Table of Contents

1About this instruction .............................................................................................5

1.1 Scope .....................................................................................................................................................5

1.2 Document conventions........................................................................................................................5

2Safe use of VCM-3 / VCM-3 Ex................................................................................5

2.1 Disclaimer of liability............................................................................................................................5

2.2 Intended use..........................................................................................................................................5

2.2.1 General Information................................................................................................................................................6

2.3 General warnings..................................................................................................................................7

2.3.1 Staff requirements..................................................................................................................................................7

2.4 Grounding information.........................................................................................................................7

3Product Description ................................................................................................8

3.1 Main functionality .................................................................................................................................8

3.2 Overview of the VCM-3 unit .................................................................................................................9

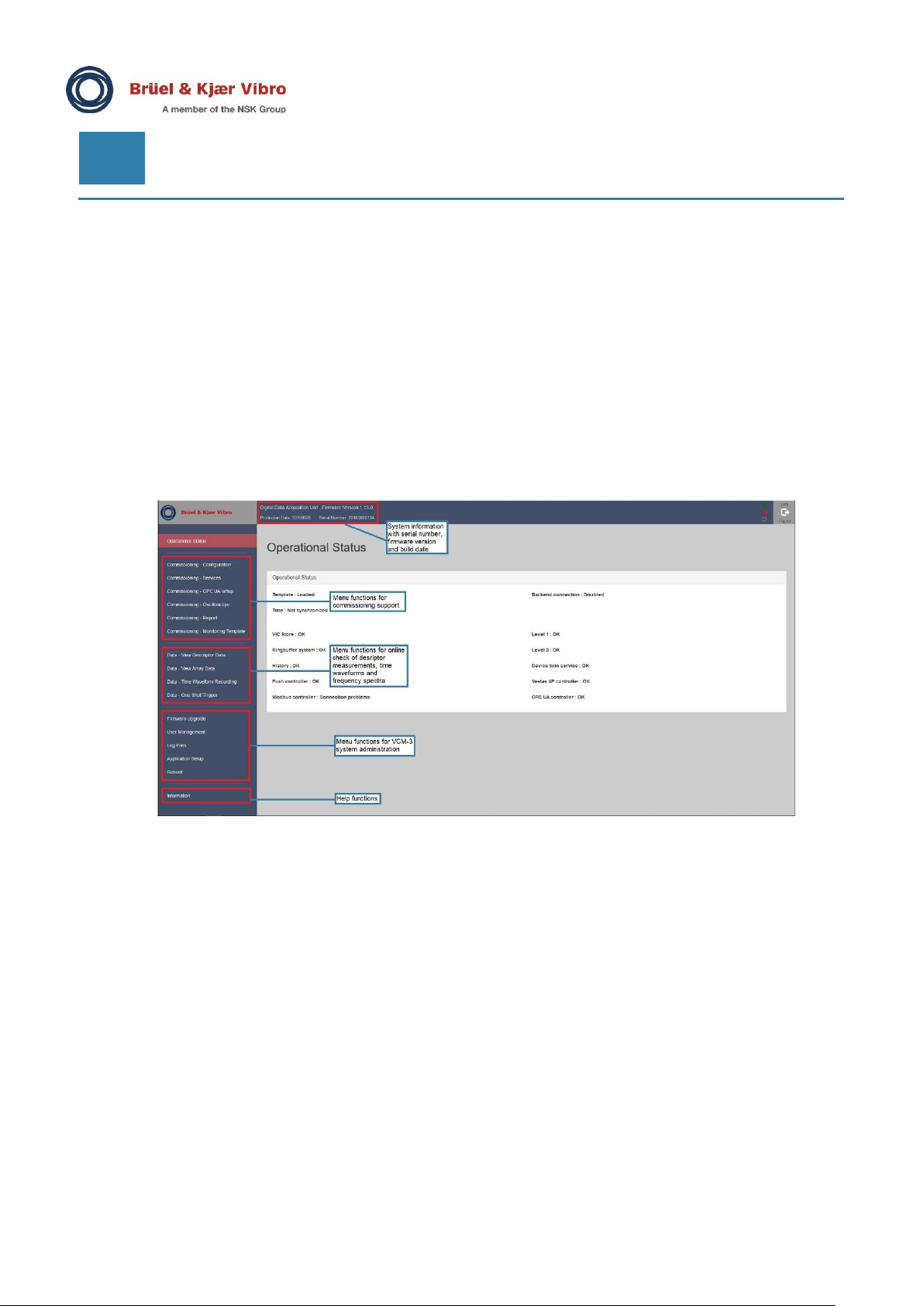

3.3 The VCM-3 Homepage........................................................................................................................10

3.4 Technical specification summary.....................................................................................................11

4Mechanical installation .........................................................................................12

5Basic operation of the VCM-3...............................................................................14

5.1 First time the VCM-3 is powered up..................................................................................................14

5.2 About LED indicators.........................................................................................................................14

5.3 Power Up/Down...................................................................................................................................15

5.4 Reset to default IP address................................................................................................................17

6Power connections................................................................................................18

6.1 Power connection –Supply current .................................................................................................18

6.2 Power connection –External sensor power....................................................................................19

7Termination of sensor signals..............................................................................20

7.1 Electrical Parts....................................................................................................................................20

7.2 Sensor connection terminals ............................................................................................................20

7.3Shielding..............................................................................................................................................21

7.4 Constant current line drive accelerometers (CCS) channel 1-12 ..................................................22

7.5 Brüel & Kjær Vibro AS-247 dual axis accelerometers on channel 11-12.....................................23

7.6 Brüel & Kjær Vibro AS-247 dual axis accelerometers on channel 1-10.......................................24

7.7 Displacement sensors (proximity probes) channel 1-10................................................................25

7.8 Displacement sensors (proximity probes) channel 11 and 12.......................................................26

7.9 Displacement sensors (proximity probes) channel 13-16..............................................................27

7.10 4-20 mA input channel 17-24 .............................................................................................................28

7.11 Speed sensor, proximity switch, PNP and NPN type......................................................................29

7.12 Rogowski probe for current and power measurements.................................................................31

7.13 Digital inputs .......................................................................................................................................32