5

that the cylinders are a good fit it the slots in the frames. Fold up the cylinders making sure they are square and fold

out the 2-to-1 arm bracket.

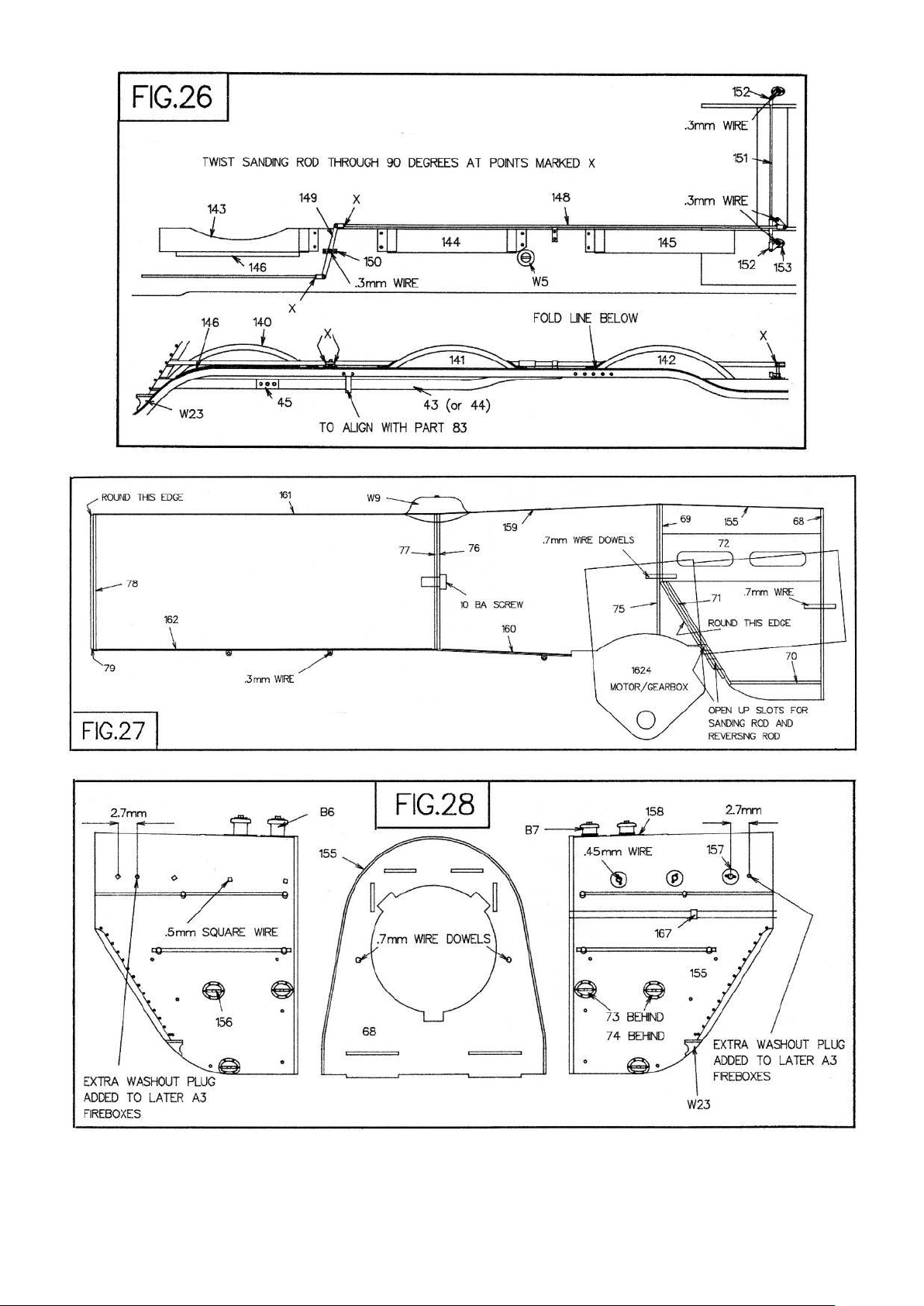

Construct the slidebars as shown in Fig. 18. Use plenty of solder whilst applying pressure to keep the laminations

together. Clean off the front and rear faces and remove the rear section. The crosshead slot will need cleaning out so

that the cross head is a good fit. This can be done with a thin file - haven't gone one? - then use a piece of emery paper

over a scrap piece of brass etch. The appearance of the slidebars is much improved by carefully filing the top smooth.

Insert the slidebars in the cylinders and tack soldered in place. After checking all is square and parallel they are

permanently attached. Attach the piston rod glands (part N4) and check that the crosshead slides properly. Solder the

valve crosshead guides (parts B17 & B18) in place aligning them with a piece of 0.8mm wire passed through the valve

rod holes.

The cylinder relief valves (part B3) were a later addition. If photographs shown you need to fit them drill out the holes

in the front cylinder covers (part N5 & N6) - marked on the inside - so that the relief valves will pass through. Attach the

front covers and, if appropriate, fit the relief valves. Add part 29 as shown in Fig. 9.

Solder together the connecting rod laminations (part 23 & 24) and add the rod boss laminations (part 25) to the big end

back and front. Drill the big end to fit the crankpins and the small end 1mm. Solder the crosshead arm (part 52 or 53) to

a piece of 1mm wire as a pin. Fit the connecting rod to the crosshead, ensuring the crosshead arm is vertical, carefully

solder the pin from the rear and file flush. Fit the connecting rods with a thin washer (part 109) between the coupling

rods and connecting rods and check the clearance of the connecting rod and the leading axle crankpin nut. You will

probably have to reduce the thickness of the nut.

Solder the slide bar bracket laminations (part 30) together back to back. Attach the cylinders to the chassis with two 10

BA bolts and fit the slide bar bracket through the frame slots and solder to the slide bars.

SECTION 12: VALVE GEAR

All the valve gear joints, with the exception of the eccentric arm/eccentric rod, are made with wire pins soldered on the

inside. This clearly runs the risk of soldering the joint solid. To minimise this:

(i) ensure the pin is a tight fit in the hole.

(ii) use oil or a proprietary solder mask.

(iii) use plenty of flux, a small amount of solder, and be quick!

Bend up, in a vice, part 37 centring the bends on the etched slot. Solder part 38 in the slot in part 37 ensuring that the

holes for the radius link pivot align horizontally and vertically. Solder the radius link brackets to part 39 as in Fig.11 and

check the assembly fits in the frame slots. Solder short pieces of 1mm wire to the brackets for the radius link pivots.

Drill out the holes in the radius link laminations (parts 34 & 35 or 36) to take the 0.3mm wire pins which align the

laminations and represent the bolt heads. Solder the inner laminations together with four lengths of 0.3mm wire

(Fig.12). Check that the slot in the inner laminations is a sliding fit with the 0.7mm wire.

Place the radius rod (part 46) and radius rod rear lamination (part 47) over the radius link, align with a piece of 0.7mm

wire, and solder the lamination to the rod. Solder the 0.7mm wire pin in place and clean off flush. The radius rod

should now move smoothly in the link. Add the fork joint (part 48) to the front of the radius rod. Open out the holes in

the radius link outer lamination (part 34) so that they are a good fit on the pivot wires on the radius link bracket. Solder

the outer laminations in place and cut off the 0.3mm wire to represent the bolt heads. Gently spring the links in place

in the brackets (insert washer part 40 as shown in Fig.40) and check that the links pivot freely and are vertical.

Form the joggle in the combination levers (part 49) with the fold lines inside reinforcing the bends with solder.

Assemble the rear valve rods (part 54) and union link (parts 50 & 51). Make the valve rods as long as possible so that

they just go in past the slide bar bracket. Pin together the combination lever, union link, valve rod and radius rod.

Add the fork joint (part 33) to the eccentric rod (part 32). Reduce the diameter and thickness of the rivet heads so that

they will fit in the recess in the back of part 108. Tap the crankpin hole in the eccentric crank (part 31) 14 BA. Oil the

tap and use it to screw the eccentric arm and a crankpin nut together as shown in fig.14. Now solder the nut to the

arm. Remove the tap and file off flange of the nut. This gives an arm with a substantial thread which can be tightened