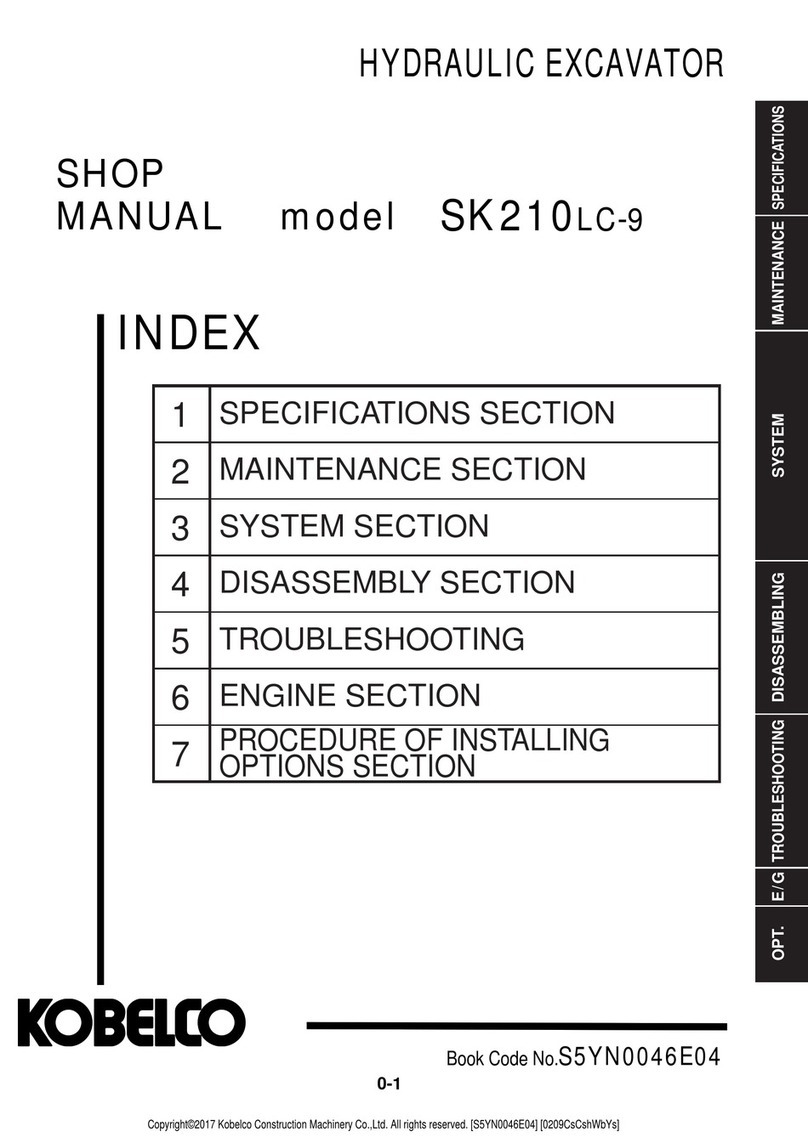

HU1-1-1

SECTIONS AND GROUPS INDEXES WX90

15501 9-35990

SECTION 1 - HOW TO USE

Group 1 - SECTIONS AND GROUPS INDEXES ........................................................... HU1-1

Group 2 - INTRODUCTION ............................................................................................ HU1-2

Group 3 - FEATURES OF THE MANUAL ...................................................................... HU1-3

SECTION 2 - SAFETY RULES

Group 1 - GENERAL INFORMATION ............................................................................ SR2-1

Group 2 - SAFETY RULES ............................................................................................ SR2-2

Group 3 - SAFETY DECALS .......................................................................................... SR2-3

SECTION 3 - SPECIFICATION

Group 1 - GENERALITY..................................................................................................SP3-1

Group 2 - TECHNICAL SPECIFICATIONS ..................................................................... SP3-2

Group 3 - LUBRICANTS AND SPECIFICATIONS .......................................................... SP3-3

SECTION 4 - SUPERSTRUCTURE

Group 1 - SUPERSTRUCTURE ......................................................................................SS4-1

Group 1A - FLEXIBLE HOSES AND CONNECTIONS ................................................ SS4-1A

Group 2 - HYDRAULIC PUMPS ................................................................................... HYP4-2

Group 3 - CONTROL VALVE ......................................................................................... CV4-3

Group 4 - SWING DEVICE ........................................................................................... SRD4-4

Group 5 - PILOT VALVES ............................................................................................... PV4-5

Group 6 - CENTER JOINT .............................................................................................. CJ4-6

Group 7 - STEERING VALVE ......................................................................................... SV4-7

Group 8 - BRAKE PEDAL VALVE ................................................................................ BRV4-8

Group 9 - ACCUMULATORS ....................................................................................... ACC4-9

Group 10 - SOLENOID VALVES ................................................................................ SOV4-10

SECTION 5 - UNDERCARRIAGE

Group 1 - UNDERCARRIAGE ........................................................................................ UC5-1

Group 2 - TRAVEL HYDRAULIC MOTOR ................................................................... HYP4-2

Group 3 - TRANSMISSION ............................................................................................ CV4-3

Group 4 - AXLES .............................................................................................................AX5-4

Group 5 - TRANSMISSION SHAFT ................................................................................ TS5-5

SECTION 6 - FRONT-END ATTACHMENT

Group 1 - FRONT-END ATTACHMENT.......................................................................... FA6-1

Group 2 - HYDRAULIC CYLINDERS ............................................................................. CY6-2

Group 3 - PINS AND BUSHINGS.................................................................................... FA6-3

SECTION 7 - HYDRAULIC SYSTEM

Group 1 - GENERALITIES ............................................................................................. HS7-1

Group 2 - MAIN HYDRAULIC SYSTEM ......................................................................... HS7-2

Group 3 - PILOT/BRAKES SYSTEM.............................................................................. HS7-3

Group 4 - STEERING SYSTEM ..................................................................................... HS7-4

Group 5 - BRAKES SYSTEM ......................................................................................... HS7-5

Group 6 - OPERATION OF CIRCUITS .......................................................................... HS7-6

Group 7 - TRAVEL CIRCUIT .......................................................................................... HS7-7

Group 8 - HYDRAULIC SYSTEM DIAGRAM ................................................................. HS7-8

1. SECTIONS AND GROUPS INDEXES PAGE

Find manuals at http://best-manuals.com/search?&s=CASE-935990