Brauniger ALPHAMFD Specification sheet

Operating and

Installation Manual

Hardware Rev 401, Software Ver 4.04 24.11.2007

Technical specifications subject to change without notice!

This operating manual must be given to customer with every ALPHA

ALPHAALPHA

ALPHAMFD

purchase!

BRÄUNIGER Flugelectronic GmbH

Dr. Karl Slevogt Str. 5 D-82362 Weilheim / Germany

Ph +49-881-64750, Fax +49-881-4561

2

1

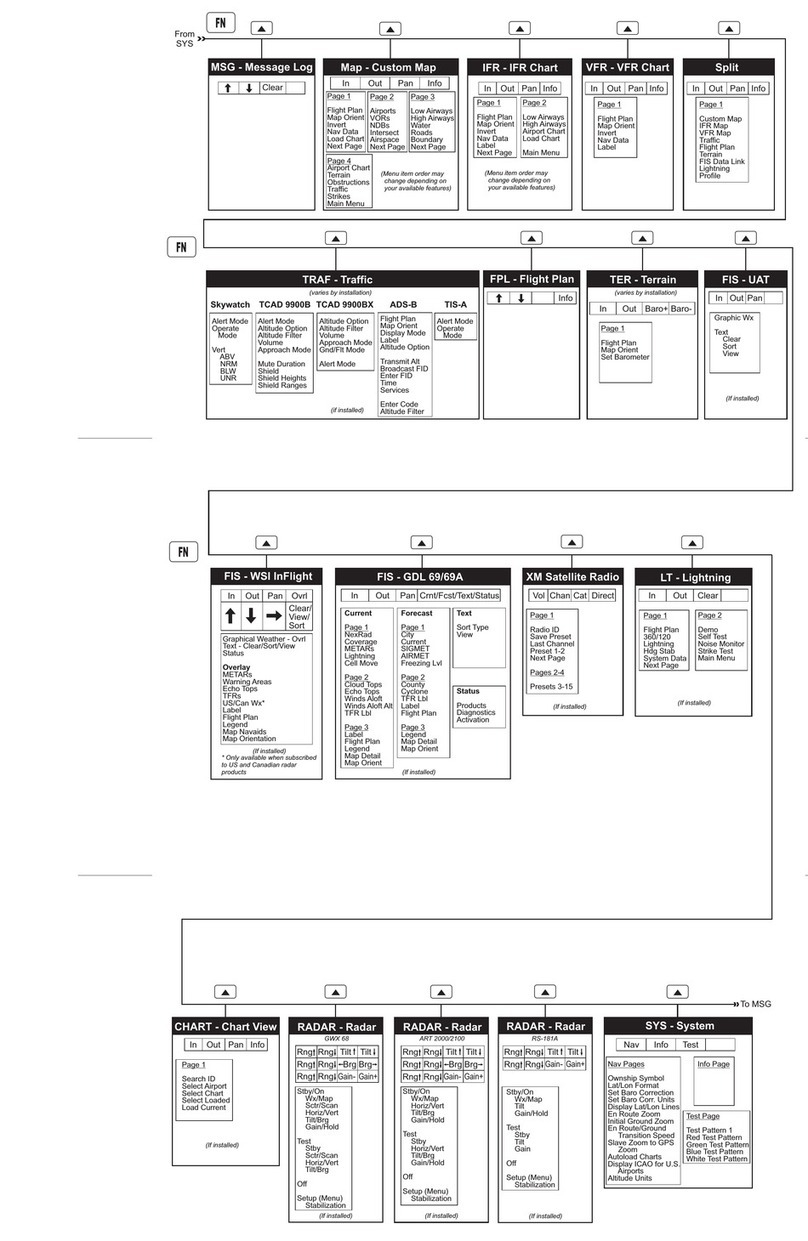

Introduction ......................................................................... 4

2

Mounting and Connections................................................... 5

2.1

Warning ................................................................................................... 5

2.2

Mounting into Cockpit................................................................................ 5

2.3

Electrical Connections................................................................................ 6

2.3.1

Switch-Off unuse Temperature Ports................................................... 7

2.3.2

Connection Plan

ALPHA

MFD (Har ware Rev 401) ................................ 9

2.3.3

Connection Boar (Har ware Rev 401).................................................10

2.4

Mounting Fuel Flow Sen er .......................................................................10

2.4.1

General Notes....................................................................................10

2.4.2

Important Safety Notes.......................................................................11

2.4.3

Important Information to Achieve Precision Measurements ....................11

2.4.4

Drawing: Fuel Flow Sen er Mounting...................................................12

2.5

Pitot Tube an Static Port .........................................................................13

2.5.1

Static Port .........................................................................................13

2.5.2

Pitot Port...........................................................................................13

3

Power On and Built-In Self-Test BIT)............................... 13

4

Flight Management ............................................................ 13

4.1

Air Spee In icator (IAS, CAS) ..................................................................13

4.1.1

Calibration of Air Spee (CAS) .............................................................14

4.1.2

Spee In ication “Stretching Schemes” / Units Air Spee .......................14

4.1.3

Stall-Alarm.........................................................................................15

4.1.4 Vne-Alarm...........................................................................................15

4.2

Altimeter an Air Pressure.........................................................................16

4.2.1

Altitu e MSL (QNH) ............................................................................16

4.2.2

Altitu e above GND / AGL (QFE)..........................................................16

4.2.3

Flight Level (FL, QNE).........................................................................16

4.3

Altitu e Gui ance Mo e (AGM)..................................................................16

4.4

VSI (Vertical Spee In icator) ...................................................................17

4.4.1

Single Pointer Display .........................................................................17

4.4.2

Sector Display....................................................................................18

4.4.3 Variometer-Acoustic..............................................................................17

4.5

Flight Time, Take-Off Time an Date of Flight.............................................18

4.6

Temperature an Voltmeter ......................................................................18

4.7

Real-Time................................................................................................19

5

Engine Management........................................................... 19

5.1

Engine RPM .............................................................................................19

5.1.1

RPM Measurement RPM Port ...............................................................19

5.1.2

Capacitive RPM Measurement at ignition cable not available for

Hardware Rev 401) ....................................................................................20

5.2

Engine Hour Meter ...................................................................................20

5.3

Fuel State an Fuel Flow (Consumption) ....................................................20

5.3.1

Important Safety Information..............................................................20

5.3.2

Fuel Flow Meter .................................................................................21

5.3.3

Precision of Fuel Flow.........................................................................22

5.3.4

Fuel Flow with Engines with Fuel Flow-Back System..............................22

5.3.5

Measuring with two flow sen ers (engines with fuel flow back system)..22

5.3.6

Recommended: Measuring with one fuel flow sen er (engines with fuel

flow back system) ..........................................................................................22

5.3.7

Display of Fuel Flow ...........................................................................23

3

5.3.8

Calibration of Fuel Flow Meter .............................................................23

5.3.9

Display of Fuel State...........................................................................24

5.3.10

How to enter the Actual Fuel State after filling up ..............................24

5.4

Cylin er Hea Temperature (CHT) an Exhaust Gas Temperature (EGT).......24

5.5

Water Temperature..................................................................................25

5.6

Oil Temperature.......................................................................................25

5.7

Display of Temperatures...........................................................................26

5.8

Oil Pressure an Low Oil Pressure Warning.................................................26

5.8.1

Oil Pressure Switch.............................................................................26

5.8.2

Analogue Oil Pressure Sen er..............................................................27

5.9

Voltmeter ................................................................................................28

5.10

Back-Up Power Supply...........................................................................28

6

Flight Data Recorder .......................................................... 29

6.1

MEMO-Mo e ............................................................................................29

7

Other Functions.................................................................. 30

7.1

Acoustic an Optical Warnings...................................................................30

7.1.1

Stall-Alarm an Vne-Alarm ..................................................................30

7.1.2

Low Voltage.......................................................................................30

7.1.3

Low Fuel ...........................................................................................30

7.1.4

Cable Breakage of Temperature Sen ers..............................................30

7.1.5

Engine Temperatures too high.............................................................31

7.1.6

Altitu e Gui ance Mo e ......................................................................31

7.1.7

Oil Pressure too low or too high...........................................................31

7.1.8

RPM too high .....................................................................................31

7.1.9

ERORR-Messages uring Power on Self-Test (BIT)................................31

7.1.10

List of ERROR-Co es .......................................................................32

7.2

Theft prevention an Passwor .................................................................33

7.2.1

Passwor Function "Off" .....................................................................33

7.2.2

Passwor -Function "Car Ra io"............................................................33

7.2.3

Passwor Function "Maximum"............................................................33

7.3

Selection of Units .....................................................................................34

7.4

Software Up ate ......................................................................................34

8

SET-Mode ........................................................................... 34

8.1

Restore Factory Settings ...........................................................................35

8.2

SET-Mo e Settings ...................................................................................35

9

Information for certain Engines......................................... 37

9.1

Rotax 582................................................................................................37

9.2

Rotax 912/912 S/914................................................................................37

9.3

Rotax 503................................................................................................37

9.4

Notes on using the ALPHAMFD on flex-wing Ultralights.............................38

10

Periodical Check................................................................. 38

11

Technical Data ………………………………………………………41

Backlight function

……..…………………………………………………………….41

12

Warranty ............................................................................ 41

4

1 Introduction

With it's innovative i eas an mo ern technology the ALPHAMFD offers a complete

system for flight an engine-management for ultralight/microlight pilots. Important

information for navigation an engine control are easily rea able, presente on an

integrate Liqui Crystal Display.

The ALPHAMFD was carefully esigne to be extremely reliable, safe an

maintenance free. A self-test on power-on, etection an warning of faulty sen ers

an the au io alarm through the Intercom make the ALPHAMFD an extremely

reliable an safe flight information system.

Using mo ern processors an a flash-memory, the software of the ALPHAMFD can

be up ate any time an thus being up ate to the latest software version without

hassle an cost. The ALPHAMFD is a soun long-term investment.

In or er to avoi information overloa of the pilot, only the most important information

like spee , vario, altitu e, RPM, EGT, CHT or water/oil-temperature, flight time, real-

time, fuel state an consumption, are permanently isplaye . More information can be

calle up by pressing only a few keys, e.g. flight log or engine hours, etc.

The innovative LC- isplay is easy to rea in any light con itions, all rea -outs are

esigne following ergonomic rules.

Because of the logical an clearly structure menus, the ALPHAMFD is very easy to

operate. You basically only have to switch on the instrument an off you go. However

we strongly recommen you rea the operation manual carefully to make the best out

of the many functions the ALPHAMFD offers.

We wish you many fantastic an safe flights with your new ALPHAMFD.

Note:

The operating instructions contain many important information which are necessary for

a safe operation of the ALPHA

ALPHAALPHA

ALPHAMFD. Please rea the instructions carefully! If you o

not un erstan something, you must not use the ALPHA

ALPHAALPHA

ALPHAMFD. If you have questions,

please contact the nearest

BRÄUNIGER

Service Centre or

BRÄUNIGER

irectly.

WARNING! This icon esignates important safety information in the

operating manual. Please rea carefully!

5

2 Mounting and Connections

2.1 Warning

The ALPHA

ALPHAALPHA

ALPHAMFD is not certifie by LBA/FAA/JAA as this is not require for Ultralights

in most countries. However, if such a certification will be require in the future, the

certification will be complete . The instrument is esigne following the most state of

the art technologies an it is extensively teste following the proce ures of LBA!

Although the ALPHA

ALPHAALPHA

ALPHAMFD is an electronic an very precise instrument, incorrect

values can be shown, mistakes in operation can be ma e an shown values can be

misinterprete . By operating the ALPHA

ALPHAALPHA

ALPHAMFD, the user confirms that he knows about

these angers an he is accepting responsibility for any possible risks.

In or er to minimize these risks, the operating instructions MUST be rea carefully. If

you have questions, please contact

BRÄUNIGER

or a

BRÄUNIGER

Service Centre.

2.2 Mounting into Cockpit

It is very easy to mount the ALPHAMFD in your cockpit. You only nee a little skill,

no special tools are require .

Dimensions of ALPHAMFD:

Front 220 x 145 mm

Cockpit Cut-out 137 x 194 mm

Drillings 207 x 87 mm, 32 mm from

bottom an 26 from the top.

All measurements in mm

Total weight only approx. 850 grs!

Inclu ing Backup battery

220

14587

125

Screws M4 Cylin er hea

6

WARNING:

The following points must be carefully observed:

• Protect the unit from too high or too low temperatures. The unit works reliably in

a temperature range of -15°C to 50° Ceslsius.

• Protect the unit from excessive shock or vibrations. It might be necessary to

mount the unit with suitable shock absorbing materials.

• Protect the unit from irt an moisture an all kin s of oils an gasoline.

• The isplay must be easy to rea , protect the unit from glare an ensure a goo

fiel of view.

• Mount instrument as far away from ra io / transpon er antennae as possible.

All points must be observed for longevity and reliability!

2.3 Electrical Connections

If you have never before installe electrical instruments an you are not exactly sure

what to o, please ask someone who has experience to help you with the installation.

When working with sen ers, please han le carefully, as they are sensitive electronic

parts.

Only use high-quality cables (highly flexible, stran e an shiel e ) an connectors.

Check that your cables run untangle an clean. Disconnect the aircraft battery before

working on electrical components!

Ni-Cr-Ni temperature sen ers require special cables which are supplie with the

sen ers!

WARNING:

All wires shoul be protecte by small metal terminals to ensure a

lasting an safe connection to the ALPHAMFD. All cables an the Pitot tube

shoul be secure against pull. There is a special mounting bracket on the rear

of the ALPHA

ALPHAALPHA

ALPHAMFD for securing against pull.

7

When mounting the senders the following points must be observed:

• Protect the sen er lea s against high temperatures.

• Protect the sen er lea s from excessive vibration. However, a certain amount of

movement must be allowe .

• The sen er lea s must not be sharply bent or abra e .

• The threa s of EGT, CHT, water- an oil temp sen ers must be treate with

Loctite Anti Seize (or a similar agent) to ensure trouble-free unscrewing.

Type K temperature senders NiCrNi) MUST be exten e with specially

compensate extension lea s. If the lea s of the sen ers are too short an must be

exten e , the special Type K extension lea s an Type K plug an sockets MUST be

use . These lea s are available from

BRÄUNIGER

:

Type Pt100 temperature senders o not nee specially compensate extension

lea s but can be exten e with stan ar copper lea s.

Please observe, that the ALPHA

ALPHAALPHA

ALPHAMFD is equipped with two different types of

temperature ports: Type K and Pt100. These ports can ONLY be used with

the respective type of sender.

Please follow the technical information of the sen ers you are using.

NOTE:

BRÄUNIGER

provi es complete cable looms an sen er kits as an option for

some popular engines. With these connection kits, it is even easier to connect the

ALPHAMFD.

2.3.1 Switch-Off unuse Temperature Ports

The ALPHA

ALPHAALPHA

ALPHAMFD has six ifferent ports where temperature sen ers can be connecte

(Two Type Pt100 an four Type K). Because with some engine configurations some

ports are not use , they can be switche off.

Because of their technical characteristics, temperature ports still show temperatures

even when no sen ers are attache , an these temperatures are of course "nonsense".

Therefore the ports can be switche off an "nonsense" values are suppresse .

8

Switching-off ports is one in SET-Mo es 31 through 37.

SET Mo e

Number

Temperature or fuel

Ports

Display Text Options

31 Pt100 WaterTemp Use Water Temp Port YES / NO

32 Pt 100 Oil temp Use Oil Temp Port YES / NO

33 EGT 1 Use EGT 1 Port YES / NO

34 EGT 2 Use EGT 2 Port YES / NO

35 CHT 1 Use CHT 1 Port YES / NO

36 CHT 2 Use CHT 2 Port YES / NO

37 Fuel flow Use Fuel Port YES / NO

Attention: Under set mode 37 it’s up from version 4.04 possible to

deactivate the fuel port. This may be helpful for trikes where the gas tank is

visible close to the pilot, or fuel systems with high flow back systems where

the flow sensor can’t work!

Note: The factory setting is all temperature ports ON!

WARNING: Make sure only unused temperature ports are switche

off! If a

use temperature port with a connecte sen er is acci entally switche off,

the temperature is not displayed and also the alarm function is

inoperative!

9

2.3.2 Connection Plan ALPHA

MFD

(Har ware Rev 401)

Sen ers

on engine

Cable

Connection ALPHA

ALPHAALPHA

ALPHAMFD

Water Temp

Pt100

Water (+) Pt100

Oil Temp

Pt100

Oil Temp (+) Pt100

Oil/Water (-)

(common for Pt100 and flow)

Flow Meter

to engine

+ 12 V OUT

Flow to engine, Signal

Flow Meter

back to tank

Flow to tank, Signal

Oil Pressure

Oil Pressure

RPM

(Rotax)

RPM

Aircraft

Battery

+ Batt Power

Supply

7...24 V

Ground

Thermocouple

Type K

(NiCrNi)

Ground case (screw)

EGT 1

Type K

EGT 1 (+)

EGT 1 (-)

EGT 2

Type K

EGT 2 (+)

EGT 2 (-)

CHT 1/EGT 3

(Water 912)

Type K

CHT 1 (+)

C

HT 1 (

-

)

CHT 2/EGT 4

(Water 912)

Type K

CHT 2 (+)

CHT 2 (

-

)

Intercom Diode

Plug

Sound (+)

Sound (-)

white

6

4

9

5

7

1

10

8

2

5

Type K Plug & Sockets

1.1.1.1.1.1

Type

re

white

white

green

brown

white

white

green

brown

or contact

black

green

white

green

white

white

white

green

green

+

+

+

+

-

-

-

-

green

green

green

green

white

white

white

white

Shiel

6

7

8

9

10

11

12

16

15

11

4

1

2

3

19

20

17

18

blue

yellow

white

green

violet

brown

grey/pink

grey

black

+

+

re

3

re

13

14

Re /blue

re

2.3.3 Connection Boar (Har ware Rev 401)

1

+

12V Out FLOW

1

12 V Power for Fuel Flow Sen ers 1 an 2

2

+

FLOW to engine

2

Fuel Flow Sen er 1 from tank to engine

3

+

FLOW to tank

3

Fuel Flow Sen er 2 from engine back to tank

4

-

GND Pt100/Flow

4

Common Groun for both Fuel Flow Sen ers an both Pt100

temperature sen ers

5

+

5

6

-

EGT 1 (Type K)

6

Exhaust Gas Temperature EGT 1 (Type K)

7

+

7

8

-

EGT 2 (Type K)

8

Exhaust Gas Temperature EGT 2 (Type K)

9

+

9

10

-

CHT 1 (Type K)

10

Cylin er Hea Temperature CHT 1 (Or Water 1 for Rotax 912) or

EGT 3 (Type K)

11

+

11

12

-

CHT 2 (Type K)

12

Cylin er Hea Temperature CHT 2 (Or Water 2 for Rotax 912) or

EGT 4 (Type K)

13

+

Water Temp (Pt100)

13

Water temperature (Type Pt100)

14

+

Oil Temp (Pt100)

14

Oil temperature (Type Pt100)

15

-

15

16

+

Intercom

16

Intercom connection for alarm soun s

17

+

BATT 7...28 V In

17

Main power supply from aircraft 7 to 28 Volts

18

-

BATT Gnd

18

Main aircraft groun

19

+

Oil Press

19

Oil pressure analog signal or switch

20

+

RPM Signal

20

RPM signal

Screw on ALPHA

ALPHAALPHA

ALPHAMFD case:

Groun for shiel of lea s

Backlight is connected to a separate 3 pin round DIN connector, pin 1 is

+12 Volt and pin 3 is ground.

Numbers are base on numbers of sticker on case an on connection plan.

Connection of lea s: Open cable cage clamps with suitable tool (screw river) an

insert lea s. Always use cable terminators!

2.4 Mounting Fuel Flow Sender

2.4.1 General Notes

The fuel capacity in icator of the ALPHA

ALPHAALPHA

ALPHAMFD works with a special fuel flow sen er.

We recommen only to use the sen er supplie by

BRÄUNIGER

, because other

sen ers are not a apte to the ALPHA

ALPHAALPHA

ALPHAMFD an precise function can not be

guarantee . The fuel flow sen ers transmits pluses accor ing to the actual fuel

consumption to the ALPHA

ALPHAALPHA

ALPHAMFD. These pulses are a e up to a fuel capacity

in icator. The sen er can be use with all kin s of fuel.

11

The

BRÄUNIGER

fuel flow sen er is loope in the fuel line between filter an engine.

Make sure all connections of fuel line are leak proof an secure. Secure all line

connections with suitable parts, e.g. hose clamps.

The fuel flow sen er is esigne in such a way, that even when the sensor wheel is

blocke , there is always enough fuel throughput to keep the engine running. Of course

the fuel flow can not be measure with a blocke sensor wheel.

2.4.2 Important Safety Notes

WARNING! To prevent air bubbles from getting stuck insi e the fuel flow

sen er, the sen er MUST be mounte in an angle of optimal 90° an

minimum 60° relative to the longitu inal axis of the aircraft. Only this way a

precise measurement can be achieve . The irection of the fuel flow MUST be

from bottom to top! Take care of the correct flow irection in icate by the

arrow on the sen er.

WARNING! The fuel flow sen er MUST be mounte AFTER the fuel filter so

that foreign matter in the fuel cannot block the sensor wheel!

WARNING! When mounting the fuel flow sen er you MUST observe the safety

an operation notes of the engine manufacturer!

2.4.3 Recommen ations to Achieve Precision Measurements

Because most fuel pumps create strong vibrations in the fuel line an these vibration

can negatively influence the precision of the fuel flow sen er, the sen er shoul be

mounte far away from the fuel pump.

The fuel flow sen er shoul be mounte close to the tank. The high temperatures in

the engine compartment can change the viscosity of the fuel which can negatively

influence measurement precision!

12

2.4.4 Drawing: Fuel Flow Sen er Mounting

Fuel Flow

Sen er

From

Tank

Fuel Filter

To engine

Min 60°

Optimal 90°

Fuel Flow Sen er Mounte on Rotax 912 S as escribe in Section 5.3.6

13

2.5 Pitot Tube and Static Port

There are 2 ifferent pressure ports on the backsi e of the case:

2.5.1 Static Port

This is the port for the static pressure. It must be connecte to the static port of the

aircraft. If you on't know where the static port of your aircraft is, ask the

manufacturer of the aircraft. A static pressure port is only necessary for aircraft with

close passenger cabin. Open flex-wing Ultralights can leave the static port open

without connecting it anywhere.

2.5.2 Pitot Port

This is the port for the pitot pressure. The pitot tube of the aircraft is connecte to the

pitot port. This is one with stan ar silicone hose. Check that the tube is neither

tangle nor sharply bent on its way from the pitot tube to the ALPHA

ALPHAALPHA

ALPHAMFD. The pitot

tube shoul be free of turbulences for precise measurements. The pitot shoul be

mounte parallel to the aero ynamic air flow uring cruise flight.

Because the i eal mounting of the pitot tube is ifferent for every aircraft type, please

contact your aircraft manufacturer for special information.

3 Power On and Built - In Self-Test (BIT)

By pressing the <ON/OFF>-key the instrument is switche on. For a short perio of

time all segments of the LC- isplay are illuminate in or er to test the function of the

isplay. Next the instrument goes into CHECK-Mo e. An internal self-test is execute

an all sen ers are checke for correct signals. If the ALPHAMFD iscovers a fault, it

isplays an ERROR-co e. A list of all possible ERROR-co es is liste in section 7.1.10 .

If everything is OK, you will see several "CHECK OK" messages an the instrument is

rea y for operation. Among others the spee range (which is set by the factory) is

isplaye . This is an a itional safety check for the pilot.

4 Flight Management

4.1 Air Speed Indicator (IAS, CAS)

The ALPHAMFD has an easy to rea large

analogue isplay of the air spee . By using a

stan ar Pitot tube the In icate Air Spee (IAS) is

isplaye . Note: IAS shows the spee in every

altitu e accor ing to the measure ynamic air

pressure. At high altitu es the actual True Air

Spee (TAS) is higher than the IAS. Displaying the

IAS has several a vantages an is also require by

various aviation authorities. For example the spee

never to excee (Vne) or the stall spee (Vso or

Vs1) can always be rea at the same spot of the

14

scale at every altitu e.

Stan ar , commercially available, Pitot tubes are use for spee -sen ers. The spee

in icator is calibrate by

BRÄUNIGER

accor ing to the correspon ing ynamic air

pressure.

4.1.1 Calibration of Air Spee (CAS)

The pilot can in ivi ually calibrate the spee in icator in SET-Mo e 15 by a justing the

SPEED GAIN factor. This way measurement errors, cause e.g. by a not optimal

position of the Pitot tube, can be in ivi ually correcte . After calibration, CAS

(Calibrate Air Spee ) is in icate . The efault value is >100<. If you a just the

SPEED GAIN e.g. to <110> the spee in ication will show a approx. 10% higher CAS.

The easiest way to calibrate the air spee in icator is to use a GPS. On a ay with no

win the Groun Spee is compare to the In icate Air Spee . You shoul fly your

entire spee range, i.e. lan ing spee , me ium spee , cruise spee an close to the

Vne. The ifferences in GS to IAS will probably vary through the spee range. It is

optimal to calibrate close to lan ing spee . It is also recommen e to fly ifferent

courses (e.g. 360°, 270°, 180° un 90°) to eliminate possible win influences.

A itionally the spee zero point can be calibrate . This is one in SET-Mo e 16

(SPEED ZERO).Press two times the “Enter” key.

.

WARNING!

The possibility to calibrate the Air Spee In icator allows for a very accurate

calibration of the Calibrate Air Spee . But if the calibration is done

incorrectly, the CAS in ication can show inaccurate speeds which can lead

to serious accidents landing!) Therefore Aircraft manufacturers can

block the settings for Speed calibration. Stall and Vne for the user.

It is also highly recommen e to calibrate the spee zero point every

2-3 months to preserve accuracy.

4.1.2 Spee In ication “Stretching Schemes” / Units Air Spee

The ALPHA

ALPHAALPHA

ALPHAMFD is available in 6 ifferent versions:

Version Speed-Units Speed-Range VSI Units

Version A Km/h 40 – 220 km/h m/s

Version B Km/h 60-340 km/h m/s

Version C Knots or mph 24 –130 kts ft/min

Version D Knots or mph 32 – 190 kts ft/min

Knots-versions can be converte to mph-versions. This must be one at the factory.

Km/h-versions can also be converte to kts or mph versions. Again this must be one

at

BRÄUNIGER

.

15

WARNING: To get a precise in ication of the air spee , some scales are

"stretche ". Please note the different resolutions of the scales. The

increment between two marks can in icate spee ifferences from 2.5 km/h to

10 km/h!

Example:

ALPHA

ALPHAALPHA

ALPHAMFD version B (340 km/h) uses the following "stretching scheme":

• From 60 km/h to 110 km/h every mark in icates a spee resolution of 2,5 km/h

(important for precise in ication of spee for lan ing or to prevent stalling)

• From 110 km/h to 210 km/h every mark in icates a spee resolution of 5 km/h

• From 210 km/h to 340 km/h every mark in icates a spee resolution of 10 km/h

A itional etails in section 11 "Technical ata"

In SET-Mo e 17 two ifferent pointer styles can be chosen accor ing to personal

preferences: Sectional pointer or single pointer. More in section 4.4.1 an 4.4.2

Because it is very important to comprehen the ifferent spee ranges at a single

glance, self a hesive coloure marker rings in white, green, yellow an re are

inclu e with every ALPHAMFD. These rings can be mounte to the spee in icator

correspon ing to the spee s of the in ivi ual aircraft (Vno, Vne, Vso, Vs1, etc.)

4.1.3 Stall-Alarm

Stall-Alarm: In SET-Mo e 6 the visual an au io warning for stall spee in lan ing

configuration (Vso) can be programme . After switching to SET-Mo e by pressing the

>FUNC/SET< key (SF = special functions) for a few secon s, select SET-Mo e 6 =

STALL ALARM by pressing the >ARROW<-keys. After pressing the >ENTER/MEMO<

key the <SET< icon will start flashing. Now the spee of the stall alarm can be

a juste . By pressing >ENTER/MEMO< again, the new value is store . Pressing the

>FUNC/SET< key leaves the SET-Mo e. To change the value for stall alarm can be

blocke by the aircraft manufacturer.

16

4.1.4 Vne-Alarm

Vne-Alarm: In Set-Mo e 7 the Velocity never to excee is set in the same way as

escribe above,( if not blocke by the manufacturer) If you excee this maximum

allowable spee an acoustic an visible (flashing spee pointer) is activate .

Note: Neither the Stall- nor the Vne - Alarm can be switche off.

WARNING! If the In icate Air Spee is faster than 50 km/h, the

ALPHA

ALPHAALPHA

ALPHAMFD cannot be switche off! This prevents the pilot from acci entally

switching off the ALPHA

ALPHAALPHA

ALPHAMFD uring flight.

4.2 Altimeter and Air Pressure

We recommen setting the correct QNH prior to every flight. This is easily one by just

pressing the ARROW up / own keys.

4.2.1 Altitu e MSL (QNH)

Usually the altimeter is set to altitu e above mean

sea level MSL. If the >m/ft/QNH/AGM< key is

presse once, the isplay switches over from meter

to feet. If the same key is presse again, the

correspon ing QNH is isplaye in hPa (or InHg).

4.2.2 Altitu e above GND / AGL (QFE)

It is also possible to set the altimeter to zero while on the groun . This way the

altitu e shows Above Groun Level (AGL or GND). When switching over to air pressure

while AGL is set, the ALPHAMFD automatically calculates the correspon ing QFE. On

many airports the QNH is given by ATC prior to take-off. You can also set the QNH by

pressing the >ARROW< keys an the ALPHAMFD automatically calculates the

correspon ing altitu e above MSL. (Kollsman-Win ow)

4.2.3 Flight Level (FL, QNE)

In some air spaces pilots are require to fly by flight levels. All aircraft set their

altimeter to the ICAO stan ar air pressure of 1013,2 hPa.

The ALPHA

ALPHAALPHA

ALPHAMFD has a special function to set this very easily. By pressing the

>ARROW UP< an >ARROW DOWN< keys simultaneously, the altimeter is set very

quickly to 1013,2 hPa (QNE). Now the altitu e is shown in flight level. Changing the

altitu e to flight level is in icate by "QNE" in the isplay.

If you want to revert to altitu e MSL, just get the new actual QNH from the nearest air

fiel an a just the altimeter accor ingly using the >ARROW< keys.

4.3 Altitude Guidance Mode (AGM)

The Altitu e Gui ance Mo e (AGM) helps pilots to maintain a chosen altitu e with the

help of an acoustic alarm. If the chosen altitu e is excee e , either too high or too

17

low, by a ifference set in the SET-Mo e 5, an au io alarm starts to soun through the

Intercom an the altitu e isplay starts flashing.

Example: A pilot flies 2000 ft MSL an wants to maintain this altitu e for a longer

perio of time because he woul otherwise enter controlle airspace when flying

higher. He oesn't want to check the altimeter all the time so he activates AGM which

will warn him if he flies too high or too low. The altitu e ifference which triggers the

alarm can be set in SET-Mo e 5. As soon as the esire altitu e to be maintaine is

reache , the AGM is activate by pressing >m/ft/QNH/AGM< for several secon s.

The isplay shows <AGM ON>.

By pressing >m/ft/QNH/AGM< again for several secon s, AGM is eactivate an

<AGM OFF> is isplaye .

Example:

2000 ft shall be maintaine . Altitu e ifference of 200 ft or greater above 2000 ft an

200 ft an greater below 2000 ft will trigger the au io alarm. As soon as the pilot

ina vertently climbs to 2200 ft an more, the alarm goes off an the altitu e isplay

starts flashing. The same happens if the pilots escen s to 1800 ft or less. As soon as

the pilot returns to within the esire altitu e range (2000 ft + 200 ft or – 200 ft), the

alarm stops automatically an the altitu e isplay stops flashing.

The altitu e range is set in SET-Mo e 5, the set value represents the maximum

allowe altitu e ifference for above an below the esire altitu e

4.4 VSI (Vertical Speed Indicator)

Climbing or escen ing spee s are shown on a large, easy to rea , analogue isplay

with a resolution of 0.25 m/s. Values between +/- 10 m/s are isplaye (or the

equivalent in ft/min)

The ALPHAMFD has two ifferent ways of in ication values on the roun analogue

scales. They can be chosen accor ing to personal preferences in SET-Mo e 17.

4.4.1 Single Pointer Display

The Single Pointer Display in icates rate of climb or sink with a conventional single

pointer. If the climb or sink rate excee s +/- 5 m/s, the values from 5 m/s to 10 m/s

are isplaye in a secon stage which is in icate by a secon pointer at 5 m/s.

Altitu e to maintain 2000 ft

Minimum altitu e 1800 ft

Maximum altitu e 2200 ft

Ma

ximum allowe alt iff +200 ft

Maximum allowe alt iff

-

200 ft

Beep Beep Beep!

Beep Beep Beep!

18

4.4.2 Sector Display

The Sector Display in icates climb or sink rate by an

"increasing" sector. If the climb or sink rate excee s +/-

5 m/s, the values from 5 m/s to 10 m/s are isplaye in

a secon stage which is in icate by the sector being

cleare . We recommen using the Sector Display in low

temperatures, because in low temperatures the LC-

isplay becomes slow an the Sector Display is better to

rea .

The VSI of the ALPHAMFD works electronically an therefore works much faster,

crisper an more precise compare to conventional mechanical VSI instruments with

their inherent long time lag.

4.4.3 Variometer Acoustic

If the motor of the airplane is switche off an the unit is climbing an acoustic signal

will be transferre to the intercom. A stronger climbing correspon s to higher

frequency an faster beep intervals.

4.5 Flight Time, Take-Off Time and Date of Flight

The flight time is measure as soon as the spee excee s 50 km/h IAS. This moment

is also registere as take-off time an can later be calle up in the MEMO-Mo e. The

flight time is stoppe as soon as the ALPHAMFD registers spee s of less than 50

km/h IAS.

WARNING! The ALPHA

ALPHAALPHA

ALPHAMFD cannot be switched off as long as it registers

an air speed of faster than 50 km/h. This prevents the pilot from

ina vertently switching off the instrument uring flight.

4.6 Temperature and Voltmeter

By pressing the >FUNC/SET< key twice (with interval inbetween), the altimeter

isplay is switche to voltmeter an temperature. In SET-Mo e 22 (UNIT

TEMPERATURE) you can choose between °C Celsius or °F Fahrenheit.

WARNING! The ALPHAMFD measures the temperature of the instrument

boar (which approx. correspon s to outsi e temperature in open flex-wing

ultralights/microlights or the cabin temperature of close fix-wing ULs). The

in icate temperature is not the actual outsi e temperature OAT. The

temperature is use for internal temperature compensation. It may NOT be

used for calculations of correcting factors to ICAO standard

atmosphere density altitude). It is only suitable for information!

19

At the same time the actual voltage of the aircraft system

is isplaye . After a few secon s both isplays switch back

to altitu e an real-time. When the ALPHAMFD switches

over to emergency power for any reason, the Voltmeter

in icates the voltage of the back-up battery.

WARNING! When the ALPHAMFD switches over to emergency power

supply by the back-up battery, the voltage of the back-up battery is in icate .

If this value rops to 7,2 V or below you must IMMEDIATELY exchange the

battery. You MUST NOT fly with a voltage of 7.2 V or below because the

emergency power supply can not be guarantee !

4.7 Real-Time

The time is shown in hh:mm.

Time an ate are set in SET-Mo es 19, 20, an 21.

5 Engine Management

5.1 Engine RPM

Engine RPM is igitally in icate to max. 9980 RPM

with a resolution of 20 RPM.

5.1.1 RPM Measurement RPM Port

Most engines have a e icate 12 V port for measuring the engine RPM. In SET-Mo e

18 the ALPHA

ALPHAALPHA

ALPHAMFD can be programme to rea the RPM signal epen ing on engine

type an ignition sequence. It is possible to set a factor "multiplie by 4, 2, or 1 or

" ivi e by 6, 4, 3, 2".

The generators of Rotax 582 an 503 engines give 6 pulses per revolution, so the

ALPHA

ALPHAALPHA

ALPHAMFD must be set to " ivi e by 6" for use with these engines.

WARNING! Do not disconnect the power supply of the ALPHA

ALPHAALPHA

ALPHAMFD before

switching it off. If the ALPHA

ALPHAALPHA

ALPHAMFD is isconnecte before it is switche off, it

cannot write information (like engine hours) into its memory an the values

are permanently lost. It will switch over to the emergency power supply an

unnecessarily rains the back-up battery!

20

For Rotax 912 engines the factor must be set to *1.

The factors for other engines can be obtaine from their manufacturers.

Because some engines use a special RPM signal, the ALPHA

ALPHAALPHA

ALPHAMFD can be programme

to un erstan this signal with a filter. This filter can be activate or eactivate in SET-

Mo e 27 (Default is ROTAX). This enables the unit to un erstan pulses from 6 … 200

Volts.

WARNING! As long as the ALPHA

ALPHAALPHA

ALPHAMFD rea s RPM from a running engine, it

cannot be switched off. This is to prevent the pilot to ina vertently switch off

the instrument uring flight.

5.1.2 Capacitive RPM Measurement at ignition cable

This function is not supported any longer)

5.2 Engine Hour Meter

The ALPHAMFD istinguishes between flight time an engine running time per flight.

Both values are isplaye an store for every flight. They can be recalle in MEMO-

Mo e (see section 6) with a resolution of 1 minute.

A itionally, the total running time of the engine of all flights (Engine Hour Meter) is

isplaye in SET-Mo e 4. This value can not be change an oes not get lost when

isconnecting the power of the ALPHAMFD. The value is shown in full hours.

WARNING! Never isconnect the ALPHAMFD from its power supply before

switching it off. If it is isconnecte from the power supply without prior

switching it off, it cannot store some information (e.g. engine hours) in its

memory. Important ata will be lost!

5.3 Fuel State and Fuel Flow (Consumption)

5.3.1 Important Safety Information

The fuel state is etermine by a special flow sen er. It is highly recommen e to only

use the flow sen er supplie by

BRÄUNIGER

, because other sen ers are not a apte

to the ALPHAMFD an correct function cannot be guarantee .

Table of contents

Other Brauniger Avionic Display manuals

Popular Avionic Display manuals by other brands

Golze Engineering

Golze Engineering ADL170 user manual

Daher

Daher TBM 960 Pilot's information manual

Aerospace Logic

Aerospace Logic EGT-100 Series Operation and installation manual

Garmin

Garmin GPSMAP 500 Series installation manual

Garmin

Garmin DA42 G1000 Cockpit reference guide

TQ

TQ AirPlus KRT2 Series User & installation manual