10

F. TO TURN ENGINE OFF (With or withoutconveyor

running).

1.TURTLE Push throttle slow button to

reducesetting to idle (this prevents

enginefloodingandhard starting).

2.STOP Push STOP button and hold

5 seconds.

NOTE: OFF can be pushed at anytime during

spreader operation to cut power to the unit;

however, you should normally use steps under F

above.

G. Do not attempt to start the engine

withtheconveyor engaged.

H. Closefuelshutoffvalveonengineif

unit is to be transported while not

running.

WARNING!

1. As with all power equipment, safety is the number

oneconcern.

2. Do not operate this equipment until you fully

understandhowitfunctions.

3. Before starting engine, be sure that no one is near

the rear of the unit and that no one is inside the unit!

4. Donotstarttheengineorengage the conveyor

(which is interconnected to the spinner) until

everyoneisclearfrommovingpartsandflying

materialfromthespinner.

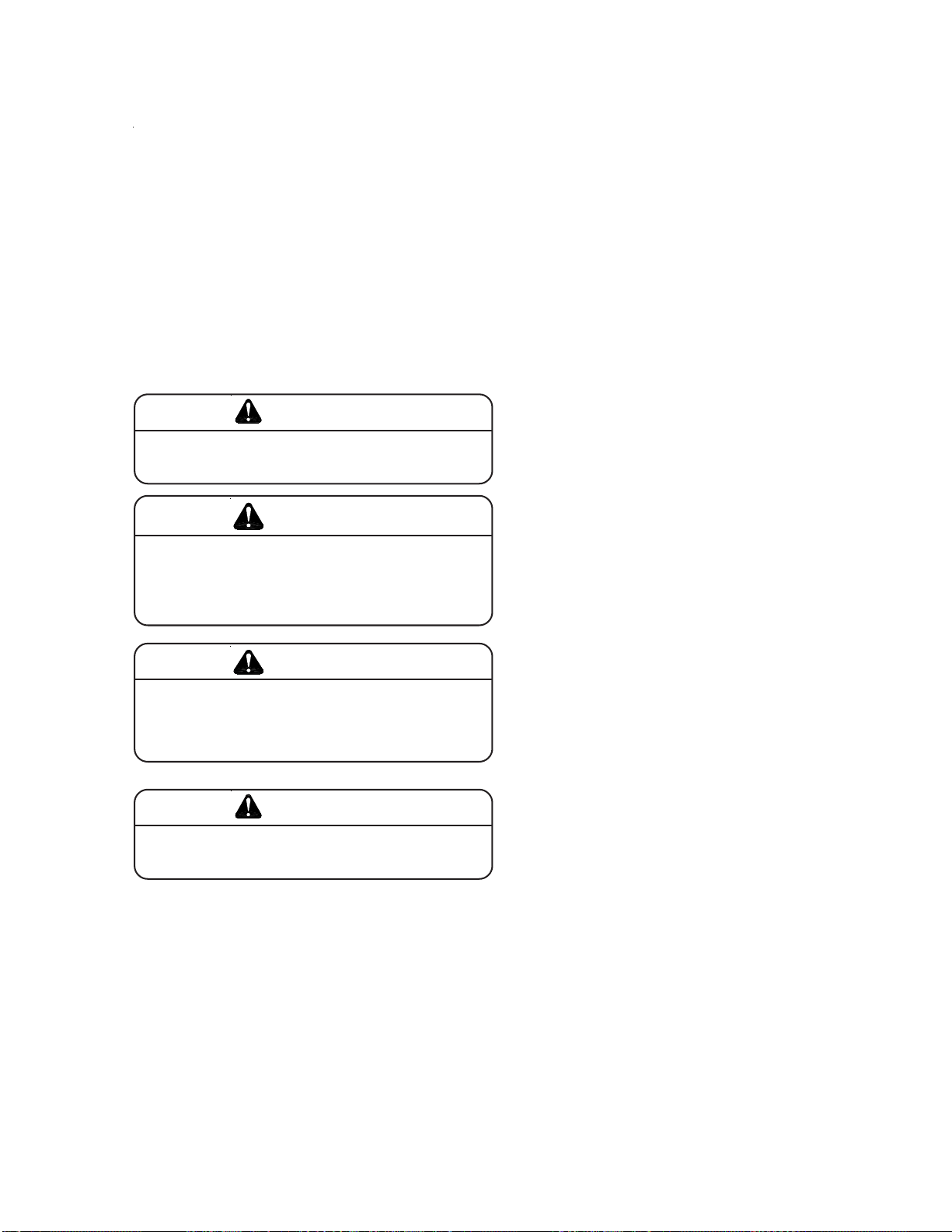

A. ON/Off Systempoweractivated(readyto

start).Spreaderenginenotrunning.

Spreaderconveyor isnotengaged.

B. START(EngineOnly)

1. Openfuelshut off valveonengine.

CHOKE (Coldengine.) Holddownfor

5 seconds to move the throttle

actuator to the choke position.

NOTE: Choking a warm engine may not be

necessary.

4.START Hold down buttonuntil engine starts.

5.TURTLE Decreases throttle speed - adjust as

engine warms up. Will stop the

chokefunction.

RABBIT Increasesthrottle speed.

C. TOENGAGESPREADERCONVEYOR

1.CONVEYOR PushCONVEYOR switch only after

you are sure no one is in the hopper

ornearthespinner!

D. TOCONTROLCONVEYORSPEED

1.RABBIT Hold RABBIT to increasespeed.Note

DO NOT hold switch in HI position

afterthedesiredRPM is achieved or

you will choke and/or stall the

engine.

2.TURTLE Hold TURTLE to decreasespeed.

E. TODISENGAGESPREADERCONVEYOR

1.CONVEYOR Push conveyor button.

Stop

Start

Choke /

Throttle Fast

Throttle Slow

Conveyor

SPREADEROPERATION

Wireless Throttle Control Button Functions

(Sequenceof Operations)