10

EASTMAN

count.Pressnumberofpliesdesired.Pressok?.Presssave

toload program.). Set edge control to AUTO by closing the

edge control actuator. Set cradle control to FEED ON

position. Program ply height and feed delay if required.

Manually drive the spreader into the right (stationary)

catcher.Stopwhenthepinbardropsontothefoldingblade.

This is your right end marker. Set spread length (Press

length.Presslengthposition.Pressok?.Presssavetoload

program.).PressthegreenSTARTbuttontobeginautomatic

spreading.Formanualspreading,use thethrottle.

Machine travels slowly to the right, then accelerates after

leaving end slowdown section. As spreader reaches end

slowdown section the spreader slows, the folding blades

engage catcher. As spreader enters catcher the cradle

allows a small amount of slack for a relaxed fold. The

spreaderthenreachestheendmarker,stoppingandrevers-

ingthespreader tocompletethefold.Asmachineleavesthe

catcher,the cradle compensates for slack cloth dispensed

(feed delay) and returns to the left. The elevator will raise

(step)asspreaderreturns.

Spreader will continue this sequence automatically until

manuallystopped, predeterminednumberofplieshavebeen

reached or machine is out of cloth.

IMPORTANT

To stop the

CR 500

at any point during spreading,

either:

- Twistandreleasethrottle.

- Press red “STOP” button on MAIN CONTROL

panel.

- Hitthe Main Power Button (red).

Face Up Spreading

(One-WayKnifeboxandMoveableCatcherRequired)

Caution:Knifeboxequippedwithsharpknife.

Warning: Safety Cams should always be checked for

proper operation before operating the

spreader..

AfterSafetyCamshavebeencheckedforproperoperation,

pulltheMainPowerbuttononandpressthegreenMainDrive

buttontoactivatepowertoallcircuits.SelectFaceUpmode

(Pressprogram.Pressmodetoselectfaceupmode.Press

savetoloadprogram.).Threadthespreader.Clampandcut

the beginning edge of the fabric. Set the counter to the

number of plies desired to spread (Press program. Press

count.Pressnumberofpliesdesired.Pressok?.Presssave

toload program.). Set edge control to AUTO by closing the

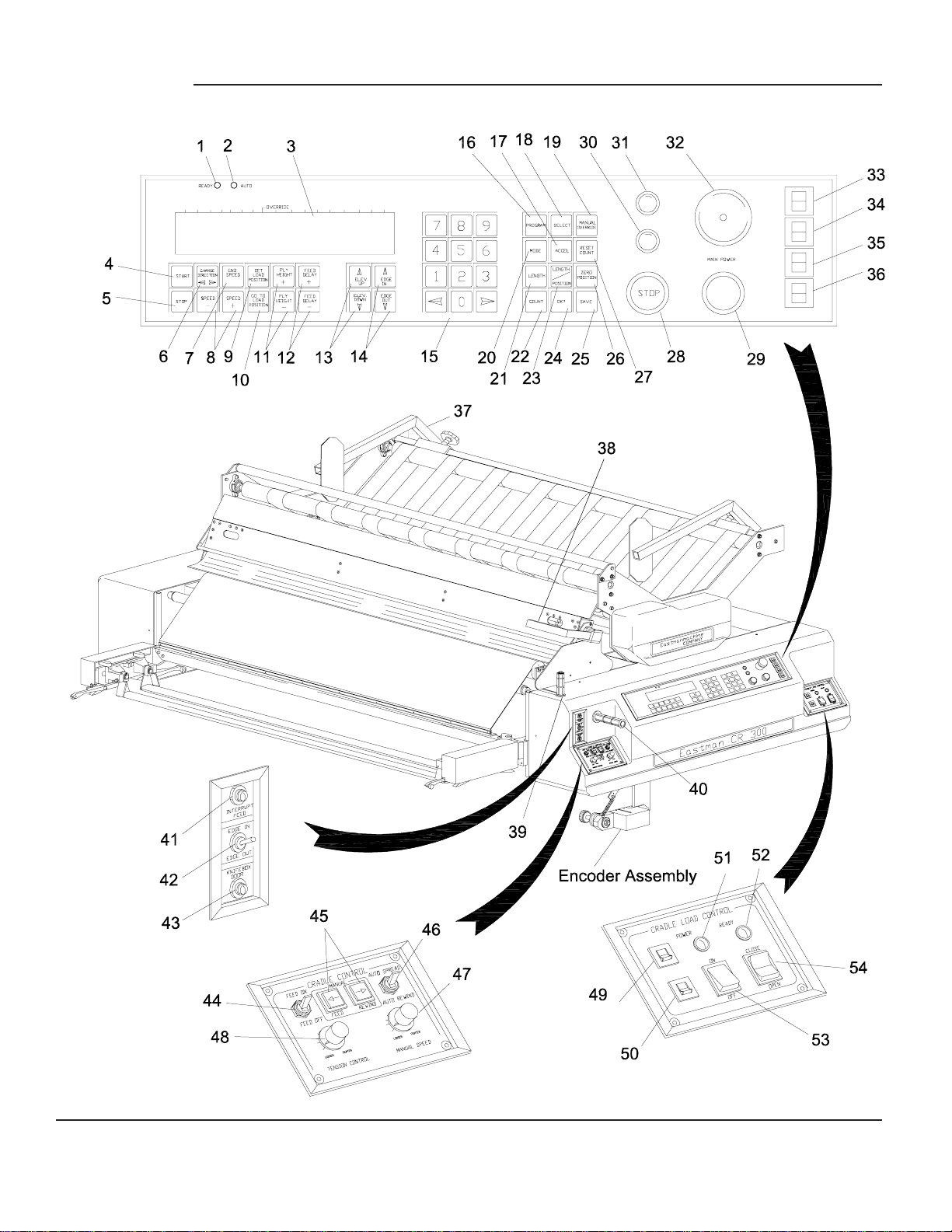

OPERATION

Loading

Activatepowertospreadingmachinebypullingmain power

(mushroom)switch.Red indicator lampadjacenttotheknob

willglowtoindicatepowerison.Pressgreen“MAINDRIVE”

button,toactivatecircuitformanualcontrol.Greenindicator

lamp adjacent to button will glow to indicate machine is

ready.

Gentlytwistthethrottleanddrivespreaderintothestationary

catcher. This is the Piece Goods Loading Area. Open the

edgecontrolreflectorswitchtodisengageautoedgecontrol

circuit. Activate cradle loading circuit by pressing on/off

power switch on the cradle load control panel. Power light

(red) will glow. If The green ready light is on, the cradle is

readyforLoading/Unloading.Ifnot,centerthecradleplatform

usingtheedgecontrolin/outbuttons.Whenthegreenready

light glows, press the Open/Close switch to open cradle.

Loadpiecegoodsroll.Moveclothalignmentarmsandsecure

inplace.Closecradle.Pressoffcradlepowerswitch.Close

theedgecontrolreflectorswitchandbeginspreadingopera-

tion.

CAUTION:Maximumweightofpiecegoodsrollis500lbs.

andextremecautionshouldbeusedwhenload-

ing maximum load rolls into cradle.

Threading

Afterpiece goods rollhas been loaded,threading can take

place. Press the manual feed button on the cradle control

panel. When feeding material, raise the dancer bar up and

guide fabric under dancer bar. Feed fabric into knifebox or

foldingblades.

Face To Face Spreading

(FoldingBlades&CatchersRequired)

Warning: Safety Cams should always be checked for

proper operation before operating the

spreader.

AfterSafetyCamshavebeencheckedforproperoperation,

threadthespreader.PulltheMainPowerbuttononandpress

thegreenMainDrivebuttontoactivatepowertoallcircuits.

Manually drive the spreader, by using the throttle, into the

Left (Moveable) catcher and place end of goods under

catcher pin bar. This is your left end marker. Press Zero

Positiononcontrolpanelsetposition.SelectFaceToFace

mode (Press program. Press mode to select face to face

mode.PressSavetoloadprogram.).Setthecountertothe

number of plies desired to spread (Press program. Press