TABLE OF CONTENTS _______________________________________________________

SAFETY INSTRUCTIONS 1

DEFINITIONS 1

INSTALLATION INSTRUCTIONS 2

OPERATING INSTRUCTIONS 2,3

MAINTENANCE 3

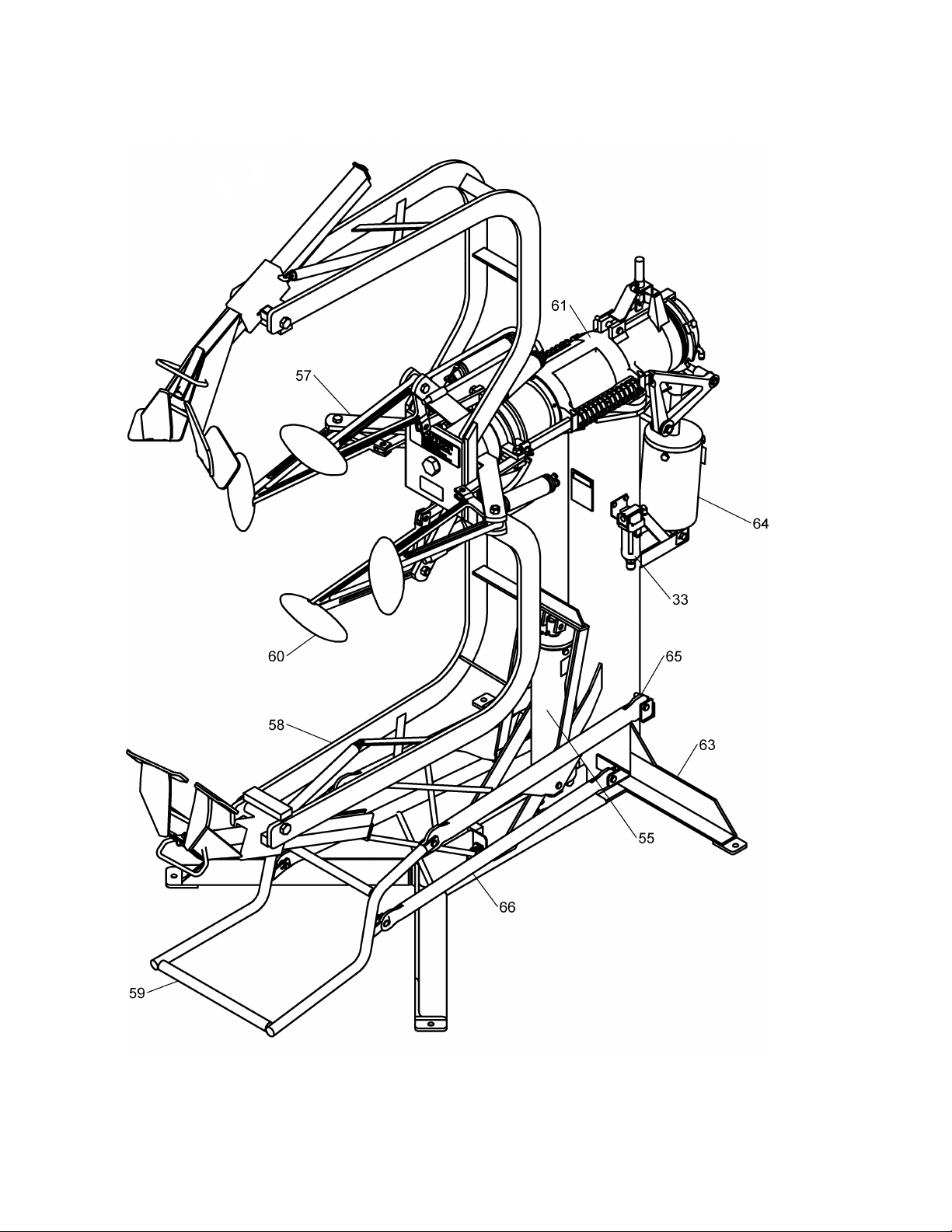

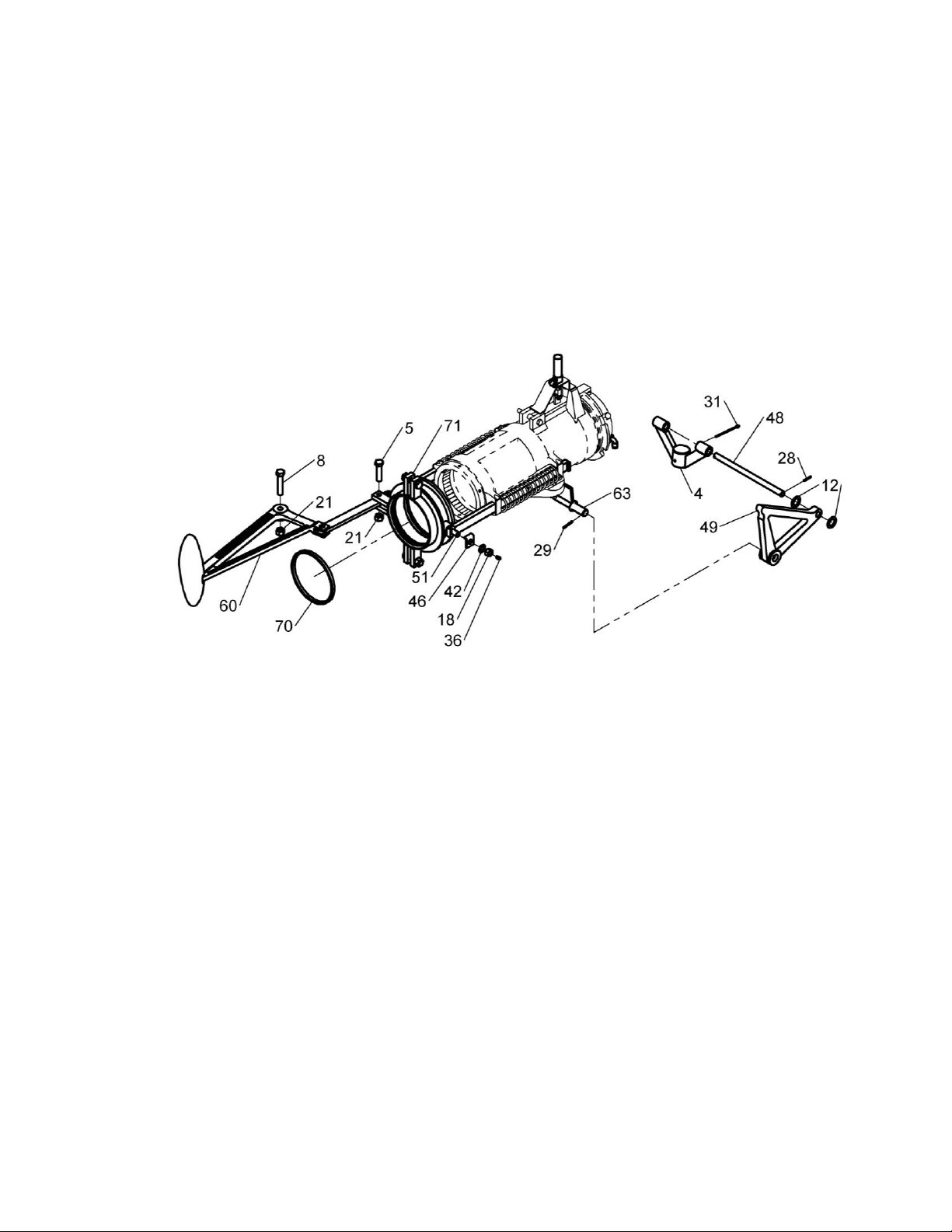

REPAIR PARTS 4-14

REPAIR PARTS LIST 9-14

WARRANTY 15

SAFETY INSTRUCTIONS _____________________________________________________

▪NEVER allow unauthorized personnel to operate this product.

▪NEVER use this product for anything other than its intended use.

▪THOROUGHLY train new employees in the proper use and care of this product.

▪PROHIBIT unauthorized personnel from being in shop area while this product is in use.

DEFINITIONS _______________________________________________________________

▪CAUTION: Indicates a potentially hazardous situation, which if not avoided, may result in damage to

property or minor personal injury.

▪HAZARD: A source of potential injury to a person.

▪MAINTENANCE: Those actions that preserve the correct and proper conditions under which the machine

shall be used. This may include adjustment, replacement of wear items, lubrication and cleaning, but not

modifications or repair of damage.

▪MAY: This word is understood to be permissive.

▪MUST: This word is understood to be mandatory.

▪OPERATION: The correct and proper use of the machine as described in this manual.

▪SAFETY ALERT SYMBOL: A symbol that indicates a potential personal safety hazard. It is composed of

an equilateral triangle surrounding an exclamation point.

▪SHALL: This word is understood to be mandatory.

▪SHOULD: This word is understood to be advisory.

▪WARNING: Indicates a potentially hazardous situation, which if not avoided, may result in death or

serious personal injury.