BOXER BHM195 Series User manual

INTRODUCTION 2 CHAPTER 1. SAFETY PRECAUTIONS 2

1.1 SAFETY 2

1.2 SAFETY PRECAUTIONS 3 CHAPTER 2. SAFETY DECALS 5CHAPTER 3. BACKHOE SPECIFICATIONS

8

3.1 BRIEF INTRODUCTION 8

3.2 HYDRAULIC SYSTEM MAIN COMPONENTS 10

3.3 BACKHOE MAIN COMPONENTS 11 CHAPTER 4. TRACTOR PREPARATION 12

4.1 ROPS SYSTEM 12

4.2 HYDRAULIC SYSTEM 12

4.3 TYRE INFLATION 12

4.4 WHEEL TREAD SETTINGS 13

4.5 ATTACHMENT 13

4.6 COUNTER WEIGHT 13 CHAPTER 5. BACKHOE MOUNTING 13

5.1 PTO CONNECTION (BHF AND BHES MODELS) 13

5.2 HYDRAULIC CONNECTION (BHEF AND BHES MODELS) 13

5.3 FITTING BACKHOE TO TRACTOR 13

5.4 REMOVE HACKHOE FROM TRACTOR 15 CHAPTER

6. BACKHOE OPERATION 17

6.1 PRECAUTIONARY NOTE 17

6.2 INITIAL BACKHOE OPERATION 19

6.3 COLD WEATHER OPERATION 19

6.4 BACKHOE HYDRAULIC CONTROLS 19

6.5 SWING AND BOOM LOCK 21

6.6 STABILIZER CLIPS (BHEF AND BHUF MODEL ONLY) 21

6.7 OPERATING HYDRAULIC SIDE SHIFT (BHES AND BHUS MODELS) 22

CHAPTER 7. LUBRICATION AND MAINTENANCE 24

CHAPTER 8. TROUBLE SHOOTING 26

CHAPTER 9. HYDRAULIC SYSTEM DIAGRAM 29

CHAPTER 10. ILLUSTRATED PARTS CATALOGUE 30

[1]

Introduction The purpose of this manual is to assist you in Maintaining and operating

your Redline backhoe. Read it carefully, it provides information and instructions that will help you achieve years of reliable

performance. Some information may be general in nature due to unknown and varying conditions. However, through

experience and these instructions, you should be able to develop operating procedures suitable to your particular situation.

“Right” and “Left” as used throughout this manual are determined by position operator is facing when in use.

The photos, illustrations and data used in this manual are current at the time of printing, but due to possible in-line

production changes, your machine may vary slightly in detail. The manufacturer reserves the right to redesign the machine

as may necessary without notification.

Important: Illustrations used in this manual may not show all safety equipment that is recommended to ensure safe

operation of tractor and backhoe. Refer to the Safety Precautions section of this manual for information concerning safety,

consult your dealer for further information. Serial Number and Location

Serial Number and Location The serial and model number is important information about the machine and it may be

necessary to know it before obtaining the correct replacement part. The identification plate is located on the right side of

control console. It is also recorded by your dealer on back page of this manual.

1.1 SAFETY

Understand that your safety and the safety of other people is measured by how you service and operate this Backhoe.

Know the position and operations of all controls prior to

operation. Make sure you check all controls in safe area

before starting.

Read this manual completely and make sure you understand all controls. All equipment has a limit. Make sure you are

aware of the stability and load characteristics of this Backhoe before you begin operating.

The Safety information given in this manual does not replace any safety codes, insurance needs, federal, state and local

laws. Make sure your machine has the correct equipment required by your local laws and regulations.

[2]

1.2 SAFETY PRECAUTIONS

Before starting the engine of your tractor, make sure all operation controls are in park lock or neutral position. Operate

controls only when seated in the operator’s seat. Equip your tractor with a ROPS cap or frame for your protection. See your

tractor operator’s manual for correct usage.

A frequent cause of personal injury or death is people falling off and being run over. Do not permit others to ride on your

tractor. Only one person, the operator, should be on the machine when it is in operation. Before leaving the tractor, stop

the engine, put all controls in neutral, engine the parking brake and remove the

key from the ignition. Operate the Backhoe smoothly when lowering or lifting loads. Stay off slopes too steep for sale

operation. Use low range gear before you start up or down a hill with a heavy load. Avoid “free wheeling”. Travel speed

should be such that complete control and machine stability is maintained at all times. Where

possible, avoid operation near ditches, embankments and holes. Reduce speed when turning, crossing slopes, and on rough,

slick or muddy surface

1.2 SAFETY PRECAUTIONS

(CONT.)

Never use your hand to check for suspected fuel or oil leaks under pressure. Use a piece of cardboard or wood for this

purpose. Escaping hydraulic oil or diesel leaking under pressure can have sufficient force to penetrate the skin and cause

infection or other injuries. If this happens seek medical attention immediately.

To prevent personal injury, relieve all pressure before disconnecting fluid lines.

Before operating hydraulic controls, make sure all hydraulic connections are tight and components are in good condition.

Contact with overhead power lines can cause severe electrical burn or electrocution. Make sure there is enough clearance

between raised equipment and overhead power lines. Add water to rear tires or fit rear wheel weights for increased

stability.

[3]

A backhoe attachment should be transported in a low

position at slow ground speeds. Make sure turns slowly and use the tractor brakes cautiously. A loaded attachment in the

raised position alters the center of gravity location of the machine and increases the possibility mishaps.

Do not stand, walk or work under a raised backhoe attachment unless it is mechanically secured in position. Accident

movement of a control lever or leak in the hydraulic system could cause the backhoe to drop, or attachment to dump,

causing severe injury.

Make sure all packed backhoe on stands are on a hard lever surface with all safety devices engaged to prevent backhoe

from falling and being damaged or injuring someone.

When using a backhoe, be alert of bucket, boom and arm position at all times.

Only operators who have been specially trained in backhoe operation and fully understand this manual can operate the

backhoe.

Keep hands, feet and clothing away from all moving parts. Wear close fitting clothing and appropriate safety equipment

(which includes, steel cap shoes, protective gloves, hard hat, safety grasses and dust mask). Prolonged exposure to loud

noise can damage hearing. Wear suitable approved hearing protection such as ear muffs or plugs, operating equipment

safely requires your full attention. Do not wear radio or music headphones. Secure hair above shoulder length.

You must be in good physical and mental health to operate the backhoe safely. Do not operate the backhoe when you

vision, co-ordination or judgment.

HIVIS clothing required when operating backhoe on work sites and road sides.

[4]

SAFETY DECALS

1Keep safety decals clean and free of obstructing material

2Replace damaged or missing safety decals with new decals from your dealer.

3If a component with a safety decal(s) affixed is replaced with a new part, ensure new safety decal(s) are attached in

the same locations on the replacement components. Refer below for correct location of decals. Note decals appear on both

sides of backhoe.

[5]

[6]

[7]

3.1 BRIEF INTRODUCTION

Redline backhoes can be attached to many brands of tractors and tracked dozers fitted with three point linkage, increasing

their versatility.

[8]

Model

BHM-195

BHL-225

Structure weight (kg)

540

700

Max digging depth (m) A

1.95

2.25

Max digging radius (m) B

2.9

3.3

Max digging height (m) C

3.17

3.45

Max unloading height (m) D

2

2.3

Stabilizer width (m)

1.7

1.7

Swing angle for boom

180

180

Bucket turning angle

195

203

Bucket turning angle

0.02

0.035

Bucket width (mm)

15L/MIN

25L/MIN

Min. hydraulic flow req.

25L/MIN

40L/MIN

Max. hydraulic flow allowed

13MPA

13MPA

Min. hydraulic press. Allowed.

16MPA

16MPA

Bucket digging force (kg)

1100

1700

Dipper arm digging force (kg)

850

1100

Item

Service

Service Interval

Hydraulic System Oil Level

Check

Daily / 10 Hours

Hydraulic System Oil/Filter

Replace

Every 50 Hours

Tyre Inflation

Check

Weekly / 50 Hours

Backhoe Pivot Points

Lubricate / Grease

Daily / 10 Hours

Backhoe Hydraulic Lines, Hoses,

Connections

Check for leaks, wear

Daily / 10 Hours

Boom, Arm, Swing and Bucket

cylinder rod packing’s

Check for seepage, service as

needed

Daily / 10 Hours

Pivot Pin Bolts and Dust Covers

Check, replace if missing

Daily / 10 Hours

Pin Wear

Check, replace if necessary

Daily / 10 Hours

Backhoe Mount Hardware

Check visually

Daily / 10 Hours

Structural Bolts and Nuts

Re-torque

Every 25 Hours

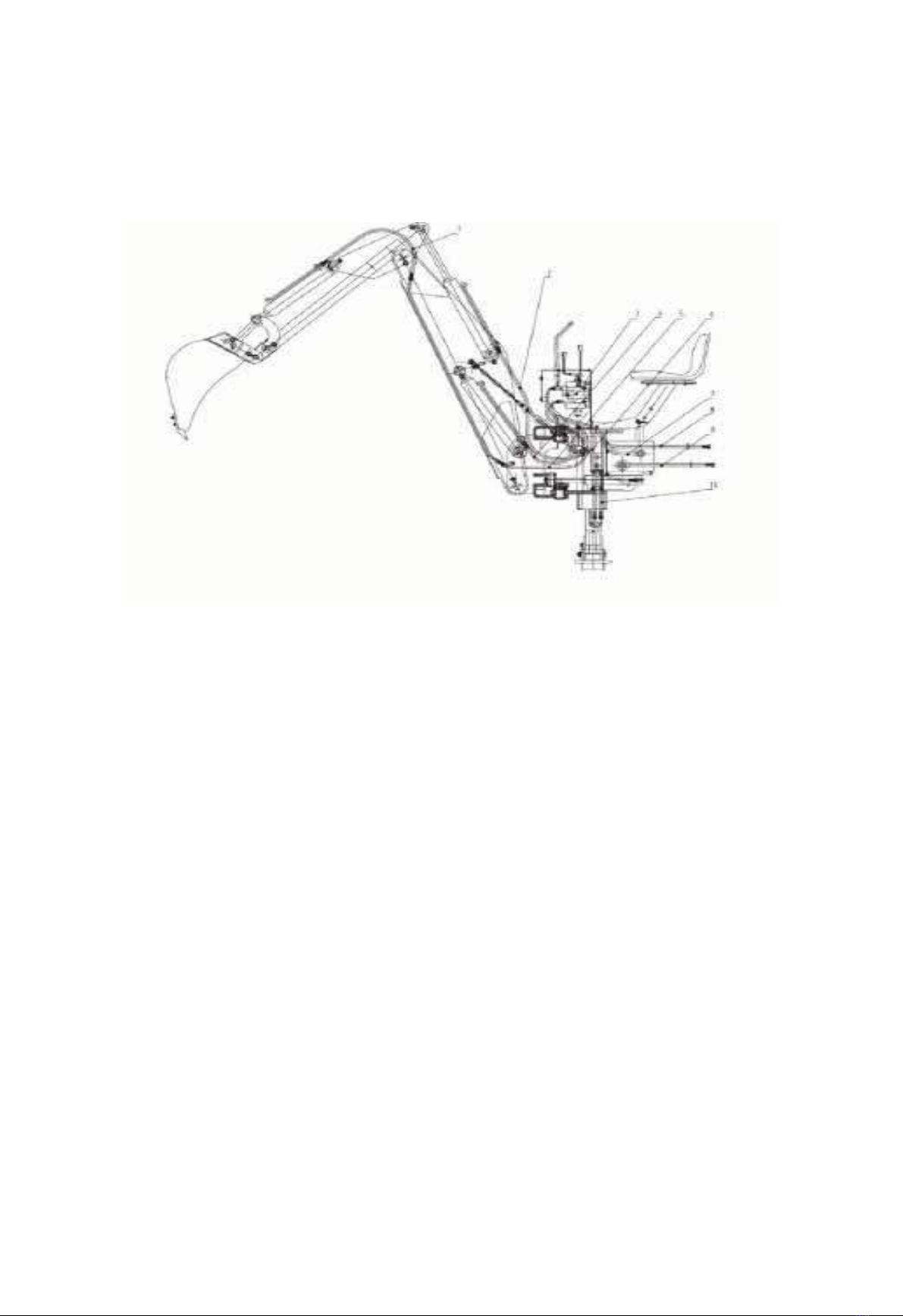

3.2 Hydraulic System Main Components

1. Front Hose-Dipper Arm 6. Hose-Turning Cylinder

2. Long Hose-Boom 7. Oil Return Cylinder

3. Control Valve DL-F20L 8. Inlet Oil Hose-Control Valve

4. Short Hose-Boom 9. Inlet Hose-Gear Pump

5. Rear Hose-Dipper Arm 10. Hose-Stabilizer

[9]

3.3 Backhoe Main Components

1. Bucket 7. Stabilizer

2. Dipper Arm 8. Swing Post

3. Boom 9. Main Frame

4. Bracket for Control 10. Sub A Frame

5. Tank 11. Boom Safety Lock Pin

6. Seat

[10]

CAUTION: Do not exceed the

manufacture’s rating for maximum gross vehicle weight. Refer to Operator’s Manual or ROPS serial plate

provided with tractor.

4.1 ROPS SYSTEM

The tractor must be equipped with an approved ROPS System to ensure adequate operator’s protection

4.2 HYDRAULIC SYSTEM

Models BHEF/ BHES Series

These models are driven by the tractors Hydraulic remotes. Tractor Operation in a backhoe application significantly increase

demands on the tractor Hydraulic System. Check the tractor Hydraulic System fluid level daily. Refer to your tractor

Operator’s Manual maintenance section for instructions regarding tractor hydraulic system maintenance

The hydraulic system powering the backhoe must be compatible with the specifications of the backhoe. Refer to the

minimum and maximum pressure and flow requirements shown in Backhoe Specifications. Many tractor hydraulic systems

exceed the flow rate specified for your backhoe. The flow may need to be reduced to an acceptable rate by throttling the

engine RPM. Adjusting the flow rate correctly could prevent sudden shock loads on the cylinders, hoses, etc. this results in a

smooth operation and reduced maintenance costs and down tine.

Adhere to recommendations in your Tractor Operator’s Manual concerning hydraulic fluid and filter specifications, and

change intervals.

Models BHUF/BHUS Series

These Models are driven by the tractors Power Off, and are fitted with an in-built Hydraulic pump and tank. Check fluid level

daily, ensure PTO shaft is greased and change hydraulic filter (refer to Lubrication and Maintenance).

CAUTION: The tractor / backhoe must only be operated with all safety equipment properly installed.

4.3 TYRE INFLATION

Front Tyres must be maintained at the maximum recommended inflation to maintain normal tyre profile with the added

weight of backhoe/material.

Rear Tyres must be maintained at equal pressure within the recommended tyre inflation range. Unequal rear tyre inflation

reduces stability and increases tipping hazard.

[11]

4.4 WHEEL TREAD SETTINGS

Tractor front wheel tread setting must be restricted to wheel tread spacing recommended in the tractor Operator’s Manual.

4.5 ATTACHMENT

Ensure your tractor’s point linkage system is fitted with sway chain attaching the backhoe. Failure to do can cause the

backhoe to swing when travelling potentially causing bodily injury or machine failure.

Inspect for any worn or damaged parts between the tractor and backhoe. Replace if necessary with parts of suitable

strength and quality.

4.6 COUNTER WEIGHT

Add recommended ballast (either front weights or from end loader) to the tractor’s front-end for increased stability. Refer

to tractor operator manual for specific recommendations on counter weighting tractor.

5.1 PTO SHAFT CONNECTION (BHUF AND BHUS

MODELS)

Ensure PTO shaft is correct length; correct PTO shaft length

must have a minimal overlap of 150mm in drive position. Connect PTO shaft to tractor PTO output shaft and backhoe

hydraulic pump shaft. Check PTO shaft has suitable angle prior to operation. Angle of PTO shaft universals must be less than

25°, to prevent major damage PTO Speed 540RPM for operation.

5.2 HYDRAULIC CONNECTION (BHEF AND BHES MODELS)

Connect the Hydraulic quick connectors to the tractor’s hydraulic remote outlets. Detent tractor hydraulic remote’s control

lever forward or back for correct flow of oil to backhoe.

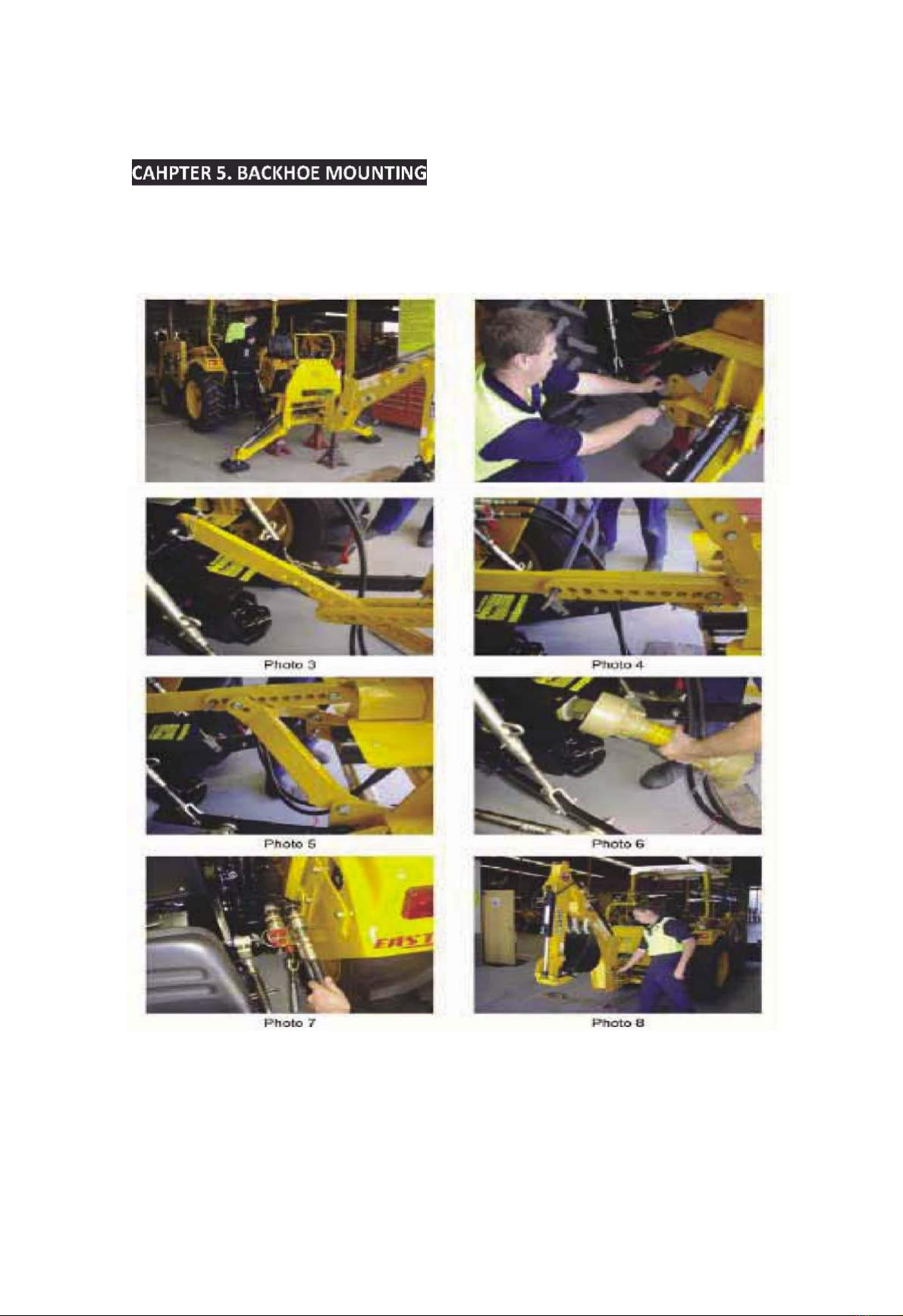

5.3 FITTING BACKHOE TO TRACTOR

-Choose some firm level ground to work on -Use hoist raise the backhoe mainframe onto 3 secured stands. -Align the

backhoe with boom parallel to tractor (Refer to Photo 1) -Connect backhoe tractor 3.P.L lower Arm (Refer to Photo 2)

-Connect solid top link at tractor end first (Refer to Photo 3) -Fit short bolt to rear hole loosely (use podgy bar to align holes)

( Refer to Photo 4) -Connect A-frame lockout bars to aligning holes and ensure all bolts are tight (Refer to Photo 5) -Connect

PTO shaft for BHUF & BHUS Model (Refer to Photo 6)

[12]

-For BHEF & BHES models, connect backhoe hydraulic

hoses to tractor hydraulic remotes (Refer to Photo 7)

-Lift boom stabilizer legs into transport mode, fit boom safety pin and adjust 3.P.L sway chains. (Refer to Photo 8)

[13]

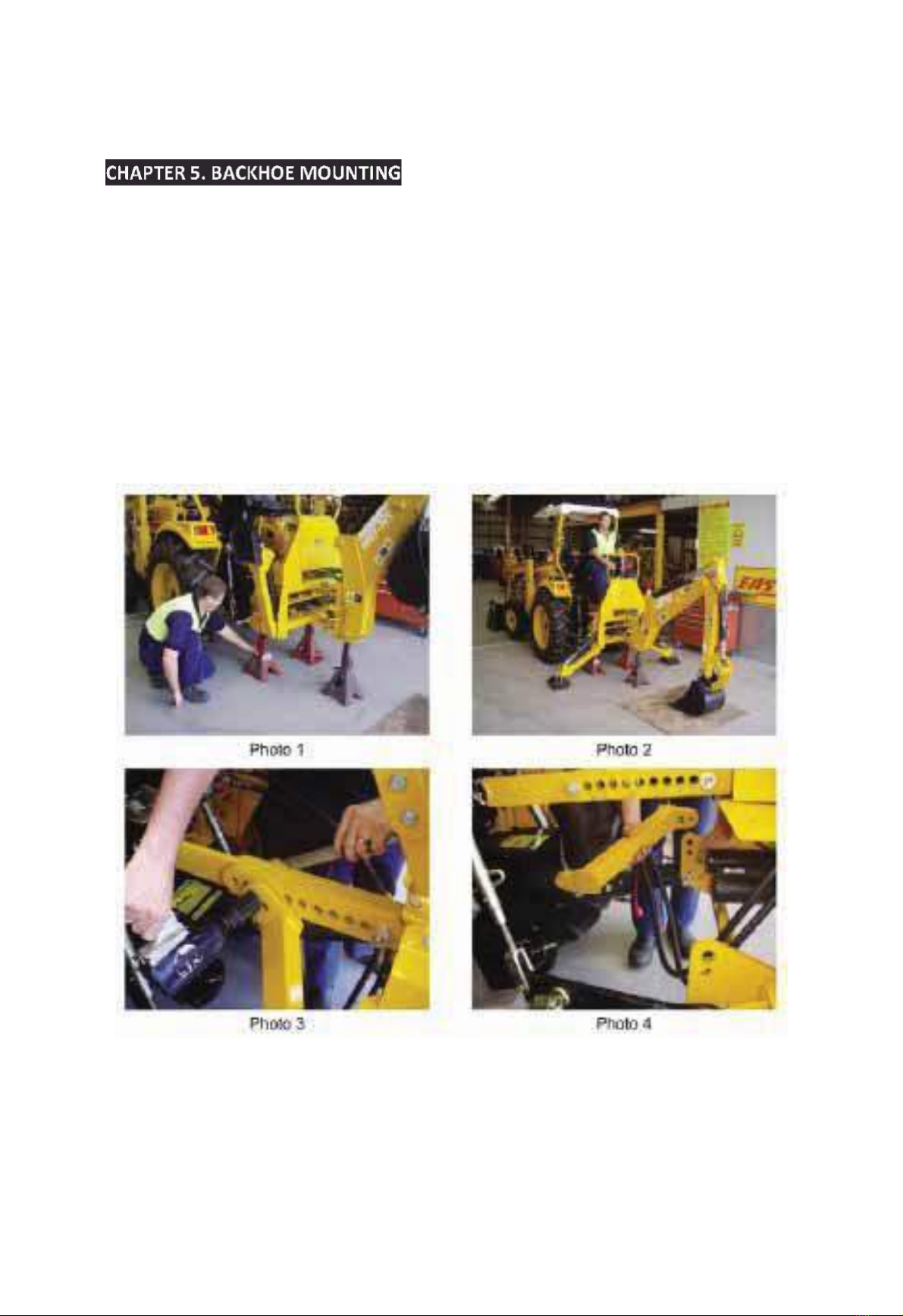

5.4 REMOVE BACKHOE FROM TRACTOR

-Choose some firm level ground to work on -Place 3 secure stands under backhoe main frame and boom carrier. (Refer to

Photo 1) -Lower stabilizer legs to ground. Position bucket flat on the ground with dipper arm vertical. (Refer to Photo 2)

-Remove A-frame lockout upper and lower bolts. (Refer to Photo 3) -Remove A-frame lockout bars. (Refer to Photo 4)

-Remove 2 piece solid top link; (Refer to Photo 5) -Lower 3.P.L onto 3 secure stands. (Refer to Photo 6) -Remove lower 3.P.L

arm pins. (Refer to Photo 7) -Remove PTO shaft for BHUF & BHUS models. (Refer to Photo 8) -Disconnect backhoe hydraulic

hoses from tractor remote outlet for BHEF & BHES models. (Refer to Photo 9 -Drive tractor forward slowly.(Refer to Photo

10)

[14]

[15]

CAUTION: Backhoe should be mounted to the tractor

three point linkages.

CAUTION: Never operate backhoe without secured solid top link and A-frame.

CAUTION: Never store backhoe without bucket attached to the backhoe.

CAUTION: Keep Feet and Hands well clear of underside of backhoe.

CAUTION: Never raise 3.P.L position / draft lever while backhoe is connected, damage could

occur to linkage and hydraulic system. Use mechanical means to secure these levers down to

tractor.

CAUTION: It is owner / Operator responsibility to ensure that the tractor 3.P.L top link & Hydraulic

lift cover area is strong enough to accept 3.P.L rigid connection and backhoe while in operation as

extra forces are exerted through top link. No liability can be accepted for damage to tractor.

CAUTION: The backhoe unit when not fully connected to the tractor is potentially unstable. Proceed

with Caution. Do not raise the backhoe boom until it is fully connected to the tractor. Failure to

comply with these requirements could cause death, bodily injury or property damage.

CAUTION: Do not operate the Backhoe if the fittings are leaking or if the hoses are damaged. A

sudden line burst would cause the boom to drop suddenly potentially causing death, bodily injury

or property damaged.

CAUTION: Before disconnecting hydraulic lines, turn the tractor off, relieve all hydraulic pressure.

Escaping hydraulic oil under pressure can have sufficient force to prevent the causing serious

personal Injury.

CAUTION: The tractor/backhoe should only be

operated with all safety equipment properly installed.

Keep assistants or bystanders a safe distance from the equipment operating area.

6.1 PRECAUTIONARY NOTE.

-Read and understand this manual to avoid accident.

-Check the hydraulic lines are correctly attached and not leaking.

-Maintain and repair (if it is needed) all parts or assemblies, check bolts and pins to be sure they are positioned tightly.

-Check tractor is prepared for operation. Refer tractor operators manual.

-Warm up and operate the tractor and backhoe carefully. Purge any air in the hydraulic lines and cylinders by fully cycling all

cylinders several times.

-Check hydraulic level in the tank to be at specified level. Add as required.

-Do not operate the hydraulics when not seated in the backhoe operator’s seat/

-Keep all assistants out of area of operation.

[16]

-Do not operate rapidly. -Do not allow riders other than the

operator to be on the tractor while operating.

Important

Limit tractor engine speed in line with your experience. At first set PTO RPM of the tractor to slow.

Do not use the boom, dipper arm, swing and stabilizers to lift, push or pull objects. Use only to maneuver and operate the

bucket.

Important

Practice turning off the engine or stopping the backhoe immediately in case of an emergency situation.

Important

Do not operate while the rear tractor wheels are raised off the ground by the stabilizer. It is dangerous to operate the

backhoe while rear wheels are off the ground.

Position the backhoe as near as possible and in such a direction as to minimize the amount of turning required to dump.

Keep the unit clean and perform regular servicing.

We urge you to follow this advice:

1Read and understand this manual as well as the Tractor Operator’s Manual.

2Remember and observe the safety precautions brought to your attention in this manual, the tractor manual and on

the machinery itself.

3Use good common sense in the everyday operation of this unit. Safety recommendations can never be allinclusive

and you are responsible for watching out for and avoiding unsafe.

4Never exceed the limits of a piece of machinery. If its ability to do the job, or to do it safely, is in question, don’t try

it.

5Don’t hurry the learning process or take the unit for granted. Ease into it and become familiar with your new

backhoe and tractor.

CAUTION: When lowing a heavy load, ease it download slowly. Never drop a loaded attachment and “Catch it

hydraulically”. Stopping a load after it has gained download momentum places undue strain on the unit and may

cause unnecessary damage to the backhoe or tractor or even worse, personal injury.

[17]

CAUTION: Before disconnecting hydraulic lines,

relieve all hydraulic pressure. Escaping hydraulic oil under pressure can have sufficient force to penetrate the skin

causing serious personal injury. If injured by escaping hydraulic oil, seek medical attention immediately.

CAUTION: Do not operate the backhoe if the fittings leaking or if the hoses are damaged. A sudden line burst

would cause the boom, or dipper arm bucket to drop suddenly, causing damaged to the tractor or backhoe or injury to

personnel.

6.2 INITIAL BACKHOE OPERATION

Before operating the backhoe, fully raise and lower the boom, arm, swing and stabilizers two or three times. Then raise the

bucket above the ground and cycle the bucket cylinders three times. Lower the bucket to the ground. Check the tractor

hydraulic oil level and add as required.

CAUTION: Before leaving the machine, stop the engine, remove the key. Place all controls in neutral, and

either set the parking brake or place tractor in park as equipped.

When possible keep cylinders in a retracted position when the backhoe is in use guard against rust and contamination which

may cause damage to the cylinder rods or hydraulic system. Also, lock the swing and boom while backhoe is being

transported and storing for an extended period of time.

6.3 COLD WEATHER OPERATION

For smooth operation in cold weather, let the tractor warm up. Slowly cycle all of the cylinders several times to warm the oil

in the hydraulic system. The backhoe may operate erratically until the hydraulic oil has warmed to operating temperatures.

CAUTION: Operate controls only when seated in the operator’s seat with seat belt on.

6.4 BACKHOE HYDRAULIC CONTROLS

The backhoe hydraulic valve features 4 control levers. Refer to the diagram below for backhoe control functions. “Left” and

“Right” are determined by the direction the operator is facing when seated in the backhoe.

The Diagram is located on the rear of the control valve bracket and is visible when operating the valve.

[18]

1. Boom / Bucket 3. Right Stabilizer

2. Dipper Arm / Swing 4. Left Stabilizer

The two levers, ‘Boom and swing control lever’ and ‘Bucket and dipper arm’, provide four simultaneous operations. Both

experience and practice are needed to eliminate excess motion and increase operating efficiency.

Do not dig near the stabilizers to avoid possible accident

Do not lift the tractor rear wheels by stabilizers. Also, be sure the stabilizers are seated on hard ground to support the

backhoe / tractor.

[19]

This manual suits for next models

2

Table of contents