Brassmasters EasiChas User manual

Brassmasters

Scale

Models

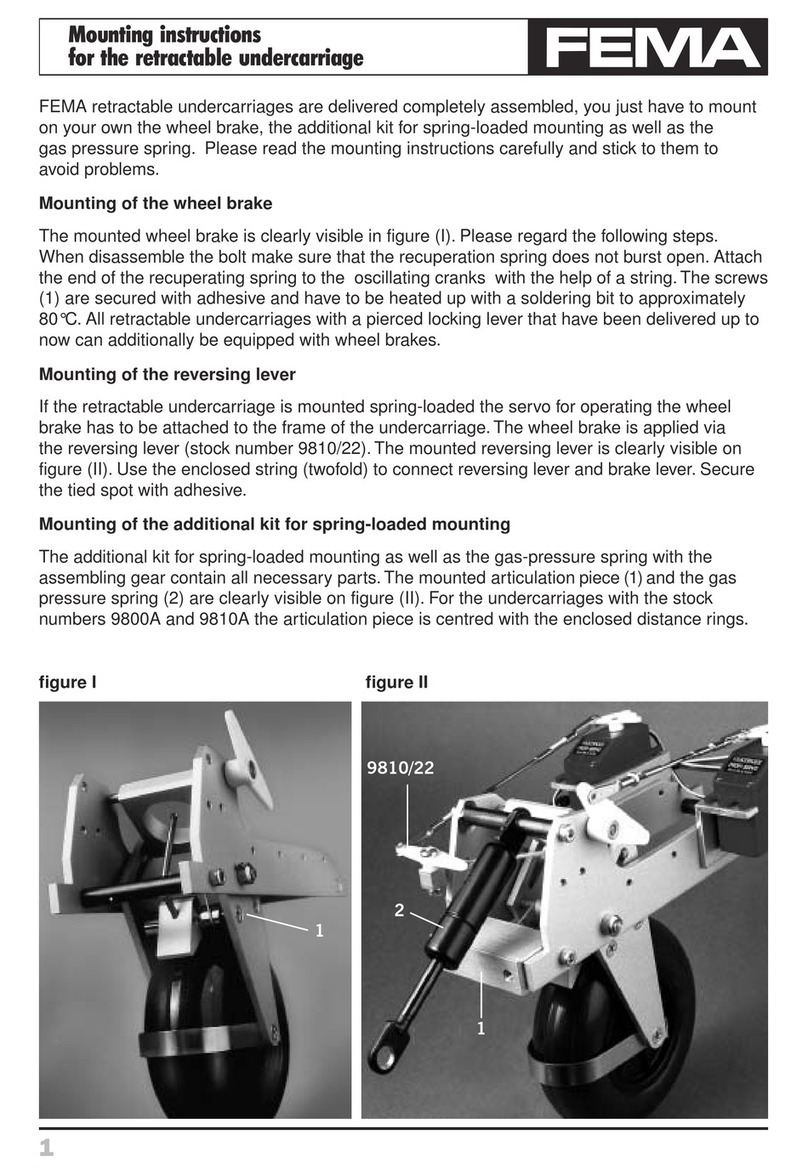

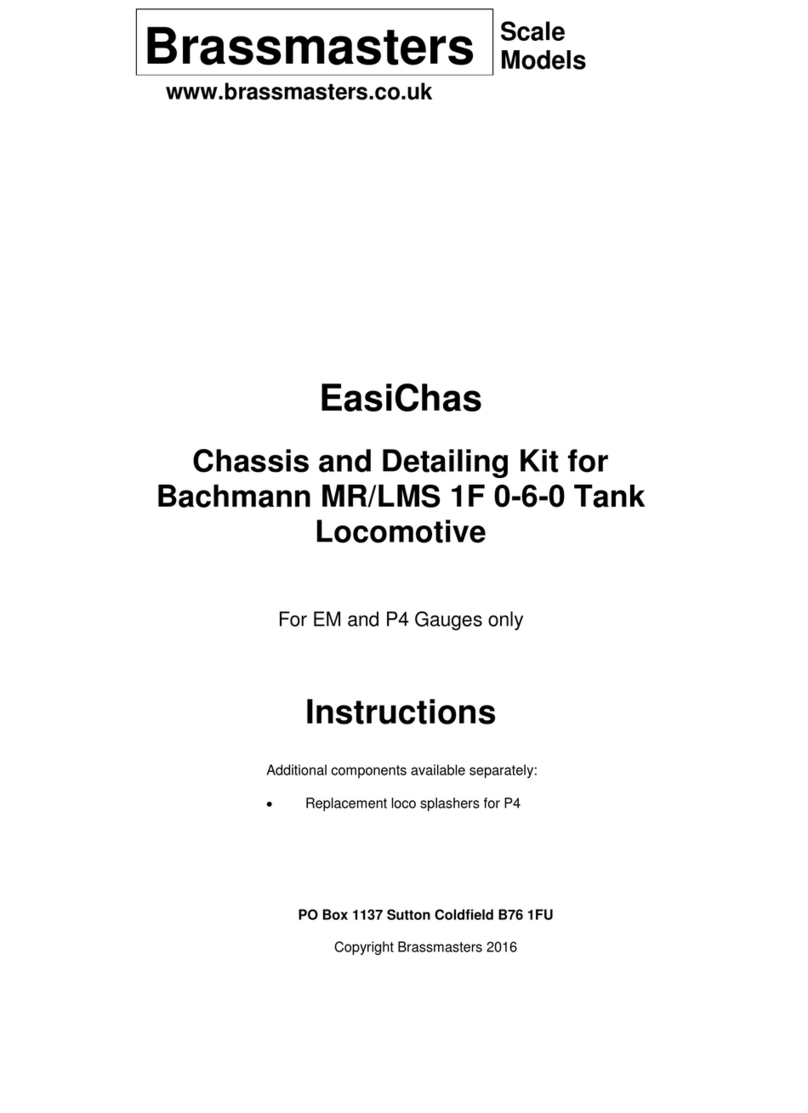

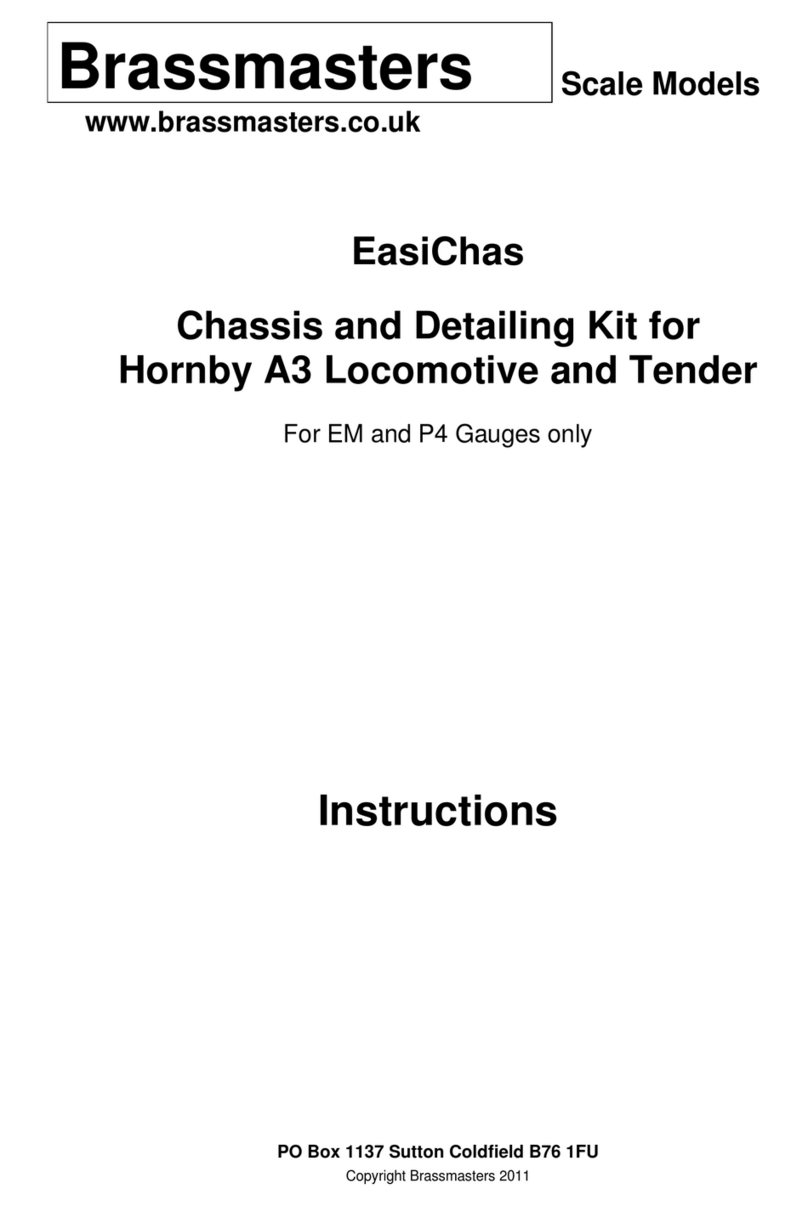

www.brassmasters.co.uk

EasiChas

Chassis and Detailing Kit for

Bachmann G2 Locomotive and

Tender

For EM and P4 Gauges only

Instructions

PO Box 1137 Sutton Coldfield B76 1FU

Copyright Brassmasters 2017

Brassmasters G2 EasiChas v1.0 1 September 2017

1 Introduction

1.1 The EasiChas frames for Bachmann G2 locomotive, based on the original concept devised by John Brighton, have been

specifically designed to allow easy conversion to EM or P4 gauge, which results in a fully sprung locomotive and tender.

Furthermore, the basic conversion can be completed without the need to solder any of the main components together.

1.2 There are various levels of conversion with the builder choosing which, of any, additional detail required beyond the basic

conversion.

1.3 Basic level of conversion makes use of:

fold up mainframes keep plate and ashpan with sprung bearings

fold up replacement tender frame with sprung bearings.

1.4 Further components are provided to add to the detail of the conversion. These are, working from the front:

replacement buffer beam

replacement buffer beam bracket

locomotive guard irons

drain cock operating linkage

replacement coupling rods –2 jointed version

replacement reach rod - both original and strengthened valve gear

sander operating linkage

replacement brake hangers and blocks

brake pull rods for single and double braked versions

cab floor

replacement tender brake gear

replacement tender guard irons

replacement tender coal rails

replacement tender frames, drag and buffer beams

lamp irons for engine and tender

replacement rear footsteps for tender cab locomotives

1.5 The replacement set of frames buffer beam etc. replaces the lower half of the Bachmann tender giving the proper

distance between the frames rather than the over wide ones on the Bachmann model. An alternative set of frames is available for

the Whale type frames with D shaped opening used on the earlier version (BC3) of the Bowen Cooke tender.

1.6 Unfortunately, it is not possible to re-use the Bachmann pick-ups on this EasiChas. However, a suggested method for

making pick-ups has been given, which has worked very successfully on the test build, although there are many other methods

which the builder may prefer to use.

1.7 Suitable wheels are available from Alan Gibson and Ultrascale. The standard replacement wheel packs with 3mm axles

are suitable for the G2 EasiChas. However, if you already have wheels with 1/8” axles, the bearings in the kit can be exchanged

for 1/8” bearings.

1.8 The earlier 3-piece coupling rods are also available from Brassmasters (ref C106).

1.9 Locomotives that can be built using the Bachmann G2 model and the Brassmasters’ EasiChas kit

The history of the LNWR 0-8-0 is long and complicated, so rather than try to include it all here, these notes deal only with the

history as it affects the locomotives that can be built from the Bachmann model and Brassmasters’ EasiChas. For the full history,

‘Eight-Coupled Goods engines’ by Edward Talbot is essential reading.

There are two different basic versions of the Bachmann locomotive, plain cab side and cab side fitted with sandbox filler, and

three different versions of the tender, plain tender, tender cab without rear steps, tender cab with rear steps. The only limitation

of locomotives that can be modelled is that the cab side sand filler was not introduced until 1946 and then only on locomotives

fitted with tender cabs and rear steps to replace the withdrawn 0-8-4 tanks at Edge Hill and Buxton, and later for other locations.

Apart from the limitation above, the Bachmann G2 can be used as a basis for any G1, G2 and G2A once fitted with Belpaire boiler

and cut down cab, both appearing from about 1924, except those fitted with steam brake.

The later batches of G1 (built in 1914 onwards) and the G2 were all built with strengthened brake gear. From 1924 strengthened

brakes were introduced on vacuum fitted locomotives. The strengthened brake gear consisted of a second brake cylinder in front

of the firebox operating the linkage on the leading two wheelsets, with the original cylinder under the cab operating the linkage on

the trailing two wheelsets. The modification commenced with the locos that had been built with vacuum brakes (G1 –LMS 9225

onwards, all G2s). As locomotives were converted from steam brake to vacuum brake most were fitted with two cylinders and the

majority were converted in the next 10 years. However, some retained steam brakes until scrapped.

The G2s were built with a modified motion with a direct drive. This was mounted higher in the frames and resulted in a cranked

reach rod in place of the straight reach rod for those locos fitted with indirect drive. From the early 1920s G1s began to be fitted

with ‘strengthened motion’ as it was known.

Brassmasters G2 EasiChas v1.0 2 September 2017

At the start of our period of interest, the G1s were fitted with three-piece rods and the G2s were fitted with one-piece jointed rods.

As time went on more locomotives were fitted with single-piece jointed rods.

G2A locomotive that appeared from 1935 were G1s that were fitted with a 175 lb/sq.in. boiler and nominally strengthened brakes

and direct motion. Some locomotives were already fitted with one or both but converted locomotives often lacked one or the other.

Various changes were introduced during the life of the locos and the most noticeable were parallel buffers (1933 onwards),

smokebox handles in place ofwheel (early WW2 onwards), strengthened buffer beam (1942 onwards) and Stanierchimney (1944

onwards). Fitting was not necessarily fast and not all locos were fitted during their life.

As for the tender, once the locos were converted to vacuum brake the locos were only paired with one of the last two designs of

Bowen Cooke tender. The Bachmann model is of the last type of Bowen Cooke tender (BC4), but the previous type (BC3) had

the same body, but with Whale type frames. The first tender cabs were built in WW1 but only one was fitted to a BC3 tender. The

tender cabs in 1946 and later were fitted only to BC4 tenders and they also had steps at the rear of the tender.

So, with this number of variations, a picture of the locomotive you wish to model at the right period is necessary to get the detail

right.

All these variations can be built using the appropriate Bachmann model, the EasiChas kit and several additional items:

Indirect or direct reach rod –EasiChas

Original or strengthened brakes –EasiChas

Three piece rods –available separately from Brassmasters (ref C105 –includes extra-long crankpins)

Single piece rods –EasiChas

LNWR buffers –sprung buffers available separately from Brassmasters (ref A217)

Parallel buffers –on Bachmann model or sprung buffers available separately from Brassmasters (ref A101)

Smokebox door wheel –on Bachmann model or in EasiChas

Smokebox door handles –on Bachmann model or available separately from Brassmasters (ref A022)

Original or strengthened buffer beam - EasiChas

LNWR chimney –whitemetal one available separately from Brassmasters (ref A251)

Stanier chimney - on Bachmann model or whitemetal one available separately from Brassmasters (ref A252)

BC4 tender frames –Bachmann model or brass in EasiChas

BC3 tender frames –available separately from Brassmasters (ref B244)

Rear tender steps to footplate –Bachmann model or in EasiChas

2 General Notes

2.1 There are four main etches, one for the Easichas for the locomotive and tender, one for the detailing kit for locomotive

and tender, one for the coupling rods and one for the replacement tender frames. There are also two supplemental etches for

replacement parts. Numbers shown in square brackets [ ] in the instructions refer to the etch (L or T for the Easichas etch, D for

the detail etch, C for the coupling rods and F for the replacement tender frames) and part numbers, e.g., [L2] is part 2 on the

Easichas etch. The part number appears on the separate etch diagrams. Certain parts, e.g. screws, wire, springs, are not

numbered.

2.2 Some of the parts are small and easily damaged, so do please take care. Parts should be removed from the sheets as

and when needed by use of a small scalpel etc., and the tabs and etch cusp removed with a small fine-cut file.

2.3 All folds and bends are made with the half-etched line on the inside unless otherwise stated.

2.4 On some parts it is necessary to emboss rivet / bolt heads from the reverse sides by use of a punch. There are half-

etched test rivet holes on the back of the etch edging strip. Use these to get used to forming uniform rivets.

2.5 You should look at instruction 5.1 regarding pre-preparing the wheels before commencing building.

2.7 User guide

We have created a user guide on our website –www.brassmasters.co.uk. In which we have taken advantage of the medium to

provide more detail than we can include in traditional paper-based Instructions. In particular, it includes selected prototype

photographs which are quick and easy to view. We hope you will find this new way of presenting our instructions helpful when

building your model, and welcome your comments on it. It is an excellent way to familiarise yourself with the kit, particularly

since the constructional photographs are reproduced in colour and to a much larger size than those included below.

Brassmasters G2 EasiChas v1.0 3 September 2017

3 Before you start

3.1 Tools Required

A selection of cross head and normal miniature screwdrivers

Small pliers

Small plastic bags and labels to identify parts & screws when dismantling

Small files

Soldering iron (for electrical connections)

A steel rule

Back to Back wheel gauge

Plastic solvent, superglue and epoxy resin (24 hour & 5 minute)

3.2 The Mazak chassis block is very soft and the retaining screws are fine pitch. If any screws are incorrectly inserted (i.e. a

self-tapper into a machine screw hole) or they are over tightened the thread will be stripped and correct fastening will be

impeded.

3.3 In all cases bag and label all small parts and source of screws as soon as removed (they are all different lengths) - trust

us on this one!

4 Dismantling the locomotive and tender

4.1 Firstly check that the locomotive works and the motor runs because the warranty is about to be invalidated! With pliers,

pull out the electrical plug under the tender and release the engine from the tender by manipulating the drawbar, plug and wires.

4.2 Unclip the brake pull rods from each brake block hanger so that the pull assembly hinges on the rear brake cylinder cross

shaft. Carefully unclip this cross shaft by bending the shaft with pliers. Unless you are very careful, the end pips will break off.

4.3 Unscrew the front and rear screws, pull the chassis vertically to remove the chassis from the body. The rear screw

releases the tender drawbar. Make sure you don’t lose this.

4.4 To remove the keeper plate (with brakes attached), remove the remaining screws. Remove the wheel sets from the

chassis, unscrew the machine screws from the wheels and remove the coupling rods. Put the screws back into the wheels for

safekeeping.

4.5 Remove the glued-on sandboxes (by twisting with pliers) and sand pipes. Store these for use later.

4.6 Remove the screw from the pickup PCB contact plate in the bottom of the chassis and pull out (the wires are quite long).

Unsolder or cut the wires to remove the PCB. Tuck the wires back into the hole for now. There are slots in the EasiChas and

keeper plate to feed the wires through for the new pickups later in the instructions.

4.7 Before carrying out the next steps, cover both the tender link electrical

socket and the gear train in the chassis with tissue to prevent swarf getting into

them.

4.8 File off the pips in the chassis block behind where the sandboxes were

fitted and also those on the underside of the chassis block at the rear. The footplate

support bracket in the middle of each side also needs filing back to clear the

EasiChas frames.

4.9 The raised area on the Bachmann chassis around the third axle slot needs

to be removed, by filling, for P4, and around both the second and third axle slots

for EM.

4.10 Finally, the cast brake shaft brackets and representation of the central

activating cylinder need to be removed from the Bachmann chassis block using a

piercing saw and files (see photo of one side completed).

4.11The chassis now looks like this (see photo):

4.12De-grease the chassis sides.

4.13We have found that only one drive gear is required on

the third axle. Using two causes problems with quartering

and is unnecessary with properly fitted coupling rods. Hold

the one of the wheels with wheels with a gear wheel and

with a twisting pulling motion pull off the wheels from the

axle. Also, slide off the brass bushes. Place the axle in a

vice such that the gear wheel is supported on the vice sides,

but the axle is loose. Tap the axle with a hammer or similar

and the gear wheel will slide off the axle. If you do not have

a vice, use a pair of pliers on one side of the gear wheel,

gently slide the plastic gear down and off the axle by holding the axle vertical and pressing down. It is very important not to

damage this gear.

Brassmasters G2 EasiChas v1.0 4 September 2017

4.14 Taking the tender, unscrew thetwo rear screws behind the buffers. The front is secured bytwo clips that extend vertically

from the front tender bulkhead down through the tender floor/platform (chassis top). Some have suffered from stray glue so need

pressure from below to free them. With the rear screws now removed lever up the rear of the tender and the front clips will release

the body.

4.15 Spring the tender side frames apart to release the brake pull rod assembly. Again, spring the tender side frames apart

to release the wheels. Remove the rear tension lock coupling (put a screwdriver below it and twist) to reveal the screw holding

the coupling pocket. Remove this.

4.16 You will now have a box of bits and an invalid Bachmann guarantee!

4.17 Wash your hands as you will have grease on them from stripping the chassis and the etches should be kept as clean as

possible.

5 Basic locomotive conversion

5.1 If you are using Alan Gibson wheels you will need to drill the

crankpin holes using a 0.65mm drill. The hole must be perpendicular to the

wheel. If fitting 3-piece rods (c105), the extra-long crankpins provided need

to be fitted to the wheels on the second and third (flangeless) axles. The

following will prevent problems with loose crankpins. Countersink the rear

of the crankpin screw holes using a 3mm drill and half screw the 12BA

screws home, if the crankpin hole is not fully clear of the centre plastic

boss then cut some of this away to aid countersinking. Using 24 hour

epoxy, smear the remaining thread and screw the 12BA screws home.

Smear a little epoxy over the head for additional security but there should not be a big blob that will catch on wheel rotation. Leave

in a warm place for 24 hours to set. This will retain the screws and stop them from rotating. See photo (before the epoxy was

applied) of a larger diameter but similar wheel. Now is also a good time to ‘fill in’ behind the ‘H’-section spokes with black plasticard

for those segments fitted with balance weights –different axles had different balance weight arrangements and there were

variations, especially on the driven (flangeless wheel) axle. Study prototype photos. Do not copy the Bachmann wheels as this

is incorrect for at least the driven axle. We cut a piece of plasticard 4mm wide and make ‘triangles’ out of this and carefully fit them

from behind fixing with super glue. This is a time-consuming job, but if you do not do it now you will regret it because it is very

noticeable on the running model!

5.1.1 Before stating on the main EasiChas frames it is necessary to make a couple of decisions.

5.2 The bottom of the Bachmannchassis block is alot lower than the bottomof the frames of theG2, so it has been necessary

to lower the bottom edge of the EasiChas frames between the wheels to partially hide the chassis block. The dimension used is

not without precedent as we have used the frame depth from the 0-8-2 and 0-8-4 tanks that had deeper frames to support the

additional weight of the tanks. However, if you want the correct height to the frames, there is a half-etched line on the back of the

frames between the wheels marking the correct height, which will need filing back to.

5.2.1 The frames include the brackets for the second brake shaft between the second and

third axles. These were fitted to G2 and G2A locos. If you are modelling a G1 or G2 with only

one brake cylinder, these brackets need to be removed. Do this by cutting through the two legs

of the bracket each side (see photo with the cut line shown dotted).

5.2.2 The EasiChas

includes replacement locomotive

buffer beam brackets. To use

them requires the cast brackets

behind the buffer beam on the

Bachmann footplate to be

removed. This is quite easy to do

with a burr in a mini-drill but can

also achieved with drills and files

See photo of the finished job. As an alternative, the leading part of the

EasiChas frames can be cut away to clear the original casting on the

footplate. For this option, cut back the frames to the half-etched lines

on the inside of the frames.

5.3 Remove the locomotive mainframes [L1] and clean up the residual tabs with a small file. With a riveting tool or sharp

implement push through the half-etched rivets at the rear and centre of each frame.

Brassmasters G2 EasiChas v1.0 5 September 2017

5.4 Place the frames flat on the bench and with a thin

metal rule fold to produce a ‘U’ section. Either again using a

ruler or using a strong pair of pliers, fold up the small top

sections along the edge of the main frames at 90 degrees, and

then on the two top sections each side towards the front which

have bend down sections, bend these down (see photo with

these folded down on back frame). For added strength, solder

these to the frame.

5.5 Fold over the rear brake shaft brackets between the

frames, with the fold line on the outside. These should lie

against the frame –solder or glue (cyanoacrylate glue or epoxy

resin) may be used to encourage this. See Photo

5.5.1 Ensure the mainframes fit over the original Bachmann

chassis. The frames should sit parallel to the Bachmann frames

and not be ‘splayed’ out at the top. If necessary, file the top sections

back to ensure this. Remove the mainframes. There is a portion of

dummy framing under the Bachmann Mazak footplate, remove the

front brakes and sandpipes from this by snapping themoff –put them

in a safe place. It makes fitting the etched frames easier if the

residual pips, etc are removed from the dummy framing byfiling them

off.

5.5.2 Check the fit of the brass bearings into the slots in the

mainframes. If tight, using a smooth sharp file, lightly file away the

cusp equally on both of the edges of the slots until the bearing slides

up and down with no binding. Itis very important that toomuch metal

is not removed resulting in a sloppy fit –no side play whatsoever is

the aim, just a smooth sliding fit.

5.6 Identify all the items within and attached to the

outside of the keep plate [L2], remove them and store

them safely. Remove the keepplate [L2]. Fold up the four

U shaped pieces between the leading and second axles

and the second and third axles. Ensure they slide

between the mainframes [L1]. Fold down the eight axle

keep plates along each side of the keep plate (G2 variant

is shown with the second brake cylinder bracket).

5.7 Test fit the keeper plate and the chassis to the

Bachmann chassis

5.8 Unless you are using the replacement etched brake

gear, fold up the ‘cups’ on the frame sides and keep plate

front that will hold the Bachmann plastic brake hangers so

that they form a flat bottom gentle ‘L’-shape with a slight sloping upright (see picture in section 5.18 lower when formed).

5.9 Fold up the ashpan [L3] by firstly bending into a ‘U’-shape along the inner bend lines and then bend

each side through 180 degrees along the outer bend line (bend line to the outside). See photo. This fits

between the frame and the keeper plate with the tongue facing forward in the correspondingly shaped cut

out.

IMPORTANT - Carefully examine the bearings because they are not symmetrical. It can be seen that the flange on one side of

the slot is wider than the other side. For EM gauge, the bearings need to be mounted in the frames with the thicker flange

towards the centre of the frames. For P4 gauge, the bearings need to be mounted with the thinner flange towards the centre of

the frames. Increased side-play on the drivers can be obtained by having the thin side of the bearings on the outside or rubbing

off the circular beading round the axle hole. For EM gauge, it will be necessary to file off the raised rim on the inside face of the

bearings to ensure the bearings move up and down freely.

5.10 Again, fit the mainframes to the

Bachmann chassis, place the bearings in

the slots and check for easy movement.

See photo.

5.11 Temporarily fit the keep plate, using

the original Bachmann screws and lower

keeper plate, plus washers [L4]. Ensure

the bearings slide to the bottom of each

slot in the keep plate. Rather than use the

washers, the screws could be shortened.

Brassmasters G2 EasiChas v1.0 6 September 2017

5.12 Take the new 3mm axles and test fit them, firstly in the axleboxes (if tight ream them out to 3mm using a reamer or, if you

do not have one, a small round file, a precision drill or a broach), then place each through the axleboxes and through the “slots”

in the Bachmann chassis block. If the axles catch the sideof the Bachmann chassis block file away the offending part of the block.

The Mazak is not the most stable material so it is surprising how much metal may need to be removed from some axle slots. This

is much easier to do at this stage than when the wheels are mounted or at an even later stage.

5.13 Take the axles and file the sharp edges of the end to a rounded profile. Use a drill bit of around 5mm diameter to chamfer

the rear of each wheel axle hole. These two actions help the axle to ‘centre’ in the wheel when they are pressed on.

5.14 Fit the Bachmann axle gear wheel onto the new axle by gentle pushing the gearwheel onto the axle, ensuring that the worm

wheel is centred on the axle so the gear wheel engages properly, and the same amount of axle protruding each side of the chassis

when it is fitted. Personally, we roll a file edge pressed very hard against the axle in the position the gear will sit before fixing,

thereby ‘knurling’ the axle and providing extra grip for the gear, but this is probably not necessary!

5.15 Mount the bearings on all axles the correct way round (see section 5.7), then any spacing washers required (there will be

about 0.8mm lateral movement of an axle with no washers in 18.83 gauge –so not many washers are required. For 18.83mm

gauge we suggest one full washer is fitted each side of axles 1, 3 and 4, for EM one half washer on each side of the leading and

trailing wheels, and finally press the wheels on the axles and quarter the wheels, remembering that the flangeless wheels should

be fitted to the axle with the gearwheel. For these ex-LNWR locos they should be quartered with the left hand wheel leading the

right hand wheel by90 degrees. However, as youwill never see both sides at the same time, and commercially available quartering

jigs have the right hand wheel leading, it won’t be the end of the world if the right hand wheels lead.

5.16 Place the bearing springs over the tongues on the frames (a small spot of grease in the spring helps to retain the springs

in place when fitting and removing the wheels), fit the wheelsets into the main frames and attach the keep plate and ashpan. See

Photo. Check that the motor turns the driven wheelset with no sign of any binding by applying power to the motor. Remove the

springs and put them safe while working on the rods and checking for free running.

5.17 If fitting the buffer beam brackets to the frames, push through the rivets in the bracket bases

[L5 left hand side, L6 right hand side] and attach to the frames ensuring the bracket web [L6] fits through

the slot in the bracket base and frames. If intending to use working sprung buffers on the front of the

locomotive the bracket webs [L6] will need to be cut back to clear the buffer tail. Attach the buffer beam

web [L7] to each side of the frames (see photo).

5.18 Attach the brake shaft bracket strengthening rings [L11] to the outside of the brake

shaft brackets on the rear of the frames and, if the locomotive has two brake cylinders, to

the brake shaft brackets on the keep plate.

5.19 Identify the footplate bracket

bases [L8] left hand side and [L9] for the right

hand side (the corner cut-out is at the

bottom and towards the rear). Position the

appropriate bracket base over the slot

in the frames and hold in position with the

footplate bracket web [L10] and secure in place.

Repeat for the other side. See photo and 7.2.5

5.20 Push through the rivets in each guard iron ([D1] for left hand side and [D2] for

the right hand side) and form to a slight ‘S’ shape. Glue, or preferably solder, to the

frames, with the curved face towards the rear, immediately behind the buffer beam

bracket. See photo.

If you wish to fit the replacement etched brake blocks and supportingbrackets, now is

a good time to jump to section 7.2 and assemble the sequence from 7.2.1 to 7.2.5.

Coupling rods

5.21 Fit the Bachmann coupling rods with the eight bushes provided. This will require each hole to be opened up to with a rat-

tail round file to accept the bushes, if you are careful these can be an interference fit. If not, the bushes have to be soldered or

glued with epoxy centrally in place. If needed, open out the bushes using a reamer, broach or file to take the Gibson crankpin

bushes - see photo.

A finer scale solution is to solder up

a new set of coupling rods, but this

of course takes longer (see section

7.1).

5.22 Fit the rods and temporarily secure with a piece of electrical wire sleeve (does not come unscrewed unlike a proper

14BA nut!). Check that all the wheels now turn without binding when power is applied to the motor and are quartered correctly.

Be careful as you tighten the retaining screws as it can distort the chassis just slightly which results in the axleboxes not sliding

freely (don’t forget to add the washers under the screw heads if using them). See photo.

Brassmasters G2 EasiChas v1.0 7 September 2017

5.23 Fit the eight springs above

the axleboxes to achieve a fully sprung

chassis. Note that the driven axle

should not drop too low to allow it to

drop out of mesh with the gear above.

If this is happening, solder or glue a

packer onto the top of the keeper plate

to stop this as it will damage the gears

if allowed to repeatedly occur.

Electrical pick-ups

5.24 Locomotive pick-ups. It is not possible to re-use the Bachmann pick-

ups so you will need to fabricate your own. Many modellers have their own

ideas on pickups, this is how we do it. Using a copperclad sleeper (cut to fit

between the keeper plate springs) and 33 swg phosphor bronze wire (not

supplied but available from Eileen’s Emporium), wind a ‘spring’ shape with

extended end. We clamp a fine screw driver in the vice and holding the wire

one end in the fingers and the other in a pair of round nose pliers, form the

spring round the screw driver shaft. Note one pickup is wound clockwise, one anti-clockwise. There is only just over 3.2mm

clearance between the keeper plate and the brake pull rods and cross shafts on this locomotive so it is wise to thin the paxalon

sleeper to about 1.5mm –it just gives you that little bit more room for the pickup wires. Solder to the copperclad (gapping it first!)

as the photo above. If you are using the existing Bachmann wires that you carefully tucked inside the chassis block it is advisable

to enlarge the hole in the keeper plate and ashpan to allowthese to come through easily –do not try and force them through small

holes or it will distort the chassis.

5.24.1 Electrics. If you are DCC, you will need to use the jump leads to the tender just as supplied by Bachmann and put the

de-coder in the tender. If you are DC, the electrical jumper can be made redundant by bridging the solder blobs on the top of the

plate where the jumper pushes in. Join each outer solder blob with the one adjacent to it. This will allow you to use the original

wires to the Bachmann pick-ups to feed the motor through the resistors that are factory fitted.

5.25 Glue the paxolin pick-ups to the chassis keeper plate in the positions shown (some will need shaping around the screw

fitting points in the photo below so they gently press on the wheel flanges). Most are virtually invisible behind the brake blocks.

Test the polarity and direction of travel with another locomotive and connect together with thin rigid wire and to the motor wire.

Test run.

5.25.1 If the locomotive is run when not sitting on the track there is a chance that the gear wheel will come out of mesh. If this

happens, reduce the amount of downward play by soldering a piece of wire on top of the axlebox retainers on the keeper plate

each side below the axle.

5.26 When happy, remove the temporary crank pins, shorten the bushes and fit the crankpin bushes (note, if you are going

to fit new coupling rods as per section 7.1 do not shorten the bushes). Shorten the crankpins flush with the front of the crankpin

nuts.

Brakes

Note –if you are replacing the brake blocks and hangers with the etched version go

to section 7.2

5.27 The Bachmann plastic brake hangers are single whereas the prototype

had two hangers, one on each side of each brake block. However, using the plastic

brake blocks does eliminate potential shorts. If you decide to fit these plastic brakes,

then carefully cut the brake blocks and hangers off the Bachmann keeper plate and

footplate casting by sawing next to the main part of the centre solid section. Once

the saw cut is started hold the brake block (not the bigger keeper plate) as they will

ping off across the room! See photo of a similar operation on a 4F. Keep safely for

later use.

Brassmasters G2 EasiChas v1.0 8 September 2017

5.28 Clean up the cut line on the plastic brake hangers to ensure there are no raised edges and if necessary shorten the

hanger back ‘studs’ (that fit in the ‘cups’) so they line up with the wheel treads. Remember the chassis is sprung and the wheels

will move upwards under the locomotive weight.

5.29 Attach the two brake hanger assemblies cut from the footplate to the leading brake hanger attachment point each side

using cyanoacrylate glue or epoxy resin.

5.30 Then attach the remaining brake hanger assemblies to the brake hanger attachment points using cyanoacrylate glue or

epoxy resin. See photo 5.32.6 after fitting the cross shafts.

5.31 When it comes to the brake pull rods there is a choice of the amount of detail you may want to include.

i. Just the pull rods and brake shafts

ii. add overlays to the pull rods and pull rod levers

iii. include the brake cylinder levers

The instructions cover the full assembly as in iii., but any items can be omitted.

5.32 If your locomotive has only the rear brake cylinder, there is only one continuous brake pull rod to assemble.

5.32.1 Take the brake pull rod etch [L12], and twist the rear section though 90 degrees (see photo 5.30.2).

5.32.2 If you are fitting the brake beam

overlays and wish to replicate the slot in the

front beam, file the front edge of the of the

front beam on the brake pull rod [L12] as

shown on the diagram in Appendix 2. Identify

the eight brake beam overlays fitted to the top

and bottom of the brake pull rods [L13 for the

front beam, L14 for the second beam, L13 for

the third beam and L15 for the rear beam]. Using a piece of 0.5mm wire through the holes, solder or glue the top and bottom

overlays to the pull rod. Trim back the wire almost flush on top of the beam but leave a small section on the bottom to represent

the nut. For the one continuous brake pull rod version fill the two blind holes on the rear overlays (it just has a bolt in the middle),

for the two part pull rod version there are two bolts through the outer holes and the centre one needs filling. See photo of one part

pull rod.

5.32.3 If you are fitting the brake cylinder lever, cut three pieces of 1.2mm dia tube 6, 2 and 3.5mm long and cut a piece of

1.0mm wire about 15mm long to fit through the brake shaft brackets. Clean up the ends of the wire and tube and make sure the

tube will slide over the wire. Adjust by filing back the wire so it is flush with the outside of the brake shaft brackets on the rear of

the frames.

5.32.4 Take the brake pull rod overlays [L16] and add to each side of the brake pull rod lever [L17].

5.32.5 Assemble the brake shaft by pushing the wire through the right hand brake shaft bracket then first placing the 6mm length

of tube over the wire, followed by the brake pull rod lever [L17] with the lever at the bottom pointing to the left, followed by the

2mm length of tube, followed by the rear brake cylinder lever [L18] with the lever to the right and upwards followed by the 4mm

long piece of tube and finally push the wire through the brake shaft bracket in the left hand frame (see drawing). DO NOT

SOLDER/GLUE the assembly together at this stage.

5.32.6 Spring the brake pull rods into

place between the brake hangers.

5.32.7 Align the half-etched end of the

brake pull rods and the brake pull rod

lever, cut back as necessary and join

together with solder or glue.

5.32.8 Rotate the rear brake cylinder

lever [L18] until the piston rod is vertical.

Carefully apply solder or glue to the

assembly to lock the levers in place on the tube and wire assembly ensuring that the brake shaft can still be sprung

out of the brake shaft brackets. (See drawing) Note that the actual brake

cylinder was some 7” off centre on the prototype which is why the vertical

actuating rod is so positioned and also the reason for removal of the

Bachmann casting (which is also incorrectly shaped).

5.32.9 To remove the brake pull rods, first unclip the brake hanger

assemblies from the end of the support wire and then unclip the brake shaft

by springing the brake shaft brackets apart.

5.33 If your locomotive has two brake cylinders there are two brake pull

rods to assemble then follow this section, otherwise jump to section 5.32.

Brassmasters G2 EasiChas v1.0 9 September 2017

5.33.1 Take the rear brake rear brake pull rods etch

[L19] and twist the rear section through 90 degrees (see

photo).

5.33.2 Identify the four brake beam overlays fitted to

the top and bottom of the rear brake pull rods, [L13] for the

front beam, and [L15] for the rear beam. Using a piece of

0.5mm wire through the holes, solder or glue the top and

bottom overlays to the pull rod. Trim back the wire almost

flush on top of the beam but leave a small section on the

bottom to represent the nut. (see photo).

5.33.3 Follow instructions 5.32.3 –5.32.8 for the rest

of the assembly of the rear pull rods and brake shaft.

5.33.4 Take the front pull rods [L20] and make sure the slot at the end will allow a 0.4mm thick etch to pass along it. If you are

fitting the brake beam overlays and wish to replicate the slot in the front beam, file the front edge of the of the front beam on the

brake pull rod [L20] as shown on the diagram Appendix 2

5.33.5 Identify the four brake beam overlays fitted to the top and bottom of the front brake pull rods, [L13] for the front beam,

and [L14] for the rear beam. Using a piece of 0.5mm wire through the holes, solder or glue the top and bottom overlays to the pull

rod. Trim back the wire almost flush on top of the beam but leave a small section on the bottom to represent the nut (see photo

of one part pull rod 5.30.2).

5.33.6 Cut two pieces of 1.0mm diameter tube 5.2mm and 5.6mm long and cut a piece of 1.0mm wire about 15mm long to fit

across between the brake shaft brackets. Clean up the ends of the wire and tube and make sure the tube will slide over the wire.

The wire should be flush with the outside of the brake shaft brackets on the keep plate.

5.33.7 Attach the brake shaft lever overlays [L21] to each side of the front brake shaft lever [L22]

5.33.8 Take the front brake cylinder lever [L23] and bend at the marks as shown in the diagram Appendix 3.

5.33.9 Assemble the brake shaft by pushing the wire through the right hand brake shaft bracket in the keeper plate, then first

placing the 5.2mm length of tube over the wire, followed by the brake cylinder lever [L23] with the lever to the right and the spigot

towards the top, followed by the brake shaft lever [L22] with the lever at the bottom pointing to the left, followed by the 5.6mm

length of tube, and finally pushing the wire through the brake shaft bracket in the left hand side of the keep plate (see drawing).

DO NOT SOLDER/GLUE THE ASSEMBLY TOGETHER AT THIS STAGE.

5.33.10 Spring the front brake pull rods into place between the brake hangers.

5.33.11 Rotate the brake shaft lever until it passes between the forked end of the front brake pull rods and join together with

solder or glue.

5.33.12 Rotate the brake cylinder lever until it is horizontal. Carefully apply solder or glue to the assembly to lock the levers in

place on the tube and wire assembly ensuring that the brake shaft can still be sprung out of the brake shaft brackets. (See drawing)

5.33.13 To remove the brake pull rods, first unclip the brake hanger assemblies from the end of the support wire and then unclip

the brake shaft by springing the brake shaft brackets apart.

Rear Sandboxes

5.34 The Bachmann rear sandboxes are the correct shape if the locomotive has the

sandbox fillers in the cab side sheets. If the locomotive has the original fillers inside the cab,

new sandboxes have to be made.

5.34.1 For the original design of sandbox, take two pieces of the 2.5mm thick plastic strip just

over 6mm long and glue together. Take the sandbox template [D3] and file the blocks of plastic

to shape. Make a second sandbox in the same way.

5.34.2 Take a sandbox bottom flange [D4] and fit tothe bottom of thesandbox with the centre

1.5mm in from the outside edge using cyanoacrylate glue or epoxy resin. Repeat for the other

sandbox making sure they form an opposite pair.

5.34.3 Drill through the hole in bottom flange to take 0.7mm wire.

5.34.4 Mount the sandboxes on the EasiChas frames so that the top is level with the top of the frames and the front edge just

covers the half-etched dot on the frames using cyanoacrylate glue or epoxy resin.

5.34.5 Make new sandpipes from 0.7mm wire and bend to shape. Attach using cyanoacrylate glue or epoxy resin.

5.35 For the sandboxes with the filler in the cab side sheet, the sandboxes are the correct shape but need to be made thicker

before refitting.

Brassmasters G2 EasiChas v1.0 10 September 2017

5.35.1 Cut a piece of 2.0mm thick plastic strip just over 7mm long and glue to the back of the Bachmann sandbox. File the

plastic strip to the same shape as the sandbox.

5.35.2 Enlarge the hole in the bottom of the sandbox to take 0.5mm

wire. Shape a piece of 0.5mm wire to a ‘J’ configuration terminating just

short of the rear wheels, remembering that the shorter diagonal edge of

the sandbox is towards the front of the locomotive. Repeat for the other

sandbox. On the prototype there was a ‘trap’ just below the sandbox.

This can be represented by a joint in the wire (refer to photos).

5.35.3 Mount the sandboxes on the EasiChas frames so that the top

is level with the top of the frames and the front edge just covers the half-

etched dot on the frames.

5.35.4 Take the left hand brake pipe support bracket [S1] and bend

over the half-etched part to 90 degrees. If necessary, curve the bracket

so that it fits flat on the frames and over the sandpipe. Repeat for the

right hand bracket [S2]. Attach the brackets to the frames and sandpipe

by soldering or using cyanoacrylate glue or epoxy resin.

Front sand pipes

5.36 Sand pipes were fitted to the front two sets

of wheels.

5.36.1 Make two notches in the top of the frame

etch to take 0.7mm wire at 20mm and 44mm from the

front edge of the frames both sides.

5.36.2 Take a piece of 0.7mm wire and bend the

first 3.5mm over at a right angle with a fairly sharp

bend, then shape the rest of the wire to shape around

the brake hanger (see prototype photo).

5.36.3 Solder in position in the top edge of the

frame.

5.36.4 Take a front sandpipe bracket [S3], curve

the end round a piece of 0.7mm wire, cut to length and

attach to the sandpipe and frames by solder or using

cyanoacrylate glue or epoxy resin.

5.36.5 Repeat for the other three sandpipes.

5.37 Re-fit the locomotive body. The basic locomotive conversion is now complete.

6 Basic tender conversion

6.1 Remove all the parts (washers etc) from

the tender frames [T1] and place them in your safe

place. There are four spacing tabs, two at each

end of the frames that need to be filed off if they

are being fitted in the plastic Bachmann tender

frames. Do not file them off if you are also building

the replacement outside frames (actually it is not

the end of the world if you do so don’t panic if you

later decide to build the replacement outside

frame). Fold up the tender frames [T1] to form a U

section, taking special care with the narrow section

on the bottom of the U towards the front of the

tender. Fold the outer half of the slotted axle

bearing sections through 180 degrees back on

themselves inside the frame. Note: the etched line

is on the outside of the bend. To ensure a tight

bend, squeeze the two halves together using a pair

of pliers. (see Photo)

6.2 Open up the slots in the tender frames [T1] so that the tender axles slide freely without any slop.

6.3 Bend at 90 degrees the eight small ears on each side of frames so they protrude outside of the frames. Bend the four

brackets that will support the vacuum reservoir through 90 degrees towards the track (see photo).

6.4 Cut off the plastic pillar which held the tension lock coupling at the rear of the Bachmann tender frames.

Brassmasters G2 EasiChas v1.0 11 September 2017

6.5 Remove the A frame towards the rear of the Bachmann tender floor. Also, the body retaining clips on the Bachman

tender body at the front of the tender need to be reduced in width to clear the EasiChas frames using a craft knife or file.

6.6 Ensure that the new frames fit into the Bachmann tender. Secure in place using the Bachmann tension lock coupler

screw in the rear hole. This is sufficient to hold the new frames in place. Remove the screw and tender frames.

6.7 Take the six axleboxes [T2] and, if necessary, open out the axle holes so that the axles rotate freely with a very slight

amount of slop.

6.8 Fold up the six axleboxes [T2]. This is best done by placing the etch with the half-etched

middle section perpendicular to the edge of a rule, or similar, to form a ‘T’ shape. Push down on

each end of the etch so that it begins to wrap over each side of the rule. See photo.

6.9 Remove from the edge of the rule and push together between the fingers. Complete the

bend by squeezing the two edges furthest from the bend with a pair of pliers (this is best done with

a 2mm axle through the two holes which ensures two holes line up).

6.10 Assemble the rear tender wheelsets by firstly fitting spacing washer(s), then a bearing,

then the second bearing, then more spacing washer(s) and finally the second wheel. Sufficient

washers need to be fitted between the wheel and the bearingto ensure there is minimumsideplay.

For guidance for P4 two full width and one half-etched washers per side is recommended on the

rear axles, one and a half on the leading and one none on the centre. For EM a single washer on

the rear is sufficient. For less than 3ft curves, fewer will be required.

A tip to check the first wheel fitted is running true, is to balance them on

a steel rule holding the axle with a file and move to left and right

spinning the wheels, and wobble can be corrected by ‘twisting’ the

wheel with finger pressure and then re-checking. See Photo.

6.11 Mount the wheelsets in the ‘U’ slots on the frames with the

axleboxes on the outside of the frame.

6.12 Take the thin 8 thou steel spring and

put a 2mm right angle bend in the end, cut to

77mm long and then slide the wire through

the frame ears and holes in the axleboxes

(this is a bit of a fiddle!). Bend over the end of

the wire to retain. See Photo.

6.13 Fit the frames to the Bachmann

tender, locating and refit the tender top.

6.14 Ensure that the tender runs smoothly

and that all the axleboxes are free to move up

and down. Adjust the Bachmann tender coupling to suit your model curves.

6.15 Re-assemble the tender. The locomotive tender coupling has quite a bit of slop in it. If desired, solder a 2mm washer to

the bottom of the coupling link over the rear hole. This then slides onto the tender pin without slop.

The basic tender conversion is now complete, but significant visual improvements can be made by replacing the tender brake

gear, see section 8.

7 Additional locomotive components

The following additional items are provided in the kit and may be used if the builder requires.

7.1 Replacement coupling rods

7.1.1 There are two types of coupling rods suitable for this locomotive, the later type made up of three jointed sections and the

earlier ones that are made up of three separate rods on each side (the centre rod overlaps the two outer ones). Generally, the 3-

part rods lasted up to WW2 to be replaced by jointed ones; however, some locomotives were built with the later type. By BR days,

the 3-part rods were very scarce. Study your photos of the prototype! The later type is provided with the kit, but the earlier type is

available separately from Brassmasters (ref C106).

7.1.2 These instructions refer to the jointed type included in the base kit. Each side is manufactured from six etches and hinged

in front of the second crankpin and behind the third crankpin. There are also overlays for the bosses. There are spares for the

bosses so don’t worry when there are some left over at the end.

7.1.3 Cut two of the centre pair of rods from fret [C1].

Brassmasters G2 EasiChas v1.0 12 September 2017

7.1.4 Open the crankpin holes using a 1.5mm drill.

When complete drill a hole using the same size drill

perpendicular in a scrap piece of wood. Leave the drill in

the hole in the wood. Tin the mating surfaces of a pair of

coupling rods and place over the drill. This holds one end

of the rods accurately ready for soldering. It is critical to

align the two halves exactly in order to make one rod, so take some time tweaking. See photo.

7.1.5 Attach a boss [C2] to the front and back of each boss, again using the drill to ensure alignment.

7.1.6 Place a little flux along the top surface of the rod and apply heat; the solder on the soldering iron will run down between

the rods and join them. The secret is to apply only a little solder at a time. Solder will fill the “cusp” and give the impression of a

solid rod. See photo. Repeat for the whole length of the rod.

7.1.7 Repeat for the second pair of centre rods [C1]. The rod below has the overlays added on the right end only and has been

dressed with the file as below in section 7.1.11.

7.1.8 Next take a pair of outer rods [C3 and C4] and open out the crankpin holes with a 1.5mm drill. Again, assemble using

the drill to align the rods.

7.1.9 Take two of the boss overlays [C5]

and attach to the front and rear of the rods

holding it in place with a cocktail stick and

solder in place using the same technique as

for joining the rods. Finally take two of the

forked joint overlays [C6] and attach either

side of the forked ends.

7.1.10 Repeat for the other three outer

rods.

7.1.11 Clean up each rod with files.

Carefully blend the bosses intothe front face

of the rods. The prototype radius of the blend at the crankpin bosses is 6” so it is best to use a file of about 4mm diameter. We

used an oval file. Referring to the middle rod in the attached photo, the file should be placed in middle step and then filed

downwards to give the result in the top rod.

7.1.12 The rods for each side of the locomotive have two knuckle joints to manufacture. They are joined with a small rivet

pushed through from the front after carefully opening the holes out to accept the rivet with a reamer. It is vitally important not

to let these holes ‘drift’ or this will result in rods that do not match the wheelbase of the chassis. See photo.

7.1.13 Using a larger drill, lightly

countersink the rear face of the forked

end.

7.1.14 To stop solder flooding the joint apply a little oil to the surfaces not to be soldered - this will prevent the solder running

into the joint. Keep the rear of the rod clean. Solder can then be quickly applied with a very hot iron to the back of the rod to fix

the rivet in place. Clean off excess solder leaving enough to keep a strong joint. See photo above of completed rods.

7.1.15 A comparison of the Bachmann and Brassmasters rods is shown in the photo.

7.1.16 Open up the crankpin holes

in order that the crankpin bushes will

rotate freely in the rods. This can be

done with a reamer, broach or a fine

Swiss file.

7.1.17 Fit the rods to the wheels and test run.

7.2 Replacement brakes and brake hangers

7.2.1 The plastic brakes are rather nicely moulded. However metal replacement brake hangers can be fitted if the Bachmann

brake hangers are lost or a metal replacement is preferred. Remember plastic doesnot produce an electrical short and the wheels

are sprung so move vertically!

7.2.2 Take the two brake hangers [L26 and L27] and open out the top and hole to clear 0.5mm wire, the centre hole to clear

0.9mm wire and the bottom hole to clear the ends of the brake pull rods [L12, L19 or L20]. Then take the brake block [L28] and

open out the hole to clear 0.9mm wire.

Brassmasters G2 EasiChas v1.0 13 September 2017

7.2.3 Drill two holes vertically in a piece of wood through the top and bottom holes in one of the brake hangers, using an a

0.5mm drill and an appropriate size drill for the bottom hole. Put two pieces of appropriately sized wires in the two holes then

place one of the brake hangers over the wires with the half-etched brake block uppermost. With a piece of 0.9mm wire through

the centre hole, mount a brake block [L28], followed by the opposite hand brake hanger with the half-etched brake block

downwards. Make sure the brake block is the same way round as the half-etched version on the brake hangers, and then solder

the three pieces together. Ensure that the top and bottom wires are not soldered to anything. Remove the assembly and cut

and file the 0.9mm wire so that a small amount protrudes on one side to represent the bolt holding the brake block. Make another

three brake blocks the same, and then another four with the 0.9mm protruding from the opposite side.

7.2.4 Solder four pieces of 0.5mm wire across the mainframes

using the holes provided so that about 7mm protrudes from the

frames on both sides, making sure there is a good solder joint inside

both sides of the frames. DO NOT CUT OFF THE WIRE BETWEEN

THE FRAMES at this stage.

7.2.5 Mount a brake hanger bracket [L29] over each one of the

wires and attach to the frames with the top edge horizontal.

7.2.6 Cut eight short pieces of 1.0mm diameter tube about

0.5mm long. This is best done using a craft knife such as a Stanley

knife and rolling the tube back and fore with the blade until it cuts

into the tube. Be careful as the piece may go flying off. Clean up the tube and also the ends of the 0.5mm wire through the frames

and make sure the tube goes over the ends of the wire.

7.2.7 With a wheelset in place, put a piece of tube over the wires adjacent wire and position the brake block assembly in the

appropriate place across the tread of the wheel. Slide the piece of tube up to the brake hanger and measure how far the outside

edge of the tube is from the frames. Remove the wheelset and the brake hanger assembly and then solder a piece of tube to

each wire the measured distance from the frame.

7.2.8 Cut back and file the outer

ends of the wire so that they protrude

through the brake hanger assembly by

about 0.5mm.

7.2.9 It is now time to cut the wire

between the frames but DO NOT USE

CUTTERS to make the first cutas it will

distort the frames; either use a piercing

saw or a triangular file. Once the wire

is cut, then cutters can be used to trim

back the wire inside the frames so that the frames can be remounted on the Bachmann chassis block.

7.2.10 Assemble the brake pull rods as per paragraphs 5.30.1 and 5.30.2 for single brake pull rods, or as per paragraphs 5.31.1,

51.2, 5.31.5 and 5.31.6 for the two sets of pull rods. Do not build the brake shafts at this time.

7.2.11 With the frames mounted on the chassis block, mount the wheels without the suspension springs and retain in place with

the keep plate.

7.2.12 If the locomotive you are modelling has only one set of brake pull rods, mount two brake block assemblies on the rear

most wire and two on the fore most wire. If the locomotive has two sets of brake pull rods, mount the brake block assemblies on

the rear most and next wires. Position the brake pull rods through the holes in the brake hangers ([L12] for the single pull rod,

[L19] for the rear pull rod).

7.2.13 With the locomotive standing

on its wheels, manoeuvre one of the

brake block assemblies so that it is

vertical and is far enough away from

the tread for the wheel and brake block

not to come into contact when the

wheel moves up and down. Solder the

brake block assembly to the pull rod.

Repeat for the other three brake block

assemblies.

7.2.14 Remove the pull rod/brake

block assembly by springing the top of

each brake block assembly over the

end of the wire. If you have used an

active flux, remove the wheels and

clean thoroughly to remove any flux.

7.2.15 If the locomotive has two sets of pull rods, repeat 7.2.12 –7.2.14, but with the brake block assemblies mounted on the

foremost and second wires and using the front brake pull rods [L20].

Brassmasters G2 EasiChas v1.0 14 September 2017

7.2.16 If the locomotive has only one pull rod, mount the remaining brake block assemblies on the wires and solder them to the

pull rods.

7.2.17 The brake shaft(s) can now beassembled as per rest of section 5.30 for the single pull rods and as per the rest of section

5.31 for the two brake pull rods.

7.2.18 Removal of the complete assembly is now carried out by springing the brake blocks assemblies off their wires and then

springing the brackets to release the brake shafts.

7.3 Cylinder drain cock mechanism and operating lever

7.3.1 Remove the frames from the chassis and the wheels from the

frames and then open out the holes in the two cylinder drain cock brackets

on the front lower edge of the frames to clear 0.4mm wire.

7.3.2 Take the drain cock operation rod [D5], open out the hole to clear

0.4mm wire and bend the end of the rod through 180 degrees with the

bend line on the outside.

7.3.3 Thread a piece of 0.4mm wire through the right hand side bracket

in the frame, through the hole in the end of the drain cock operating rod,

making sure it is correctly orientated, and then through the hole in the

opposite frame.

7.3.4 Position the operating rod so that it is close to the right hand frame. With

the vertical part of the operating rod parallel with the axlebox, hold in position and

solder to the frames (Weused a miniature wood clothes peg from the really useful

set sold by Eileen’s Emporium for less than £1).

7.3.5 Position the other end of the rod slightly way from the bracket and solder

to the wire and then solder the wire in the bracket. Solder the wire to the bracket

at the other end as well.

7.3.6 Cut the wire between the rod on one side and the bracket on the other,

BUT DO NOT USE CUTTERS TO MAKE THE FIRST CUT because it will distort the frames; use either a piercing saw or a

triangular file. Then you can use cutters to make the second cut.

7.3.7 Cut back the wire on the outside of the brackets and file flush

with the front.

7.3.8 Reassemble the frames on the chassis block.

7.3.9 Take the cylinder drain cock operating mechanism etch [S4],

and bend up each side (see photo). Be careful when handling this

etch –hold at the ends otherwise the rods distort –guess how we

know!

7.3.10 Cut a piece of 0.6mm wire 14mm long and solder across the

etch in the slot provided, with an equal amount protruding each side.

Position the assembled etch on the underside of the chassis block and

cut back the wires until it fits in position and the wire clears the bracket on the frames at one end and the operating lever at the

other.

7.3.11 Attach the etch to the chassis block with the extension piece towards the front using cyanoacrylate glue or epoxy resin.

7.4 Replacement buffer beams

7.4.1 The locomotives were fitted with two types of buffer beam, the original [D7] and the strengthened [D8] fitted to some

locomotives from mid-1942.

7.4.2 Take the locomotive body and remove the Bachmann buffers by gripping with a pair of pliers and wriggling then until

they come loose.

7.4.3 Remove the detail from the cast Bachman buffer beam with a file (We actually use a burr in a mini-drill for removing the

buffer bases). Now is the ideal time to solder replacement coupling hook to the etched replacement buffer beam –we use a

Brassmasters one! (ref MC005)

7.4.4 If refitting the Bachmann buffers, after pushing through the rivets, attach the buffer bases [D9] to the buffer beam by by

solder or using cyanoacrylate glue or epoxy resin.

7.4.5 Attach the buffer beam to the locomotive using cyanoacrylate glue or epoxy resin.

7.4.6 Fit replacement buffers or replace the Bachmann buffers. Undoubtedly you will have damaged the Bachmann red paint

so it is probably best to remove this from all the buffer body before refitting.

Brassmasters G2 EasiChas v1.0 15 September 2017

7.5 Replacement reach rod

7.5.1 The prototype locomotives were fitted with two versions of Joy valve gear, the original indirect drive, and the later direct

drive, each type having a different reach rod and weighbar lever. The indirect drive can be identified as the reach rod is straight,

on direct drive it is cranked (the bend is behind the second splasher sand box). By the 1930s direct drive was far more common.

If you need to study photographs, 9204 on p117 of LNWR Eight coupled locomotives is indirect drive, 9061 p107 is direct. As well

as providing for the different reach rods and weighbar levers, the kit also provides for the valve gear to be in the mid position or

the full forward position.

7.5.2 Remove the boiler and cab from the footplate by undoing the screws underneath the footplate under smoke box and

under the firebox backplate. The backplate can then be removed and the boiler/cab assembly can be lifted off. Remove the cab

handrail for safe keeping.

7.5.3 Remove the reach rod by cutting behind the sandbox and cutting between the rod and the bracket on the third splasher.

Do not damage the bracket as it is used with the new reach rods.

7.5.4 The sandbox on the second splasher is too wide to allow the reach rod to pass down the back. Reduce the width of the

sandbox from the back by 0.5mm (the prototype did this too).

Earlier indirect valve gear

7.5.5 In this version of the valve gear, the weighbar was mounted low down in the frames. Firstly chose whether the valve gear

is to be in mid position or full forward.

7.5.6 Select the appropriate weighbar lever front and back (for mid gear [D10] lever front, [D11] lever back, for forward gear,

[D12] lever front, [D13] lever back).

7.5.7 Open out the two upper holes to clear 6mm wire then carefully bend the lever front and lever back as shown in the

diagram (there is a half-etched dimple where the outer rod needs to be bent at the bottom). A piece of 6mm wire passed through

the holes needs to be parallel to the footplate. When satisfied solder together.

7.5.8 Take the indirect each rod [D14], open out the hole to clear 6mm wire and push through the rivets for the joint from the

back. Attach the joint plate [D15] to the back of the rod behind the rivets.

7.5.9 The weighbar lever is attached to the footplate in the position shown in the diagram, using cyanoacrylate glue or epoxy

resin. However, if you are going to fit replacement sander levers (see section 7.6) it is best to attach the reach rod and weighbar

after these.

Brassmasters G2 EasiChas v1.0 16 September 2017

7.5.10 Trim back the reach rod at the cab end so

that it clears the cab front whenin position. Using the

washers [D16] between the reach rod and the back

of the weighbar lever, Make sure the rod will sit in

the correct position out from the boiler, thinning the

back of the bracket on the splasher if necessary.

7.5.11 Place the reach rod in position and insert a

short length of 6mm wire through the joint with the

weighbar lever. Secure the reach rod in position

behind the bracket on the third splasher using

cyanoacrylate glue or epoxy resin.

7.5.12 Solder or glue the joint wire in position and

trim to length.

7.5.13 If not fitting the replacement sander operating rods, re-assemble the boiler, cab and footplate.

Later direct valve gear

7.5.14 In this version of the valve gear the weighbar was mounted level with the top

of the frames. First chose whether the valve gear is to be in mid position or full

forward.

7.5.15 Take the bearing base [D17] and carefully bend at right angle along the back

of the full etched piece (see photo of an direct weighbar). Attach a spacer [D18] to

the bottom.

7.5.16 Select the appropriate weighbar lever front and back (for mid gear, [D19]

lever front, [D20] lever back, for forward gear, [D21] lever front, [D22] lever back).

7.5.17 Open out the two upper holes to clear 6mm wire then carefully bend the

lever front and lever back as shown in the diagram. A piece of 6mm wire passed

through the holes needs to be parallel to the footplate. When satisfied, solder

together.

7.5.18 Solder the weighbar levers to the back of the bearing base (see photo).

7.5.19 Take a piece of 2.0mm wire and file the end 4mm into a ‘D’- shape, such that the ‘D’is slightly less than half the original

diameter (0.8mm). Cut two lengths 1.5mm long.

7.5.20 Attach one length to the top of the bearing base (see photo).

7.5.21 Make the bearing for the opposite end of the weighbar by taking two

spacers [D18] and soldering them together. Attach the second piece of the D

shaped wire to the top (see photo).

7.5.22 Take the direct reach rod [D23] and open out the hole to clear 6mm wire

and push through the rivets for the joint from the back. Attach the joint plate [D15]

to the back of the rod behind the rivets.

7.5.23 Make two bends at right angles in the reach rod at

the half-etched bend lines. Apply a generous fillet of solder to

the inside of both bends to represent the shape of the rod at

this point (see diagram).

7.5.24 The weighbar lever and opposite bearing are

attached to the footplate in the positions shown in the

diagram, using cyanoacrylate glue or epoxy resin.

7.5.25 Trim back the reach rod at the cab end so that it

clears the cab front when in position. Make sure the rod will

sit in the correct position out from the boiler, thinning the back

of the bracket on the splasher if necessary.

7.5.26 Place the reach rod in position and insert a short length of 6mm wire through the joint with the weighbar lever. Secure

the reach rod in position behind the bracket on the third splasher using cyanoacrylate glue or epoxy resin. However, if you are

going to fit replacement sander levers (see section 7.6), it is best to attach the reach rod and weighbar after these.

Brassmasters G2 EasiChas v1.0 17 September 2017

7.5.27 Solder or glue the joint wire in position

and trim to length.

7.5.28 If not fitting the replacement sander

operating rods, re-assemble the boiler, cab and

footplate.

7.6 Replacement sander operating rods

7.6.1 If not already done so, remove the boiler/cab

assembly as in 7.5.2. This is what you are aiming for.

7.6.2 Carefully cut off the plastic sander operating

mechanism below the lever and behind the bracket on the

splasher (see photo). File the top of the mechanism flat –you

will need to leave about 1.35mm of the upstand present. If

you leave too much, the mechanisms foul the boiler cladding.

Strangely, the right hand side of the Bachmann boiler seems

closer to the sandboxes than the left –be aware of this when

you are making these mechanisms and try a ‘dry run’ of fitting the boiler before securing these mechanisms. Also, it will be

necessary to carve the back of the bracket on the splasher until it is slightly thinner.

7.6.3 Drill a 0.35mm hole vertically in the centre of

each sander valve (see photo)

7.6.4 Drill a 0.35mm hole horizontally through the

sander bracket on the splasher (see photo)

7.6.5 Take four sander levers [D30] and reduce the

overall length to 2mm to help clear the boiler cladding.

Ensure the holes clear 0.33mm wire.

7.6.6 Drill a 0.33mm hole vertically in a piece of

wood, insert a short length of 0.33 wire in the hole, place

a sander lever over the wire and solder in place. Trim

the wire on one side of the lever almost flush.

7.6.7 Repeat for the other three levers.

7.6.8 Take the two sander operating rods ([D31} left hand side and D32] right hand side) and make sure the holes in the bottom

clear 0.33 wire.

7.6.9 Using the same piece of wood, insert a short length of 0.33 wire in the hole, place a sander operating rod over the wire

and solder in place. Trim the wire on the inside of the rod almost flush.

7.6.10 Repeat for the other sander operating rod.

7.6.11 Place two of the sander levers in the left hand sandboxes and inset the left hand operating rod [D31] into the back of the

bracket on the footplate.

7.6.12 Carefully adjust the position of the levers and rod so

that the rods are horizontal and the two levers are in the

correct position. Secure in place using cyanoacrylate glue or

if you are brave a tiny dab of solder between the lever and the

rod.

7.6.13 Repeat for the right hand sander rod and levers.

7.6.14 Replace the boiler and cab assembly on the

footplate by reversing the sequence in 7.5.2

7.7 Cab footplate floor

7.7.1 Check that the cab footplate floor [D33] fits in position before attaching using cyanoacrylate glue or epoxy resin.

7.8 Lamp irons

7.8.1 The lamp irons provided on the locomotive are plastic and are therefore too thick. Etched replacements are provided for

the footplate ones and the one on the top front of the smokebox.

Brassmasters G2 EasiChas v1.0 18 September 2017

7.8.2 Remove the plastic lamp irons on the Bachmann footplate by carving them off and fill any resultant holes with filler.

7.8.3 Take three footplate lamp irons [D34] and bend them at right

angles where the upright joins the base. Glue in position on the footplate

using cyanoacrylate glue or epoxy resin. The centre one should be

offset to the right (looking at the locomotive front) by just over 0.5mm

(0.67mm) and the same distance back from the front edge of the

footplate. The other two are in line with the buffers and again just over

0.5mm (0.67mm) from the footplate edge. Remember, the vertical part

of the bracket is furthest away from the buffer beam with the section

with two bolts to the front.

7.8.4 If you are going to fit a replacement whitemetal LNWR

chimney, jump to section 7.10 as it is safer to do that now. The top lamp

iron is quite respectable especially if carefully thinned with a file. Be

careful not to damage the rivets on the smokebox top. To fit the

replacement brass smoke box top lampiron [D35] requires the handrails

to be removed and this means that the three handrail knobs on the front

of the smokebox have to be pulled out. This can be done quite easily

be putting the points of a pair of tweezers either side of the handrail knob from the outside of the smokebox and levering very

gently on the smokebox door (We put a piece of cardboard over the door to lever on so as not to mark the door). Remove the

handrail by pulling it out of the knobs down the left hand side of the locomotive and out of the hole on the right hand side of the

locomotive.

7.8.5 Carefully remove two knobs from the short end of the wire. Put

one carefully away, but the other will need to be mounted in a pin chuck

with the base outwards. This is best done by mounting the hand rail on a

short piece of wire, putting the wire into the chuck between the jaws and

then tightening the chuck on the knob.

7.8.6 Using the wire to orientate the knob, file flats on each side of the

knob spigot at right angles to the wire until the slot on the lamp iron [D35]

slides over the spigot. File a similar flat on what will be the top side of the

spigot to ensure the lamp iron sits down on the knob far enough. Finally,

reduce the thickness of the knob base by filing around the spigot.

7.8.7 Cut off the top plastic lamp iron and file the top of the smokebox smooth. Be careful

not to damage the rivets on the smokebox. Carefully carve off the representation of the lamp

iron base on the smokebox front. Don’t forget that the smokebox door opens. Clean up any over

enthusiastic application of glue by Bachmann round the other holes.

7.8.8 Remount the removed handrail knobs on the wire, the centre one first and in the correct

orientation. Refit the wire handrail to the loco, being careful that the knobs do not fall off the end

of the wire as you do so (We thought we had lost one of ours!). Push the knobs into place into

their original holes.

7.8.9 Pull each of the outer two knobs out in turn, carefully apply a small spot of glue to the

spigot and push back in. Apply a small spot of glue to the rear of the top lamp iron, pull the centre

knob out slightly, position the lamp iron and push the knob into place. We used cyanoacrylate for

this, but epoxy resin would also work.

Smokebox Door Handles

Some Bachmann models come with twin smokebox door darts (a wartime fitting and far from universal); also the plastic wheel is

quite heavily moulded.

7.9 To replace either the outer handle or wheel, remove the plastic handle or wheel. Take the smokebox door wheel [D61]

and open up the centre hole to accept 0.3mm wire. Solder a piece of 0.3mm wire through the hole. Drill a 0.33mm hole in the

centre of the inner handle and glue in place using cyanoacrylate or epoxy resin.

LNWR chimney

7.10 All the Bachmann models come with Stanier chimneys, which were not fitted until the late

1930s and did not become common until the 1950s. A replacement cast whitemetal LNWR chimney

is available from Brassmasters (ref A251).

7.11 Cut off the plastic chimney with cutters finishing off with files and fine emery paper. It is

essential that a smooth smokebox top is formed.

7.12 Clean up the whitemetal chimney and shorten the base stub which fouls on the Bachmann

weight inside the smokebox.

7.13 Drill out the top to a deeper level as this improves appearances and fit with glue.

Brassmasters G2 EasiChas v1.0 19 September 2017

8 Additional tender components

8.1 Replacement brake gear

8.1.1 The Bachmann tender brake gear is moulded as part of the frames and is perhaps the weakest visual area of the model..

8.1.2 Cut the brake gear away and clean up the cuts, especially the inside of the ‘round ended’ cut-outs.

8.1.3 Bend up the front brake shaft bracket [D37] and solder in position across the top of the EasiChas frames with the centre

tongue engaging in the frame cut-out. These brackets should be immediately behind the tender frames, the plastic frames are

further apart than prototypical so if you are not fitting replacement Brassmasters frames but retaining the plastic Bachmann ones

then adjust the bends (there is a second half-etched line above the ‘V’) so they are in this position.

8.1.4 Solder the brake shaft bracket overlays [D38] in position on the outside of the rear brake shaft brackets on the EasiChas

frames with the bolt heads in a square configuration (like :: ) bolts parallel to the track.

8.1.5 Identify the handbrake lever [D39], the handbrake pull rods [D40] and the vacuum brake lever [D41] and open out the

holes in the end to clear 0.6mm wire. Also ensure the holes in the two brake shaft brackets will also clear 0.6mm wire.

8.1.6 Cut two pieces of 0.6mm wire long enough to go across the two brake shaft brackets and be flush on the outside.

8.1.7 For the rear brake shaft cut three pieces of 1.2mm x 0.6mm inside diameter tube, 1.8mm, 6.8mm and 2.2mm long.

8.1.8 Place a piece of 0.6mm wire through the rear brake shaft bracket and position the handbrake lever [D39] over the wire

and then push the wire through the opposite bracket. Hold the handbrake lever against the inside of the right hand frame (left

hand when looking from below) and with the end against the base of the EasiChas, solder in position at the base end. DO NOT

SOLDER TO THE WIRE.

8.1.9 Pull the wire back so that it just goes through the bracket and handbrake lever and then assemble the rear brake shaft

by first mounting the 1.8mm piece of tube on the wire, then one of the handbrake pull rods [D40] (the end with the slot is towards

the front - see photo to get the correct orientation), then the 6.8mm piece of tube, then the second joining rod and then 2.2mm

piece of tube. Finally push the wire through the opposite side bracket. Check that the tube does not cause the brackets to splay

out sideways.

8.1.10 For the front brake shaft cut, four pieces of 1.2mm x 0.6mm inside diameter brass tube 7.5mm (8.0mm if fitting to the

plastic frames of the Bachmann tender), 5.6mm, 0.8mm and 7.5mm long (8.0mm if fitting to the plastic frames of the Bachmann

tender).

8.1.11 Now assemble the front brake

shaft by putting the wire through the left

hand side bracket (again the right when

looking from underneath) and then