B+K precision DAS1700 User manual

User Manual

DAS1700

High Speed Data Acquisition System

bkprecision.com

2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during all

phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the instrument

at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specied by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards of design,

manufacture, and intended use of the instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements.

Category rating

The IEC 61010 standard denes safety category ratings that specify the amount of electrical energy available and the

voltage impulses that may occur on electrical conductors associated with these category ratings. The category rating is

a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to be tested,

which denes the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be connected to the

mains supply. The voltages in the environment are typically derived from a limited-energy trans-

former or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected to the mains

supply at a standard wall outlet or similar sources. Example measurement environments are portable

tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be connected to the mains

installation of a building. Examples are measurements inside a building’s circuit breaker panel

or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be connected to the primary

power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specied in this manual

for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than the

instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the category rating

of the measuring system.

3

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power should be

115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is appropriate for your

country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground. This

instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive parts

(including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet and the

recommended three-conductor AC line power cable may result in injury or death.

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential only

and is not to be used as a safety ground. Do not operate in an explosive or ammable atmosphere.

Do not operate the instrument in the presence of ammable gases or vapors, fumes, or nely-divided particulates.

The instrument is designed to be used in oce-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or ammable fumes, gases, vapors, chemicals, or nely-divided particulates.

• In relative humidity conditions outside the instrument’s specications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any liquid can condense

on the instrument.

• In air temperatures exceeding the specied operating temperatures.

• In atmospheric pressures outside the specied altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air ow, even if the air temperatures are within specications.

• In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature range is

0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by this instrument

may be outside specications if the instrument is used in non-oce-type environments. Such environments may include

rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric elds, or strong magnetic elds.

4

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside the

instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be operated,

and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any contamination of the

instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents, acids/bases,

or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in this manual. Not

for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a life-support

device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal adjustments must

be made by qualied service-trained maintenance personnel who are aware of the hazards involved when the instrument’s

covers and shields are removed. Under certain conditions, even with the power cord removed, dangerous voltages may

exist when the covers are removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect

all other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there

are no hazardous voltages present on any conductors by measurements with a properly-operating voltage-sensing device

before touching any internal parts. Verify the voltage-sensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test for both DC and AC voltages. Do not attempt

any service or adjustment unless another person capable of rendering rst aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the circuit

exists.

Fuse replacement must be done by qualied service-trained maintenance personnel who are aware of the instrument’s fuse

requirements and safe replacement procedures. Disconnect the instrument from the power line before replacing fuses.

Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings specied in this manual or on

the back of the instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a re. Failure

to use the specied fuses will void the warranty.

Servicing

5

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air ow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

Safety Symbols

Symbol Description

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

indicates a hazardous situation which, if not avoided, could result in death or serious injury

indicates a hazardous situation which, if not avoided, will result in minor or moderate injury

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

Chassis ground

Earth ground

This is the In position of the power switch when instrument is ON.

This is the Out position of the power switch when instrument is OFF.

is used to address practices not related to physical injury.

Contents

1 Important Information 11

1.1 Particular Precaution Measures 11

1.2 Security Instructions 11

2 Presentation 12

2.1 General 12

2.2 Description 12

2.3 Bar Graph Patterns 15

2.4 Screen Keys 16

2.5 Updating the Internal Software 18

3 Setup and Precautions 19

3.1 Power 19

3.2 Turning On the Instrument 19

3.3 Conguration at Start-Up 19

3.4 Connection to the Measurement Networks 20

3.4.1 Connections: 20

3.4.2 Voltage Measurement 20

3.4.3 Temperature Measurement with a Thermocouple 20

3.4.4 Gauge Strain Measurement 21

3.4.5 Temperature measurement with PT100, PT200, PT500 and PT1000 22

3.4.6 Intensity measurement 22

3.4.7 Earth 23

3.5 Routine Maintenance 23

3.6 Calibration of the osets 24

3.7 Default setup 24

3.8 User mode 24

3.9 Keyboard locking 25

4 Key Functions 26

4.1 « Mode Memory » key 26

4.2 « Mode File » key 26

4.3 « Go/No-go » key 26

4.4 « User manual » key 27

4.5 « Power Analysis » key 27

4.6 « Setup Analyzer » key 27

4.7 « Setup » key 27

4.7.1 Analogical channels 29

4.8 Functions between channels 31

4.8.1 Script editor 32

4.8.2 Error messages 34

4.8.3 Common Errors 34

4.8.4 Script editor advanced use 35

4.9 « Logic channels » key 35

4.10 « F (t) » key 36

4.11 « XY » key 39

4.12 « Numeric » key 40

4.13 « Trigger » key 41

4.14 « Replay » key 42

4.15 « Start/Stop » key 43

4.16 « Screen copy » key 43

4.17 « Home » key 43

7

5 Triggers 44

5.1 Trigger with Combination Analog channel 44

5.1.1 Analog channel (only one threshold) 45

5.1.2 Combination Analog channel (several thresholds) 45

5.1.3 Threshold triggering 47

5.1.4 Parasites 47

5.1.5 Slope trigger 48

5.1.6 Trigger with Logical Channels 48

6 Mathematical Calculations 50

6.1 Denitions 50

6.2 Types de calculations 50

7 Memory Mode 51

7.1 Setup and triggering of the data acquisition 51

7.2 Sampling period 52

7.3 Internal memory _ blocks 53

7.4 Trigger position 53

7.5 Double Trigger Mode 54

7.6 Recording 54

7.7 Memory output 55

8 GO-NOGO Mode 57

8.1 Setup and triggering of the data acquisition 57

8.2 Creation of the caliber 58

8.3 Use of the caliber 59

9 File Mode 60

9.1 Setup and triggering of the data acquisition 60

9.2 Secondary le 61

9.3 Annotation 61

9.4 Compare les and reference 62

9.4.1 Reference le 62

9.4.2 Text File 62

9.4.3 Compare with wall paper 63

9.5 Limitation 64

10 Power Analyzer 65

10.1 GENERAL 65

10.2 Installation: "Setup Analyzer" Menu 65

10.3 Display of the signal 67

10.4 Trigger Menu 68

10.4.1 Parameter acquisition le 68

10.4.2 Acquisition le of the harmonics 69

10.4.3 Recordable parameters 69

10.5 Record 70

10.6 Measurement method 71

11 Canlin Option 72

11.1 Activating the CANLIN option 72

11.2 CAN bus 73

11.2.1 Technical specication 73

11.2.2 CAN Input parameters conguration 74

11.2.3 Output conguration 76

11.2.4 Hardware ltering 77

11.2.5 Power supply output of the CAN connector 78

11.2.6 CANdb input for automatic conguration 79

11.3 LIN Bus 80

11.3.1 Technical specications 80

8

11.3.2 LIN input parameters conguration 81

11.4 Incoming frames real-time viewer 82

11.5 CAN LIN analogue waveform conversion 83

11.5.1 Conversion parameters 83

11.5.2 Converted input parameters 84

11.6 CSV format recording 85

12 File Management 86

12.1 General 86

12.2 Managing the setup les 87

12.2.1 Saving setup les 87

12.2.2 Loading setup les 88

12.3 Managing the data acquisition les 88

12.4 Saving acquisition les 88

12.4.1 Loading acquisition les 88

12.5 Recycle bin 89

13 Printing 90

13.1 Setup and start of the plot 90

13.2 Selection of the printer 91

13.3 Printer for USB connection 92

14 Input/Output 93

14.1 Additional Input / Output Connector 93

14.2 Logical inputs 94

14.2.1 Use 94

14.3 Alarm outputs 94

14.3.1 Use 94

14.4 Power supply output 94

14.5 Extension box for input/output interface 95

14.5.1 Use 97

15 Interface 98

15.1 Ethernet interface 98

15.1.1 General 98

15.2 NTP Protocol 99

15.3 PTP protocol 99

15.4 IRIG synchronization (optional) 100

15.5 WIFI connection 100

15.6 Create a wi hotspot 103

15.7 Operating software 104

15.7.1 File transfer under FTP 104

15.7.2 Display under SeframViewer 105

15.7.3 Control with VNC Viewer: 105

15.8 Send mail 106

15.8.1 Conguration of parameters to send mail 106

15.8.2 Dierent method of sending email 107

15.8.3 Operation 109

15.8.4 Limitation 109

15.8.5 Warning 109

16 Technical Specications 110

16.1 Isolated 1000V inputs 110

16.1.1 General characteristics 110

16.1.2 Voltage record 110

16.1.3 RMS record 110

16.1.4 Derivative and integral record 111

16.1.5 Frequency record 111

9

16.1.6 Counting record 111

16.1.7 Sampling 111

16.1.8 Bandwidth 111

16.1.9 Numeric lters 112

16.2 Isolated 500V inputs 112

16.2.1 General characteristics 112

16.2.2 Voltage recording 112

16.2.3 RMS recording 113

16.2.4 Derivative and integral record 113

16.2.5 Temperature record 113

16.2.6 Frequency record 114

16.2.7 Counting record 114

16.2.8 PWM record 114

16.2.9 Sampling 114

16.2.10 Bandwidth 114

16.2.11 Input impedance 115

16.3 Multiplexed inputs 115

16.3.1 General Characteristics 115

16.3.2 Voltage record 115

16.3.3 RMS record 116

16.3.4 Counting record 116

16.3.5 Derivative and integral record 116

16.3.6 Temperature record 116

16.3.7 Sampling 116

16.3.8 Bandwidth 116

16.4 Strain gauge inputs 117

16.4.1 General characteristics 117

16.4.2 Voltage record 117

16.4.3 RMS record 117

16.4.4 Derivative and integral record 117

16.4.5 Strain gauge record 118

16.4.6 Temperature record 118

16.4.7 Sampling 118

16.4.8 Bandwidth 118

16.5 Additional Inputs / Outputs 119

16.5.1 Logic channels 119

16.5.2 Alarm Outputs 119

16.5.3 16.5.3. External power supply 119

16.6 Circuit analysis 119

16.6.1 Ranges and Accuracies Voltage and Intensity 119

16.6.2 Frequency 120

16.6.3 Power Factor 120

16.6.4 Peak factor 120

16.6.5 Harmonics rate calculated in power analysis 120

16.6.6 Multiple circuits 120

16.7 Display 120

16.8 Memory acquisition 121

16.9 Acquisition on les 121

16.10 Communication interface 121

16.11 Miscellaneous 121

16.11.1 USB connector 121

16.11.2 Screen connector 121

16.12 Environmental conditions DAS 1700/DAS700/DAS701 121

16.12.1 Weather conditions 121

16.12.2 Mains 122

16.12.3 Dimensions and weight 122

16.13 Electromagnetic compatibility, security 122

10

16.13.1 Security, Isolation Class, Installation Category 122

16.14 Miscellaneous 123

16.14.1 Internal saving battery 123

16.15 Accessories 123

16.15.1 Accessories provided with the appliance 123

16.15.2 Accessories and options 123

16.15.3 Consumable items 123

16.16 Battery option 124

16.17 IRIG board option 124

17 Appendix 125

17.1 Information about the caliber of the inputs 125

17.1.1 Inputs of isolated voltage type 125

17.1.2 Inputs of multiplexed card voltage type 126

17.2 Accuracy of the thermocouple measurements 126

17.3 Measurement accuracy for PT100,PT200,PT500,PT1000 127

17.4 Accuracy of instant measurementaccording to the lters 128

17.5 Note on the measurement unites for a guage strain 129

17.5.1 Conversion rules 129

17.5.2 Calculation details 129

18 Service Information 131

19 LIMITED TWO-YEAR WARRANTY 132

Important Information

Please read carefully the following instructions before using your Data Acquisition solution.

1.1 Particular Precaution Measures

• Do not use this product for any purpose else that scheduled.

• To prevent electric shock, observe the following precautions when you are working with dangerous voltages as re-

quested.

• Before use recording device, make sure that the instrument and necessary equipment needed for its use (test leads,

external housing…) are safe to run. Check that the cables are not damaged.

• The instrument may only be used in measurement ranges specied.

• The instrument may only be used in category of measuring circuit for which it was designed.

• The instrument complies with CEM EN 61326. Otherwise, in rare cases, it may happen that an electrical device is

disturbed by the electric eld of the instrument or that that the instrument is disturbed by an electrical device.

• The instrument should only be operate by a qualied personnel.

• Test leads used for connection of the instrument at measurement points should be comply with standard.

• To prevent shock hazards, do not connect or disconnect measuring leads when connected to an electrical voltage

source.

• Do not use in a humid environment.

• Do not use in an explosive environment.

• Operational safety is no longer guaranteed if the instrument is changed or impaired.

• Safety is not guaranteed in this cases, e.g. :

- Damage to the instrument (distortion or breakage)

- After a drop of the instrument

- Measurements / required test of the instrument cannot be performed

- Unfavourable conditions over an extended period of time

- Damage in transportation

- Battery leakage

- Improper use or improper connection

• In case of a failure or maintenance, only a BK Precision servicer engineer should be allowed to operate. In this case,

it is necessary to use spare parts by BK Precision.

• Do not open the instrument if power is applied.

1.2 Security Instructions

For a correct use of the appliance, the users must abide by the security and use requirements as described in this manual.

Specic alert signals appear all along this manual. In case of need, there are alert symbols on the appliance:

You MUST NOT disconnect the protective of the appliance.

Presentation

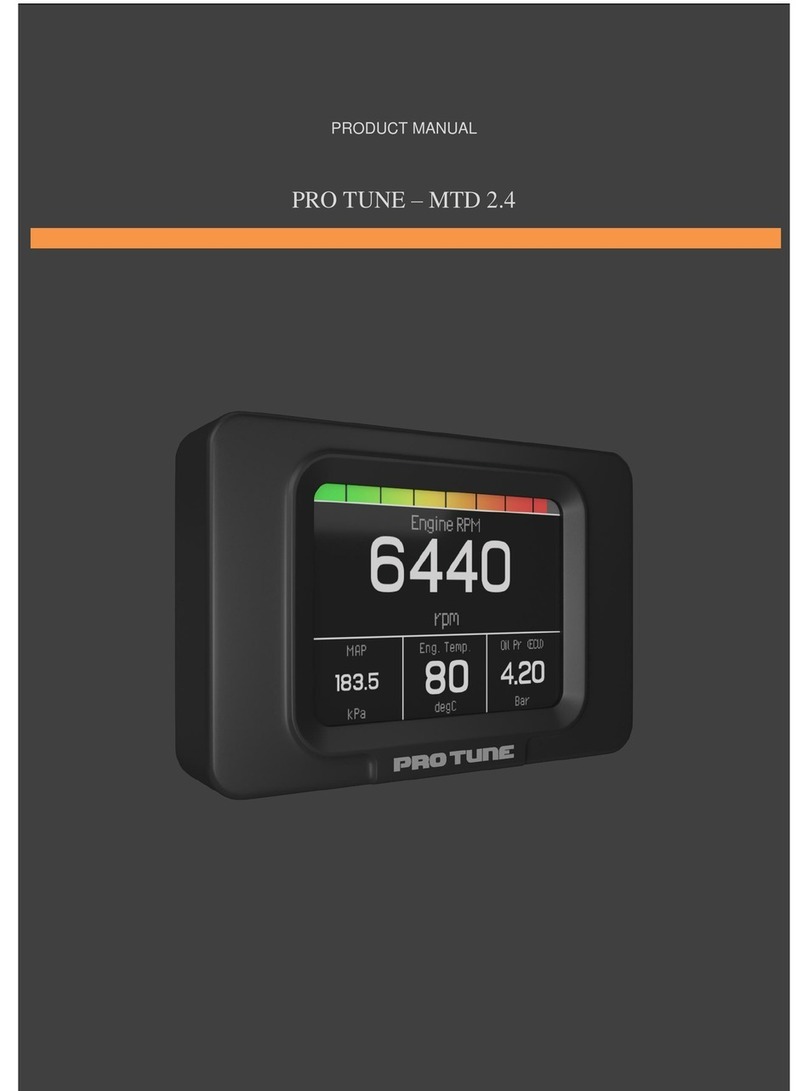

2.1 General

The DAS1700/ DAS700 and DAS701 are programmable recorders that allow to measure and record voltages, intensities,

temperatures etc. as well as on 16 logic channels.

The DAS1700 can be congured with 6 boards maximum (72 channels max), universal isolated or isolated strain gauge,

or non-isolated multiplexed. The DAS700 has not an integrated thermal printer and possesses just 1 board.

You have 4 available types of inputs:

• isolated universal inputs through 6-channel module, up to 6 modules

• non-isolated dierential inputs, multiplexed through 12-channel module, up to 6 modules

• isolated strain gauge through 6-channel modules

• 1000 V inputs through 6-channels modules

Several work modes are available:

• a Memory mode for acquisition on internal fast memory

• a File mode for acquisition on an internal hard drive or USB stick

• a Template mode for acquisition on a pre-recorded template

• a Circuit Analysis mode to make measurements on the circuit

Only the File mode is available for the DAS701.

The "operator-recorder" dialog is made easier thanks to very clear menus on a wide LCD screen. The measurement

parameters can be easily congured: you can do it with the keyboard on the touch screen, with a stylus or with a mouse

and an external keyboard.

The recorders can be fully programmed through Ethernet link.

2.2 Description

The recorders have the same input-output connectors on the rear side.

1. Top Pannel

a. a RJ45 connector for the ETHERNET 10/100/1000BaseT interface

b. a SUB-D 15-pin connector for monitor output

c. 4 USB-2 ports at the rear and 2 USB ports at the edge for the DAS700/DAS701/DAS1700

d. a SUB-D 25-in connector for the 16 logic inputs and the alarm outputs

e. access to the 3 A, B and C input modules (isolated or non-isolated according to the conguration of the appliance)

Presentation 13

f. an earth pole

2. Rear Pannel

a. Power supply ON/OFF switch. In the case of a device with the battery option, this button doesn’t switch ON or

OFF the DAS but only switch on or o the battery charge.

b. a mains plug

c. (Battery option) Device ON/OFF.

d. (IRIG option) BNC plug to connect the external IRIG clock

Isolated universal input modules have 2 safety terminals for each input:

- 1 red terminal: “+” input

- 1 black terminal: “-” input

Non-isolated dierential input modules have 5 screw terminals for each input:

- 2 terminals marked as “+” and “-” for the voltage input

- 2 terminals marked as “I+” and “I-” for the PT100 input

- 1 earth terminal connected to a ground

For other input/output poles, see chapter ??.

Figure 2.1 DAS1700 – DAS700 –DAS701

Presentation 14

Figure 2.2 Description of the Screen

Selection Description

STATUS Acquisition mode, acquisition status or printing status.

VALIDATION Selection of the channels to use.

CHANNEL Name of the currently used channel .

PARAMETERS Name of the modiable parameters and their current values.

PRINTING SCREEN Display for the recorder on screen.

COPY CHANNEL Copies the congurations of a channel to the selected channels.

LOGIC INPUTS Real time status of the logic channels.

MODE Current mode (here Memory mode)

ANALOGIC INPUTS Bargraph of the current values of the inputs.

MAIN MENU Gives access to the main menu to change the mode, the function, access to the notice...

GRAPHICAL ZONE Visualization of the printings.

SHORTCUTS

Presentation 15

2.3 Bar Graph Patterns

The bar graph, located in the screen’s left corner, has two dierent running mode depending on the number of board

connected to the device.

• Less than 3 board connected : All the channels are displayed

• More than three board connected : A new menu appears at the bar graph top letting you choose between three

dierent channels groups

Figure 2.3 Bar Graph Patterns

Visualization modes

Modes Description

SORT BY BOARD Choose the board from which you want to display channels.

CHANNELS ON Only the selected channels will be displayed

FUNCTIONS Only the mathematical channels will be displayed

Presentation 16

2.4 Screen Keys

USER MANUAL key: display of the instruction manual

LOGIC CHANNELS key: conguration of the logic channels

CONFIG key: general conguration of the appliance (language, date and time, alarm outputs, software updates…)

CHANNEL »key: access to the parameters of each channels, access to the functions between channels

VALIDITY key: selection of the channels for each acquisition ( screen, internal memory or le)

SETUP ANALYZER key: conguration of the parameters for circuit analysis

POWER ANALYSIS key: launching measurements of power, harmonics... of the circuit

TRIGGER key: launching parameters of the acquisitions (on paper, internal memory or le according to the current

MODE)

Presentation 17

REPLAY key: display on screen of the acquisitions on internal memory or le, measurement cursors, zoom, calculations

Start/Stop key: launching of the data acquisition under the all MODES

MODE : MEMORY key: conguration of the parameters of measurement record into internal memory

MODE : FILE »key: conguration of the parameters of measurement record on le

MODE : GO/NOGO key: conguration of the parameters of measurement record into internal memory under a template

XY key: real time display on screen of the validated channels in XY mode

F(t) key: real time display on screen of the validated channels

C key: real time display on screen of the digital values of the validated channels

Presentation 18

2.5 Updating the Internal Software

The internal software is regularly updated with its latest evolutions. These updates are available on our website.

To update the software, copy the le provided onto an USB stick. Plug it on one of the USB ports at the rear of the

appliance.

Press the key, then select the Modication Version/Option » parameter line and validate

« Charge ».

A window pops up; select « modify » on the line « Modication Version ».

The internal software copies automatically the required les to the new version. Turn o and on when the update is

nished.

Setup and Precautions

3.1 Power

The recorders work on normalized mains (See chapter Technical specications).

They are designed for indoor use.

MAINS CONNECTION

These instruments must be connected to the mains with the provided cord.

SECURITY

These instruments are security class I according to the classication CEI1010 (NF EN 61010) Security rules for electrical

appliances for measurement, regulation and laboratory.

They must be powered on a 1-phase circuit according to the installation category II (overvoltage category).

GROUNDING

These instruments must be connected to the earth with the provided cord.

It is FORBIDDEN to interrupt the grounding inside or outside the instrument:

it would make the instrument DANGEROUS.

3.2 Turning On the Instrument

You turn the recorders on at the rear of the appliance, by triggering the ON/OFF switch to "I".

Battery option: press the (9) key at the rear of the instrument to start and stop the recorder. This key allows you to

start the appliance by supplying it directly with the battery if the mains switch (indication 7 on the gure) is on 0 or with

a main power supply if the mains key is on 1. The switch (1) must be on 1 to charge the battery when the instrument

is switched on or switched o.

After starting up the internal software, the recorder displays a homepage specifying:

- the software version: Version x.y

- the number of channels: 6, 12, 18 or more

Then switches automatically to a visualization mode « F(t) » or « XY » (oscilloscope).

3.3 Conguration at Start-Up

At power up, les appliance starts with the conguration at the latest stop (voluntarily or after power shortage).

Setup and Precautions 20

If the conguration has changed at the power-up, contact the after-sales service.

If the initial conguration is wrong, you can start with the default conguration:

You must then press several times the top right of the appliance at the start-up until the homepage shows up (at the

place of the main Menu key under normal conditions).

3.4 Connection to the Measurement Networks

3.4.1 Connections:

Strain gauge input mode

1 measurement input –

2 measurement input +

3 ground of the measurement drawer (connection of the cable shield)

4 - pole of the powering of the strain gauge bridge (-1V or -2.5V)

5 control of the powering – of the eld (6-wire mode)

6 + pole of the powering of the strain gauge bridge (+1V or +2.5V)

7 control of the powering + of the eld (6-wire mode)

8 I+ pole

on-isolated dierential input module

1 measurement input +

2 measurement input -

3 ground of the measurement drawer (connection of the cable shield)

4 I+ pole

5 I - pole

3.4.2 Voltage Measurement

Isolated input module 500V: The voltage measurement is made between the red and black poles of the inputs with

wires equipped with male security banana plugs (according to CEI 1010).

Isolated input module 1000V: Voltage measurement is made between the red and white poles.

Non-isolated dierential input module: The voltage measurement is made between the « + » and « - » poles of the

inputs with wires on the screw terminal block.

Isolated strain gauge input module: The voltage measurement is made between the « + » and - » poles of the inputs

with wires on the screw terminal block.

3.4.3 Temperature Measurement with a Thermocouple

Isolated input module: The voltage produced by the thermocouple eect must be measured between the red and black

poles of the concerned input. To guarantee a right measurement, connect directly both ends of the thermocouple cord

on banana plugs. Plug these two banana plugs onto the input you want with respect for the polarity.

This manual suits for next models

2

Table of contents

Popular Data Logger manuals by other brands

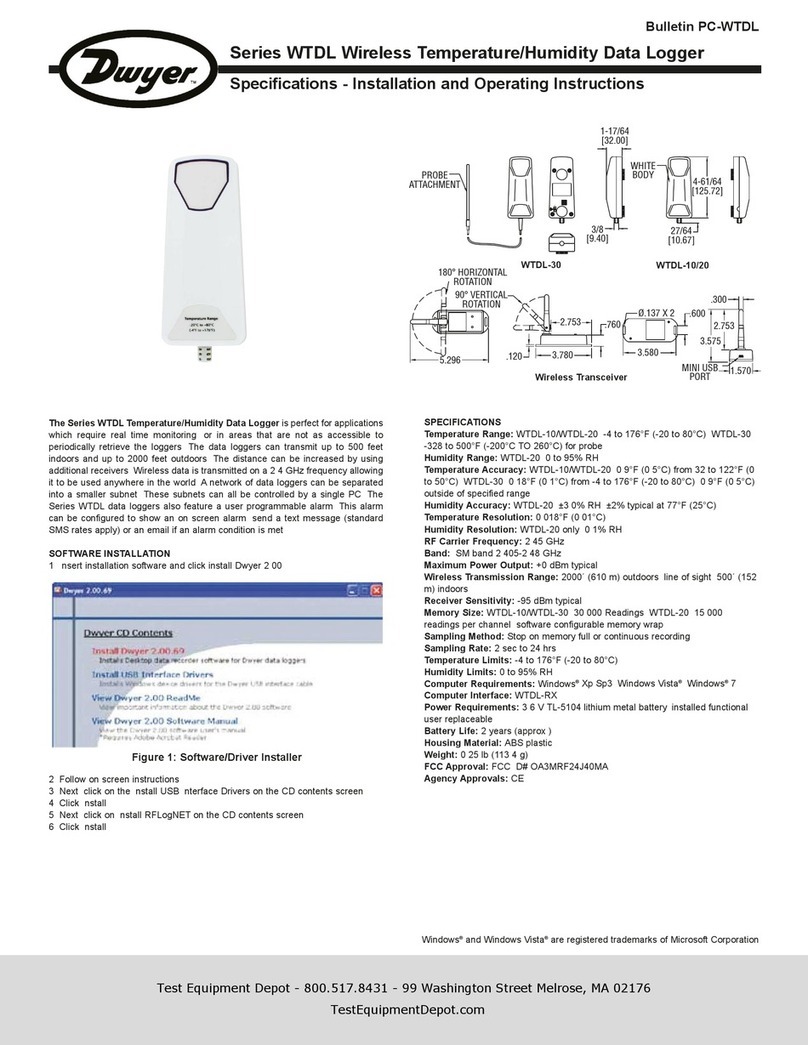

Dwyer Instruments

Dwyer Instruments WTDL-30 Installation and operating instructions

Geonics Limited

Geonics Limited EM61LX2 operating instructions

VOLTCRAFT

VOLTCRAFT SEM5000 CH operating instructions

Capetti Elettronica

Capetti Elettronica WSD10DGII user manual

KeeLog

KeeLog SerialGhost DB-9 user guide

APAR

APAR AR207 operating instructions