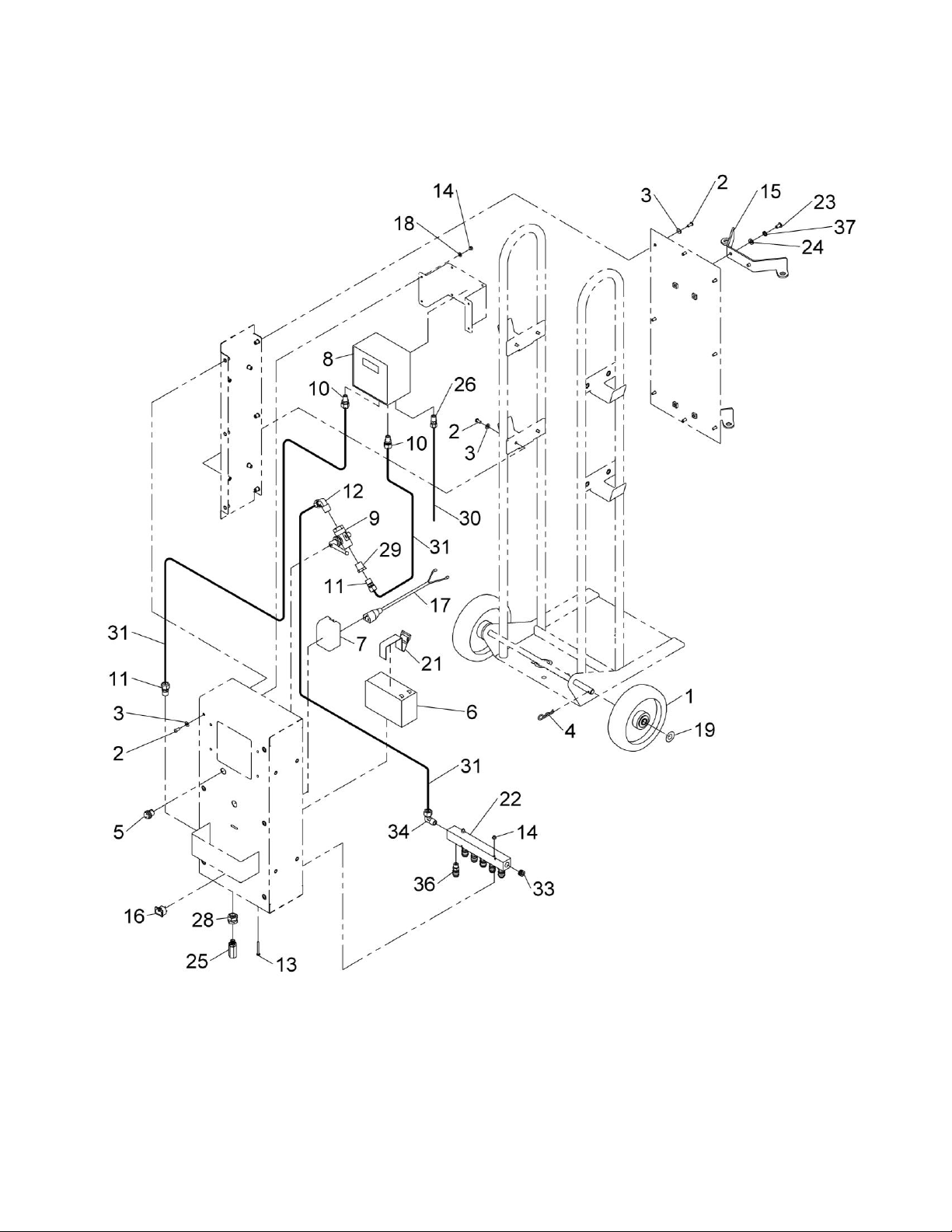

DIGITAL INFLATOR OPERATING INSTRUCTIONS ________________________________

___________________________________________________________________________

1 Decrease Key

2 Increase Key

3 Top-Off Key

4 Nitrogen Purge Cycle Key

___________________________________________________________________________

Converting Air Filled Tires to Nitrogen

1. Turn the Fill Control Valve handle to the STOP position and flip the ON/OFF button to turn on power.

2. Connect the output hoses to the valve stems of the tires and ensure that leaks do not exist.

3. Set the tire pressure with the and buttons on the front panel.

Note: The target pressure should be the vehicles recommended tire pressure found on the sticker inside

the driver’s door jamb or inside the fuel access door.

4. Turn the Fill Control Valve handle to FILL.

5. Press the button to start the nitrogen conversion.

6. When the alarm sounds the cycle is complete.

7. Turn the Fill Control Valve handle to STOP and remove hoses from valve stems.

8. Flip the ON/OFF button to turn inflator off.

Filling Tires to Two Different Pressures

Some vehicles require two different tire pressure settings from the front tires to the rear. In this example, the front

tires require 32 psi while the rear tires require 40 psi.

1. Go through steps 1 through 6 above in “Converting Air-filled Tires to Nitrogen” using the lowest of the two

pressures (32 psi) as the target pressure.

2. After finishing step 6, turn Fill Control Valve handle to STOP. Disconnect the hoses from the tires that are

at their final pressure (in this example the front tires are at 32 psi).

3. Change the target pressure for the remaining two tires using the or buttons (in this example press

the button to 40 psi).

4. Turn the Fill Control Valve handle to FILL position.

5. Press the button.

6. When the alarm sounds the cycle is complete.

7. Turn the Fill Control Valve handle to STOP and remove hoses from valve stems.

8. Flip the ON/OFF button to turn inflator off.

To Top-off Tires Already Filled with Nitrogen

1. Turn the Fill Control Valve handle to the STOP position and flip the ON/OFF button to turn on power.

2. Connect the output hoses to the valve stems of the tires and ensure that leaks do not exist.