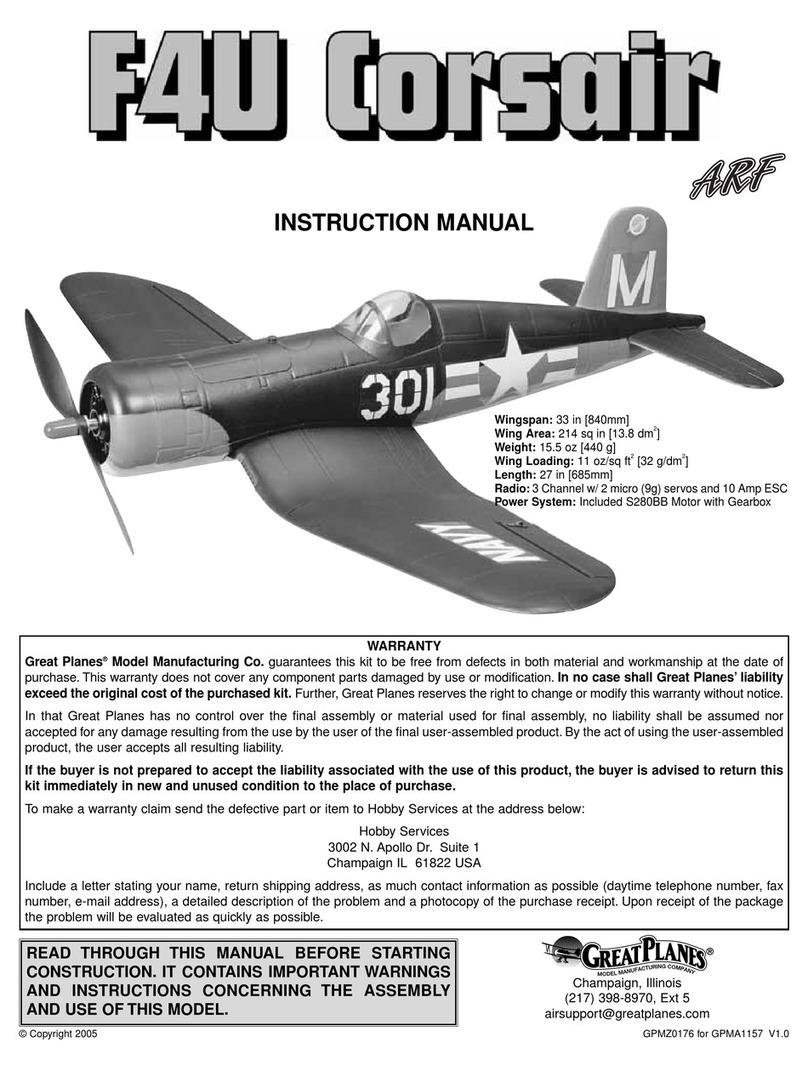

Brassmasters GWR 3000 User manual

Brassmasters

Scale Models

www.brassmasters.co.uk

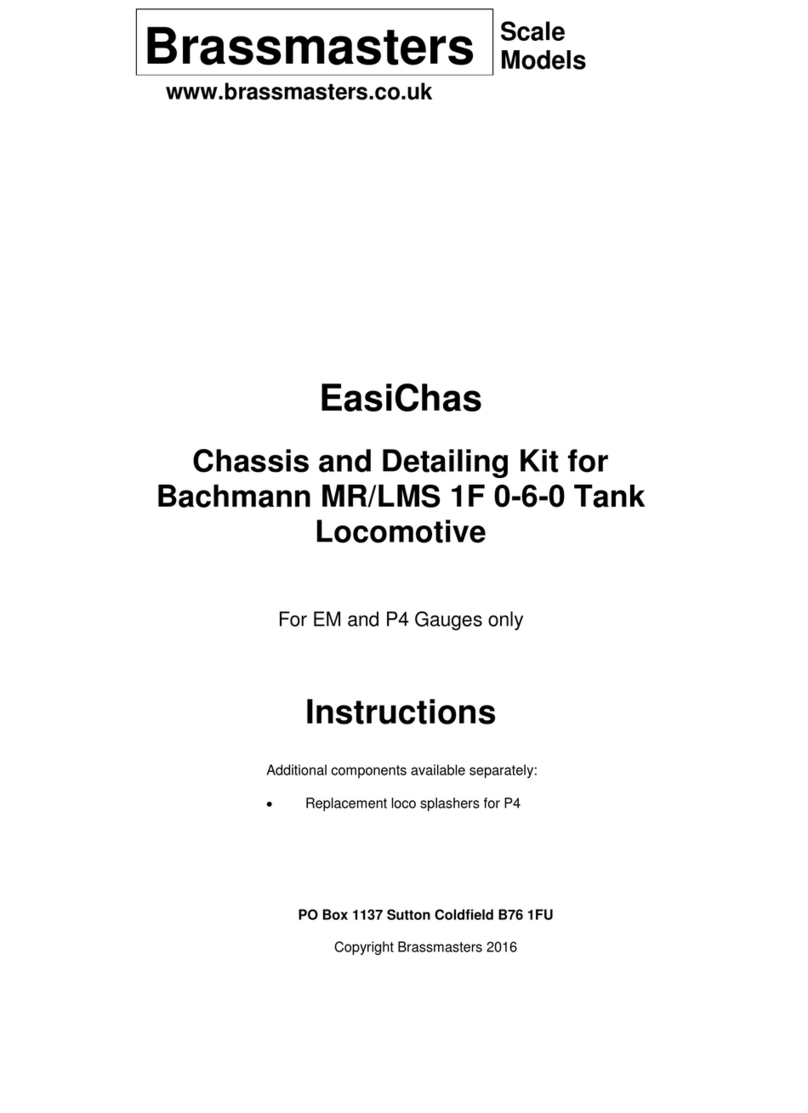

GREAT WESTERN RAILWAY

DEAN 3,000 GALLON

TENDER KIT

Designed by Martin Finney

4MM SCALE

OO - EM - P4

INSTRUCTIONS AND

PROTOTYPE NOTES

PO Box 1137 Sutton Coldfield B76 1FU

Copyright Brassmasters 2015

1

SECTION 1: BRIEF HISTORICAL DETAILS

Between 1884 and 1906 the GVR built 397 tenders with a water capacity of 3000 gallons, all to basically the same

design. They had a coal capacity of 5 tons, a wheelbase of 15 feet, and weighed 36t. 15c. full and 17t. 9c. empty.

They were built under 27 different lots as follows:

Lot Numbers Dates

A5 852 4/84

A10 904-923 4/89-2/90

All 924-933 2/90-6/90

A12 934-953 9/90-11/91

A14 954-973 10/91-4/92

A15 974-1003 10/91-5/92

A17 1004-1023 8/92-1/93

A18 1024-1043 1/93-6/93

A19 1044-1047 4/94-5/94

A20 1048-1057 6/94-9/94

A21 1058-1077 9/94-4/95

A31 1219-1238 12/97-9/98

A32 1239-1258 4/97-1/99

A36 1309-1314 4/99-9/99

A45 1436-1455 4/00-2/01

A47 1462-1467 3/01-4/01

A48 1468-1487 5/01-8/01

A49 1488-1507 8/01-1/02

A50 1508 3/01

A52 1519-1538 2/02-9/02

A54 1540-1559 1/03-6/03

A57 1562-1571 7/03-9/03

A61 1583-1602 3/04-10/04

A62 1603-1611 4/05-7/05

A63 1612-1621 7/05-1/06

A64 1622-1631 11/05-2/06

A71 1685-1694 10/06-12/06

These tenders were used with singles, 2-4-0s, all classes of double-framed 4-4-0s, 2301 class, Aberdares, 28xx and

2251 class.

The first withdrawals took place in 1927 and the only survivor is No.1506 with engine No. 3440 "City of Truro".

The kit is based on the following Swindon drawings: 13550 (3/97), 14262 (3/98), 15821 (11/99), 21093 (9/02).

The first two of these drawings are in Great Western Engines (Vol. 1) by J.H.Russell which also contains many useful

photographs to which I shall refer.

There were many modifications made to the basic design during the 22 years over which the tenders were in

production and many more subsequent changes as they were rebuilt.

The earliest tenders had coal rails and no water scoop (page 45-fig.111). The water filler was a cylindrical casing and

the sandboxes were mounted on the footplate in front of the tank. They also had Identical toolboxes on each side and

some were fitted with an overflow pipe and fountain for use with engines equipped with crosshead driven water feed

pumps.

Page 43-fig, 108 shows a later tender fitted with a water scoop and a combined water filler/scoop fountain. The front

of the scoop was subsequently fitted with a plate presumably to prevent 'foreign bodies” entering. The operating

mechanism for the drip trap on the steam heating pipe can be clearly seen. This drip trap was not a permanent feature

later photographs not showing it. These early tenders also have narrow footplates, a "drop" in the flare on the tank

sides at the front, front steps with a curve on the leading edge and hornguide ties of the rod type. (See fig 2)

2

From Lot A45 the flare on the tank sides was carried through to the front (page 171-fig.494) the coal rails extended

forward and the footplate widened at the front. These tenders were built for the new 4-4-0s and consequently had a

raised footplate at the front.

Shortly afterwards steps with a straight leading edge and strip type hornguide ties (page 175-fig.505) were introduced.

From Lot A54 coal plates replaced the coal rails and the last lots had the wide footplate throughout and a separate

water pickup dome and filler.

Subsequently all were rebuilt with coal plates, a different pattern toolbox on the left hand side and fire iron trays and

were fitted with water level gauges. Most appear to have had the sandboxes removed and replaced by a single

sandbox on the left hand side at the front of the coal space.

All of these variations are allowed for in the kit and before starting construction I urge you to identify, as far as possible,

from photographs, all the features your model will have.

SECTION 2: CONSTRUCTING THE CHASSIS.

Start by folding the side frames (parts 1 & 2) at 90° along the half-etched lines. Emboss the etched dimples in the side

frames to make the rivet detail. Check that the bearings fit in appropriate slots (Fig. 5) carefully opening the slots with

a needle file if necessary and solder the rear pinpoint bearings in place. Construct appropriate hornguide ties as in Fig.

2 and fold up the brackets for the front brake cross shaft, strengthening the folds with a fillet of solder.

Emboss the rivets on the well tank (part 3), fold up along the half-etched lines and solder the seams. Fold down the

brackets for the vacuum pipe and the rear scoop cross shaft.

Construct the compensation beam by soldering the two halves (part 5) together. Cut the piece of 1/16" brass tubing

to fit between the sides of the well tank and solder the beam on it, centrally. Fit the beam inside the well tank using

the piece of 1/16" brass wire as the pivot.

If appropriate, attach the plate (part 17) to the front of the water scoop casting, first bending it through approximately

10° along the half-etched line, Sow attach the water scoop to the well tank and add the stays from 0.45mm wire

passing them through the holes in the front plate and the slots in the well tank bottom and attaching them to the

scoop at the rear aligning them with the grooves in the scoop casting. Add the scoop cross shaft from 0.45mm wire

and fit part 14 at the same time.

Make up the wheelsets carefully setting the back to back measurement with a gauge. Assemble the side frames and

the well tank bolting them together with 10 BA bolts and nuts through the holes at the front and back. Check that the

assembly is square and that the top surface of the assembly is flat. Remove one of the front bolts, pivot the frames

apart, fit the wheelsets and refit the bolt. Sow check that the compensation works properly and that the chassis is

level. The height can be adjusted by filing the ends of the compensation beam and the side play on the centre axle can

be limited by using the washers (part 91),

When you are satisfied with the mechanical performance of the chassis carefully solder the sideframes to the well

tank, avoiding soldering the bolts, then remove the bolts and complete the soldering. Fold up the scoop cross shaft

bracket on the front plate (part 4) and solder it in position.

Complete the scoop operating mechanism by assembling parts 13, 15, 12 & 16 as shown in Fig.1. Attach the steam

brake cylinder casting and assemble the front brake cross shaft as in Fig.1 using parts 9,10 & 11.

Before proceeding any further with the chassis the basic shell must be constructed as described in section 3.

Solder together the 3 pieces (part 20) to make the vacuum pipe drip trap. Drill out the small holes on either side to fit

0.7mm wire and construct the vacuum pipe as shown in Fig. 4 soldering the rear bracket inside the well tank and

bending the pipe to align with the vacuum pipe on the rear buffer beam. Similarly make the steam heating pipe as in

Fig.3 soldering it to the bottom of the well tank on the opposite side to the vacuum pipe.

Solder the brake shoes (part 7) together, back to back, and solder them between the hangers (part 6) using 0.45mm

wire as pins. Solder the hangers in place suspending them from pieces of 0.45mm wire as in Fig. 1, Check the clearance

between the brake shoes and the wheels making any necessary adjustments. Using 0.45mm wire as cross shafts fit

the pull rods (part 8) and attach them to part 9 using pieces of 0.45mm wire as pins.

3

Form sandpipes from 0.45mm wire attaching them through the holes in part 4. The rebuilt tenders with the

repositioned sandbox only have a sandpipe on the left side of course. Lastly attach the axlebox castings using the

castings with the rear slot on the centre and front axles so that the bearings are free to move.

SBCTION 3: CONSTRUCTING THE BODY.

Having decided on the appropriate footplate width, proceed as follows:

Narrow - Remove front side extensions as in Fig.7, Wide -Fold up sides of front step treads as in Fig.6

Emboss the rivets on the brake standard and water pickup standard bases. ¥ow fold at right angles the coal space rear

and fold at right angles the small tabs on each side. Solder a 10 BA nut above the body mounting holes at the back and

front of the footplate.

If your tender is to have coal rails remove the coal plate brackets from the tank former (part 24). Fold up the tank

former taking care that the coal plate brackets, if not removed, are not bent. Solder the front of the tanks around the

outside of the former top.

Solder the tank top overlay (part 25) to the tank former and then file it flush with the sides of the former. Drill out

holes from inside the tank for water filler, dome, overflow pipe fountain, vents, water level gauge and fire iron bracket

having first determined from the diagrams which holes are appropriate and using the holes in the former as a guide.

Fit the tank former to the footplate, feeding the tabs through the slots. Fold over the tabs outwards at 90°. Check that

the assembly is square and that the footplate is flat before soldering it together.

Fold the tank side/front overlay (part 26) along the narrow slots and solder in place.

Modify the sides/back wrapper (part 27) if appropriate as in Fig. 9 using parts 28 & 29. Emboss the rivets for the rear

step brackets.

Carefully form the flare in part 27 by bending around a rod of suitable diameter and using the jig (part 92), Form the

rear corners in the sides/back wrapper (the holes for the handrails are on the centre of the bend) and then solder it

to the tank former. This requires plenty of heat and flux. Carefully curve to shape the small 'fingers' at the corners, fill

the gaps with solder and then file to shape. I have found low melt solder works best after first tinning the area with

ordinary solder. This should be left until all other soldering is complete to avoid the possibility of a meltdown!

If coal plates are to be fitted shape the coal plate brackets and solder them to the flare. How fit the coal plates (part

56),

Emboss the two rivets on the coupling hook base on part 37 and then solder it to part 36. Solder together the two

coupling hook laminations and attach to the rear bufferbeam. Solder the rear bufferbeam in place allowing the

footplate to overhang very slightly.

Solder the valences (parts 64 & 65) in place against the edge of the tank former tabs. Mote the valences are handed -

see the rivet pattern. Emboss the rivets on the front bufferbeam overlay (part 39) and then solder to part 38, Solder

the complete front bufferbeam in place.

Bend at 90° the sides of the front steps (parts 66 & 67), Solder the appropriate overlay (parts 68, 69, 70 & 71) to the

steps and attach them behind the valence. Similarly attach the rear steps (parts 72, 73, 74 & 75). Check the fit of the

body with the chassis and the alignment of the fixing holes.

Solder in place against the front of the tank the quadrant plates (parts 49, 50). If the original type sandboxes are to be

fitted use parts 30, 31 and position them against the quadrant plates. For the later sand box arrangement first emboss

all the rivets in parts 32, 33 & 34. Form the sandbox to shape using the top (part 33) as a guide to the correct profile

and then solder on the top and position on the left side behind the quadrant plate. (Fig. 12). Similarly for the casing

on the right side.

The raised footplate (part 51) can be modified to accommodate the various sandbox and footplate height options

using the half-etched lines on the underside as a guide. Modify the footplate and fit using parts 52 & 53 as supports

as appropriate.

4

The alternate positions of the rear coal plate (part 40 or 41 - laminate back to back) and the front quadrant coal plates

(part 42 or parts 43 & 44) are marked on the tank top overlay by small 'nicks' in the sides. Using these marks attach

the front and rear coal plates.

For a rebuilt tender with coal plates form the fire iron tray (part 45) into a shallow 'U’ section and fold the rear plate

at 90°. Solder the spacers (part 46) into the half-etched slots and attach the complete tray as in Fig. 12.

Attach the coal rail (part 57) if appropriate. The coal rail extensions (parts 58, 59) are used for the later tenders without

the 'drop1 in the sides at the front. Modify part 57 by removing the rails in front of the end bracket and replace with

the extensions.

Fix the brake and water scoop standards in place. Fold the handrail brackets (part 54 - note they are handed) along

the half-etched line and strengthen the fold with a fillet of solder. Modify the brackets as in Fig. 7 if required. Fix the

brackets over the standards and attach inside the sides. Make the front handrails from 0.45mm wire. If the coal rail

extensions have been used the handrail is fixed to the extension on the small half-etched recess. On the rebuilt tenders

the wide mounted handrails are attached behind the coal plates and using the brackets (part 55).

The remaining parts can now be attached in any order. The following notes should be used.

Emboss rivets on part 61 before forming to shape.

Rear handrails from 0.45mm wire.

Handles for brake and scoop standards from 0.45mm wire.

Emboss two rivets on part 48 before attaching.

Emboss rivets on lamp brackets before folding to shape.

The lower brackets are attached to the bufferbeam.

Align vacuum pipe with notch in rear of footplate.

Steam heating pipe tap handle (part 89) fits on the lower spigot on the casting.

The small brackets (part 84) fold along the narrow slots before being attached against the toolboxes.

The weather sheet supports (part 86) are fixed inside the coal plates, at the front, of the rebuilt tenders.

I hope you enjoy building and using your tender as much as I have enjoyed researching and designing it. If you have

any problems with the kit or any criticisms or suggestions please feel free to contact me.

Best wishes

Martin Finney

July 1988

If you have any problem with the kit or any criticisms or suggestions please feel free to contact Brassmasters.

5

COMPONENT DESCRIPTION - 0.012" BRASS

CHASSIS

BODY (cont’d)

1

Frame - left side

46

Fire iron tray spacers - (2)

2

Frame - right side

47

Fire iron bracket

3

Well tank

48

Fire iron bracket base

4

Front plate

49

Front beaded quadrant plate - left

5

Compensation beam - (2)

50

Front beaded quadrant plate - right

6

Brake hangers - (12)

51

Raised footplate

7

Brake shoes - (12)

52

Raised footplate support - rear

8

Brake pull rods - (2)

53

Raised footplate support - sides and front

9

Lever - brake pull rod to cross shaft - (4)

54

Bracket - front handrail to front of side

10

Lever - brake cylinder to cross shaft - (2)

55

Bracket - front handrail to top of side

11

Lever - brake standard to cross shaft - (2)

56

Side coal plate - (2)

12

Water scoop actuating lever (long)

57

Coal rail

13

Lever - front scoop cross shaft to scoop standard - (2)

58

Coal rail extension - left

14

Lever - rear scoop cross shaft to scoop

59

Coal roil extension - right

15

Lever - between part 12 and front scoop cross shaft - (2)

60

Combined water filler/scoop fountain base

16

Lever - between part 12 and rear scoop cross shaft

61

Combined water filler/scoop fountain wrapper

17

Water scoop front plate

62

Combined water filler/scoop fountain top

18

Washer - 2mm

63

Water pickup dome base

19

Washer - 10 BA

64

Footplate valence - left

20

Vacuum pipe drip trap - (3 pieces)

65

Footplate valence - right

21

Vacuum pipe rear bracket

66

Front step - left

67

Front step –right

BODY

68

Front step overlay - early lots - left

22

Footplate –narrow

69

Front step overlay - early lots - right

23

Footplate - wide

70

Front step overlay - later lots - left

24

Tank former

71

Front step overlay - later lots - right

25

Tank top overlay

72

Rear step - left

26

Tank side/front overlay

73

Rear step - right

27

Sides/back

74

Rear step overlay - left

28

Overlay to modify shape of sides - right

75

Rear step overlay - right

29

Overlay to modify shape of sides - left

76

Front step tread - lower - (2)

30

Sand box - original type - (2)

77

Front step tread - upper (2)

31

Sand box lid - original type - (2)

78

Rear step tread - lower - (2)

32

Sand box (rebuilt tender) - left side

79

Rear step tread - upper - (2)

33

Sand box top (rebuilt tender) - left side

80

Step - tank rear - (2)

34

Casing (rebuilt tender) - right side

81

Lamp bracket upper

35

Casing top (rebuilt tender) - right side

82

Lamp bracket lower - outer - (2)

36

Rear buffer beam

83

Lamp bracket lower - centre

37

Rear buffer beam overlay

84

Bracket - toolbox to tank top - (2)

38

Front buffer beam

85

Padlock - toolbox - (2)

39

Front buffer beam overlay

86

Weather sheet support - (2)

40

Rear coal plate -original type (2)

87

Coupling hook lamination - (2)

41

Rear coal plate -rebuilt tender (2)

88

Screw coupling

42

Front quadrant coal plate - original type (2)

89

Steam heating pipe tap handle

43

Front quadrant coal plate - rebuilt tender - left

90

Rivet strip (2)

44

Front quadrant coal plate - rebuilt tender - right

91

Washer –(2)

45

Fire iron tray

92

Jig for side plate flare

6

OTHER COMPONENTS

WHITEMETAL CASTINGS

2mm bore clearance small top hat bearing - (2)

Axlebox & spring - hole at rear - (2)

Brass 10 B.A. screw - (2)

Axlebox & spring - slot at rear - (4)

Brass 10 B.A. nut - (2)

Toolbox - symmetric shape - (2)

1/16” brass wire for compensation beam pivot

Toolbox - quadrant shape

1/16" inside diameter brass tube for compensation beam

Brake cylinder

Handrail knob - (4)

Water filler

Cast brass brake standard - (2)

Water pickup dome

Brass wire 0.33mm

Water pickup scoop

Brass wire 0.5mm

Water level gauge

Brass wire 0.7mm

Tank vent - (2)

Brass wire 0.9mm

Overflow pipe fountain

Buffer heads. Bushes and springs

Sandbox lid

Water feed valve lever - (2)

Front buffer - (2)

Rear buffer housing - (2)

COMPONENTS NOT SUPPLIED

Vacuum pipe

Wheels (6)

Steam heating pipe

(prototype - 4' 1" diameter - 12 spoke)

- Ultrascale

- Alan Gibson

- Markits

Pinpoint axle (2)

Plain extended axle (4)

7

8

9

10

11

Other Brassmasters Toy manuals

Brassmasters

Brassmasters EasiChas User manual

Brassmasters

Brassmasters EasiChas User manual

Brassmasters

Brassmasters BULLDOG User manual

Brassmasters

Brassmasters LNER V2 2-6-2 User manual

Brassmasters

Brassmasters A1 4-6-2 User manual

Brassmasters

Brassmasters EasiChas User manual

Brassmasters

Brassmasters EasiChas User manual

Popular Toy manuals by other brands

REVELL

REVELL Dassault Rafale B Armee del l'Air Assembly manual

Mattel

Mattel MATCHBOX Rocky the Robot Truck instructions

Amewi

Amewi AMXFLIGHT TURBO BUSHMASTER manual

MTHTrains

MTHTrains GG-1 Operator's manual

Fisher-Price

Fisher-Price BigIdeas VeggieTales Thankful Larry Bedtime Friend... instruction sheet

Hasbro

Hasbro Fur Real Friends Cuddles My Giggly Monkey manual