Dry

Max. Overcoating

Belzona®2911

45 mins

24 hours

Belzona®2921

75 mins

Belzona®2941

8 hours

NOTE:

i) Relative humidity should be between 30 & 90% and surface

temperature at least 5°F (3°C) above dew point during the

application and drying of the Conditioner.

ii) At lower temperatures and humidity a longer drying time is

required.

iii) These times may be extended when applied to rubber

substrates.

iv) If in doubt leave Conditioner longer to dry but under no

circumstances should maximum overcoat time be exceeded.

SHELF LIFE

Belzona®2941 & Belzona®2921 have a 24 month shelf life and

Belzona®2911 has an 18 month shelf life from date of manufacture

when stored at 41 - 77°F (5 - 25°C) and must be used before the stated

“use-by” date.

WHERE BELZONA®2141 SHOULD NOT ADHERE

Brush on Belzona®9411 (Release Agent) and allow to dry for 15 - 20

minutes before proceeding to step 2.

2. COMBINING THE REACTIVE

COMPONENTS

Both Base and Solidifier components must remain sealed until the

application stage.

a) Transfer the entire contents of the Base into the Solidifier container.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Safety Data Sheets.

Belzona 2141 - Instructions for Use - (2) Publication No. 43-03-20

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify the

technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a

particular purpose.

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright © 2020 Belzona International Limited. Belzona® is a registered trademark.

Belzona products are

manufactured under an

ISO 9001 Registered

Quality Management System

b) Immediately mix together for at least 3 minutes and use all material

within the times shown in the table below:-

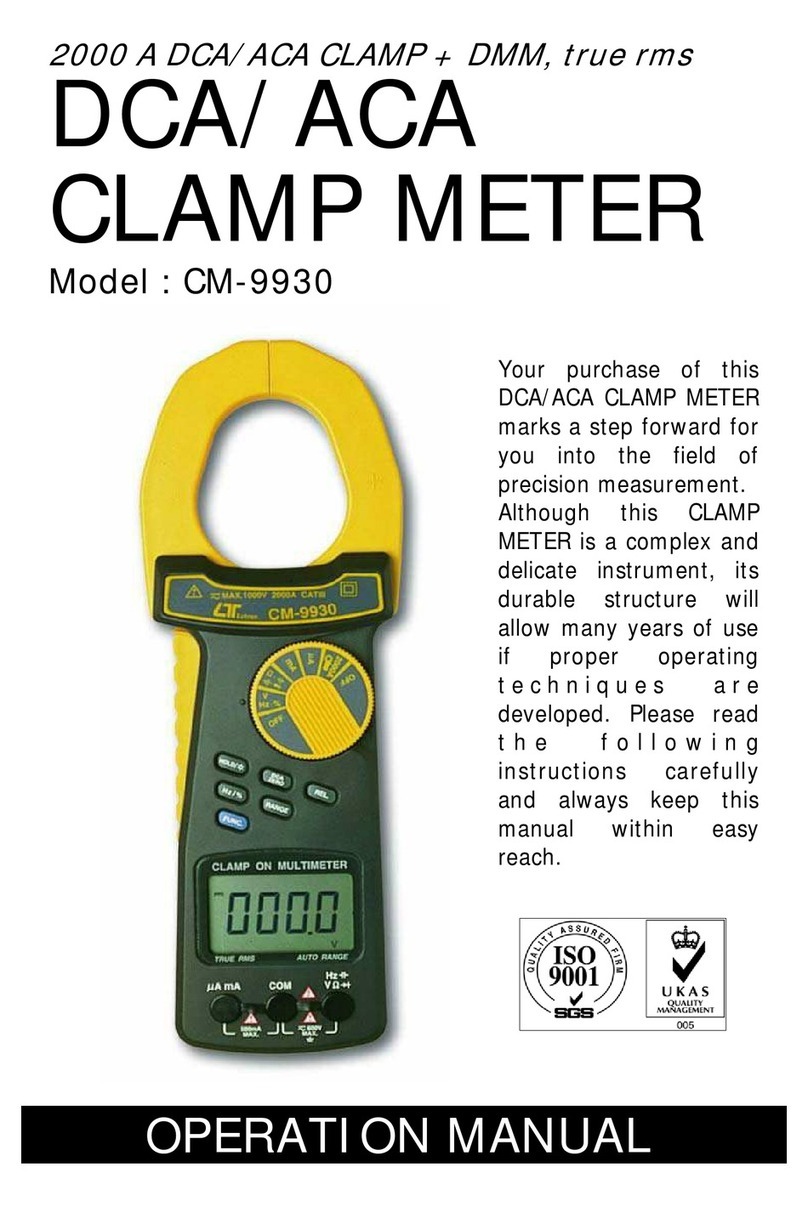

Temperature

59°F (15°C)

77°F (25°C)

86°F (30°C)

Use all

material within

25 min

13 min

10 min

VOLUME CAPACITY OF MIXED BELZONA®2141

682 cm³ (41.6 cu.in.) per 750g unit.

3. APPLYING BELZONA®2141

FOR BEST RESULTS

Do not apply when:-

i) The temperature is below 41°F (5°C) or the relative humidity is

above 90%.

ii) Rain, snow, fog or mist is present.

iii) There is moisture on the surface or is likely to be deposited by

subsequent condensation.

iv) The working environment is likely to be contaminated by

oil/grease from adjacent equipment or smoke from kerosene

heaters or tobacco smoking.

Where application conditions permit, Belzona®2141 can be applied as a

single coat but where it is not possible to achieve a uniform coating, the

material should be applied as a two coat system.

Apply the Belzona®2141 to the conditioned surface with a stiff bristled

brush or the plastic applicator provided to achieve the required

thickness.

Apply a second coat of Belzona®2141 as above following the

overcoating instructions in Section 6.

Recommended

number of coats

2

1

Target thickness

1st coat

20 mils (500

microns)

40 mils (1mm)

Target thickness 2nd

coat

20 mils (500

microns)

N/A

Minimum total DFT

32 mils (800

microns)

32 mils (800 microns)

Maximum DFT per coat

Only limited by sag resistance

Theoretical coverage

rate 1st coat

14.6sq.ft. (1.36m²)/

750g unit

7.3sq.ft. (0.68m²)/

750g unit

Theoretical coverage

rate 2nd coat

14.6sq.ft. (1.36m²)/

750g unit

N/A

Theoretical coverage

rate to achieve

minimum recommended

system thickness

9.1sq.ft. (0.85m²)/

750g unit

9.1sq.ft. (0.85m²)/

750g unit

CLEANING

Mixing tools should be cleaned immediately after use with Belzona®

9111 or any other effective solvent e.g. MEK. Brushes, injection guns

and other application tools should be cleaned using a suitable solvent

such as Belzona®9121, MEK, acetone or cellulose thinners.

4. COMPLETION OF THE MOLECULAR

REACTION

Allow Belzona®2141 to solidify as below before subjecting it to the

conditions indicated:

Movement or

use involving

no loading or

immersion

Full

mechanical or

thermal

loading

Immersion

41°F/ 5°C

12 hours

5 days

10 days

50°F/10°C

8 hours

4 days

7 days

59°F/15°C

6 hours

3 days

6 days

68°F/20°C

4 hours

2 days

5 days

77°F/25°C

3 hours

2 days

4 days

86°F/30°C

2 hours

2 days

3 days

5. STORAGE

Store in a dry environment between 41°F (5°C) and 77°F (25°C).

Inadvertent storage of Belzona®2100 Base below 41°F (5°C) or

Belzona®2141 Solidifier below 15°C may result in partial solidification. If

this occurs, the material can be restored to its normal form by resealing

the container and warming to between 104°F (40°C) and 122°F (50°C)

for 3 hours in a well-ventilated, dry area.

6. OVERCOATING

Application of subsequent layers of Belzona®2141 can be carried out

typically between a minimum of 2 hours and maximum of 3 days after

the previous application without need of any surface treatment other

than removal of contamination. Belzona®2100 series products should

never be applied “Wet on Wet”.

Overcoating of aged Belzona®2141 is possible at any time after initial

application, provided that the surface preparation techniques for flexible

surfaces described in Section 1 are employed.