B+K precision MDL001 User manual

MDL Series

Programmable DC Electronic Load

Models: MDL001, MDL002, MDL200, MDL252,

MDL302, MDL305, MDL400, MDL505, MDL600

USER MANUAL

2

Safety Summary

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument. We

assume no liability for the Customer’s failure to comply with these requirements.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use, pollution degree 2 environments. It is designed to

operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the

specifications tables for the AC mains voltage requirements and ambient operating temperature

range.

BEFORE APPLYING POWER

Verifythat allsafety precautions are taken. Note the instrument's externalmarkings described

under "Safety Symbols".

GROUND THE INSTRUMENT

This product isa Safety Class1 instrument (provided with a protective earth terminal). To minimize

shock hazard, the instrument chassis and covermust be connected to an electrical ground. The

instrument must be connected to the AC mains power through a grounded power cable, with the

ground wire firmly connected to an electrical ground (safety ground)at the power outlet. Note:

Any interruption of the protective (grounding) conductor or disconnection of the protective earth

terminal will causea potential shock hazard that could result in personal injury.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of fumes or flammable gases.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument coversexcept as instructed in this guide for

installing or removing electronic load modules. Component replacementand internal adjustments

must be made only by qualified service personnel. Do not replace components with power cable

connected. Undercertain conditions dangerous voltages may exist even with the power cable

removed. To avoid injuries, always disconnect power, discharge circuits, and remove external

voltage sources before touching components.

3

DO NOT SERVICE OR ADJUST ALONE

Do not try to do some internal service or adjustment unless another person capable of rendering

first aid resuscitation is present.

Safety Symbols

Direct current

Alternating current

Both direct and alternating current

Protective earth (ground) terminal

Attention (refer to accompanying documents)

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which,

if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a

WARNING sign untilthe indicated conditions are fully understood and met.

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which,

if not correctly performed or adhered to, could result in damage to or destruction of part or all of

the product. Do not proceed beyond a CAUTION sign until the indicated conditionsare fully

understood and met.

4

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union andother

European countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European Parliament and the Councilof the

European Union on waste electricaland electronicequipment (WEEE), and injurisdictions adopting

that Directive, is marked as being put on the market after August 13, 2005, and should not be

disposed of asunsorted municipal waste. Please utilize your local WEEEcollection facilities inthe

disposition of this product and otherwise observe all applicable requirements.

CE Declaration of Conformity

The DC electronic load meets the requirements of Low Voltage Directive 73/23/EEC and

Electromagnetic Compatibility Directive 89/336/EEC amended by 93/68/EEC.

Low Voltage Directive

-EN61010-1: 2001

EMC Directive

-EN50081-1

-EN50082-1

5

Table of Contents

Safety Summary....................................................................................2

Compliance Statements.........................................................................4

Product Overview .................................................................................8

Description..............................................................................................................................8

Features..................................................................................................................................9

Front Panel............................................................................................................................10

Rear Panel.............................................................................................................................11

Protection Functions..............................................................................................................12

Overvoltage Protection (OVP) ............................................................................................12

Overcurrent Protection (OCP).............................................................................................12

Overpower Protection (OPP)..............................................................................................14

Overtemperature Protection (OTP).....................................................................................15

Reverse Voltage Protection (LRV/RRV) ...............................................................................15

Menu List ..............................................................................................................................16

Setup Menu .......................................................................................................................16

Configuration Menu...........................................................................................................19

Automatic Test Menu.........................................................................................................20

Installation..........................................................................................21

Inspection .............................................................................................................................21

Cleaning................................................................................................................................21

Installing Modules.................................................................................................................22

Channel Number ...................................................................................................................24

Location ................................................................................................................................25

Input Voltage Selection..........................................................................................................27

Turn-On Checkout .................................................................................................................28

If the Electronic Load Does Not Turn On.................................................................................29

Load Connection .................................................................................30

Remote Sense Connection.....................................................................................................31

Parallel Connection................................................................................................................32

Mainframe 8-pin Control Connector.......................................................................................33

External Trigger Connections .................................................................................................34

6

External ON/OFF Control Connection.....................................................................................35

Mainframe Extension Connection..........................................................................................35

PC Control Connection...........................................................................................................36

Operation ...........................................................................................37

Operating Modes...................................................................................................................37

Constant Current (CC) mode...............................................................................................37

Constant Voltage (CV) Mode ..............................................................................................39

Constant Resistance (CR) Mode..........................................................................................40

Constant Power (CW) Mode...............................................................................................41

Constant Impedance (CZ) Mode..........................................................................................42

Setting CV, CC, CR, CW, CZ Mode........................................................................................44

Local Operation.....................................................................................................................45

Mainframe Panel................................................................................................................45

Module Panel.....................................................................................................................48

Module Panel Lock.............................................................................................................49

Switching Channels ............................................................................................................49

Channel Synchronization....................................................................................................49

VFD Indicator Function Description ....................................................................................50

Transient Operation ..............................................................................................................51

Continuous.........................................................................................................................51

Pulse..................................................................................................................................52

Toggle................................................................................................................................53

Setting Up A/B Transient Operation ...................................................................................53

List Operation........................................................................................................................56

Setting Up List Operation Mode..........................................................................................56

Triggered Operation ..............................................................................................................60

Trigger Function.................................................................................................................60

Trigger Source....................................................................................................................60

Short Operation.....................................................................................................................60

Input On/Off Operation.........................................................................................................61

Von Operation.......................................................................................................................61

7

Setting Up Von Function.....................................................................................................62

Save and Recall Operation.....................................................................................................63

Module Controlling Link.........................................................................................................64

Voltage Failure Indication...................................................................................................65

Current Monitoring............................................................................................................65

Digital I/O..........................................................................................................................65

Remote Sense Function......................................................................................................66

External Analog Control......................................................................................................66

Automatic Test......................................................................................................................66

Setting Up Test Files...........................................................................................................66

Recall Test Files..................................................................................................................72

Remote Operation.................................................................................................................72

USB Interface.....................................................................................................................73

Ethernet Interface..............................................................................................................73

GPIB Interface....................................................................................................................73

RS-232 Interface.................................................................................................................74

RS-232 Data Format.................................................................................................................74

Baud Rate.................................................................................................................................74

Parity........................................................................................................................................74

RS-232 Flow Control.................................................................................................................75

RS-232 Connections.................................................................................................................75

RS-232 Troubleshooting...........................................................................................................76

Communication Setting......................................................................................................76

Specifications......................................................................................77

Supplementary Characteristics...............................................................................................79

SERVICE INFORMATION.......................................................................80

LIMITED THREE-YEAR WARRANTY .......................................................81

8

Product Overview

This section describes the main features and menus of the MDL Series DC Electronic Load. The MDL

Series is comprised of two parts, mainframes and modules. The mainframes mentioned are the

MDL001 mainframe and the MDL002 mainframe extension. Modules in this series include the

MDL200, MDL252, MDL302, MDL305, MDL400, MDL505, and MDL600. Unless otherwise noted,

this document will refer to all of these instruments as “electronic load”. The range of each

module’s specific voltage, current, and power is listed in the Specifications section.

Description

The MDL Series is a multi-channel programmable DC electronic load system. With programming

and remote control capabilities, the MDL Series DC electronic load can provide multiple solutions

according to the requirements of your design and is suitable for testing a wide range of power

sources from multi-output DC power supplies to batteries, fuel cells, and photovoltaic arrays.

Up to four modules can be installed into the MDL001 mainframe to support up to a total of 8

channels. Adding the MDL002 mainframe extension will enable the system to support four

additional module slots for a maximumof 16 channels. The electronic load is configured by

installing user-selectable modules into the mainframe and operated usingthe front panel keypad

and rotary knob.It can also becontrolled remotely via USB, RS-232, LAN, or GPIB interface. The

electronic load modules all have similar functions, but may differ in range of input voltage, current,

and power. The high resolution voltageand currentmeasurement system provides both accuracy

and convenience.

The electronic load can be used in one of five different operation modes: constant voltage (CV),

constant current (CC), constant resistance (CR), constant power (CW), or constant impedance (CZ).

All panel operation and programming functions are carried out on the MDL001 mainframe panel. A

wide range of dynamic loading applications can be simulated through user-programmable slew

rates, load levels, duration, and conducting voltage.

9

Features

•CC/CV/CR/CW/CZ operating modes

•Removable modules for easy system flexibility

•Bright VFD displayfor both mainframe and modules

•Power range up to 2400 W (4800 W with mainframe extension)

•Supports up to 16 channels with mainframe extension

•Operate identical modules in parallel mode for high current applications

•Synchronous load on/off function

•16-bit voltage and current metering providing high resolution of 0.1 mV and 0.01 mA

•Transient mode up to 25 kHz

•List mode (sequence mode) – minimum 20 us step width with 84user programmable steps

•Adjustable slew rate in CC mode

•Automatic test function

•101 memory areas to save/recall setting parameters

•Analog current control and monitoring

•Remote sensing

•Standard LAN, GPIB, USBTMC compliant USB, and RS-232 interfaces with SCPI protocol

support

•OVP/OCP/OPP/OTP and reverse voltage protection

10

Front Panel

Figure 1 - MDL Series Front Panel

1) VFD DISPLAY

Displays electronic load information.

2) MODULE PANEL KEYS

Controls module functions. Refer to Module section for more details on the use of these

keys.

3) ADJUSTMENT KNOB

Used to change parameters.

4) MAINFRAME FUNCTION KEYS

Controls each channel’s operating status. Refer to Mainframe section for more details on

the use of these keys.

5) MAINFRAME NUMERIC ENTRY AND SHIFT KEYS

Refer to Mainframe section for more details on the use of these keys.

6) POWER SWITCH

Turns the system on or off.

7) MAINFRAME

8) MODULES

11

Rear Panel

Figure 2 - MDL Series Rear Panel

1) GPIB interface

2) Input terminal of module

3) Remote measurement and external input control terminal

4) Current monitoring output

5) Digital I/O and VF output terminal

6) Extended module interface

7) AC Power input socket

8) USB interface

9) Line voltage selection switch (110V/220V)

10)Trigger I/O and load on/off terminals

11)LAN interface

12)RS-232 interface

13)Not used – for factory use only

12

Protection Functions

The electronic load has the following protection functions: Overvoltage protection (OVP),

overcurrent protection (OCP), overpower protection (OPP), overtemperature protection (OTP), and

local and remote reverse voltage protection (LRV/RRV).

The mainframe will act appropriately once any of the above protections are active. You can press

any button on the front panel to restore the protection function. For example, if the electronic

load triggers the overtemperature protection, the buzzer will alarm, the input will automatically

turn off, and the mainframe VFD will display OTP.

Overvoltage Protection (OVP)

If the OVP circuit has triggered, input will turn off, buzzer alarm will gooff, and the status register’s

OV and VF bit will be set. The mainframe will display OVP and the condition will remain untilthey

are reset. Once overvoltage protection occurs, the 8-pin connector’s VF pin on the rear panel will

output TTL high voltage level. You can control the output state of the power supplyundertest via

this pin (see Figure 31).

Operations to Clear the OVP State

Check whether the input voltage is within the electronic load’s rated voltage or the programmed

protection voltage ranges. If it is outside the range, please disconnect the device under test. Then

press any key on the front panel or remotely send SCPI command PROTection:CLEar. The OVP

displayed on the front panel will turn off and the electronic load exits OVP protection state.

Overcurrent Protection (OCP)

The electronic load includes both hardware and software overcurrent protection features.

Hardware OCP - The electronic load’s maximum input current will be limited to approximately

110% of the current range. Once thehardware OCP is triggered, the statusregister’s OC bit willbe

set. When the hardware OCP is removed, the status register’s OC bit will be reset. Hardware

overcurrent protection will not affect the electronic load’s on/off state.

Software OCP - Users can set the electronic load’s software OCP value with the following steps.

13

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press Shift + ⑧to enter Configuration menu.

Sync On Set

Von

Meter

Protect

List

Ext. Ctrl Set

About

Exit

3. Press key to select <Protect>and press Enter to go into protection

menu.

Max Power Set

Alimit State

Alimit Point

Alimit Delay

Plimit Point

Plimit Delay

OnTimer State

OnTimer Set

Exit

4. Press key to select <Alimit State> and press Enter. Select <On>

and press Enter to confirm.

On

Off (Default)

5. Press key to select <Alimit Point> and press Enter. Input OCP

current value and press Enter to confirm.

Current Limit

Set= 40.000A

6. Press key to select <Alimit Delay> and press Enter. Input delay

time before alarm and press Enter to confirm.

Current Limit

Delay= 3S

7. Press Esc key to exit menus.

If the electronic load’s current value is above the set overcurrent protection value, the electronic

load will automaticallyturn off and the VFD willdisplay OCP. At the sametime, the OC and PS bits

in the status register will be set and remain until they arereset.

Operations to Clear the OCP State

Check whether the input current is within the electronic load’s rated current or the programmed

protection current ranges. If it is outside the range, disconnect the device under test. Then press

any key on the front panel or remotely send SCPI command PROTection:CLEar. The OCP displayed

on the front panel will turn off and theload exitsOCP protection state.

14

Overpower Protection (OPP)

The electronic load includes both hardware and software OPP features.

Hardware OPP – In the event that the electronic load’s input power exceeds the set power

protection limit, the hardware OPP will limit the power. Once the hardware OPP is triggered, the

status register’s OP bit will be set. When the hardware OPP is removed, the status register’s OP bit

will be reset. Hardware overpower protection will not turn the electronic load’s input off.

Software OPP - Users can set the electronic load’s software OPP value with the following steps.

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press Shift + ⑧to enter Configuration menu.

Sync On Set

Von

Meter

Protect

List

Ext. Ctrl Set

About

Exit

3. Press key to select <Protect>and press Enter to go into

protection menu.

Max Power Set

Alimit State

Alimit Point

Alimit Delay

Plimit Point

Plimit Delay

OnTimer State

OnTimer Set

Exit

4. Press key to select <Plimit Point> and press Enter. Input OPP

power value and press Enter to confirm.

Power Limit

Set= 210.00W

5. Press key to select <Plimit Delay> and press Enter. Input delay

time before alarm and press Enter to confirm.

Power Limit

Delay= 3S

6. Press Esc key to exit menus.

If the electronic load’s power value is above the set overpower protection value, the electronic

load will automatically turn off and the VFD will display OPP. At the same time, the OP and PS bits

in the status register will be set and remain until they arereset.

15

Operations to Clear the OPP State

Check whether the input power iswithin the rated power range or the programmed protection

ranges. If it is outside the range, disconnect the device under test. Then press any key on the front

panel or remotely send command PROTection:CLEar. The OPP displayedon the frontpanel will

turn off and the electronic load exits OPP protection state.

Overtemperature Protection (OTP)

Each module has an overtemperature protection circuit, which will turn off the input if the internal

temperature exceeds safe limits. When the electronic load’s internal circuit temperature is over

85°C, the load will enable OTP. Input will automatically be turned off and the VFD will display OTP.

At the same time the OT and PS bits in the status register will be set and remain until they are

reset.

Operations to Clear the OTP State

When the electronic load temperature hasdropped below the protection point, press any key on

the front panel or remotely send command PROTection:CLEar. The OTP displayed on the front

panel will turn off and the electronic load exits OTP protection state.

Reverse Voltage Protection (LRV/RRV)

Thisfunction protects the electronic load in case theinput DC voltage lines areconnected with the

wrong polarity. When a reverse voltage (LRV – local reverse voltage, RRV – remote reverse voltage)

connection condition is detected, the input will immediately turn off, the buzzer will alarm the

user, and the status register’s reverse voltage (LRV/RRV) and VF bits will be set. The mainframe will

display LRV/RRV until they are reset.

In this condition, the 8-pin connector’sVF pin willoutput ahigh level.You can disconnect the

power supply via this signal (see Figure 31).

Operations to Clear the Reverse Voltage State

Check whether the connection is reversed. If so, disconnect the deviceto be measured and the

reverse voltage statewill be cleared.

16

Menu List

The following menus can be viewed on the VFD display. Use keys to scroll through the menu

list and press Enter key to enter the selected menu function. Use keys to scroll through the

VFD screen and press Enter keyto enter its submenu. Press Esc to go back to theprevious menu

selection. Pressing number keys can directly select a channel.

Setup Menu

Press Setup key to enter the setup menu.

SETUP

MODE

Select working mode

CONST CURRENT

Load works in CC mode

CONST VOLTAGE

Load works in CV mode

CONST RESISTANCE

Load works in CR mode

CONST POWER

Load works in CW mode

CONST IMPEDANCE

Load works in CZ mode

CC/CV RANGE

Switch the range

HIGH RANGE

Set high range

LOW RANGE

Set low range

I / V / R / W SET

Set the working current/voltage/resistance/power value

Vmax/Amax

Set up the maximum voltage/current limit for Automatic test mode

Vmin/Amin

Set up the minimum voltage/current limit for Automatic test mode

∫=2.500A/us

Set the rising slew rate (only in CC mode)

∫=2.500A/us

Set the falling slew rate (only in CC mode)

TRAN A=0.00A

Set up level A value

Ta=0.0005S

Set up level A width

TRAN B=0.00A

Set up level B value

Tb=0.0005S

Set up level B width

T MODE

Set up the transient mode

CONTINUOUS

Continuous mode

PULSE

Pulse mode

TOGGLE

Toggle mode

RLC R=7500.0Ω

Set up the resistance value

RLC L=0uH

Set up the inductance value

RLC C=10uF

Set up the capacitance value

EXIT

Exit the setup menu

17

System Menu

Press Shift + ⑦key to enter the System menu.

MENU

INITIALIZE

INITIALIZE DEFAULT SET

Resume all configuration to default settings

POWER ON SET

RST (DEFAULT)

Set the load’s input state to default at power on

SAV0

Set the load’s input state to SAV0 at power on

BUZZER SET

Set up the buzzer state

ON

Enable the function

OFF (DEFAULT)

Disable the function

LOAD ON KNOB

Module knob mode setting

UPDATE (DEF)

Real-time update

OLD

No update (when turning load ON/OFF, original

value before use of rotary knob will be set)

TRIGGER SOUR.

Set up the trigger mode

MANUAL (DEF)

Manual trigger

EXTERNAL

External signal trigger mode

HOLD

Hold trigger mode

BUS

Bus trigger mode

TIMER

Timer trigger

TRIGGER TIMER

Trigger timer setting

TRIGGER TIMER SET

Set the time of the trigger timer

COMMUNICATION

Select the interface for remote communication

RS232 (DEF)

USBTMC-USB488

GPIB

ETHERNET

RS232 SET

BAUDRATE SET

Set up the communication baud rate

4800 (DEFAULT)

9600

19200

38400

57600

115200

18

RS232 SET

PARITY SET

Set up the communication parity

NONE (DEFAULT)

ODD

EVEN

HANDSHAKE SET

Select the handshake protocol

NONE (DEFAULT)

CTS/RTS

XON/XOFF

GPIB ADDRESS

GPIB address setting

GPIB ADDRESS SET

Set up communication address

ETHERNET SET

Ethernet settings

GATEWAY SET

Gateway setting

IP SET

IP setting

MASK SET

Mask setting

PORT SET

Port setting

EXIT

EXPAND MODULE

Module expansion

ON

Enable the function

OFF (DEFAULT)

Disable the function

LANGUAGE SET

Communication protocol

SCPI (DEFAULT)

SCPI protocol

EXTEND TABLE

Expand SCPI protocol, compatible with others

ABOUT

Mainframe production information

MDL###

Mainframe production model number

SN:

################## Mainframe production serial number

VER: 1.43

Mainframe software version

EXIT

19

Configuration Menu

Press Shift + ⑧key to enter the channel Configuration menu.

MENU

SYNC ON SET

Setup Synchronization ON / OFF function

ON (DEFAULT)

Turn on synchronization function

OFF Turn off synchronization function

VON

VON POINT

Set the load’s Von point

VON LATCH

Von latch state

ON (DEFAULT)

Turn on Von latch

OFF

Turn off Von latch

EXIT

Exit the menu

AVERAGE

COUNT Average count setting 2^X (adjustable from 2^2 to 2^16)

V AUTORANGE

Auto switching voltage range

ON (DEFAULT)

Enable this function

OFF

Disable this function

PROTECT

Load protecting function

MAX POWER SET

Set up hardware power protection state

ALIMIT STATE

Set up software current protection state

ON

Turn on software current

protection state

OFF (DEFAULT)

Turn off software current

protection state

ALIMIT POINT

Set up software current protection value

ALIMIT DELAY

Set up software current protection delay

PLIMIT POINT

Set up software power protection value

PLIMIT DELAY

Set up software power protection delay

ON TIMER STATE

Set up LOAD ON timer state

ON TIMER SET

Set up LOAD ONtimertime

EXIT

Exit the menu

LIST

FUNCTION MODE

Select mode

FIXED

Choosefixed operation mode

LIST

Chooselist operation mode

RECALL LIST

Recall list operation file

20

EDIT LIST

Edit list operation file

HIGH RANGE

Edit high range of list operation

LOW RANGE

Edit low range of list operation

EXT. CTRL SET

External analog control function

ON

Turn on external analog control function

OFF (DEFAULT)

Turn off external analog control function

REM SENSE SET

Remote sense function

ON

Enable remote sense function

OFF (DEFAULT)

Disable remote sense function

ABOUT

Module production information

MDL###

Channel production model

SN:

################## Channel production serial number

VER: 1.35

Channel software version

EXIT

Exit the menu

Automatic Test Menu

Press Shift + ⑨key to enter the program menu.

PROGRAM

RUN PROGRAM

Run the testing file

RECALL PROG

Recall the testing file

EDIT PROGRAM

Edit the testing file

EXIT

This manual suits for next models

13

Table of contents

Other B+K precision Control Unit manuals

Popular Control Unit manuals by other brands

Quanser

Quanser SRV02 Series user manual

ABB

ABB SACE PR212/D-L instruction manual

INOXPA

INOXPA INNOVA S Installation, service and maintenance instructions

Trinamic

Trinamic PD28-1-1021 Hardware manual

Grundfos

Grundfos CIM 500 instructions

Guntermann & Drunck

Guntermann & Drunck G&D UCON-Audio-s Installation and operation

Stanley

Stanley STW0101N Applications manual

turck

turck excom I/O System Integration manual

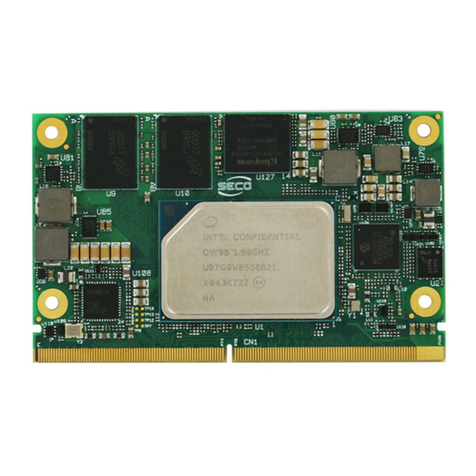

Seco

Seco Smarc SM-C93 user manual

Larson Electronics

Larson Electronics LM-SYM-XX-CTRL-R1 instruction manual

Stenner Pumps

Stenner Pumps PCM series Installation and maintenance manual

Moxa Technologies

Moxa Technologies ABC-01 Quick installation guide