PCM ERWIN XL slope User manual

Erwin XL slope building Instruction August 2018

www.pcm.at 1

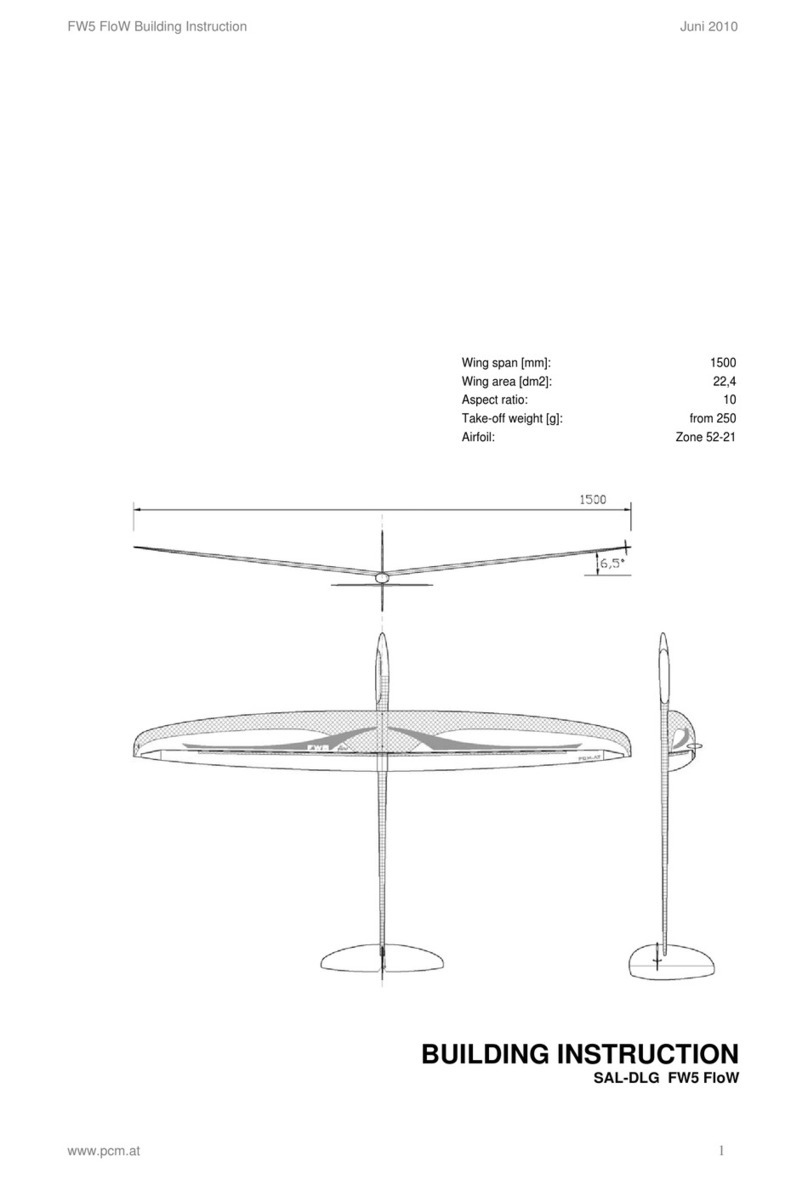

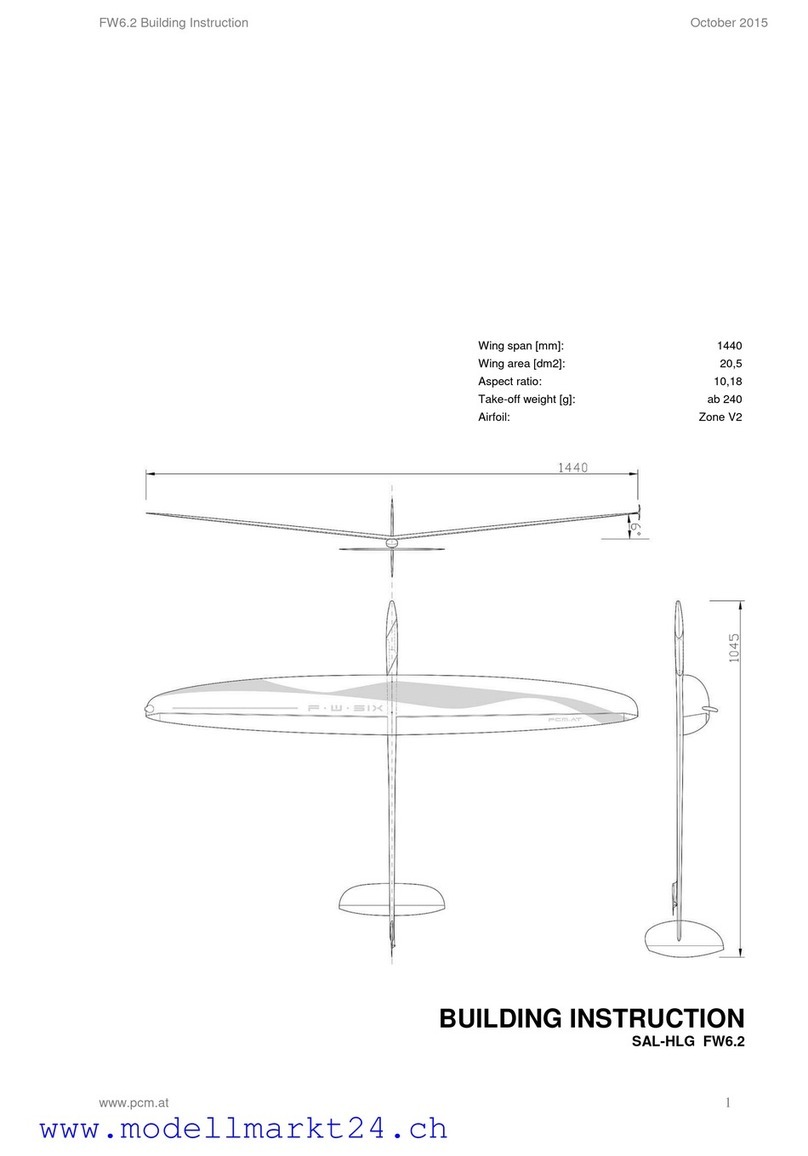

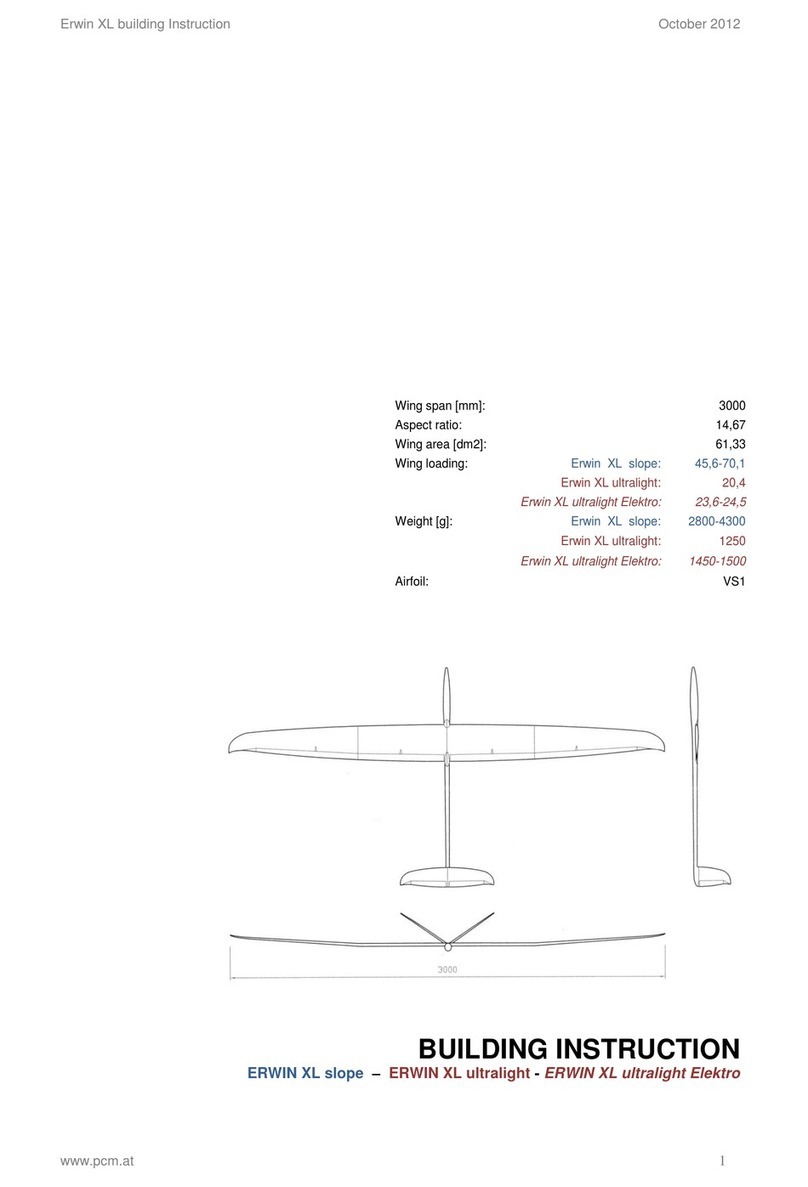

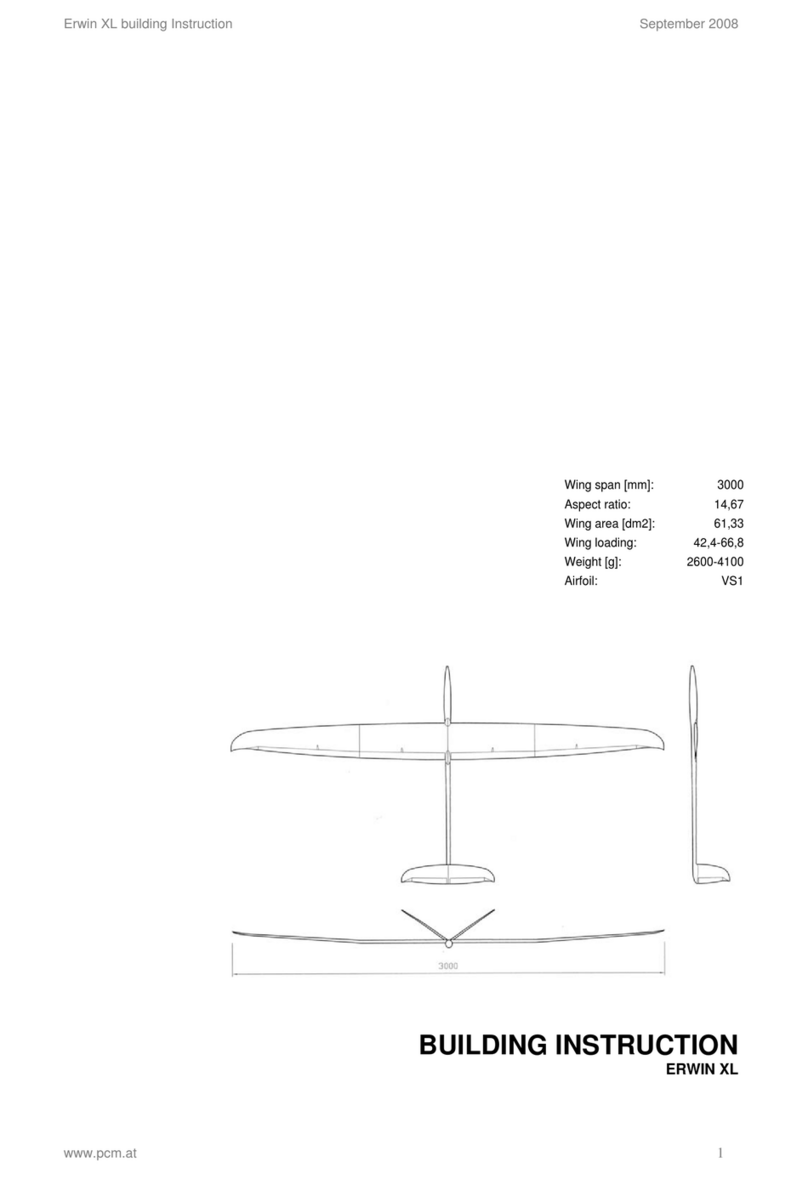

Wing span [mm]:

3000

Aspect ratio:

14,67

Wing area [dm2]:

61,33

Wing loading:

49-70

Weight [g]:

3000-4500

Airfoil:

VS1

BUILDING INSTRUCTION

ERWIN XL slope

Erwin XL slope building Instruction August 2018

www.pcm.at 2

CONTENTS

DATA

1. Kit –Contents

2. What else do you need?

3. Electronic equipment

4. Settings for the first flight

ASSEMBLING THE MODEL

5. V-tail

6. Gluing of fuselage

7. Electronic components in fuselage

8. Wing

9. Installation of antenna

BEFORE THE FIRST FLIGHT

10. Ballast system

11. Fixing of the wing

12. Check list before starting

13. Attention, Erwin XL is sensitive to the sun

3

3

4

5

6

7

8

9

11

12

13

13

13

Erwin XL slope building Instruction August 2018

www.pcm.at 3

DATA

1. Kit –Contents

Fuselage, in two parts, incl. canopy and cover for end of fuselage

Wing, in two parts

V-Tail

Covers for servos on wing, 4 pieces

Levers for rudders, 4 pieces

Servo board

Assembly board for hook for winch start

Ball connectors for the elevator, 2 pieces

Brass pipes for the elevator, 2 pieces

Pipes and push rod, 2 pieces each

Threaded coupler, 2 pieces

Plugs and frames for connection of wing and fuselage, 4 pieces each

Screws, 2 pieces, for fixing the V-tail

Connectros / ballast (more ballast available on demand):

Segler / Glider

Elektro

Normal (Slope)

2x Kohlestab / carbon rod

2x Stahl kurz / steel short

1x Stahl lang / steel long (auf Anfrage / on demand)

2x Kohlestab / carbon rod

Medium

1x Kohlestab / carbon rod

2x Stahl kurz / steel short

1x Kohlestab / carbon rod

1x Stahl kurz / steel short

Ultralight

1x Kohlerohr / carbon pipe

1x Kohlerohr + Stahl innen /carbon pipe + steel core

1x Stahl kurz / steel short

1x Kohlerohr / carbon pipe

Building instruction (please download from our homepage)

2. What else do you need:

Controls of the wing:

Connectors for push rods, M2,5mm, 8 pieces

Welding rod, d=2mm

Steel wire 1,5mm, 0,8mm

Hook for winch start and nut

On-off switch / socket for loading

Cables (electricity)

Cable for antenna, possibly steel wire for extension of

antenna

Plugs

Epoxy-glue (for example UHU 300 endfest or Stabilit, no

fast hardening epoxy resin)

Cotton flocks to thicken glue

Hook for winch start

Connector for push rods, M2,5mm

Erwin XL slope building Instruction August 2018

www.pcm.at 4

3. Electronical equipment

Servos for the wing

Futaba

S3150

Graupner

DES 448

Servos for the V-tail

Graupner

C261 (these servos will fit into the gap of the servo board)

DES 281

C2081

Hitec

HS65HB or MG

Robbe

S3107 (weak)

Receiver:

2,4GHz:

all (lead antennas outside the fuselage)

35 MHz:

Graupner DS19

Simprop Scan 7

Accumulator:

Eneloop 2000 mA/h

Erwin XL slope building Instruction August 2018

www.pcm.at 5

4. Settings for the first flight

(measure from the leading edge of the wing to the back)

Centre of gravity: weak conditions: 88-94mm (f.e. plain, soft wind on slope)

strong wind on slope: up to 110mm possible

Hook for winch start: 10-20mm before centre of gravity (start with 20mm)

Difference in angle of attack: +1°

Ailerons und flaps (soft)

(measure between aileron and flap and on deepest point of the elevator)

Ailerons und flaps (strong / dual rate)

(measure between aileron and flap and on deepest point of the elevator)

Butterfly (landing position)

(measure between aileron and flap and on deepest point of the elevator)

Flaps positive

(measure between aileron and flap and on deepest point of the elevator)

Flaps negative

(measure between aileron and flap and on deepest point of the elevator)

Erwin XL slope building Instruction August 2018

www.pcm.at 6

ASSEMBLING THE MODEL

5. V-tail

The v-tail is ready prepared with holes for screws to be

fixed on the fuselage.

Controlling of the elevator:

Bend two brass levers as shown below and glue the ball

connectors to one end each. Then glue the levers to the

control surfaces of the elevator. The gluing spot should

be as near as possible to the turning axis of the controls

(silicone hinge).

Ready mounted levers with ball connectors.

(Here to be seen on Erwin XL ultralight)

Erwin XL slope building Instruction August 2018

www.pcm.at 7

6. Gluing the fuselage

Check the alignment of the V-tail regarding the axis of the

fuselage, so that it is fixed symmetrically.

To do this, mount v-tail and wing on the fuselage. Look at

Erwin XL from the front and slowly lower the tail, until the

ends of the elevator disappear behind the wing.

If both ends of the elevator disappear at the same time,

the v-tail is aligned correctly.

If the v-tail isn’t aligned correctly, chamfer the edges of

the fitting. Put the two parts of the fuselage together again

and turn one part until the v-tail is mounted symmetrically.

Furthermore, check, if the difference in angle of attack of

+1° can be set without problems.

For this, put the 2 parts together and place the fuselage on a flat surface. The distance between

fuselage and surface should be 7mm at the joining spot. You can f.e. check this with a small

piece of wood, which you place under the fuselage.

If you can’t assemble the 2 parts of the fuselage in this position, grind at the fitting.

Then glue the parts together. Use epoxy-glue and some cotton flocks to thicken the glue.

Erwin XL slope building Instruction August 2018

www.pcm.at 8

7. Electronic components inside the fuselage

First of all, thread a steel wire of 1,5 mm into the outer

tubes of the push rods. By this, they get a lot stiffer and

you can thread them into the fuselage easily. Once the

tubes are inside the fuselage, you can bring them to the

right position from outside by using magnets.

(On photo white outer tubes were used.)

You can fix the tubes easiest by applying runny super

glue (with very thin viscosity) on both ends of the tubes

and letting it run along the tubes.

If you prefer to glue the tubes with 5 minute epoxy (mixed

with cotton flocks), you must apply the glue before you

thread the tubes into the fuselage. Put glue app. every

25cm.

In both cases, the ends should not be glued to keep

them still mobile. Therefore, place the final sticking point

about 10 to 12 cm from the ends of the tubes.

The servos for the elevator are mounted on the servo

board. The wholes are prepared for Graupner servos

C261.

Glue the servo board into the fuselage as shown on the

photo. Grind the gluing areas thoroughly and glue with

“UHU endfest 300” (epoxy 2 component glue) thickened

with cotton flocks.

Then, thread the thin pipes into the tubes, which act as

pushrods for controlling the elevator.

To stiffen the push rods, thread a 0,8mm steel wire

inside. We recommend this especially at the ends, where

the push rods are not led inside the outer tubes anymore.

Glue the threaded couplers to the ends of the pushrods.

These couplers are turned into the plastic part of the ball

connector.

Here you can adjust later the length of the pushrods.

Erwin XL slope building Instruction August 2018

www.pcm.at 9

We use a very simple solution to mount the canopy.

Just glue the carbon stick into the canopy.

8. Wing

The openings for the servos are big enough for all

appropriate standard servos including mounting frame,

such as Futaba S3150.

Lead the cable through the wing as shown below.

The connection to the levers on the rudder goes crosswise

through the wing.

Before you glue the levers into flaps and ailerons, grind

the gluing spots on the control surfaces and on the

levers.

Aileron Flap

Erwin XL slope building Instruction August 2018

www.pcm.at 10

For gluing the lever use epoxy-glue with cotton flocks.

When fitting the lever in the correct position, notice that the

hole in the lever should be situated vertically above the

hinge line.

To connect the servos to the levers use two connectors

M2,5mm. In between, use a welding rod (diameter 2mm),

which you solder inside the both connectors.

To find the right length of the welding rod put all servos in

0-position. If the length isn’t exact after soldering, you can

heat the soldered point with the soldering iron until the

the wire can be moved to the correct position.

The root ribs have recesses for the plugs between

fuselage and wings for easy electrical connection.

Fix the covers of the servos with a double-sided adhesive.

In order to move the triangular ends of the ailerons,

connect the two control surfaces with an adhesive tape.

Erwin XL slope building Instruction August 2018

www.pcm.at 11

9. Installation of antenna

If you want to install 2,4 Ghz, let the antennas stand out

of the carbon fuselage as shown on the photo of Elvira.

The angle between the antennas should be 90°.

35 / 40 MHz:

As Erwin XL slope is completely made of carbon, a part

of the antenna must be situated outside the model.

One possiblity is to „extend“ the fuselage at the rear end

with a steel wire of about 450mm. Fix the end of the

antenna to this steel wire.

Another solution is to fix the antenna to the end of the

elevator. Lead the antenna inside the fuse behind the wing

and then leave the fuselage. You should add the length

between receiver and the breakthrough of the fuselage to

the end of the antenna, so that the original length of the

antenna is completely outside the fuselage.

Always test the reception on ground before you fly!

Erwin XL slope building Instruction August 2018

www.pcm.at 12

BEFORE THE FIRST FLIGHT

10. Ballast system

You can easily change the weight by varying between the different connectors.

You should always use two connectors when flying Erwin XL slope.

If the glider accelerates too slowly, don’t hesitate to add further weight. Erwin XL slope can do well

with more weight, in the air as well as when landing.

(Photos made from an older version of the root rib.)

2x carbon short, 150g

1x carbon short, 1x steel short, 450g

1x steel short, 1x steel long, 1125g

2x steel long, 1500g

(Order an additional steel bar if you need it)

Erwin XL slope building Instruction August 2018

www.pcm.at 13

11. Fixing of the wing

When attaching the wings, make sure that the connector

will not be postponed again.

First, push the connector into the first wing half as far

as possible. Note, that the shorter part of the connector

should disappear inside the wing. Then, push the

fuselage onto the connector and finally the 2nd wing

half.

Close the gap between wings and fuselage with adhesive

tape. By this way, the wing halves are fixed to the

fuselage.

12. Check list before starting:

1. Check centre of gravity (the angle of attack is pre-set)

2. Check rudders:

Do rudders move in the correct direction?

Check the greatest swings of the rudders

All control surfaces are continuously connected to the wing along the hinge line.

3. Check reception:

Leave the antenna inside the radio control and go away from the glider up to a distance of

about 60m. The rudders should not tremble.

2,4 Ghz: depending on radio controller (f.e. reduce transmission power)

13. Attention, Erwin XL is sensitive to heat!

Pay attention, that Erwin XL does not heat up! That means,

- don’t let the model lie in the car, when the sun is heating up the car.

- don’t let the model lie in the sun too long. Protect wing and elevator with bags, if you don’t fly.

- Avoid all other possibilities to heat up Erwin XL.

The model is heated up to 50° during production, but in the sun the model can easily reach higher

temperatures. During flight the model is sufficiently cooled by the airstream.

This sensitiveness is high shortly after production / purchase and will get less gradually.

Other manuals for ERWIN XL slope

1

Table of contents

Other PCM Toy manuals

PCM

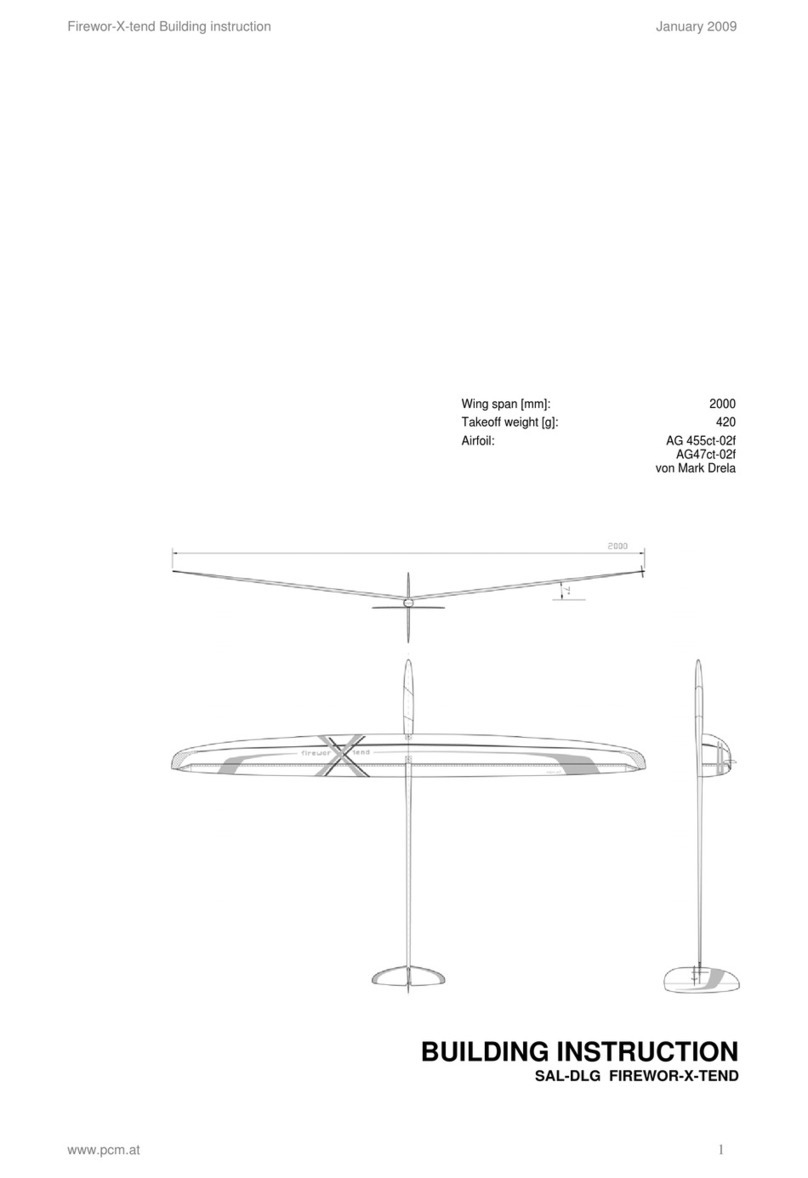

PCM FW6 Instruction Manual

PCM

PCM FW6.2 User manual

PCM

PCM SAL-DLG FIREWOR-X-TEND Instruction Manual

PCM

PCM ELVIRA User manual

PCM

PCM Erwin XL Ultralight Electro User manual

PCM

PCM GLIDER MINI-RACE User manual

PCM

PCM DV8R Technical specifications

PCM

PCM ERWIN XL slope User manual

PCM

PCM Erwin XL User manual

PCM

PCM MINI-S Instruction Manual

Popular Toy manuals by other brands

Dancing Wings Hobby

Dancing Wings Hobby T09 AeroMax instruction manual

Hasbro

Hasbro TIGER ELECTRONICS FurReal friends Guinea Pig instruction manual

Pro Boat

Pro Boat Formula owner's manual

V-tech

V-tech DigiArt Spirals & Sounds Parents' guide

Aeronaut

Aeronaut SkyMAXX instructions

Step 2

Step 2 Canopy Wagon 7868 manual