Part I

GENERALINSTRUCTIONS AND TOOLSUGGESTIONS

Small Phillips & Flat Screwdrivers Pin Vise

Liquid Plastic Cement with Brush #57 Drill Bit

Cyanoacrilate Cement (ACC) Plastic Cutters

Modelers Knife Small Tweezers

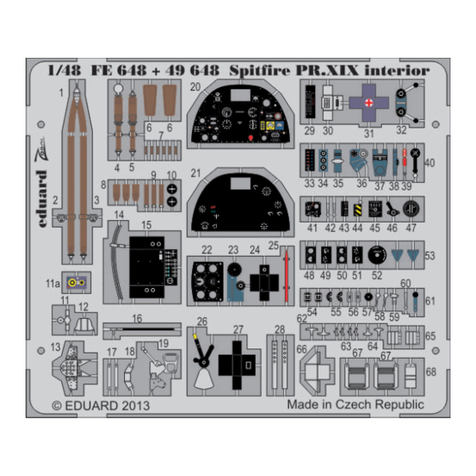

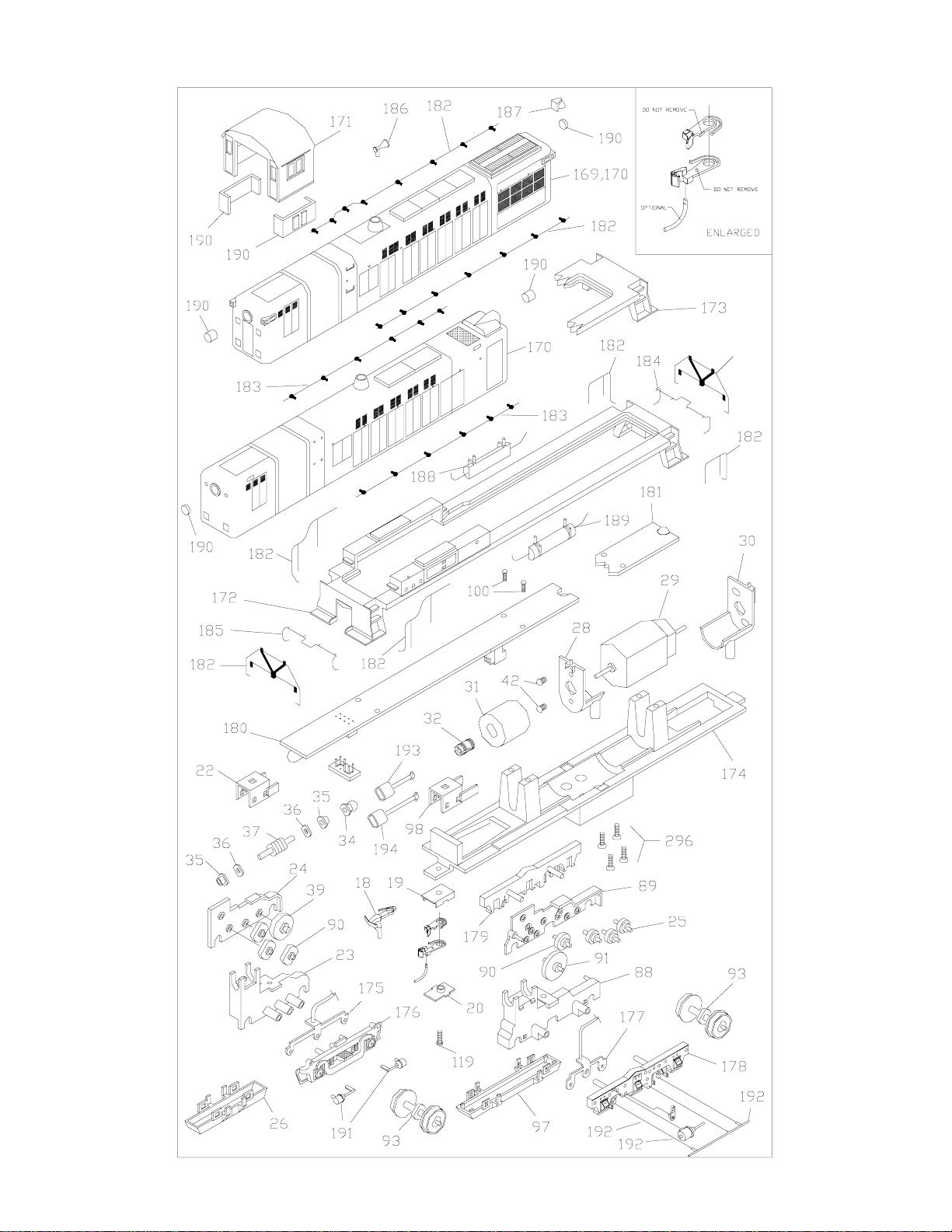

Note: Refer to the exploded view during assembly. The front, rear, left, and right

side of each unit is identified. Remove parts from the sprue carefully, verifying

that all gate material has been removed. Glue must be applied sparingly from the

inside of the shell, allowing capillary action to draw the cement into the joint or

hole.

Part II

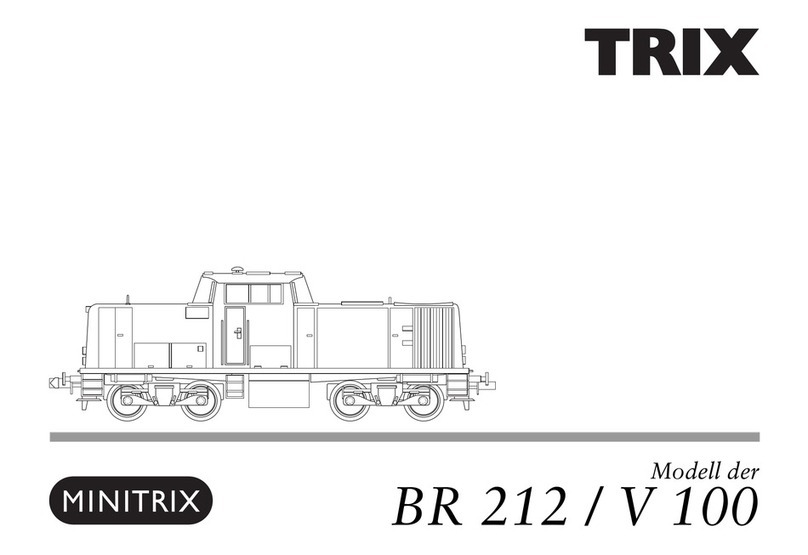

SUPERSTUCTUREASSEMBLY

Step (1). The hood (1 or 2), cab (3) and the deck (4 or 5) are snapped together

and fastened to the chassis with two screws (66). Remove each screw (66) to

separate the superstructure from the chassis.

Step (2). Begin to separate the superstructure by removing the cab (3). Unsnap

the hood (1 or 2) from the deck (4 or 5).

Step (3). Refer to the exploded view diagram to install appropriate handrails and

lift bars (39 – 50) using the provided mounting holes.

Step (4). Choose a location for the horn (51). Drill a hole using the pin vise and

#57 drill bit. Apply cyanoacrilate (ACC) glue to the stem of the horn. Install the

horn into the hole.

Step (5). AS16 / 616 ONLY: Install the bell (52) using ACC glue in the notch

provided at the front of the hood (1).

Step (6). Install the cab glass (57 & 58).

Step (7). AS16 / 616 ONLY: Install the short headlight lens (55) into the front of

the body (1), and the long headlight lens (56) into the rear of the body (1). Install

each from the outside after noting the front and rear orientation on the exploded

view instruction sheet.

Step (8). RS12 ONLY: Install the long headlight lens (56) into the front of the

body (1), and the short headlight lens (55) into the rear of the body (1). Install

each from the outside after noting the front and rear orientation on the exploded

view instruction sheet.

Step (9). Snap the hood (1 or 2) into the deck (4 or 5). Slide the cab (3) into place

over the hood (1 or 2). Place the ends of the handrails (44,45) into the holes in the

cab rear. Note: If you do not see holes for the handrails on the cab rear, then the

cab is installed backward.

Part III

FINALASSEMBLY

Step (1).AS16 & RS12 ONLY: Install each brake cylinder (59) into the holes in the

sideframes (18). The use of cyanoacrilate (ACC) cement is optional.

Step (2). AS616 ONLY: Install each brake cylinder (60), brake arm (61), and brake

rod (62) into the provided holes in the sideframes (28). The use of cyanoacrilate

(ACC) cement is optional.

Step (3). Place the assembled superstructure over the powered chassis. Note: The

frame (6) must be properly oriented to allow the deck (4 or 5) to seat properly.

Refer to the exploded view diagram. Notice that the rear of the frame (6) has

an extension of metal that is not present in the front of the piece.Also, note the

front and rear orientation of the hood (1 or 2). Turn the assembly upside down

and place on a padded flat surface. Assemble the coupler (63) or select the X2F

(67) and place it into the coupler box (64) and install the coupler lid (65). Slide the

coupler assembly into the opening of the pilot. Install using the provided screw

(66). Note: Do not use the shallow coupler boxes that are enclosed in the hand-

rail parts bag. They are used fora different version of this model. Only use the

parts as shown on the exploded view drawing to install the couplers.

Step (4). Press the air tanks (53 & 54) into the receptacles on the underside of the

deck (4 or 5).

Part IV

GENERALINFORMATION

Painting Truck Sideframes

Modelers who wish to paint or weather truck sideframes (18, or 28 & 29) may wish

to remove them to prevent paint over spray from impairing electrical pickup. Begin

disassembly by removing the each screw (38) that hold the circuit board (35 or 36)

in place. Rotate the circuit board for access to the worm housing (20 or 31). Each

worm housing has two legs extending inward. Release the housings by prying the

legs outward with a small flat screwdriver. Disconnect the connector wires (17 or

27) from the Molex connectors on the underside of the circuit board by sliding the

Molex housing toward the middle of the board. Pull lightly on the wire if necessary

using a needle nosed pliers. The worm gear assembly (32, 33, 34, 71) and univer-

sal shaft (69 or 70) can be removed by prying upward with a small flat screwdriver.

The frame (6) can now be lifted upward and away from the trucks. The sideframes

are locked in place by a retainer clip (19 or 30). Four tabs extend upward from this

clip. These tabs are only visible when viewing the truck from directly overhead.

The retainer clip can be removed by gently prying outward on the tabs. Sideframes

can now be pulled away.

DCC Information

For DCC users, a DCC compatible plug socket has been provided. Remove the

DCC Plug (37) from the main circuit board (35 or 36). Reference your DCC manual

for proper decoder installation.

Detailing

RS12 ONLY: Drill bit starter guides have been placed at various locations on the

shell for Detail Associates #2202 Grab Irons (not included).

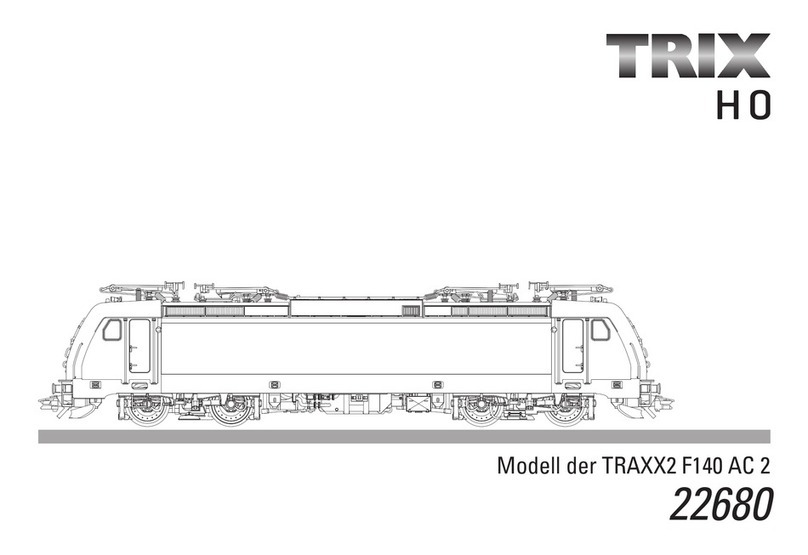

Note:Our modelsare veryclose in appearance to theBaldwin DRS-4-4-1500(similar

to AS16), DRS-4-4-1000 (similar to RS12), and the DRS-6-4-1500 (similar to the

AS616).

Questions or Problems

We hope that you will be happy with this finely detailed kit. If any questions or

problems occur, please inform us. Any problems with defective parts will be re-

sponded to promptly.

Baldwin Road Switchers

AS16, AS616, RS12

Bowser - Stewart Hobbies

PO Box 322

Montoursville PA 17754

www.bowser-trains.com

www.stewarthobbies.com