Brainchild PR Series User manual

PR Series Process Control Card PC201 User Guide

UMPC201A

October 2016

Page 2 of 113

Warning Symbol

The Symbol calls attention to an operating procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in personal injury or damage to or destruction of part

or all of the product and system. Do not proceed beyond a warning symbol until the indicated

conditions are fully understood and met.

Preface

Original equipment manufacturer reser es the right to change information a ailable in this

document without notice. Manufacturer is not liable for any damages incurred to

equipment/personal during installation or use of equipment as explained in this document. User

must acquire sufficient knowledge & skills prior to use the equipment in the application and follow

all the local standards & regulations to meet safety requirements

Copyright

The documentation and the software included with this product are copyrighted 2016 By

Brainchild Electronic Co. Ltd. All rights are reser ed. Brainchild Electronic Co., Ltd. reser es the

right to make impro ements in the products described in this manual at any time without notice.

No part of this manual may be reproduced/ copied/ translated or transmitted in any form or by any

means without the prior written permission of Brainchild Electronic Co .,Ltd. The information we

supply is belie ed to be accurate and reliable as of this printing. Howe er, we assume no

responsibility for its use.

Contact Information

Head Office & Factory

Brainchild Electronic Co. Ltd.

209 Chongyang Road, Nangang Dist.,

Taipei 11573,Taiwan

Tel: +886-2-2786-1299 Fax: +886-2-2786-1395

Website: www.brainchild.com.tw

Email: sales@brainchild.com.tw; ser ice@brainchild.com.tw

China Sales Office

Brainchild Electronic (Kunshan) Co. Ltd.

Room 405, Building #6, Huamin Gentlefolk Garden

No. 13, Qianjin Central Road, Kunshan City, Jiangsu 215300, China

Tel: +86-512-5511-6133 Fax: +86-512-5511-6113

Website: www.brainchild.com.cn

Email: sales@brainchild.com.cn ;

ser ice@brainchild.com.cn

Page 3 of 113

TABLE OF CONTENTS

1

INTRODUCTION ----------------------------------------------------------------------------------------------------- 8

1.1

I

NTRODUCTION

----------------------------------------------------------------------------------------------------- 8

1.2

F

EATURES

----------------------------------------------------------------------------------------------------------- 8

1.3

P

ROCESS

C

ONTROL

C

ARD

------------------------------------------------------------------------------------------ 9

1.3.1

Flexible Configuration of Program ------------------------------------------------------------------ 11

1.3.2

Maximum Capacity of Program --------------------------------------------------------------------- 11

1.3.3

Event Input ----------------------------------------------------------------------------------------------- 11

1.3.4

Programmable Event Outputs ----------------------------------------------------------------------- 11

1.3.5

High ccuracy ------------------------------------------------------------------------------------------- 11

1.3.6

Fast Sampling Rate ------------------------------------------------------------------------------------- 11

1.3.7

Fuzzy Control -------------------------------------------------------------------------------------------- 12

1.3.8

uto-tuning ---------------------------------------------------------------------------------------------- 12

1.3.9

Lockout Protection ------------------------------------------------------------------------------------- 12

1.3.10

Bumpless Transfer -------------------------------------------------------------------------------------- 12

1.3.11

Digital Filter --------------------------------------------------------------------------------------------- 12

1.3.12

Soft-start Ramp ----------------------------------------------------------------------------------------- 12

1.3.13

Pump Control -------------------------------------------------------------------------------------------- 12

1.4

E

XPANSION

I/O

M

ODULES FOR

PID ----------------------------------------------------------------------------- 12

1.4.1

PID Control Module ------------------------------------------------------------------------------------ 12

1.5

S

MART

M

ECHANISM

--------------------------------------------------------------------------------------------- 13

1.6

P

ROCESS

C

ONTROL

C

ARD

PC201

O

RDERING

C

ODE

------------------------------------------------------------- 13

1.7

S

PECIFICATION

---------------------------------------------------------------------------------------------------- 14

1.7.1

Input1 ----------------------------------------------------------------------------------------------------- 14

1.7.2

Input2 ----------------------------------------------------------------------------------------------------- 15

1.7.3

Input3 (Event Input) ------------------------------------------------------------------------------------ 16

1.7.4

Output1/Output2 --------------------------------------------------------------------------------------- 16

1.7.5

larm 1/ larm 2 --------------------------------------------------------------------------------------- 17

1.7.6

Control Mode -------------------------------------------------------------------------------------------- 17

1.7.7

Digital Filter --------------------------------------------------------------------------------------------- 18

2

INSTALLATION AND WIRING----------------------------------------------------------------------------------- 19

2.1

U

NPACKING

------------------------------------------------------------------------------------------------------- 19

2.2

I

NPUT

O

UTPUT

W

IRING

C

ONNECTION

--------------------------------------------------------------------------- 20

2.2.1

Wiring Precautions ------------------------------------------------------------------------------------- 20

2.2.2

PID Control Module ------------------------------------------------------------------------------------ 20

3

PROCESS CONTROL CARD FEATURES ----------------------------------------------------------------------- 22

3.1

C

ONFIGURATION

-------------------------------------------------------------------------------------------------- 22

3.2

C

ONTROLLER

------------------------------------------------------------------------------------------------------ 22

3.3

R

AMP

&

D

WELL

F

UNCTION

-------------------------------------------------------------------------------------- 22

3.4

O

N

F

IELD

C

ALIBRATION

------------------------------------------------------------------------------------------- 22

4

PROCESS CONTROL CARD FUNCTIONS ---------------------------------------------------------------------- 23

4.1

M

ENUS

------------------------------------------------------------------------------------------------------------ 23

4.2

S

TATUS

B

AR

------------------------------------------------------------------------------------------------------- 32

Page of 113

4.3

P

ROCESS

C

ONTROL

C

ARD

C

ONFIGURATION

--------------------------------------------------------------------- 33

4.3.1

Process Control Card Configuration ---------------------------------------------------------------- 34

4.3.1.1

Controller --------------------------------------------------------------------------------------------------------- 35

4.3.1.1.1

Name ---------------------------------------------------------------------------------------------------------- 36

4.3.1.1.2

Parameter ---------------------------------------------------------------------------------------------------- 36

4.3.1.1.3

Channel ------------------------------------------------------------------------------------------------------- 72

4.3.1.1.4

Sample Configuration of Process Control Card ------------------------------------------------------ 76

4.3.1.1.4.1

eat Only ON-OFF Control ------------------------------------------------------------------------- 76

4.3.1.1.4.2

Cool Only ON-OFF Control -------------------------------------------------------------------------- 78

4.3.1.1.4.3

eat Cool Control ------------------------------------------------------------------------------------ 78

4.3.1.1.4.4

eater Break Alarm ---------------------------------------------------------------------------------- 80

4.3.1.1.4.5

Loop Break Alarm ------------------------------------------------------------------------------------ 81

4.3.1.1.4.6

Sensor Break Alarm ---------------------------------------------------------------------------------- 81

4.3.1.1.4.7

Failure Transfer --------------------------------------------------------------------------------------- 82

4.3.1.1.4.8

Bumpless Transfer ----------------------------------------------------------------------------------- 83

4.3.1.1.4.9

PV1 Shift ------------------------------------------------------------------------------------------------ 84

4.3.1.1.4.10

SP1 Range --------------------------------------------------------------------------------------------- 85

4.3.1.1.4.11

Dwell Timer ------------------------------------------------------------------------------------------ 85

4.3.1.1.4.12

Process Alarms -------------------------------------------------------------------------------------- 86

4.3.1.1.4.13

Deviation Alarm ------------------------------------------------------------------------------------- 88

4.3.1.1.4.14

Deviation Band Alarm ------------------------------------------------------------------------------ 90

4.3.1.1.4.15

Event Input ------------------------------------------------------------------------------------------- 91

4.3.1.1.4.16

Second Set Point ------------------------------------------------------------------------------------ 93

4.3.1.1.4.17

Second PID Set --------------------------------------------------------------------------------------- 93

4.3.1.1.4.18

Ramp & Dwell ---------------------------------------------------------------------------------------- 94

4.3.1.1.4.19

Remote Set Point ----------------------------------------------------------------------------------- 96

4.3.1.1.4.20

Differential Control --------------------------------------------------------------------------------- 97

4.3.1.1.4.21

Output Power Limit--------------------------------------------------------------------------------- 98

4.3.1.1.4.22

Digital Filter ------------------------------------------------------------------------------------------ 98

4.3.1.1.4.23

Auto-Tuning and Manual Tuning ---------------------------------------------------------------- 99

4.3.1.2

Ramp & Dwell(Profile) ----------------------------------------------------------------------------------------- 102

4.3.1.2.1

Ramp & Dwell: --------------------------------------------------------------------------------------------- 103

4.3.1.2.2

Segments: --------------------------------------------------------------------------------------------------- 104

4.3.1.2.2.1

Ramp Segment Parameters: ---------------------------------------------------------------------- 105

4.3.1.2.2.2

Dwell Segment Parameters: ---------------------------------------------------------------------- 108

4.3.1.2.2.3

Go Back Segment Parameters: ------------------------------------------------------------------- 108

4.3.1.2.2.4

End Segment Parameters: ------------------------------------------------------------------------- 108

4.3.1.2.2.5

Time to Target Segment Parameters: ----------------------------------------------------------- 109

4.3.1.2.3

Start/End Jobs ---------------------------------------------------------------------------------------------- 109

4.3.1.2.4

Start/Stop Profile(Ramp &Dwell) ---------------------------------------------------------------------- 109

4.4

D

ISPLAY

---------------------------------------------------------------------------------------------------------- 111

5

APPLICATION ----------------------------------------------------------------------------------------------------- 112

5.1

O

VEN

C

ONTROL WITH

Z

ONE

T

EMPERATURE

R

ECORDING

------------------------------------------------------ 112

Page 5 of 113

Table of Figure

Figure 1-1.Fuzzy PID System Block Diagram ...................................................................................................... 9

Figure 1-2.PID System Stability with an without Fuzzy ................................................................................... 10

Figure 2-1.Process Control Car Wiring Diagram ............................................................................................. 21

Figure 3-1.Configuration Layout ..................................................................................................................... 22

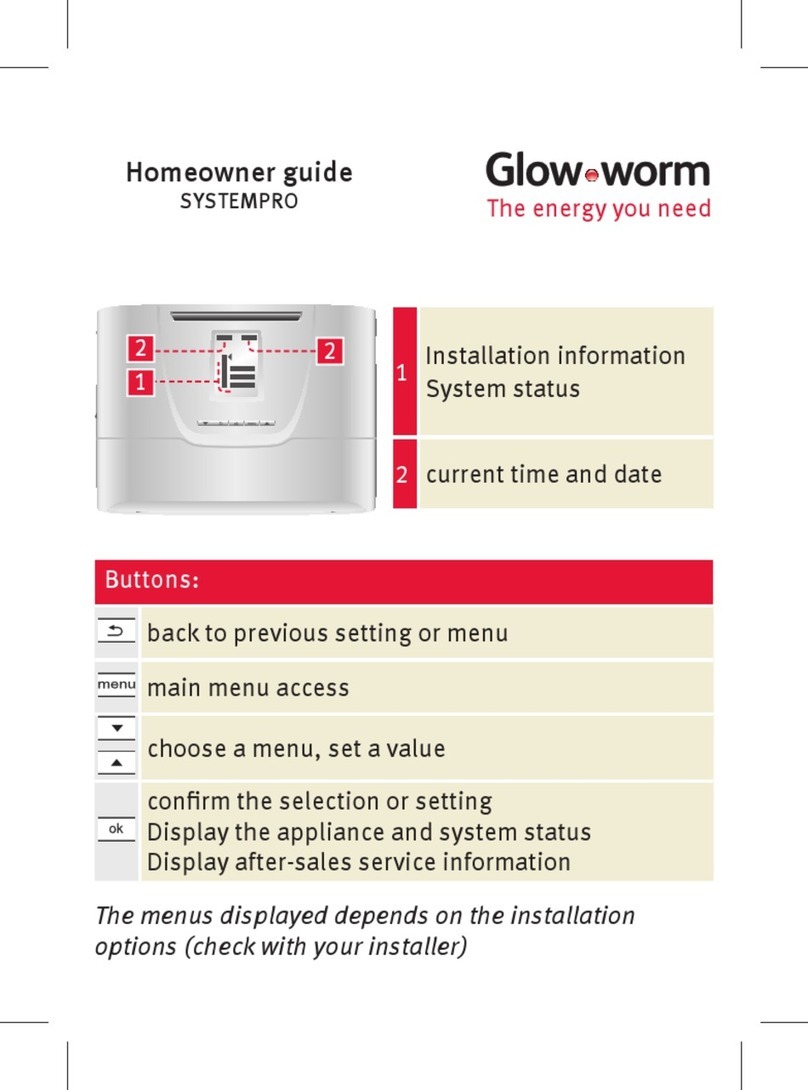

Figure 4-1.Home Screen ................................................................................................................................. 23

Figure 4-2.Menu Screen ................................................................................................................................. 24

Figure 4-3.Real Time Menu ............................................................................................................................ 24

Figure 4-4.Overview Display .......................................................................................................................... 25

Figure 4-5.PID Controller Mo ule Display ....................................................................................................... 25

Figure 4-6.Display Mo es .............................................................................................................................. 26

Figure 4-7.Real Time Alarms .......................................................................................................................... 26

Figure 4-8.Historical Data Screen ................................................................................................................... 27

Figure 4-9.Event History ................................................................................................................................ 28

Figure 4-10.Report Screen ............................................................................................................................. 29

Figure 4-11.More Menu ................................................................................................................................. 29

Figure 4-12.Operate Menu ............................................................................................................................. 30

Figure 4-13.Configuration Layout ................................................................................................................... 31

Figure 4-14.More Menu ................................................................................................................................. 32

Figure 4-15.Status Bar During Logging ............................................................................................................ 32

Figure 4-16.Status Bar During Logging Stoppe ............................................................................................... 32

Figure 4-17.Status Bar uring Logging with Batch function ............................................................................. 32

Figure 4-18.Status Bar During Logging Stoppe with Batch Function ................................................................ 32

Figure 4-19.Tree Type Configuration Layout ................................................................................................... 33

Figure 4-20.Process Control Car Channel Configuration ................................................................................. 35

Figure 4-21.Process Control Car Channel Configuration ................................................................................. 36

Figure 4-22.Process Control Car Configuration Win ow ................................................................................. 37

Figure 4-23.Process Control Car Configuration Win ow for Rea only Parameter ........................................... 37

Figure 4-24.Process Control Car Channel Configuration ................................................................................. 72

Figure 4-25.Log Spee ................................................................................................................................... 74

Figure 4-26.Events with Job ........................................................................................................................... 74

Figure 4-27. Event Configuration Example ...................................................................................................... 76

Figure 4-28.Heat Only ON-OFF Control ........................................................................................................... 77

Figure 4-29.Cool Only ON-OFF Control ............................................................................................................ 78

Figure 4-30. Heater Break Alarm .................................................................................................................... 80

Figure 4-31.Without Bumpless Transfer .......................................................................................................... 83

Figure 4-32.With Bumpless Transfer ............................................................................................................... 84

Figure 4-33.PV1 SHIFT Application.................................................................................................................. 85

Figure 4-34.SP1 Range ................................................................................................................................... 85

Figure 4-35.Dwell Timer ................................................................................................................................. 86

Figure 4-36.Normal Process Alarm ................................................................................................................. 87

Figure 4-37.Latching Process Alarm ................................................................................................................ 87

Figure 4-38.Hol ing Process Alarm ................................................................................................................. 88

Figure 4-39.Latching / Hol ing Process Alarm ................................................................................................. 88

Figure 4-40.Normal Deviation Alarm .............................................................................................................. 89

Figure 4-41.Latching Deviation Alarm ............................................................................................................. 89

Figure 4-42.Hol ing Deviation Alarm .............................................................................................................. 89

Figure 4-43.Latching/Hol ing Deviation Alarm ................................................................................................ 90

Figure 4-44.Normal Deviation Ban Alarm ...................................................................................................... 90

Figure 4-45.Latching Deviation Ban Alarm .................................................................................................... 91

Figure 4-46.Hol ing Deviation Ban Alarm ..................................................................................................... 91

Page 6 of 113

Figure 4-47.Latching/Hol ing Deviation Ban Alarm ....................................................................................... 91

Figure 4-48.Ramp Function ............................................................................................................................ 94

Figure 4-49.Dwell Timer ................................................................................................................................. 95

Figure 4-50.Ramp Accompanie with Dwell Timer .......................................................................................... 96

Figure 4-51.Relationship Between PV1 & PV2 for Differential Control .............................................................. 97

Figure 4-52.Power Limit Function ................................................................................................................... 98

Figure 4-53.Filter Characteristics .................................................................................................................... 99

Figure 4-54.Process Control Mo ule Real time .............................................................................................. 100

Figure 4-55.Auto-Tuning .............................................................................................................................. 100

Figure 4-56.Auto-Tuning In progress ............................................................................................................. 101

Figure 4-57.Manual Tuning In Progress ......................................................................................................... 101

Figure 4-58.Ramp & Dwell Configuration Win ow ........................................................................................ 102

Figure 4-59.Set Point Profile ........................................................................................................................ 103

Figure 4-60.Ramp Segment .......................................................................................................................... 105

Figure 4-61.Hol Back on Dwell .................................................................................................................... 107

Figure 4-62.Hol Back on Positive Ramp ....................................................................................................... 107

Figure 4-63.Hol Back Negative Ramp .......................................................................................................... 107

Figure 4-64.Dwell Segment .......................................................................................................................... 108

Figure 4-65.Go Back Segment....................................................................................................................... 108

Figure 4-66.En Segment ............................................................................................................................. 108

Figure 4-67.Time To Target Segment ............................................................................................................ 109

Figure 4-68.Profile Start/En Job .................................................................................................................. 109

Figure 4-69.Run Profile ................................................................................................................................ 110

Figure 4-70.Profile Running.......................................................................................................................... 110

Figure 5-1.Oven Control with Zone Temperature Recor ing .......................................................................... 112

Figure 5-2. Oven Control with Zone Temperature Recor ing System .............................................................. 113

Page 7 of 113

Table of Table

Table 1-1. Input 1 Characteristics ................................................................................................................... 15

Table 1-2. Input 2 Characteristics ................................................................................................................... 16

Table 1-3. Output Characteristics ................................................................................................................... 16

Table 1-4. SSR Output Characteristics ............................................................................................................. 17

Table 2-1.Environmental Specification ........................................................................................................... 19

Table 4-1.PID Parameter List .......................................................................................................................... 47

Table 4-2.Process Control Car Input Range ................................................................................................... 48

Table 4-3.Range of A1SP ................................................................................................................................ 48

Table 4-4.Range of A2SP ................................................................................................................................ 48

Table 4-5.Range Of SP2 .................................................................................................................................. 48

Table 4-6.Mo e Selection .............................................................................................................................. 49

Table 4-7.Communication Mo e .................................................................................................................... 49

Table 4-8.Communication Protocol ................................................................................................................ 50

Table 4-9.Communication Bau Rate ............................................................................................................. 50

Table 4-10.Communication Data Length ......................................................................................................... 51

Table 4-11.Communication Parity .................................................................................................................. 51

Table 4-12.Communication Stop Bit ............................................................................................................... 51

Table 4-13 Function of AOFN ......................................................................................................................... 52

Table 4-14 Selection of IN1 Type .................................................................................................................... 53

Table 4-15.Display Unit for IN1 & IN2 ............................................................................................................. 53

Table 4-16.Decimal Digit for DP1&DP2 ........................................................................................................... 53

Table 4-17.IN2 Input ...................................................................................................................................... 54

Table 4-18.EIFN Function ............................................................................................................................... 55

Table 4-19.OUT1 Action ................................................................................................................................. 55

Table 4-20.OUT1 & OUT2 Type ....................................................................................................................... 55

Table 4-21.OUT2 Function ............................................................................................................................. 56

Table 4-22.Display Function ........................................................................................................................... 56

Table 4-23. Alarm1 & Alarm 2 Function .......................................................................................................... 57

Table 4-24.Alarm1 & Alarm2 Operation Mo e ................................................................................................ 57

Table 4-25.Alarm1 & Alarm2 Failure Transfer Mo e ....................................................................................... 58

Table 4-26.Auto Tuning ................................................................................................................................. 58

Table 4-27.Sleep Mo e .................................................................................................................................. 58

Table 4-28.PV Mo e Selection ....................................................................................................................... 59

Table 4-29.SP2 Set Point Format .................................................................................................................... 59

Table 4-30 Filter Damping Time Constant of PV .............................................................................................. 59

Table 4-31 Set Point Mo e Selection .............................................................................................................. 60

Table 4-32 SEL Selection ................................................................................................................................ 61

Table 4-33 Default File Selection .................................................................................................................... 61

Table 4-34.Error Co es an Corrective Actions................................................................................................ 68

Table 4-35 PROG CODE .................................................................................................................................. 69

Table 4-36 Mo e ........................................................................................................................................... 70

Table 4-37.Unit Determination for A1SP,A1DV,A1HY ...................................................................................... 70

Table 4-38.Unit Determination for A2SP,A2DV,A2HY ...................................................................................... 71

Table 4-39.RAMP Unit ................................................................................................................................... 71

Table 4-40 .Unit Determination of AOLO & AOHI ............................................................................................ 71

Table 4-41.Heat Cool Control Mo es .............................................................................................................. 79

Page 8 of 113

1 Introduction

1.1 Introduction

Generally most of the furnace applications require Controller and Recorder separately to

control and record the data. Some Furnaces application requires Ramp & Dwell controllers .The

new generation Paperless Recorder pro ides PID Control, Ramp & Dwell Control and Recording in

one de ice by using the new process control Card PC201 . This is a single loop controller for

Furnace applications. This will reduce Cost ,Space ,Wiring required for using controller and

Recorder separately.

1.2 Features

The Process Control Card has lot of unique Features on its hardware and Software. The

unique Features are listed below.

PID Controller, Ramp & Dwell Controller and Recorder 3 in one De ice

Plug and Play I/O Options

18-bit Uni ersal input A-D for PID Control

15-bit output D-A

Fuzzy + PID microprocessor-based control

Fast input sampling rate 200msec for PID Control

Two le el of function complexity

50 Profiles,1000 Segments in Total

Differential control

Auto-tuning and Self Tuning function

Sleep mode function

" Soft-start " Ramp and Dwell timer

Uni ersal inputs( Thermocouple, RTD, mA, VDC )

Analog input for remote set point and CT

E ent input for changing function & set point

Programmable digital filter

Hardware lockout + remote lockout protection

Loop break alarm

Heater break alarm

Sensor break alarm + Bumpless transfer

Pump control

Page 9 of 113

100msec Sampling rate and log speed for Data Acquisition

Real time and Historical Trends for PV and SV

1.3 Process Control Card

The Process Control Card uses Fuzzy Logic plus PID microprocessor technology for its

control. The Fuzzy Logic plus PID microprocessor based technology enables a process to reach a

predetermined set point in the shortest time, with the minimum of o ershoot during power-up or

external load disturbance. The module can be easily plugging into the rear side IO slots of the

paperless recorder. Various control and input parameters can be configured easily by using the

touch screen menus and na igations.

This Process Control Card can be configured by using the Configuration Menu on the

de ice or by using the PC Based Configuration Software.

E en though PID control has been used and pro ed to be an efficient controlling method

by many industries for more than a decade, yet the PID is difficult to deal with some sophisticated

systems such as second and higher order systems, long time-lag systems, during set point change

and/or load disturbance circumstance etc. The PID principle is based on a mathematic modeling

which is obtained by tuning the process. Unfortunately many systems are too complex to describe

in numerical terms precisely. In addition to these, systems may be ariable from time to time. In

order to o ercome the imperfection of PID control, the Fuzzy Technology is introduced.

What is the Fuzzy Control? It works like a good dri er. Under different speeds and

circumstances, he can control a car well with experiences he had before and does not require the

knowledge of kinetic theory of motion. The Fuzzy Logic is a linguistic control which is different from

the numerical PID control. It controls the system by experiences and does not need to simulate the

system precisely as been controlled by PID.

Figure 1-1.Fuzzy PID System Block Diagram

Page 10 of 113

The function of Fuzzy Logic is to adjust PID parameters internally in order to make

manipulation output alue MV more flexible and adapti e to arious processes.PID + Fuzzy Control

has been pro en to be an efficient method to impro e the control stability as shown by the

comparison of cur es shown below.

Figure 1-2.PID System Stability with and without Fuzzy

The Fuzzy Rule works like the below.

If temperature difference is large and temperature rate is large, then MV is large.

If temperature difference is high and temperature rate is small, then MV is small.

By using proprietary Fuzzy modified PID technology the control loop will minimize the

o ershoot and undershoot in a shortest time.

This Process Control Card can be configured as a single set point controller (static mode)

or a ramp and dwell profiling controller (profile mode). The profile mode feature allows the user to

program up to 50 profiles with up to 32 free format Segments (ramp, dwell, jump or end) each. The

total segments a ailable for the product are 1000 segments.

The Process Control Card contains the following features.

Page 11 of 113

1.3.1

Flexible Configuration of Program

There are up to 32 segments can be defined for a profile. Each segment can be configured

as a ramp or a dwell (soak) segment or defining a repeat number of cycles at arbitrary location

within the profile and finally terminated by an end segment. The user can edit a currently running

profile.

1.3.2

Maximum Capacity of Program

There are at most 50 Profiles can be defined and 1000 segments totally a ailable for all

profiles. Each Profile can contain maximum of 32 Segments and limited to 1000 Segments in Total.

1.3.3

Event Input

The E ent input feature allows the user to select one of eight functions below.

Enter Profile Run Mode

Enter Profile Hold Mode

Abort Profile Mode

Enter Manual Mode

Perform Failure Transfer

Enter Off Mode

Ad ance to the next segment

Select second set of PID alues

1.3.4

Programmable Event Outputs

Up to 3 Relays are configurable for e ent outputs and the state of each output can be

defined for each segment and end of profile.

1.3.5

High Accuracy

This Process Control Card is manufactured with custom designed ASIC(Application

Specific Integrated Circuit ) technology which contains a 18-bit A to D con erter for high resolution

measurement ( true 0.1 F resolution for thermocouple and PT100 ) and a 15-bit D to A con erter for

linear current or oltage control output. The ASIC technology pro ides impro ed operating

performance with low cost and enhanced reliability and higher density.

1.3.6

Fast Sampling ate

The sampling rate of the input A to D con erter reaches 5 times/second (200msec). The

fast sampling rate allows this Process Control Card to control fast processes.

Page 12 of 113

1.3.7

Fuzzy Control

The function of Fuzzy control is to adjust PID parameters from time to time in order to

make manipulation output alue more flexible and adapti e to arious processes. The results are to

enable a process to reach a predetermined set point in the shortest time with the minimum of

o ershoot and undershoot during power-up or external load disturbance.

1.3.8

Auto-tuning

The auto-tuning function allows the user to simplify initial setup for a new system. A

cle er algorithm is pro ided to obtain an optimal set of control parameters for the process, and it can

be applied either as the process is warming up ( cold start ) or as the process has been in steady

state ( warm start ).

1.3.9

Lockout Protection

According to actual security requirement, a password is pro ided to pre ent the unit from

being changed abnormally.

1.3.10

Bumpless Transfer

Bumpless transfer allows the controller to continue to control by using its pre ious alue as

the sensor breaks. Hence, the process can be well controlled temporarily as like the sensor is

normal.

1.3.11

Digital Filter

A first order low pass filter with a programmable time constant is used to impro e the

stability of process alue. This is particularly useful in certain application where the process alue is

too unstable to read.

1.3.12

Soft-start amp

The ramping function is performed during power up as well as any time the set point is

changed. It can be ramping up or ramping down. The process alue will reach the set point with a

predetermined constant rate.

1.3.13

Pump Control

In addition the fast sampling rate, this Process Control Card has superior noise rejection

capability. So it can be used for pressure control of a Pump which is dri en by Variable Frequency

Dri es.

1.4 Expansion I/O Modules for PID

The Paperless Recorder ha e the option to use PID function on it by using the

Process Control Card in to it on the one of the 4 rear slots .

1.4.1

PID Control Module

This module is useful for single loop PID Control. This consists of Two

Signal Inputs, one E ent Input and control output and Alarm output as per the specification.

Page 13 of 113

1.5 mart Mechanism

The data is recorded in manufacturer special binary format. It is not possible to manipulate

the data. This feature guarantees the security and reliability of the recorded data .

1.6 Process Control Card PC201 Ordering Code

PC201- □ □ □ □

A B C D

A: Output 1

0: None

1: Relay 2A/240VAC

2: Pulse voltage to drive SSR, 5V/30 A

3: Isolated 4-20 A/0-20 A (OM95-3)

4: Isolated 1-5V/0-5V (OM95-4)

5: Isolated 0-10V (OM95-5)

6: Triac output 1A/240VAC,SSR

C: Pulse voltage to drive SSR, 14V/40 A (OM94-7)

B: Output 2

0: None

1: Relay 2A/240VAC

2: Pulse voltage to drive SSR, 5V/30 A

3: Isolated 4-20 A/0-20 A (OM95-3)

4: Isolated 1-5V/0-5V (OM95-4)

5: Isolated 0-10V (OM95-5)

6: Triac output 1A/240VAC,SSR

7: Isolated 20VDC/25 A power supply (DC94-1)

8: Isolated 12VDC/40 A power supply (DC94-2)

9: Isolated 5VDC/80 A power supply (DC94-3)

C: Pulse voltage to drive SSR, 14V/40 A (OM94-7)

C: Alarm 1

0: None

1: For C relay 2A/240VAC

D: Alarm 2

0: None

1: For A relay 2A/240VAC

Page 1 of 113

1.7 pecification

1.7.1

Input1

Resolution: 18 bits

Sampling Rate: 5 times / second

Maximum Rating: -2 VDC minimum, 12 VDC maximum (1 minute for mA input)

Temperature Effect: 1.5uV/°C for all inputs except mA input, ±3.0uV/°C for mA input

Sensor Lead Resistance Effect:

T/C: 0.2uV/ohm;

3-wire RTD: 2.6°C/ohm of resistance difference of two leads;

2-wire RTD: 2.6° C/ohm of resistance sum of two leads

Burn-out Current: 200nA

Common Mode Rejection Ratio (CMRR): 120dB

Normal Mode Rejection Ratio (NMRR): 55dB

Sensor Break Detection:

Sensor Open for TC, RTD and mV inputs

Sensor short for RTD input

Below 1 mA for 4-20 mA input,

Below 0.25V for 1 - 5 V input,

Una ailable for other inputs.

Sensor Break Responding Time:

Within 4 seconds for TC, RTD and mV inputs,

0.1 second for 4-20 mA and 1 - 5 V inputs.

Characteristics:

Type Range Accuracy @ 25°C Input Impedance

J -120°C to 1000°C ( -184°F to 1832°F )

±2°C 2.2 MΩ

K -200C to 1370 C ( -328°F to 2498°F ) ±2°C 2.2 MΩ

T -250°C to 400°C ( -418°F to 752°F ) ±2°C 2.2 MΩ

E -100°C to 900°C( -148°F to 1652°F ) ±2°C 2.2 MΩ

B 0°C to 1800°C( 32°F to 3272°F ) ±2°C( 200°C to 1800° C )

2.2 MΩ

Page 15 of 113

Type Range Accuracy @ 25°C Input Impedance

R 0°C to 1767.8°C( 32°F to 3214°F ) ±2°C 2.2 MΩ

S 0°C to 1767.8°C( 32°F to 3214°F ) ±2°C 2.2 MΩ

N -250°C to 1300°C( -418°F to 2372°F ) ±2°C 2.2 MΩ

L -200°C to 900°C( -328°F to 1652°F ) ±2°C 2.2 MΩ

PT100(DIN)

-210°C to 700°C ( -346°F to 1292°F ) ±0.4°C 1.3KΩ

PT100(JIS) -200°C to 600°C( -328°F to 1112°F ) ±0.4°C 1.3Ω

mV -8mV to 70mV ±0.05% 2.2 MΩ

mA -3mA to 27mA ±0.05% 70.5Ω

V -1.3V to 11.5V ±0.05% 302KΩ

able 1-1. Input 1 Characteristics

1.7.2

Input2

Resolution: 18 bits

Sampling Rate: 5 times / second

Maximum Rating: -2 VDC minimum, 12 VDC maximum (1 minute for mA input)

Temperature Effect: 1.5uV/°C for all inputs except mA input, ±3.0uV/°C for mA input

Common Mode Rejection Ratio (CMRR): 120dB

Normal Mode Rejection Ratio (NMRR): 55dB

Sensor Break Detection:

Below 1 mA for 4-20 mA input,

Below 0.25V for 1 - 5 V input,

Una ailable for other inputs.

Sensor Break Responding Time: 0.5 Seconds

Characteristics:

Type Range Accuracy @ 25°C Input Impedance

CT94-1

0.0 to 50.0 A ±2% of Reading ±0.2A

302KΩ

Page 16 of 113

Type Range Accuracy @ 25°C Input Impedance

mA -3mA to 27mA

±0.05% 70.5Ω+(0.8V/Input Current)

V -1.3V to 11.5V

±0.05% 302KΩ

able 1-2. Input 2 Characteristics

1.7.3

Input3 (Event Input)

Logic Low: -10V minimum, 0.8V maximum.

Logic high: 2V minimum, 10V maximum

External pull-down Resistance: 400 KΩ maximum

External pull-up Resistance: 1.5 MΩ minimum

Functions: Select second set point and/or PID, Reset alarm 1 and/or alarm 2,

Disable output 1 and/or output 2, Remote lockout.

1.7.4

Output1/Output2

Relay Rating:

2A/240 VAC, life cycles 200,000 for Resisti e load

Pulsed Voltage:

Source Voltage 5V, current limiting resistance 66Ω

Linear Output Characteristics:

Type Zero Tolerance

Span Tolerance

Load Capacity

4 to 20mA

3.8-4 mA 20-21 mA 500 Ω max

0 to 20mA

0 mA 20-21 mA 500 Ω max

0 to 5V 0 V 5 -5.25 V 10KΩ min

1 to 5V 0.95 to 1V 5 -5.25 V 10KΩ min

0 to 10V 0 V 10 - 10.5 V 10KΩ min

able 1-3. Output Characteristics

Linear Output

Resolution: 15 bits

Output Regulation: 0.01 % for full load change

Output Settling Time: 0.1 sec. (stable to 99.9 %)

Isolation Breakdown Voltage: 1000 VAC

Page 17 of 113

Temperature Effect: ±0.0025 % of SPAN /°C

Triac (SSR) Output

Rating: 1A / 240 VAC

Inrush Current: 20A for 1 cycle

Min. Load Current: 50 mA RMS

Max. Off-state Leakage: 3 mA RMS

Max. On-state Voltage: 1.5 V RMS

Insulation Resistance: 1000 MΩ minimum at 500 VDC

Dielectric Strength: 2500 VAC for 1 minute

Type

Tolerance

Maximum Output Current

Ripple Voltage

Isolation Barrier

20V ±0.5 V 25 mA 0.2 Vp-p 500 VAC

12V ±0.3 V 40 mA 0.1 Vp-p 500 VAC

5V ±0.15 V 80 mA 0.05 Vp-p 500 VAC

able 1-4. SSR Output Characteristics

1.7.5

Alarm 1/ Alarm 2

Alarm 1 Relay: Form A or Form B, Max. Rating 2A/240VAC, life cycles 100,000 for

resisti e load.

Alarm 2 Relay: Form A, Max. Rating 2A/240VAC, life cycles 200,000 for resisti e load.

Alarm Mode: Normal, Latching, Hold, Latching / Hold.

Dwell Timer: 0 - 6553.5 minutes

Alarm Functions: Dwell timer, De iation High / Low Alarm, De iation Band High / Low

Alarm, PV1 High / Low Alarm, PV2 High / Low Alarm, PV1 or PV2 High

/ Low Alarm, PV1-PV2 High / Low Alarm, Loop Break Alarm, Sensor

Break Alarm.

1.7.6

Control Mode

Output 1: Re erse (heating) or direct (cooling) action

Output 2: PID cooling control, cooling P band 1~255% of PB

ON-OFF: 0.1 - 100.0(F) hysteresis control (P band = 0)

P or PD: 0 - 100.0 % offset adjustment

Page 18 of 113

PID: Fuzzy logic modified Proportional band 0.1 ~ 900.0°F, Integral time: 0 - 1000

Seconds, Deri ati e time 0 - 360.0 seconds

Cycle Time: 0.1 - 100.0 seconds

Manual Control: Heat (MV1) and Cool (MV2)

Auto-tuning: (MV2) Cold start and warm start

Self-tuning: Select None and YES

Failure Mode: Auto-transfer to manual mode while sensor break or A-D con erter damage

Sleep Mode: Enable or Disable

Ramping Control: 0 - 900.0°F/minute or 0 - 900.0°F/hour ramp rate

Power Limit: 0 - 100 % output 1 and output 2

Pump / Pressure Control: Sophisticated functions pro ided

Remote Set Point: Programmable range for oltage or current input

Differential Control: Control PV1-PV2 at set point

1.7.7

Digital Filter

Function: First Order

Time Constant: 0, 0.2, 0.5, 1, 2, 5, 10, 20, 30, 60 seconds programmable

Page 19 of 113

2 In tallation and Wiring

Some times Dangerous oltages capable of causing death are present in this instrument. Before

doing installation or any troubleshooting procedures the power to the equipment must be switched off and

isolated. Units suspected of being faulty must be disconnected and remo ed to a properly equipped

workshop for testing and repair. Component replacement and internal adjustments must be made by a

qualified maintenance person only.

To minimize the possibility of fire or shock hazards, do not expose this instrument to rain or

excessi e moisture

Do not use this instrument in areas under hazardous conditions such as excessi e shock,

ibration, dirt, moisture, corrosi e gases or oil. The ambient temperature of the areas should not

exceed the maximum rating specified in the specification

2.1 Unpacking

Upon receipt of the shipment remo e the unit from the carton and inspect the unit for

shipping damage. If any damage found then contact local representati e immediately. Note the

model number, serial number for future reference when corresponding with our ser ice center. The

serial number (S/N) is labeled on the box and the housing of Paperless Recorder

Remo e stains from this equipment using a soft, dry cloth. Do not use harsh chemicals,

olatile sol ents such as thinner or strong detergents to clean the equipment in order to a oid

deformation.

The Paperless Recorder is designed for indoor use and not in any hazardous area. It

should be kept away from shock, ibration, and electromagnetic fields such as ariable frequency

dri es, motors and transformers. It is intended to operate under the following en ironmental

conditions.

Environmental Parameter Specification

Operating Temperature 0°C to 50 °C

Humidity 20% to 90% H(Non-condensing)

Altitude 2000 M Maximum

able 2-1.Environmental Specification

Page 20 of 113

2.2 Input Output Wiring Connection

2.2.1

Wiring Precautions

Sometimes Dangerous oltages capable of causing death are present in this

instrument. Before doing installation or any troubleshooting procedures the power to the equipment

must be switched off and isolated. Units suspected of being faulty must be disconnected and

remo ed to a properly equipped workshop for testing and repair. Component replacement and

internal adjustments must be made by a qualified maintenance person only.

Utmost Care must be taken to ensure that the maximum oltage rating specified on

the label is not exceeded.

It is recommended to use an external fuse or an external switch rated at 2A/250

VAC for panel mount type wiring.

The tightening torque on the Screw terminals should not exceed 0.4 N-m (3.6 Lb-in

or 4.0 Kg F-cm).

Except Thermocouple Wiring, all other wires used to be Standard Copper

Conductor With maximum Gauge of 18AWG

Grounding must be connected prior to turning on the Equipment with minimum of

1.6mm diameter conductor for protecti e grounding.

2.2.2

PID Control Module

This is a single loop PID Control Module which consists of Uni ersal Input.

The Modules needs to be inserted to the rear slots or removed from the rear slots at

the Power OFF condition. Failure to do so may cause damage to the module or device or

both. The De ice will automatically detect the Module at Power ON, once it is inserted in to the rear

slots.

The Module output can be configured by using the configuration Menu. The configuration

Menu can be reached by pressing Menu and then pressing More and then pressing Config key. It

will display a tree type configuration layout for easy user configuration. By using Up/Down Key and

Enter Key, PID Controller and Profile configuration window can be reached. In this window the user

can configure the Controller parameters and profiles of PID Control Module. The user can select the

desired output type and other parameters for analog output in this window.

Other manuals for PR Series

1

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

IBC control

IBC control VariMax100 manual

SimTech

SimTech SimCom SIM5218E Hardware design

PROPOINT

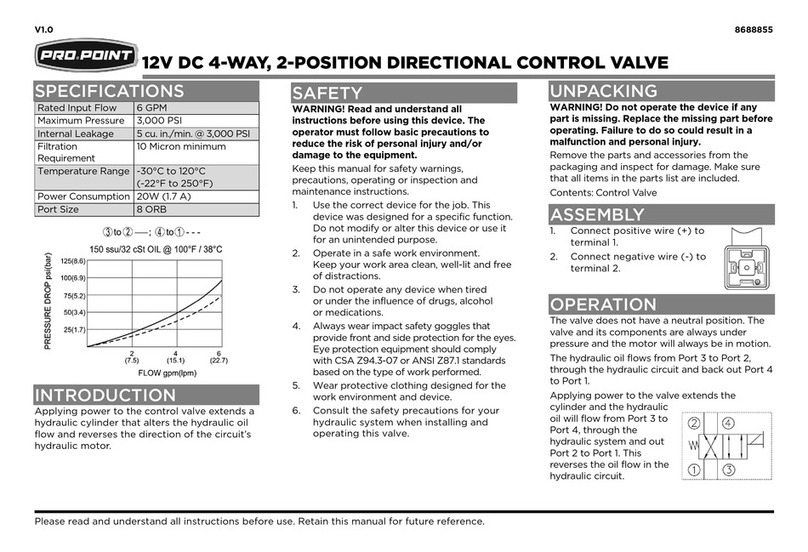

PROPOINT 8688855 quick start guide

SIGMA TEK

SIGMA TEK KL 180 instruction manual

Heath Zenith

Heath Zenith DUAL BRITE SL-5597 user manual

Spraying Systems

Spraying Systems TeeJet Technologies AEROS 9040 user guide