2

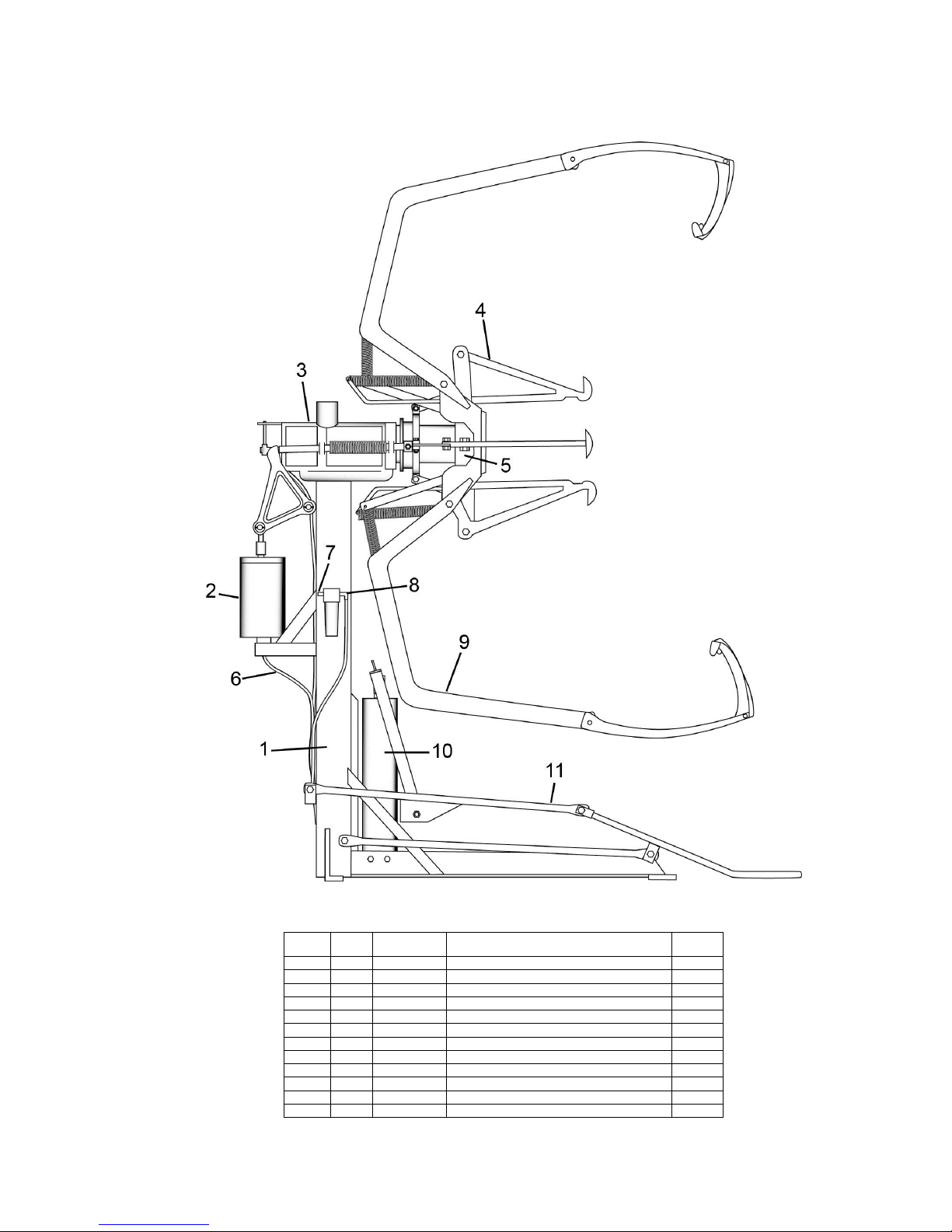

2) While keeping tire on inner bead hooks, step on center foot valve to spread and fully

engage all four hooks on inner bead of tire.

3) Grasp both outer bead hook arms by the handles and pull to center of tire. Push forward

and allow bead hooks to engage outer bead of tire. Make certain all hooks are securely

engaged with tire beads before spreading tire.

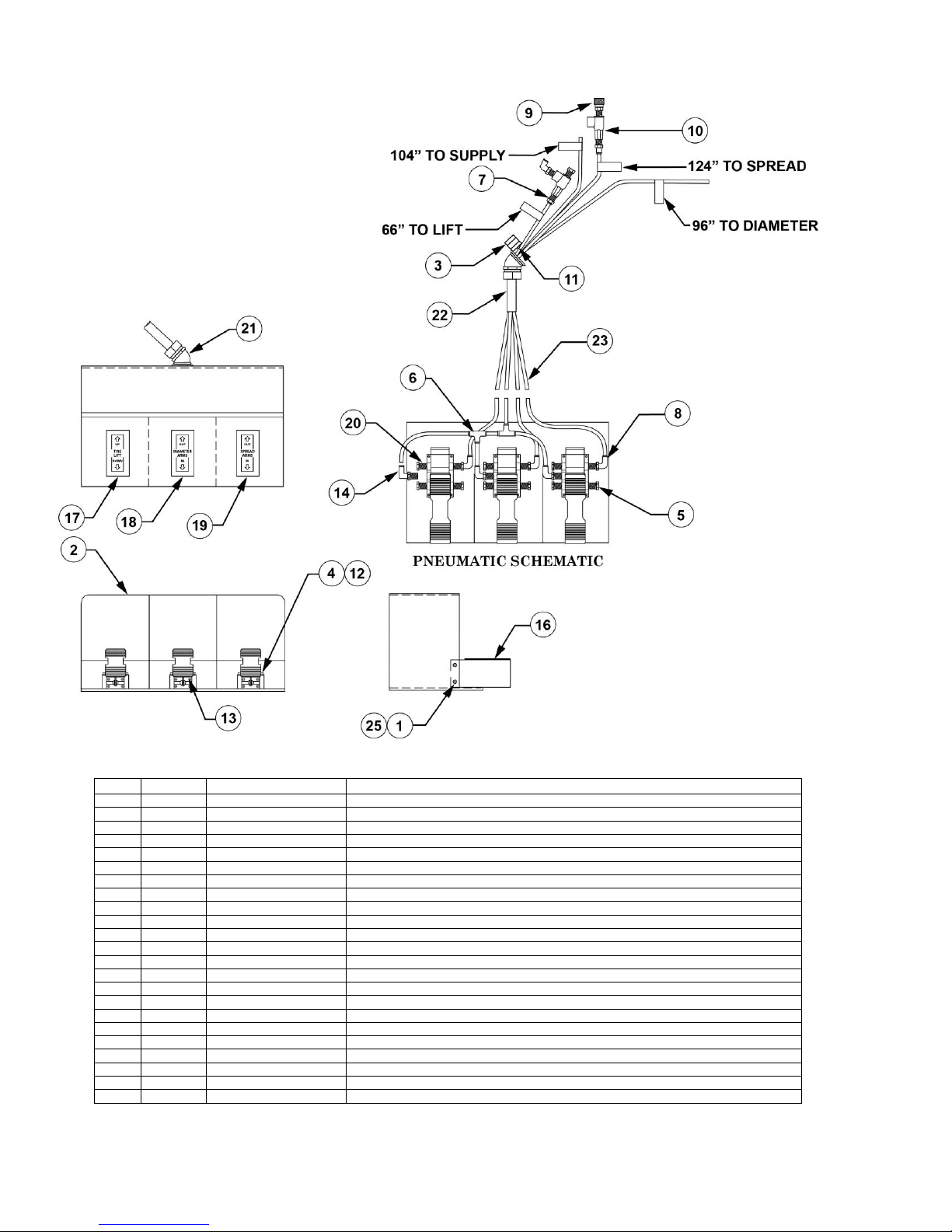

4) To spread the tire, step on right foot valve to obtain desired spread. Tire can now be

rotated and inspected.

5) To remove tire, release spread arm control valve (right valve) and remove outer bead hook.

6) Release pressure on inner bead hooks by stepping on diameter control valve (center

valve).

7) With tire hanging on inner hooks, raise lift cradle (left valve) up to contact tire. While

holding onto tire, raise tire slightly above inner bead hooks and lean tire outward and

release pressure on lift valve to lower tire to floor.

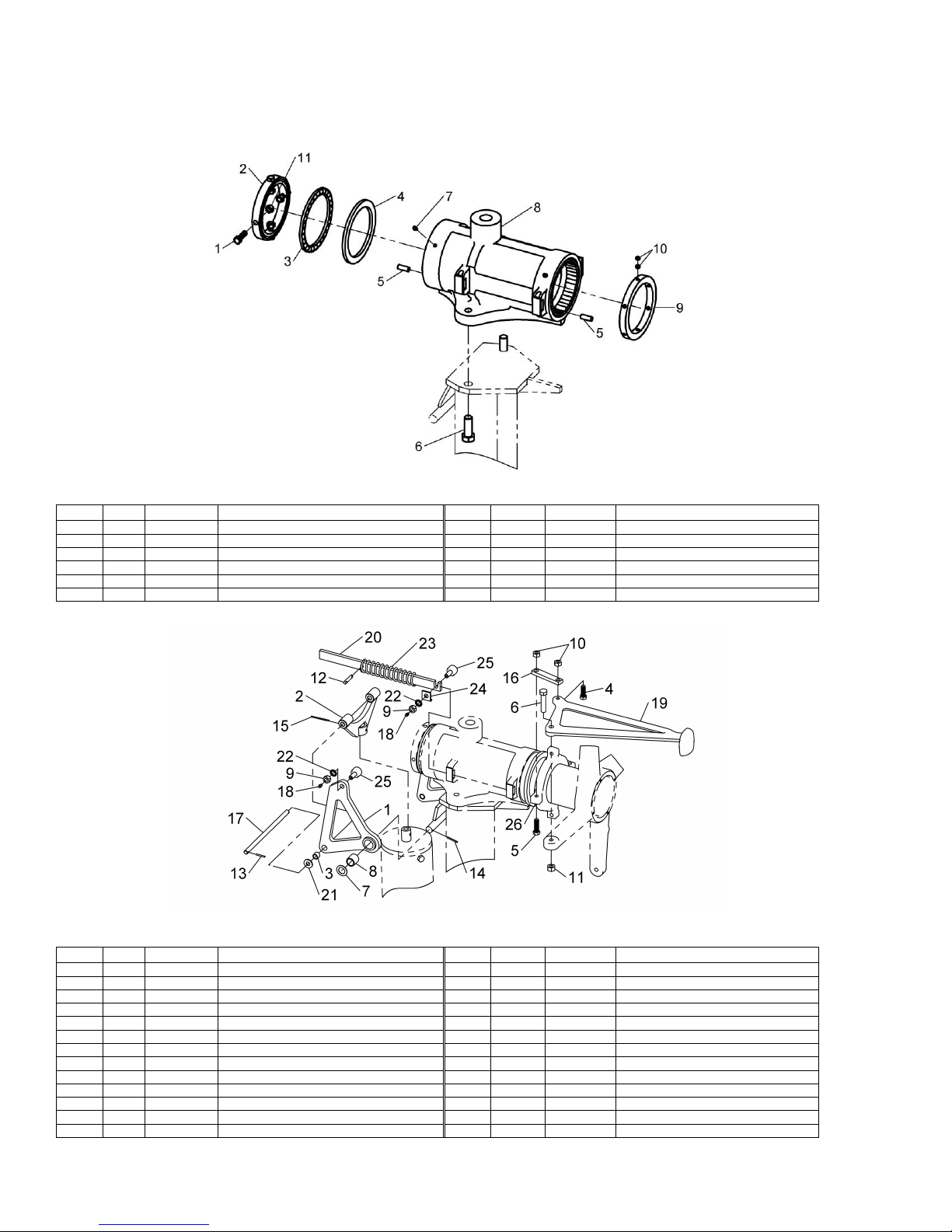

MAINTENANCE

MONTHLY –Put a few ounces of 10 or 20 weight oil in all cylinders.

Lubricate all moving parts (bolts, hinges, rollers, etc.) with a lubricating oil.

Grease cylinder bearings through the grease zerk fittings. Apply some grease to

the races of the bearings also.